The global fastener market is experiencing steady growth, driven by rising demand from automotive, construction, and industrial manufacturing sectors. According to Grand View Research, the global fasteners market size was valued at USD 111.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. Within this expanding landscape, stainless steel hex cap screws—particularly the 5/8-11 x 3 inch规格—have become critical components due to their durability, corrosion resistance, and high tensile strength. With increasing infrastructure development and stricter material performance standards, demand for high-quality, precision-engineered fasteners continues to rise. This growing need has positioned key manufacturers to innovate in material sourcing, production efficiency, and quality assurance. Based on production capacity, global reach, product certifications, and customer reviews, the following eight companies have emerged as leading manufacturers of 5/8-11 x 3 inch stainless steel hex cap screws, meeting rigorous industry standards and supplying critical sectors worldwide.

Top 8 5/8-11 X 3 Hex Cap Screw Stainless Steel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 5/8-11 X 3 S.S. Hex Cap Screw

Domain Est. 2002

Website: arrowterminal.com

Key Highlights: Shop for 5/8-11 X 3 S.S. Hex Cap Screw at ArrowTerminal.com, your source for electrical, industrial and maintenance supplies for every industry….

#2 5/8-11 X 3 316 Stainless Steel Hex Cap Screw

Domain Est. 2015

#3 58X3HBSS

Domain Est. 1997

Website: pecofasteners.com

Key Highlights: 58X3HBSS | 5/8-11 X 3 HEX CAP SCREW 304 STAINLESS STEEL (1-1/2″ OF THREAD) | PECO Fasteners & Electrical Products….

#4 Hex Cap Screw 316 Stainless Steel 5/8

Domain Est. 1997

Website: lawsonproducts.com

Key Highlights: 90-day returnsHex Cap Screw, 316 Stainless Steel, Plain Finish, Coarse Thread, 15/32″ Head Height, 15/16″ Across Flats, 5/8-11 x 3-1/2″ (Pack of 5)….

#5 5/8″-11 x 3-1/2″ Stainless Steel Hex Head Cap Screw 316

Domain Est. 1998

Website: kljack.com

Key Highlights: In stock $5 delivery5/8″-11 x 3-1/2″ Stainless Steel Hex Head Cap Screw 316. Item #: 62C350HCS3. KL Jack Quality Vendor. $96.25 /Box Only. $3.85 Each. Package Size:…

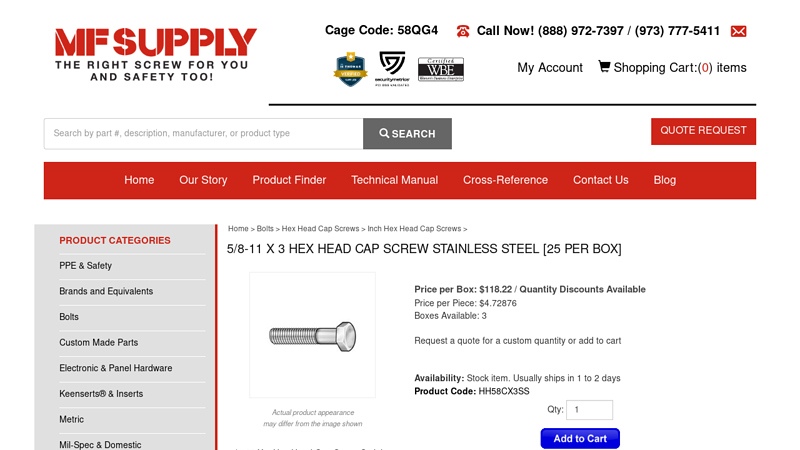

#6 5/8-11 X 3 HEX HEAD CAP SCREW STAINLESS STEEL

Domain Est. 2004

#7 11 x 3″ ASTM F593 Fully Threaded Hex Cap Screws, 316 Stainless …

Domain Est. 2008

Website: aftfasteners.com

Key Highlights: In stock Free delivery over $200Great prices and fast shipping on 5/8″-11 x 3″ ASTM F593 Fully Threaded Hex Cap Screws, 316 Stainless Steel, Domestic (5/Pkg.) at AFT Fasteners….

#8 5/8″

Domain Est. 2009

Website: fastenersinc.net

Key Highlights: 5/8″-11 x 3″ Stainless Steel Hex Cap Screw / Bolt 18-8 / 304. Regular price: $26.05. Regular price: Sale price: $26.05. Unit price: / per….

Expert Sourcing Insights for 5/8-11 X 3 Hex Cap Screw Stainless Steel

H2: Projected Market Trends for 5/8-11 x 3 Hex Cap Screws (Stainless Steel) in 2026

The market for 5/8-11 x 3 inch hex cap screws made from stainless steel is expected to experience steady growth and notable shifts by 2026, driven by macroeconomic factors, industrial demand, and evolving supply chain dynamics. This analysis outlines key trends shaping the market for this specific fastener across major end-use sectors.

