The global demand for durable, weather-resistant fabrics has driven significant growth in the technical textiles market, with 600D Oxford cloth emerging as a preferred material across industries such as outdoor gear, luggage, automotive covers, and protective apparel. According to Grand View Research, the global technical textiles market was valued at USD 231.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030—fueled by rising industrial applications and consumer demand for high-performance materials. As a widely used synthetic fabric known for its strength, water resistance, and affordability, 600D Oxford cloth—typically made from 600-denier nylon or polyester—has become a staple in functional product design. This growing demand has amplified the importance of choosing reliable, high-volume manufacturers capable of delivering consistent quality and scalability. Based on production capacity, geographical reach, certifications, and innovation in coating technologies (such as PU and PVC enhancements), we’ve analyzed the leading players in the 600D Oxford cloth space. Here are the top seven manufacturers shaping the industry with data-backed performance and market presence.

Top 7 600D Oxford Cloth Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oxford Fabric 600D

Domain Est. 2018

Website: wenjiaooxford.com

Key Highlights: 600D Oxford cloth is a high-quality textile fabric with excellent water and stain resistance. After special treatment, it can meet the usage requirements in ……

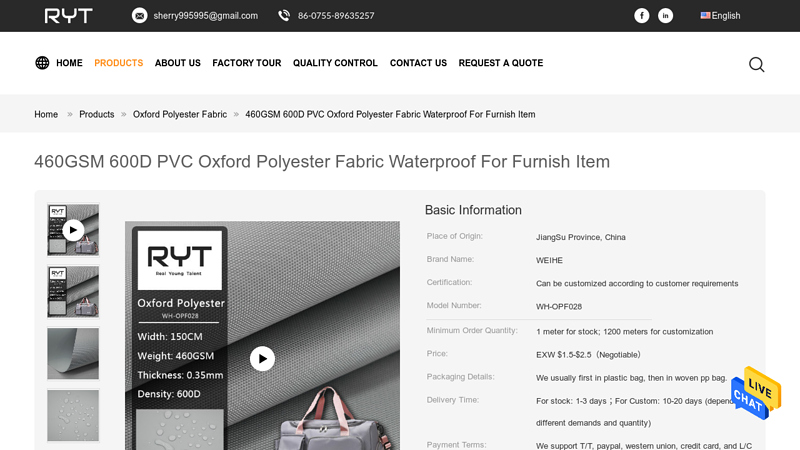

#2 460GSM 600D PVC Oxford Polyester Fabric Waterproof For Furnish …

Domain Est. 2022

Website: oxfordpolyesterfabric.com

Key Highlights: Rating 4.9 (131) Good Quality 460GSM 600D PVC Oxford Polyester Fabric Waterproof For Furnish Item From China – Shenzhen RYT Industrial Co.,Ltd….

#3 Top 15 Oxford Fabric Manufacturers in 2025

Website: szoneierfabrics.com

Key Highlights: The most popular Oxford fabrics in 2025 include 210D and 420D nylon Oxford, 600D polyester Oxford with PU/PVC backing, organic cotton Oxford ……

#4 Polyester

Domain Est. 2001

Website: mh-chine.com

Key Highlights: The 600D oxford fabric is coated with PVC (polyvinyl chloride) to provide additional strength, water resistance, tear-resistance and durability….

#5 600D Polyester Oxford Fabric

Domain Est. 2014

Website: oxford-material.com

Key Highlights: Out of stock600D Cationic polyester fabric has the characteristics of soft hand feeling, not easy to fade, anti-wrinkle and abrasion resistance….

#6 600D Polyester Oxford Tear

Domain Est. 2017

Website: kmtextilesupplier.com

Key Highlights: It is a traditional combed cotton fabric made mainly of polyester or nylon. Oxford cloth is used for many purposes, such as the production of bags, the ……

#7 600D Oxford Fabric

Domain Est. 2023

Website: ioxfordfabric.com

Key Highlights: Our 600D Oxford fabrics are 100% polyester with PU or ULY coating, which are used widely for bags, backpacks, tents, and outdoor gear….

