The industrial air compressor market is experiencing robust growth, driven by increasing demand across manufacturing, automotive, and construction sectors. According to Grand View Research, the global air compressor market size was valued at USD 35.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. A key segment within this growth is two-stage air compressors, which offer higher efficiency and consistent pressure output—making them ideal for heavy-duty applications. Among various sizes, the 60-gallon two-stage model stands out for its optimal balance of capacity and portability, widely used in mid-to-large scale operations. With rising energy efficiency standards and automation adoption, manufacturers are investing in advanced, durable compressors that reduce operational costs and downtime. Based on performance metrics, output reliability, energy efficiency, customer reviews, and market presence, the following eight manufacturers have emerged as leaders in the 60-gallon two-stage air compressor space.

Top 8 60 Gallon Two Stage Air Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quincy QT

Domain Est. 1997

Website: aircompressors.com

Key Highlights: In stock 30-day returnsThe Quincy QT-54 5 Horsepower 60-Gallon Vertical Tank Two-Stage Air Compressor (230V 1-Phase) delivers powerful, reliable performance for industrial use….

#2 Saylor

Domain Est. 1997 | Founded: 1915

Website: saylor-beall.com

Key Highlights: Since 1915, Saylor-Beall has been a trusted name in the manufacturing of industrial-quality, two-stage air compressors….

#3 US Air Compressor

Domain Est. 2003

Website: usaircompressor.com

Key Highlights: Purchase a high-quality industrial air compressor and experience our 10-Year Bumper-to-Bumper Warranty, ensuring zero downtime and predictable costs….

#4 Two Stage Air Compressors

Domain Est. 2014

Website: compressorpros.com

Key Highlights: Free delivery · 7-day returnsDiscover top-tier two stage air compressors at CompressorPros! Ideal for industrial tasks, our powerful models deliver high pressure and airflow….

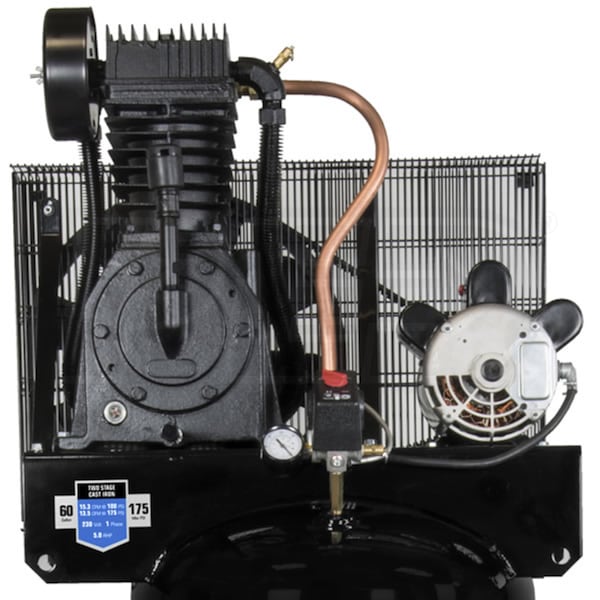

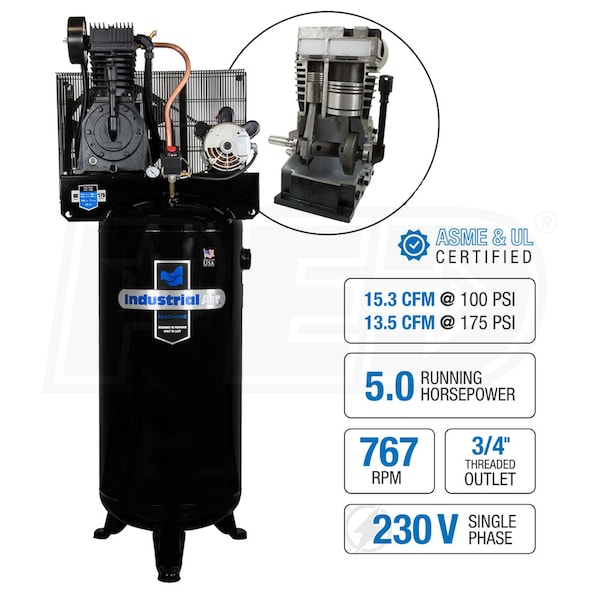

#5 60 Gallon 2 Stage Air Compressor (CE5002)