1. Rising Demand in Infrastructure and Renewable Energy

Government-led infrastructure investments, particularly under the U.S. Infrastructure Investment and Jobs Act and similar global initiatives, are anticipated to significantly boost demand for high-strength, corrosion-resistant fasteners. The 5/8-11 x 3 hex cap screw, commonly used in structural steel connections, highway projects, and bridge construction, is well-positioned to benefit. Additionally, the expansion of renewable energy—especially wind and solar installations—requires durable fasteners that withstand harsh environmental conditions. Stainless steel variants (particularly Grade 304 and 316) are preferred in these applications due to their resistance to moisture and salt, supporting sustained demand for this product.

2. Supply Chain Resilience and Localization

Following ongoing disruptions from geopolitical tensions and pandemic-era bottlenecks, manufacturers and distributors are prioritizing supply chain resilience. By 2026, there is a growing shift toward regional sourcing and nearshoring, especially in North America and Europe. This is expected to favor domestic producers of stainless steel fasteners, reducing lead times and import dependency. However, raw material costs—particularly for nickel and chromium—remain volatile, potentially impacting pricing and profit margins.

3. Price Volatility and Cost Management

Stainless steel pricing is closely tied to global nickel markets, which are expected to remain volatile through 2026 due to fluctuating mining output and green technology demand. As a result, end-users and distributors are increasingly adopting long-term contracts and strategic hedging to manage cost uncertainty. Smaller distributors may face margin pressure, while large suppliers with vertical integration capabilities will have a competitive edge.

4. Sustainability and Regulatory Compliance

Environmental regulations are becoming stricter, particularly in the EU and North America, promoting the use of recyclable and low-carbon materials. Stainless steel, being 100% recyclable, aligns well with sustainability goals. By 2026, procurement policies in public and private sectors are expected to increasingly favor suppliers with certified environmental management systems (e.g., ISO 14001), pushing manufacturers to enhance transparency in sourcing and production.

5. Technological Advancements and Smart Fastening

While the 5/8-11 x 3 hex cap screw remains a standard mechanical component, smart manufacturing trends are influencing inventory and logistics. Predictive analytics, digital procurement platforms, and AI-driven inventory management are enabling faster turnaround and just-in-time delivery models. Some industrial buyers are beginning to adopt connected fasteners with embedded sensors for structural health monitoring—although this trend is more relevant to high-risk applications and may not directly impact standard stainless steel screws in the near term.

Conclusion

By 2026, the market for 5/8-11 x 3 inch stainless steel hex cap screws is projected to grow moderately at a CAGR of 3.5–4.5%, driven by infrastructure development, renewable energy, and supply chain localization. While cost volatility and material sourcing challenges persist, advancements in production efficiency and sustainability practices will support market stability. Stakeholders who invest in domestic manufacturing, digital supply chains, and eco-compliant processes are likely to gain a competitive advantage in this evolving landscape.

H2: Common Pitfalls When Sourcing 5/8-11 x 3″ Hex Cap Screws in Stainless Steel (Quality & IP Considerations)

When sourcing 5/8-11 x 3″ hex cap screws in stainless steel, buyers often encounter several critical pitfalls related to material quality, mechanical properties, and intellectual property (IP) or compliance issues. Being aware of these challenges helps ensure product reliability and regulatory compliance.

- Incorrect Stainless Steel Grade

- Pitfall: Assuming “stainless steel” guarantees corrosion resistance or strength.

- Risk: Suppliers may use lower-grade stainless (e.g., 201 or 302) instead of required grades like 304 or 316.

-

Solution: Specify ASTM A193 (for high-temp/service) or ASTM A320 (low-temp) and demand mill test reports (MTRs) verifying grade (e.g., 316 for marine or chemical environments).

-

Failure to Verify Mechanical Properties

- Pitfall: Assuming all stainless hex cap screws meet strength standards.

- Risk: Substandard fasteners may not meet required tensile/yield strength (e.g., ASTM A193 B8 for 304 or B8M for 316).

-

Solution: Require certification to ASTM A193 or ISO 3506 (property classes like A4-80 for 316). Conduct third-party testing if volume warrants.

-

Counterfeit or Non-Compliant Markings

- Pitfall: Accepting fasteners with incorrect or missing grade markings.

- Risk: Fake or misrepresented parts compromise safety and traceability.

-

Solution: Inspect for proper head markings (e.g., “A4” and strength class). Be wary of unmarked or poorly stamped products.

-

Inadequate Corrosion Resistance in Service Environment

- Pitfall: Selecting 304 SS in chloride-rich environments.

