The global aluminum market continues to expand, driven by increasing demand for lightweight, high-strength materials across aerospace, automotive, and industrial sectors. According to Grand View Research, the global aluminum market was valued at USD 217.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. A key contributor to this growth is the rising adoption of high-performance aluminum alloys such as 6061-T6, prized for its optimal balance of mechanical properties, corrosion resistance, and weldability. With applications spanning structural components, marine fittings, and precision machining, 6061-T6 aluminum has become a benchmark alloy in advanced manufacturing. As demand intensifies, a select group of material manufacturers have distinguished themselves through consistent quality, rigorous certification standards, and innovation in alloy processing. Below, we profile the top seven producers of 6061-T6 aluminum based on material consistency, technical data transparency, production scale, and market presence.

Top 7 6061 T6 Aluminum Material Properties Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Aluminum 6061

Domain Est. 1995

Website: glemco.com

Key Highlights: Aluminum 6061-T6 is generally heat treated and artificially aged for maximum strength. Applications & Usage. Wings and Fuselages; Helicopter and Plane ……

#2 Aluminum Alloy 6061

Domain Est. 1996

Website: unitedaluminum.com

Key Highlights: It has good mechanical properties and exhibits good weldability. It is one of the most common alloys for general purpose use. 6061 aluminum alloy can be heat ……

#3 Aluminum 6061-T6 (UNS AA96061)

Domain Est. 1997

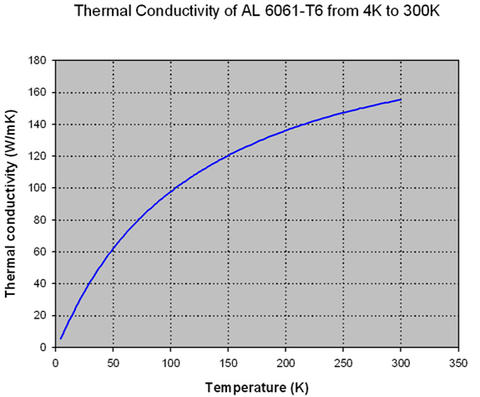

Website: nist.gov

Key Highlights: Thermal Conductivity, Specific Heat. UNITS, W/(m-K), J/(kg-K). a, 0.07918, 46.6467. b, 1.0957, -314.292. c, -0.07277, 866.662….

#4 Aluminum 6061

Domain Est. 1997

#5 Industry Standards

Domain Est. 1998

Website: aluminum.org

Key Highlights: The 6xxx series are versatile, heat treatable, highly formable, weldable and have moderately high strength coupled with excellent corrosion resistance. Alloys ……

#6 Aluminum 6061: Properties, Uses, and Composition

Domain Est. 1998

Website: ryerson.com

Key Highlights: Aluminum 6061 is an alloy consisting primarily of aluminum, with magnesium and silicon as its major alloying elements….

#7 6061 T6 Aluminum Plate

Domain Est. 2019

Website: aviationaluminum.com

Key Highlights: Known for its excellent corrosion resistance, good machinability, and impressive mechanical properties, this aluminum plate is an ideal choice for projects ……

Expert Sourcing Insights for 6061 T6 Aluminum Material Properties

H2: 2026 Market Trends for 6061-T6 Aluminum Material Properties

As the global manufacturing and engineering sectors continue to evolve, the demand for high-performance, lightweight, and cost-effective materials remains strong. In 2026, 6061-T6 aluminum—a widely used heat-treated alloy known for its excellent strength-to-weight ratio, corrosion resistance, and machinability—is expected to experience notable shifts in application and market dynamics based on its material properties. This analysis explores how the inherent characteristics of 6061-T6 aluminum align with emerging industry needs and technological advancements shaping the 2026 market landscape.