Expert Sourcing Insights for 600D Oxford Cloth Material

H2: 2026 Market Trends for 600D Oxford Cloth Material

The global market for 600D Oxford cloth material is poised for significant evolution by 2026, driven by shifting consumer preferences, technological advancements in textile manufacturing, and rising demand across key end-use industries. This durable and cost-effective fabric, known for its water resistance, strength, and versatility, continues to gain traction in sectors such as outdoor gear, luggage, military equipment, automotive interiors, and industrial applications.

-

Rising Demand in Outdoor and Lifestyle Sectors

By 2026, the outdoor recreation market—encompassing camping, hiking, and urban travel—is expected to grow steadily, particularly in North America, Europe, and parts of Asia-Pacific. As consumers prioritize functional and long-lasting products, 600D Oxford cloth is increasingly favored for backpacks, tents, coolers, and travel accessories due to its balance of durability and moderate weight. Enhanced finishes, such as PU coatings and UV resistance, are making the fabric more suitable for extreme weather conditions, further boosting its appeal. -

Expansion in E-Commerce and Fashion-Forward Utility Products

The rise of direct-to-consumer (DTC) brands and e-commerce platforms is influencing product design and material selection. Many modern luggage and urban utility brands are using 600D Oxford cloth not only for its performance but also for its ability to be dyed in vibrant colors and finished with a sleek, technical aesthetic. By 2026, customization and lightweight composite versions of 600D Oxford fabric are expected to gain popularity, aligning with fashion and sustainability trends. -

Sustainability and Eco-Friendly Innovation

Environmental concerns are shaping the future of textile production. In response, manufacturers are developing recycled 600D Oxford fabrics using post-consumer PET bottles and bio-based polyesters. Major outdoor and lifestyle brands are setting sustainability targets, increasing demand for eco-certified textiles. By 2026, a growing share of 600D Oxford cloth is expected to be produced from recycled content, particularly in Europe and North America, where regulatory pressures and consumer awareness are strongest. -

Growth in Industrial and Protective Applications

Beyond consumer goods, 600D Oxford cloth is seeing increased use in industrial and protective applications, including truck covers, safety gear, and military-grade equipment. Its abrasion resistance and ability to be laminated with other materials (e.g., PVC or TPU) make it ideal for heavy-duty use. Emerging markets in Southeast Asia and Latin America are investing in infrastructure and logistics, driving demand for durable tarpaulins and protective covers made from 600D Oxford. -

Regional Market Dynamics

Asia-Pacific remains the largest producer and consumer of 600D Oxford cloth, with China and India leading in manufacturing capacity. However, by 2026, localized production in Southeast Asia (Vietnam, Bangladesh) is expected to rise due to supply chain diversification efforts. Meanwhile, North America and Western Europe are projected to focus on high-value, specialty-grade 600D fabrics with advanced performance features, creating opportunities for innovation and premium pricing. -

Price Volatility and Raw Material Challenges

The market may face challenges related to fluctuating prices of raw materials, particularly crude oil derivatives used in polyester production. Geopolitical tensions and supply chain disruptions could impact costs. However, advancements in chemical recycling and alternative feedstocks may help stabilize production costs and support long-term market resilience.

In conclusion, the 600D Oxford cloth market in 2026 will be characterized by innovation, sustainability, and expanding applications. While competition from higher-denier fabrics (e.g., 1000D) and alternative materials persists, 600D Oxford remains a sweet spot for many applications—offering a compelling balance of durability, weight, and cost. Companies that invest in eco-friendly production, functional enhancements, and smart design integration are likely to lead the market in the coming years.

Common Pitfalls When Sourcing 600D Oxford Cloth Material (Quality and Intellectual Property)

Sourcing 600D Oxford cloth—a popular synthetic fabric known for its durability and water resistance—can present several challenges, particularly concerning material quality and intellectual property (IP) risks. Being aware of these pitfalls helps buyers, manufacturers, and brands avoid costly mistakes, product failures, or legal complications.

Poor Material Quality and Inconsistent Specifications

One of the most frequent issues when sourcing 600D Oxford cloth is receiving material that does not meet the advertised specifications. Suppliers may claim the fabric is 600D, but in reality, it may use lower denier yarns or reduced thread counts to cut costs.