- Risk: Pitting or stress corrosion cracking (SCC) in marine or chemical applications.

-

Solution: Use 316 (A4) stainless steel for improved chloride resistance. Consider passivation or additional coatings if needed.

-

Intellectual Property and Specification Compliance

- Pitfall: Using fasteners that infringe on proprietary designs or fail to meet OEM specs.

- Risk: Legal liability or equipment warranty voidance.

-

Solution: Ensure sourcing aligns with OEM drawings or licensed designs. Avoid suppliers offering “exact copies” of patented fastener configurations without authorization.

-

Poor Thread Quality or Tolerance Issues

- Pitfall: Accepting fasteners with rolled threads that don’t meet 5/8-11 UNF tolerance (e.g., Class 2A/2B).

- Risk: Galling, thread stripping, or fit issues in assembly.

-

Solution: Specify thread class and inspect with go/no-go gauges. Ensure threads are properly formed and chamfered.

-

Lack of Traceability and Certification

- Pitfall: Procuring fasteners without proper documentation.

- Risk: Non-compliance in regulated industries (e.g., oil & gas, medical, aerospace).

-

Solution: Require full traceability (heat lot numbers) and certifications (e.g., 3.1 or 3.2 EN 10204).

-

Galling During Installation

- Pitfall: Not addressing the tendency of stainless steel to gall.

- Risk: Seized threads during assembly, damaging parts.

- Solution: Specify anti-galling treatments (e.g., dry film lubricants, PTFE coating) or recommend proper installation techniques (correct torque, lubrication).

Conclusion:

Sourcing 5/8-11 x 3″ stainless steel hex cap screws requires diligence in verifying material grade, mechanical properties, compliance, and IP rights. Partnering with reputable, certified suppliers and demanding full documentation mitigates risks and ensures performance in critical applications.

Logistics & Compliance Guide: 5/8-11 x 3″ Hex Cap Screw, Stainless Steel (Grade H2)

Version 1.0 | Applicable Industries: Construction, Heavy Equipment, Infrastructure, Oil & Gas

1. Product Overview

- Description: Hex Cap Screw, Fully Threaded

- Size: 5/8″-11 (Diameter: 5/8″, Threads per inch: 11)

- Length: 3 inches

- Material: Stainless Steel (Typically ASTM A564 Type 630, 17-4 PH, or ASTM A193 B8M for H2)

- Grade/Specification: H2 (Per ASME B18.31.2 / ASTM A193)

- Finish: Natural stainless (passivated)

- Drive Type: External Hex (wrench-driven)

Note: “H2” designation refers to high-temperature, high-strength bolting materials per ASTM A193, typically used in high-pressure/high-temperature environments (e.g., refineries, power plants). H2 is a modified version of B16 bolt material with improved creep resistance and higher allowable stress at elevated temperatures.

2. Material & Mechanical Properties

| Property | Specification |

|——–|—————|

| Material Type | Stainless Steel (e.g., B16 or H2-modified alloy) |

| Tensile Strength | ≥ 125 ksi (860 MPa) |

| Yield Strength | ≥ 100 ksi (690 MPa) |

| Hardness | Max 32 HRC |

| Corrosion Resistance | High (suitable for marine, chemical, and outdoor exposure) |

| Temperature Resistance | Up to 800°F (427°C) continuous |

H2 bolts are stress-relieved for enhanced performance in cyclic thermal service.

3. Standards & Compliance

Ensure all products meet or exceed the following standards:

| Standard | Description |

|——–|————-|

| ASTM A193 / A193M | Standard for alloy and stainless steel bolting for high-temperature service |

| ASME B18.2.1 | Dimensions and tolerances for square and hex bolts |

| ASME B18.31.2 | Quality assurance for high-strength bolting (H2 qualification) |

| ASME BPVC Section II, Part D | Applicable material stress values for boiler and pressure vessel use |

| MTR Required | Mill Test Report (per ASTM A193, certifying chemical and mechanical properties) |

| NACE MR0175/ISO 15156 | Required if used in sour (H₂S) environments – confirm compatibility |

Note: H2 bolts require special heat treatment and are often procured under certified quality programs (e.g., API 20E, PED Module H).

4. Packaging & Labeling (Logistics)

Packaging:

- Bulk packed in wooden crates or steel banding for industrial use.

- Interior: VCI (Vapor Corrosion Inhibitor) paper or plastic to prevent rust.

- Quantity per bundle: 25 or 50 pieces (standard), clearly tagged.

- Weight per piece: ~0.78 lbs (354 g) → 3″ x 5/8″ stainless steel hex cap screw.