1. Increased Demand in Lightweight Transportation

One of the most significant drivers for 6061-T6 aluminum in 2026 is the ongoing push for lightweight materials in the automotive and aerospace industries. With global emissions regulations tightening and electric vehicle (EV) adoption accelerating, manufacturers are prioritizing weight reduction to improve energy efficiency and extend battery range. The tensile strength of 6061-T6 (approximately 45,000 psi) combined with its low density (2.7 g/cm³) makes it ideal for structural components such as chassis parts, frames, and heat sinks in EVs. In aerospace, its weldability and moderate strength support its use in non-critical airframe components and drone manufacturing, where cost and processability are key considerations.

2. Growth in Renewable Energy Infrastructure

The expansion of solar and wind energy systems is fueling demand for durable, corrosion-resistant materials. In 2026, 6061-T6 aluminum is widely used in solar panel mounting structures and heat exchangers due to its excellent resistance to atmospheric corrosion and ability to maintain integrity under cyclic thermal loading. Its ease of extrusion allows for customizable profiles that enhance installation efficiency and reduce labor costs—critical factors in large-scale renewable projects.

3. Advancements in Additive Manufacturing and Hybrid Fabrication

Although traditionally processed via extrusion, forging, or machining, 6061-T6 is increasingly being adapted for use in additive manufacturing (AM), particularly in hybrid production workflows. By 2026, improvements in laser powder bed fusion (LPBF) techniques have enabled better control over the heat treatment and microstructure of 6061 aluminum, mitigating cracking issues historically associated with its high magnesium and silicon content. This opens new applications in rapid prototyping and low-volume, high-complexity parts for defense and robotics sectors.

4. Sustainability and Recycling Pressures

Environmental regulations and corporate sustainability goals are reshaping material selection. 6061-T6 aluminum scores highly in this domain due to its recyclability—requiring only 5% of the energy needed for primary aluminum production. In 2026, closed-loop recycling systems in the automotive and construction industries are increasingly sourcing recycled 6061-T6, supported by improved quality control and alloy consistency. This trend is expected to lower lifecycle costs and reduce carbon footprints, enhancing the alloy’s market appeal.

5. Competitive Pressure from High-Performance Alternatives

Despite its advantages, 6061-T6 faces growing competition from newer aluminum alloys (e.g., 7000-series for higher strength or 5000-series for marine applications) and advanced composites. In high-stress aerospace or defense applications, materials like 7075-T6 offer superior strength, while carbon fiber composites provide greater weight savings. However, 6061-T6 maintains a strong market position due to its balanced properties, lower cost, and ease of fabrication—factors that continue to make it a preferred choice for mid-tier performance applications.

6. Regional Market Dynamics and Supply Chain Adjustments

Geopolitical factors and supply chain localization efforts are influencing 6061-T6 availability and pricing. In 2026, regions like North America and Europe are investing in domestic aluminum processing to reduce reliance on imported raw materials. This shift supports stable supply for precision extruders and job shops using 6061-T6, particularly in precision machining and automation industries. Meanwhile, Asia-Pacific remains the largest consumer, driven by construction, transportation, and electronics manufacturing.

Conclusion

In 2026, the market for 6061-T6 aluminum remains robust, anchored in its versatile material properties—good strength, weldability, corrosion resistance, and formability. While technological and environmental trends are reshaping demand, 6061-T6 continues to serve as a foundational material across transportation, renewable energy, and industrial sectors. Its adaptability to evolving manufacturing methods and sustainability requirements ensures that it will remain a material of choice for cost-conscious, performance-driven applications in the coming years.

Common Pitfalls in Sourcing 6061-T6 Aluminum: Quality and Intellectual Property Concerns

Sourcing 6061-T6 aluminum, a widely used structural alloy, can present several challenges related to material quality and potential intellectual property (IP) issues. Being aware of these pitfalls helps ensure reliable supply, performance consistency, and legal compliance.

Inconsistent or Unverified Material Quality

One of the most frequent issues when sourcing 6061-T6 aluminum is receiving material that does not meet the required mechanical or chemical specifications. Suppliers, especially from less-regulated markets, may provide material labeled as 6061-T6 without proper certification or testing. This can result in variations in tensile strength, yield strength, elongation, or chemical composition, leading to part failure in critical applications. Always require mill test reports (MTRs) or certified material test reports (CMTRs) that validate compliance with ASTM B221, AMS 4027, or other relevant standards.