Domain Est. 1997

Website: campbellhausfeld.com

Key Highlights: This Campbell Hausfeld, 2 Stage, stationary electric air compressor (CE5002) features a cast iron, oil lubricated pump. 175 PSI max pressure allows the user ……

#6 2

Domain Est. 2001

Website: ingersollrand.com

Key Highlights: The Ingersoll Rand 60 gallon, electric-driven two-stage air compressor has the flexibility to provide both intermittent and continuous power….

#7 Two

Domain Est. 2003

Website: stellarindustries.com

Key Highlights: Stellar Two-Stage Air Compressors are an ideal choice for service trucks, offering ample power and compressed air to help you get the job done….

#8 Air Compressors Direct

Domain Est. 2003

Website: aircompressorsdirect.com

Key Highlights: BelAire 5-HP 60-Gallon Two-Stage Air Compressor (230V 1-Phase). (40 Reviews). $1,174.00 · Read ……

Expert Sourcing Insights for 60 Gallon Two Stage Air Compressor

H2: Projected 2026 Market Trends for 60 Gallon Two-Stage Air Compressors

The market for 60-gallon two-stage air compressors is anticipated to experience steady growth and notable shifts by 2026, driven by industrial modernization, increased demand for energy-efficient equipment, and evolving regulatory standards. This analysis explores key market trends shaping the demand, innovation, and competitive landscape for this specific category of industrial air compressors.

-

Rising Demand in Manufacturing and Construction Sectors

By 2026, the 60-gallon two-stage air compressor is expected to maintain strong adoption in heavy manufacturing, automotive repair, and construction industries. These sectors require consistent, high-pressure air output for tools like impact wrenches, sandblasters, and paint sprayers—applications where two-stage compressors excel due to their efficiency and durability. Infrastructure development programs in North America, Europe, and parts of Asia-Pacific are projected to bolster demand for reliable industrial-grade compressors. -

Focus on Energy Efficiency and Sustainability

Energy efficiency will be a dominant trend influencing design and purchasing decisions. Manufacturers are increasingly integrating variable speed drives (VSD), enhanced cooling systems, and smart controls into 60-gallon models to reduce power consumption and carbon footprint. Regulatory pressures, such as updated ENERGY STAR guidelines and regional emissions standards, are pushing OEMs to innovate. By 2026, energy-efficient two-stage compressors are expected to capture a larger market share, especially among environmentally conscious industrial users. -

Technological Integration and Smart Features

The integration of IoT (Internet of Things) and predictive maintenance technologies is poised to transform the 60-gallon two-stage compressor market. Leading brands are incorporating sensors and cloud-connected monitoring systems that provide real-time data on pressure levels, temperature, oil condition, and maintenance alerts. This shift toward “smart compressors” enhances operational uptime and reduces long-term costs, making them attractive for large-scale industrial users seeking automation and data-driven maintenance. -

Shift Toward Quiet and Portable Designs

Noise reduction technologies and improved portability are becoming key differentiators. As workshops and job sites prioritize worker safety and comfort, demand is growing for quieter compressors—especially those operating under 75 decibels. Enhanced wheel kits, compact footprints, and vibration-dampening features are being incorporated into newer 60-gallon models. By 2026, compressors that balance high performance with low noise and mobility will gain competitive advantage. -

Competitive Landscape and Regional Dynamics

North America is expected to remain the largest market for 60-gallon two-stage compressors due to robust industrial activity and a large base of small to medium-sized enterprises (SMEs). However, Asia-Pacific, particularly India and Southeast Asia, is projected to witness the fastest growth, driven by expanding manufacturing and construction sectors. Major players like Ingersoll Rand, Quincy, Campbell Hausfeld, and Saylor-Beall are likely to intensify product differentiation through innovation, service networks, and direct-to-consumer sales channels. -

Price Sensitivity and Aftermarket Opportunities

While initial purchase cost remains a factor, total cost of ownership (TCO)—including maintenance, energy use, and lifespan—is becoming a more critical decision criterion. This trend is boosting demand for premium models with extended warranties and lower lifetime costs. Concurrently, the aftermarket for replacement parts (e.g., valves, belts, filters) and servicing is expected to grow, creating new revenue streams for manufacturers and third-party providers.