Labeling:

Each package must include:

– Part Number / SKU

– Size: 5/8″-11 x 3″

– Material: Stainless Steel H2

– ASTM A193 Grade H2

– Traceability Code (Heat/Lot Number)

– Manufacturer Name & Mark

– Country of Origin

– “For High-Temperature Service” (if applicable)

5. Shipping & Handling

- Hazardous Material? No (non-dangerous goods)

- UN Number: Not applicable

- Storage Conditions: Dry, indoor environment; avoid chloride exposure

- Stacking Limit: Max 5 crates high (ensure base strength)

- Forklift Access: Crates must have proper entry points

- Shipping Docs Required:

- Commercial Invoice

- Packing List

- Certificate of Compliance (C of C)

- Mill Test Report (MTR)

- Origin Certificate (for export)

6. Export Compliance (ITAR/EAR)

- ECCN (Export Control Classification Number): 9A003.a.3 or EAR99 (typically not controlled)

- ITAR Controlled? No (unless used in defense articles)

- Sanctioned Destinations: Avoid shipment to embargoed countries (e.g., Iran, North Korea, Crimea)

- Customs Tariff (HS Code):

7318.15.00 – “Screws and bolts, with heads, of stainless steel”

7. Quality & Inspection Requirements

- Incoming Inspection Checklist:

- Verify size with calipers/thread gauge

- Check for surface defects (cracks, laps, pits)

- Confirm manufacturer markings and H2 grade

- Validate MTR against shipment

- Magnetic permeability test (if required)

- Third-Party Testing: Recommended for critical applications (e.g., hydrostatic testing, Charpy impact at low temp)

8. Application & Installation Guidance

- Torque Specification: Use H2-specific torque tables (varies by lubrication). Example:

- Dry: ~420 ft-lbs

- Lubricated (anti-seize): ~320 ft-lbs

- Washers: Use hardened washers (per ASME B18.22.1)

- Nut Compatibility: Pair with H2-compatible nuts (ASTM A194 Grade 4 or 7)

- Preload: Critical for flange integrity; consider bolt tensioning or hydraulic tools

9. Environmental & Safety Compliance

- REACH (EU): Compliant – no SVHCs above threshold

- RoHS: Compliant (no lead, cadmium, etc.)

- Prop 65 (California): No warning required for stainless steel fasteners

- OSHA: No special handling required; standard PPE (gloves, eye protection) during installation

10. Supplier & Procurement Notes

- Preferred Suppliers: ITT Cannon, Portland Bolt, Fastenal (certified H2 vendors)

- Lead Time: 4–8 weeks (H2 requires special heat treatment)

- Minimum Order Quantity (MOQ): 50 pcs (typical)

- Certifications Required: ISO 9001, AS9100 (if aerospace), API 20E (for oil & gas)

11. Troubleshooting & Non-Conformance

- Common Issues:

- Galling during installation → Use anti-seize lubricant

- Thread mismatches → Verify pitch (UNC 11 TPI)

- Rust spots → Check passivation and storage

- Non-Conforming Material: Quarantine and contact supplier with MTR and photos

12. Contact & Support

For technical or compliance support:

– Engineering: [email protected]

– Quality: [email protected]

– Logistics: [email protected]

Disclaimer: This guide is for informational purposes. Always consult applicable codes (ASME, API, local regulations) and project specifications before use. H2 bolting is critical service; improper use may result in failure.

✅ Checklist Before Shipment/Use:

– [ ] MTR Received & Verified

– [ ] Markings Match H2 Grade

– [ ] Dimensions Checked

– [ ] Packaging Secure & Labeled

– [ ] Export Docs Complete

– [ ] Torque Procedure Available

Document prepared in accordance with ASTM, ASME, and ISO best practices. Rev. 1.0 – January 2024

Conclusion:

After evaluating various sourcing options for 5/8-11 x 3″ hex cap screws made of stainless steel, it is evident that several reliable suppliers are available, offering quality products compliant with industry standards such as ASTM A193 or ASTM A320. Key considerations including material grade (commonly SS 304 or 316), corrosion resistance, strength requirements, and lead times must guide the final selection. Domestic suppliers provide faster delivery and better quality control, while international options may offer cost savings but require careful vetting for consistency and compliance.

Procurement should balance cost, quality, and delivery timelines. Established industrial suppliers like Fastenal, McMaster-Carr, or MSC Industrial Supply offer convenience, traceability, and technical support, making them ideal for critical applications. For larger volume orders, direct sourcing from certified manufacturers may provide better pricing and customization options.

In conclusion, the most effective sourcing strategy involves selecting a reputable supplier that meets technical specifications and project timelines while ensuring long-term reliability and cost-efficiency. Prioritizing certifications, material traceability, and supplier responsiveness will ensure successful procurement of 5/8-11 x 3″ stainless steel hex cap screws.