Lack of Traceability and Certification

A major quality pitfall is the absence of full material traceability. Without proper heat lot traceability, it becomes impossible to verify the origin of the material or investigate issues if a batch fails in service. Reputable suppliers provide traceable documentation linking each shipment to specific production batches. Sourcing from vendors who cannot provide this documentation increases the risk of counterfeit or mixed-alloy material entering the supply chain.

Non-Compliance with Temper Specifications

The “T6” in 6061-T6 refers to a specific heat treatment process (solution heat-treated and artificially aged). Improper heat treatment—either under-aging or over-aging—can result in suboptimal mechanical properties. Some suppliers may mislabel material or skip proper aging processes to cut costs. This leads to inconsistent performance, reduced strength, or poor machinability. Ensure suppliers adhere to standardized aging cycles and can provide evidence of proper temper processing.

Counterfeit or Misrepresented Material

In global supply chains, counterfeit aluminum—where material is falsely labeled as 6061-T6—is a growing concern. This includes material that may be a lower-grade alloy (e.g., 6063 or recycled scrap blends) or off-spec 6061. These materials often fail under stress or do not meet dimensional stability requirements. Third-party verification through spectrographic analysis or mechanical testing may be necessary when sourcing from unfamiliar or high-risk suppliers.

Intellectual Property Risks in Custom Forms or Processes

When sourcing custom extrusions, forgings, or machined components made from 6061-T6, IP concerns can arise. Suppliers may use proprietary tooling or processes developed by your company without proper contractual protection. Ensure that engineering drawings, molds, dies, and process know-how are protected through non-disclosure agreements (NDAs), IP assignment clauses, and clear ownership terms in procurement contracts. Failure to do so can result in unauthorized replication or reverse engineering by the supplier or its affiliates.

Inadequate Supplier Qualification

Relying on unqualified or uncertified suppliers increases the risk of both quality and IP issues. Suppliers should be audited for quality management systems (e.g., ISO 9001, AS9100 for aerospace), process controls, and compliance history. A lack of formal qualification processes leaves buyers exposed to inconsistent deliveries and potential legal vulnerabilities, especially in regulated industries.

Conclusion

To mitigate these pitfalls, establish a robust sourcing strategy that includes verified supplier audits, mandatory material certifications, traceability requirements, and strong IP protection protocols. Proactive due diligence ensures that 6061-T6 aluminum meets performance expectations and safeguards your organization against quality failures and intellectual property exposure.

Logistics & Compliance Guide for 6061-T6 Aluminum Material Properties

Overview of 6061-T6 Aluminum

6061-T6 aluminum is one of the most widely used aluminum alloys in engineering, construction, and manufacturing due to its excellent combination of mechanical properties, weldability, and corrosion resistance. The “T6” designation indicates that the material has undergone a specific heat treatment process—solution heat-treated and artificially aged—to achieve optimal strength. Understanding the material properties of 6061-T6 is essential for ensuring compliance with industry standards and for effective logistics planning in procurement, handling, storage, and transportation.