Conclusion

By 2026, the 60-gallon two-stage air compressor market will be characterized by technological advancement, sustainability, and smarter, more efficient equipment. Companies that prioritize innovation in energy efficiency, connectivity, and user-centric design will lead the market. As industrial automation and green manufacturing gain momentum, the 60-gallon two-stage compressor will remain a vital tool—evolving to meet the demands of a modern, connected, and eco-conscious industrial world.

H2: Common Pitfalls When Sourcing a 60 Gallon Two-Stage Air Compressor

Purchasing a 60-gallon two-stage air compressor is a significant investment, and avoiding common pitfalls is crucial for ensuring you get reliable, efficient, and safe equipment that meets your operational needs. Here are the key areas where buyers often go wrong:

1. Overlooking Build Quality and Component Durability

- Cheap Materials: Prioritizing low cost often leads to compressors with thin steel tanks, aluminum heads prone to cracking, or cast iron components of inferior grade. These fail prematurely under heavy use.

- Substandard Pumps & Motors: Low-quality pumps (e.g., non-industrial grade) wear out quickly, lose efficiency, and require frequent repairs. Undersized or poorly cooled motors overheat and burn out.

- Weak Seals and Hoses: Poor-quality O-rings, gaskets, and discharge hoses lead to air leaks, pressure drops, and safety hazards.

2. Ignoring Critical Industrial-Grade Specifications (IP)

- Insufficient CFM (Cubic Feet per Minute): Failing to match the compressor’s CFM output (at the required PSI) to the total demand of all tools used simultaneously. Two-stage units are chosen for high CFM needs; under-specifying defeats the purpose.

- Inadequate Duty Cycle: Selecting a compressor with a duty cycle (e.g., 50/50) lower than required for continuous operation. Industrial applications often need 100% duty cycle (continuous run).

- Incorrect Voltage/Phase: Ordering a 3-phase compressor without confirming 3-phase power is available, or vice-versa. Mismatched voltage causes motor damage or failure to start.

- Poor Air Filtration & Aftercooling: Overlooking the quality of intake air filters and aftercoolers. Inadequate cooling leads to moisture buildup, damaging tools and pneumatic systems; poor filtration reduces pump life.

3. Neglecting Safety and Regulatory Compliance

- Missing/Invalid ASME Certification: Operating a non-ASME certified pressure vessel (the tank) is illegal in most jurisdictions and a major safety liability. Always verify the ASME “U” stamp and National Board registration.

- Inadequate Safety Valves: Ensuring the unit has properly sized, correctly installed, and regularly tested pressure relief valves (PRVs) is non-negotiable.

- Lack of Overload Protection: Motors must have proper thermal overload protection to prevent fire hazards from overheating.

- Ignoring Local Codes: Not checking compliance with local electrical, noise, and emissions regulations.

4. Underestimating Maintenance Requirements and Costs

- Inaccessible Design: Choosing a unit where oil drains, air filters, and belts are difficult to access, leading to skipped maintenance and premature failure.

- Using Wrong Lubricants: Assuming any compressor oil is suitable. Using non-detergent or incorrect viscosity oil drastically shortens pump life.

- Ignoring Moisture Management: Failing to install or maintain adequate coalescing filters, air dryers, and drain valves (manual or automatic), leading to water in the air lines and system corrosion.

- Overspending on Repairs: Opting for a cheap unit without considering the long-term cost of frequent repairs and downtime versus a higher-quality, lower-maintenance model.