Common quality-related pitfalls include:

– Inaccurate denier count: Some suppliers mislabel fabrics by using lower denier fibers (e.g., 500D or less) while marketing them as 600D.

– Inconsistent weaving density: Poor weave quality leads to reduced strength and abrasion resistance, undermining the fabric’s durability.

– Substandard coatings: The polyurethane (PU) or PVC coating applied for water resistance may be too thin or uneven, resulting in poor weather performance.

– Color fading and shrinkage: Low-quality dyes and improper finishing processes can cause color bleeding or fabric shrinkage after washing or exposure to sunlight.

To mitigate these risks, request material test reports (MTRs), conduct third-party lab testing, and perform thorough quality audits of supplier facilities.

Misrepresentation of Fabric Origin and Certifications

Suppliers—especially in competitive markets like China or Southeast Asia—may misrepresent the origin of the fabric or falsify certifications related to environmental compliance (e.g., REACH, OEKO-TEX) or sustainability claims (e.g., recycled content).

Red flags include:

– Unverifiable or generic certifications.

– Inconsistent labeling between batch shipments.

– Lack of traceability in the supply chain.

Always verify certifications through official databases and require batch-specific documentation.

Intellectual Property Infringement Risks

Using 600D Oxford cloth in branded products can expose companies to IP risks, particularly if the fabric incorporates patented technologies or mimics protected designs.

Key IP pitfalls include:

– Unauthorized use of branded textiles: Some high-performance Oxford fabrics incorporate proprietary technologies (e.g., ripstop patterns, moisture-wicking finishes) protected by patents or trademarks. Sourcing a “look-alike” material may still infringe on IP rights.

– Counterfeit or cloned materials: Certain suppliers replicate well-known branded fabrics (e.g., Cordura®-style weaves) without licensing, putting end-product manufacturers at legal risk.

– Design patent violations: Embossed textures, weave patterns, or colorways may be protected under design patents, especially in premium luggage, outdoor gear, or military applications.

To avoid IP disputes, conduct due diligence on fabric technology, consult with IP counsel, and ensure suppliers warrant that materials do not infringe third-party rights.

Lack of Supply Chain Transparency

Many sourcing issues stem from opaque supply chains. The actual manufacturer may be several tiers removed from the supplier you’re dealing with, making quality control and accountability difficult.

Mitigation strategies:

– Audit both direct suppliers and sub-contractors.

– Require full disclosure of mills and coating facilities.

– Use blockchain or digital traceability tools where feasible.

Conclusion

Sourcing reliable and legally compliant 600D Oxford cloth requires more than just competitive pricing. Buyers must prioritize verified quality standards, authentic certifications, and IP compliance to avoid reputational damage, product recalls, or legal action. Partnering with reputable suppliers, conducting regular audits, and investing in material verification are essential steps in mitigating these common pitfalls.

Logistics & Compliance Guide for 600D Oxford Cloth Material

This guide outlines key logistics and compliance considerations when sourcing, transporting, and handling 600D Oxford cloth, a durable and widely used synthetic fabric typically made from 100% polyester. Adhering to these guidelines ensures smooth operations, regulatory compliance, and product integrity.

Material Specifications & Identification

600D Oxford cloth refers to a tightly woven polyester fabric with a denier count of 600, indicating its thickness and durability. It is commonly used in bags, luggage, outdoor gear, and protective covers. Ensure all shipments include accurate labeling specifying:

– Material composition (e.g., 100% Polyester)

– Denier count (600D)

– Width and weight per square meter (gsm)

– Color and finish (e.g., PU-coated, water-resistant)

– Lot or batch numbers for traceability

Regulatory Compliance

Compliance with international, regional, and local regulations is essential for legal import/export and safe use.

REACH (EU)

Ensure the material complies with the EU’s REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations. Confirm that restricted substances (e.g., phthalates, azo dyes, heavy metals) are absent or within permissible limits. Request a REACH compliance certificate from the supplier.

RoHS (Applicable Electronics Applications)

If the fabric is used in electronic enclosures or accessories, verify compliance with RoHS (Restriction of Hazardous Substances) directives, particularly concerning lead, cadmium, mercury, and certain flame retardants.