Key Material Properties

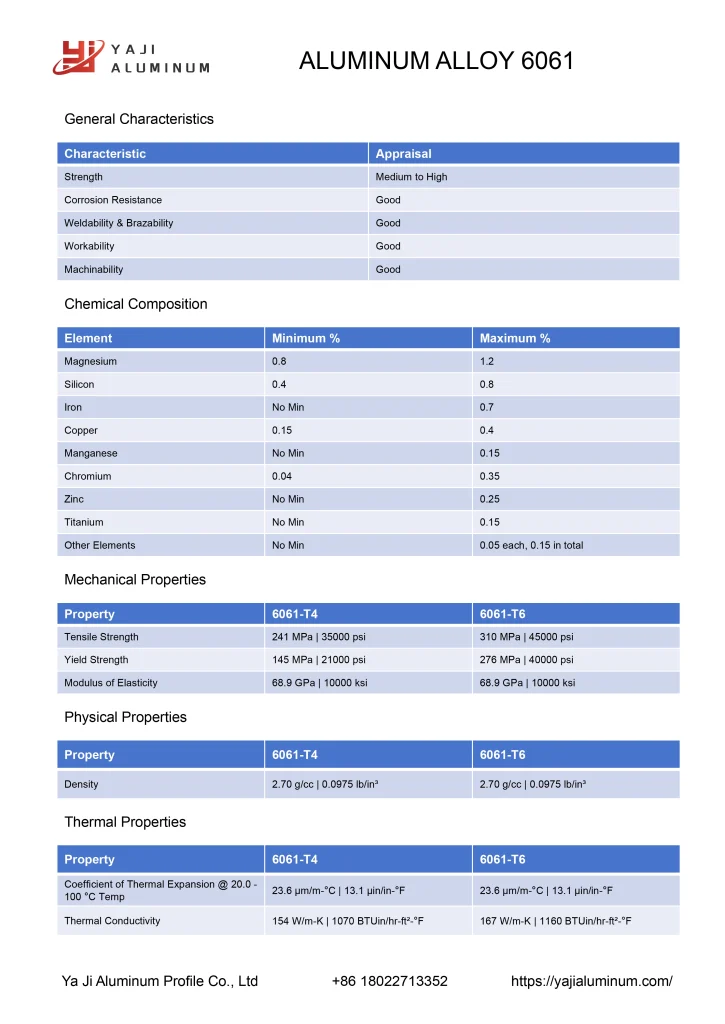

Mechanical Properties

- Ultimate Tensile Strength: 45,000 psi (310 MPa)

- Yield Strength (0.2% offset): 40,000 psi (276 MPa)

- Elongation at Break: 8–12% (depending on product form)

- Modulus of Elasticity: 10,000 ksi (68.9 GPa)

- Hardness (Brinell): 95 HB

- Fatigue Strength: ~14,000 psi (96.5 MPa) at 500 million cycles

These mechanical characteristics make 6061-T6 suitable for structural applications such as aircraft components, automotive parts, marine fittings, and architectural elements.

Physical Properties

- Density: 0.098 lb/in³ (2.70 g/cm³)

- Melting Range: 1,080–1,205°F (582–652°C)

- Thermal Conductivity: 130 Btu-in/hr-ft²-°F (188 W/m·K)

- Electrical Conductivity: 40% IACS

- Coefficient of Thermal Expansion: 13.1 µm/m·°C (7.3 µin/in·°F)

These physical attributes support efficient thermal management and lightweight design, critical in aerospace and transportation industries.

Corrosion Resistance & Surface Characteristics

6061-T6 exhibits good resistance to atmospheric corrosion and many chemicals. It forms a protective oxide layer naturally, but can be further enhanced with surface treatments:

– Anodizing: Improves wear and corrosion resistance; commonly used in architectural applications.

– Powder Coating or Painting: Provides aesthetic and protective finishes.

– Chromate Conversion Coating: Offers temporary protection during shipping and storage.

Proper surface protection is vital during logistics to prevent scratches, moisture exposure, and galvanic corrosion.

Logistics Considerations

Packaging & Handling

- Protection: Use edge protectors, plastic wraps, or wooden crating to prevent surface damage during transit.

- Separation: Keep aluminum materials isolated from dissimilar metals (e.g., steel, copper) to avoid galvanic corrosion. Use non-conductive spacers or coatings when necessary.

- Lifting: Employ non-marring slings or vacuum lifters to avoid surface indentation, especially on extrusions and sheet products.

- Moisture Control: Store in dry, climate-controlled environments or use vapor corrosion inhibitors (VCI) in packaging if humidity is a concern.

Storage

- Environment: Store indoors, away from direct rain, snow, and high humidity. Avoid contact with concrete floors unless protected—use wooden pallets or plastic sheets.