5. Falling for Misleading Marketing and Hidden Costs

- “Peak” CFM vs. “Rated” CFM: Vendors may advertise inflated “peak” CFM numbers. Focus on the continuous, sustained CFM rating at your required operating pressure (e.g., 90-100 PSI).

- Omitting Ancillary Equipment Costs: The compressor is just the start. Budget for essential extras: high-quality air lines, filters, regulators, dryers, receivers (if needed), tools, and installation.

- Poor Warranty and Support: Choosing a brand with a short warranty (e.g., <1 year on pump/motor) or no local service network leads to high repair costs and downtime.

- Ignoring Noise Levels (dB): Two-stage compressors are loud. Not considering decibel ratings can lead to workplace safety violations or the need for costly sound enclosures.

6. Poor Sourcing Channel Selection

- Unreliable Online Retailers: Buying from obscure online marketplaces increases the risk of counterfeit parts, non-compliant units, or no recourse for defects.

- Lack of Technical Support: Choosing a supplier unable to answer detailed technical questions about specs, compatibility, or installation.

- Ignoring Lead Times and Logistics: Failing to account for long delivery times or the complexity/cost of delivering a heavy industrial unit to the site.

Mitigation Strategy: Always prioritize reputable industrial suppliers, demand full specifications (CFM at PSI, duty cycle, motor HP/kW, voltage/phase, ASME certification proof), get quotes that include essential accessories, and factor in total cost of ownership (purchase, installation, energy, maintenance, downtime) rather than just the initial price tag.

H2: Logistics & Compliance Guide for 60 Gallon Two-Stage Air Compressor

Proper logistics planning and regulatory compliance are critical when transporting, storing, and operating a 60-gallon two-stage air compressor. This guide outlines key considerations to ensure safe handling, transportation, and regulatory adherence throughout the equipment lifecycle.

1. Transportation & Logistics

1.1 Packaging & Handling

- Secure Crating: The compressor should be shipped in a wooden or heavy-duty palletized crate to prevent damage during transit.

- Forklift Pads: Ensure unit has reinforced lifting points or skid base for forklift handling.

- Vibration Protection: Use anti-vibration mounts or padding to protect internal components during transport.

- Orientation: Always transport upright to prevent oil migration into air lines or cylinders.

1.2 Weight & Dimensions

- Typical Specs:

- Weight: 350–550 lbs (varies by model and motor type)

- Dimensions: Approx. 36″ H x 30″ W x 72″ L

- Confirm exact dimensions and weight from manufacturer’s spec sheet before planning shipment.

1.3 Transportation Mode

- Ground Freight (LTL/Full Truckload):

- Use freight carriers experienced with industrial equipment.

- Provide accurate freight class (typically NMFC 150–175 based on density and handling).

- Include lift gate service if delivery site lacks a loading dock.

- International Shipments:

- Comply with export regulations (e.g., U.S. Commerce Department EAR).

- Include proper export documentation (Commercial Invoice, Packing List, etc.).

- Consider containerization and moisture protection for ocean freight.

1.4 Delivery Site Requirements

- Clear Access: Minimum 36″ clearance for doorways and hallways.

- Floor Load Capacity: Ensure floors can support concentrated weight (check psi load).

- Unloading Plan: Confirm availability of forklift, pallet jack, or crane as needed.

2. Regulatory Compliance

2.1 Electrical Compliance

- Voltage & Phase:

- Most 60-gallon two-stage compressors require 208–240V or 460V, 3-phase power.

- Verify local electrical codes (e.g., NEC Article 690 in the U.S.).

- Certifications:

- Must bear UL/cUL (U.S./Canada) or CE (Europe) certification.

- Confirm NEMA enclosure rating (e.g., NEMA 1 for indoor, NEMA 3R for outdoor use).

2.2 Pressure System Regulations

- ASME Certification:

- The air tank must comply with ASME Boiler and Pressure Vessel Code (Section VIII).