CPSIA (USA)

For consumer products intended for children (e.g., backpacks), compliance with the U.S. Consumer Product Safety Improvement Act (CPSIA) is required. This includes limits on lead content and phthalates in children’s products.

Prop 65 (California, USA)

Ensure the material does not contain chemicals listed under California Proposition 65 without appropriate warnings, especially if sold in the U.S. market.

Textile Labeling Laws

Adhere to country-specific textile labeling requirements (e.g., FTC rules in the U.S., EU Textile Regulation 1007/2011), which mandate accurate fiber content disclosure on product labels.

Packaging & Handling

Proper packaging protects the material during transit and storage.

- Roll Packaging: 600D Oxford is typically shipped in rolls. Use sturdy cardboard cores and wrap rolls in polyethylene film to prevent moisture, dust, and abrasion.

- Palletization: Secure rolls on wooden or plastic pallets using stretch wrap or strapping. Ensure even weight distribution and stackability.

- Labeling: Clearly label each roll and pallet with SKU, material type, dimensions, weight, batch number, and handling instructions (e.g., “Keep Dry,” “Do Not Stack Excessively”).

- Storage Conditions: Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources to prevent UV degradation and maintain fabric integrity.

Transportation & Logistics

Efficient and safe transportation minimizes risks and delays.

- Mode of Transport: Suitable for road, sea, and air freight. Choose based on urgency, cost, and destination.

- Documentation: Prepare a commercial invoice, packing list, bill of lading/airway bill, and certificates of compliance (e.g., REACH, Certificate of Origin).

- Customs Clearance: Ensure Harmonized System (HS) code accuracy—typically 5407.42 or 5903.10 for coated or uncoated polyester woven fabrics. Provide accurate product descriptions to avoid delays.

- Insurance: Insure shipments against loss, damage, or delay, especially for high-value or long-distance transport.

Environmental & Sustainability Considerations

Growing demand for sustainable textiles requires attention to environmental compliance.

- Recyclability: Confirm if the 600D Oxford is recyclable. PU-coated versions may be harder to recycle than plain polyester.

- Recycled Content: If using recycled polyester (rPET), verify certification (e.g., GRS – Global Recycled Standard) and maintain chain of custody documentation.

- Chemical Management: Ensure dyes and coatings comply with environmental standards such as ZDHC (Zero Discharge of Hazardous Chemicals).

Quality Assurance & Traceability

Maintain quality and accountability through rigorous QA processes.

- Pre-Shipment Inspection: Conduct inspections to verify color, weight, coating quality, and absence of defects.

- Testing Reports: Request test reports for key properties: tensile strength, tear resistance, water column (waterproofness), and color fastness.

- Batch Tracking: Implement a system to trace material back to its source for quality control and compliance audits.

Conclusion

Managing the logistics and compliance of 600D Oxford cloth requires attention to material specifications, regulatory frameworks, proper handling, and documentation. By following this guide, businesses can ensure reliable supply chains, avoid customs issues, and meet global market requirements for safety and sustainability.

Conclusion for Sourcing 600D Oxford Cloth Material:

After a thorough evaluation of suppliers, material quality, pricing, and sustainability factors, sourcing 600D Oxford cloth is a viable and strategic decision for applications requiring durable, water-resistant, and abrasion-resistant fabric. This material offers an optimal balance of strength, weight, and cost-effectiveness, making it ideal for products such as luggage, backpacks, outdoor gear, and protective covers.

Reliable suppliers have been identified both domestically and internationally, with several offering eco-friendly options such as recycled polyester (rPET) 600D Oxford, which aligns with growing sustainability goals. Key considerations such as minimum order quantities (MOQs), lead times, and compliance with environmental and safety standards (e.g., REACH, OEKO-TEX) have been assessed to ensure a resilient and ethical supply chain.

In conclusion, proceeding with the selected suppliers for 600D Oxford cloth ensures access to high-performance material that meets quality, cost, and sustainability requirements, thereby supporting long-term product reliability and brand integrity. Regular quality audits and supplier relationship management will be essential to maintain consistency and drive continuous improvement.