- Stacking: Limit stack height to prevent deformation, especially for thin sheets or long extrusions. Rotate stock using FIFO (First In, First Out) to prevent long-term storage degradation.

- Labeling: Clearly label material with alloy designation (6061-T6), heat number, dimensions, and certification status for traceability.

Transportation

- Ground Transport: Secure loads to prevent shifting. Use protective linings in trucks or containers to avoid scratching.

- Marine Shipping: Ensure waterproof packaging and desiccants to prevent saltwater and humidity exposure. Comply with IMO and IATA regulations if shipping internationally.

- Air Freight: Adhere to IATA Dangerous Goods Regulations; aluminum is generally non-hazardous but must be packaged to prevent damage.

Compliance & Certification Requirements

Industry Standards

6061-T6 must conform to recognized material specifications, including:

– ASTM B221: Standard for aluminum extruded bars, rods, wire, profiles, and tubing.

– ASTM B209: Standard for aluminum and aluminum-alloy sheet and plate.

– AMS 4027 / AMS 4117: Aerospace-grade specifications (if applicable).

– ISO 6361: International standard for wrought aluminum and aluminum alloy sheets, strips, and plates.

Material Certification

Suppliers must provide:

– Mill Test Certificate (MTC) / Certificate of Conformance (CoC): Includes chemical composition analysis and mechanical test results.

– Heat Traceability: Each batch should be traceable to its production heat number.

– Third-Party Testing Reports: Required in regulated industries (e.g., aerospace, defense, medical).

Regulatory Compliance

- REACH & RoHS (EU): Confirm that the aluminum alloy contains no restricted substances (typically compliant, but verify with supplier).

- Conflict Minerals (Dodd-Frank Act, U.S.): While aluminum is not a conflict mineral, supply chain due diligence may still be required for reporting.

- Customs & Import Regulations: Provide Harmonized System (HS) Code 7604.10 or 7606.12 for aluminum alloys, along with accurate country of origin documentation.

Quality Management Systems

Ensure suppliers are certified to:

– ISO 9001: Quality management.

– AS9100 (if aerospace): Aerospace-specific quality standards.

– ISO 14001: Environmental management (for sustainability compliance).

Conclusion

Effective logistics and compliance for 6061-T6 aluminum require a detailed understanding of its material properties, proper handling throughout the supply chain, and strict adherence to industry standards and regulatory requirements. By implementing best practices in packaging, storage, transportation, and documentation, organizations can ensure material integrity, regulatory compliance, and operational efficiency. Always source 6061-T6 from certified suppliers with full traceability and up-to-date certifications to mitigate risk and maintain quality assurance.

Conclusion on Sourcing 6061-T6 Aluminum Material Properties

When sourcing 6061-T6 aluminum, it is essential to consider its well-balanced combination of mechanical, physical, and fabrication characteristics, which make it one of the most widely used aluminum alloys in structural, aerospace, marine, and industrial applications. Its excellent strength-to-weight ratio, good corrosion resistance, weldability, and machinability contribute to its popularity across various industries.

Key properties of 6061-T6 aluminum—such as a tensile strength of approximately 45,000 psi (310 MPa), yield strength around 40,000 psi (276 MPa), and Brinell hardness of about 95—ensure reliable performance under moderate loads. Additionally, its thermal and electrical conductivity, coupled with good surface finish potential, make it suitable for both functional and aesthetic applications.

When sourcing this material, verifying mill certifications (such as AMS 4027 or ASTM B221) and ensuring compliance with required standards is crucial to guarantee consistent quality and performance. It is also important to source from reputable suppliers who provide traceability and documented testing to confirm the T6 temper condition, which is achieved through solution heat treatment and artificial aging.

In summary, 6061-T6 aluminum is a versatile, high-performance material that offers an optimal blend of strength, workability, and durability. Proper sourcing with attention to material specifications, certifications, and supplier reliability ensures that the material will meet engineering and application requirements effectively.