- Look for the ASME “U” stamp and a permanently affixed nameplate with:

- Maximum allowable working pressure (MAWP)

- Test pressure

- Manufacturer ID

- Serial number

- Date of manufacture

- DOT Compliance (if transported charged):

- If the tank is shipped pressurized, it may fall under DOT 49 CFR for compressed gas (though typically exempt if below certain thresholds).

- Best practice: Depressurize completely before shipping.

2.3 Environmental & Emissions

- Oil-Lubricated vs. Oil-Free:

- Oil-lubricated models must comply with proper disposal regulations for used oil (EPA 40 CFR in the U.S.).

- Avoid discharging contaminated condensate into drains; use oil/water separators if needed.

- Noise Compliance:

- Sound levels typically 70–85 dB(A); ensure compliance with OSHA 29 CFR 1910.95 (hearing protection zones if >85 dB).

- Use acoustic enclosures in noise-sensitive environments.

2.4 Workplace Safety (OSHA & Local Codes)

- Installation Clearance:

- Maintain minimum 30″ clearance around compressor for ventilation and service access.

- Ventilation:

- Install in a well-ventilated area to prevent heat buildup and accumulation of exhaust fumes (if engine-driven).

- Personal Protective Equipment (PPE):

- Operators must use hearing protection, eye protection, and appropriate clothing.

- Lockout/Tagout (LOTO):

- Follow OSHA 29 CFR 1910.147 during maintenance.

3. Import & Customs (International Shipments)

3.1 Harmonized System (HS) Code

- Typical HS Code: 8414.80.90 (Other air pumps and compressors)

- Confirm with local customs authority for precise classification and duty rates.

3.2 Required Documentation

- Commercial Invoice

- Bill of Lading/Air Waybill

- Packing List

- Certificate of Origin

- Product Compliance Certificates (CE, UL, etc.)

3.3 Import Restrictions

- Some countries regulate high-pressure equipment or motors above certain horsepower.

- Check local standards (e.g., CCC in China, PSE in Japan).

4. Storage & On-Site Handling

- Indoor Storage: Preferred to avoid moisture and temperature extremes.

- Outdoor Use: Use only if unit is rated for outdoor conditions (NEMA 3R or higher) and protected from direct rain/sun.

- Long-Term Storage:

- Drain tank completely.

- Apply light coat of oil to cylinder bores if stored for >30 days.

- Cover with breathable tarp to prevent dust buildup.

5. Maintenance & Compliance Recordkeeping

- ASME Tank Inspections:

- Perform periodic internal/external inspections as per jurisdiction (typically every 1–5 years).

- Maintain log of hydrostatic tests (usually every 10 years).

- Service Logs:

- Record oil changes, filter replacements, belt tensioning, and safety valve testing.

- Safety Valve Certification:

- Pressure relief valve must be tested and tagged per ASME requirements.

Conclusion

Transporting and operating a 60-gallon two-stage air compressor requires careful attention to logistics, safety, and regulatory standards. Always consult the manufacturer’s manual and local regulations. Prioritize ASME compliance, proper electrical installation, and worker safety to ensure reliable and legal operation.

Note: Regulations vary by country and jurisdiction. Engage a qualified mechanical or safety engineer when in doubt.

—

End of Guide

In conclusion, sourcing a 60-gallon two-stage air compressor requires careful consideration of power requirements, intended applications, duty cycle, durability, brand reputation, and long-term maintenance costs. A two-stage compressor provides greater efficiency, consistent pressure output, and longer run times compared to single-stage models, making it ideal for heavy-duty industrial use, automotive repair shops, or manufacturing environments. Key factors in the sourcing decision should include CFM (cubic feet per minute) output, horsepower, motor type, tank construction, portability, warranty, and customer support. Comparing reputable brands such as Quincy, Campbell Hausfeld, Saylor-Beall, or Ingersoll Rand can help ensure reliability and performance. Additionally, evaluating both initial investment and operational costs—such as energy efficiency and maintenance—will lead to a cost-effective and sustainable choice. Ultimately, selecting the right 60-gallon two-stage air compressor involves aligning technical specifications with operational needs to ensure optimal productivity and longevity.