The global 3D printing market is experiencing robust expansion, driven by rising demand for rapid prototyping, customized manufacturing, and advancements in additive technologies. According to Grand View Research, the market was valued at USD 16.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 23.7% from 2023 to 2030. Key segments within this surge include desktop and industrial-grade 3D printers, particularly models with a balanced build volume such as 500×500 mm, which cater to both prototyping and small-batch production across industries like aerospace, automotive, and healthcare. As adoption accelerates, especially in emerging economies, manufacturers offering reliable, scalable 500×500 3D printing solutions are gaining strategic prominence. Based on production capabilities, innovation, and market reach, the following nine companies have emerged as leading manufacturers in the 500×500 3D printer space.

Top 9 500X500 3D Printer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

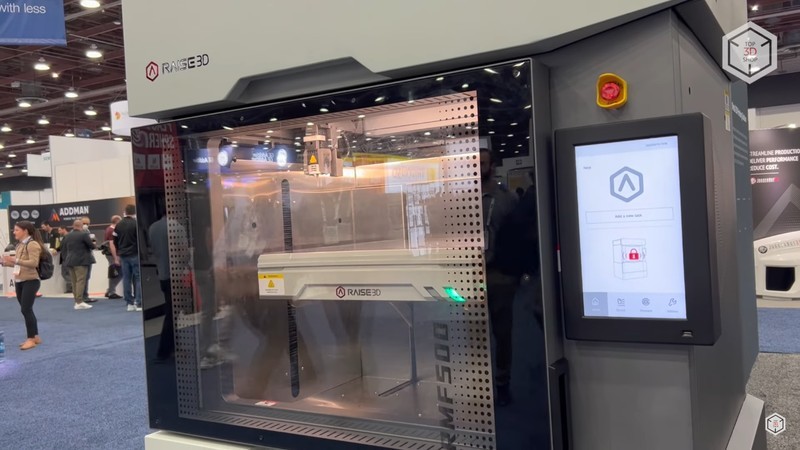

#1 RMF500 printer makes Composite End-use Parts

Domain Est. 2014

Website: raise3d.com

Key Highlights: Free delivery over $90 30-day returnsRaise3D RMF500 has a large build volume of 500 x 500 x 500 mm and a maximum printing speed of 500 mm/s, making it an ideal choice for industria…

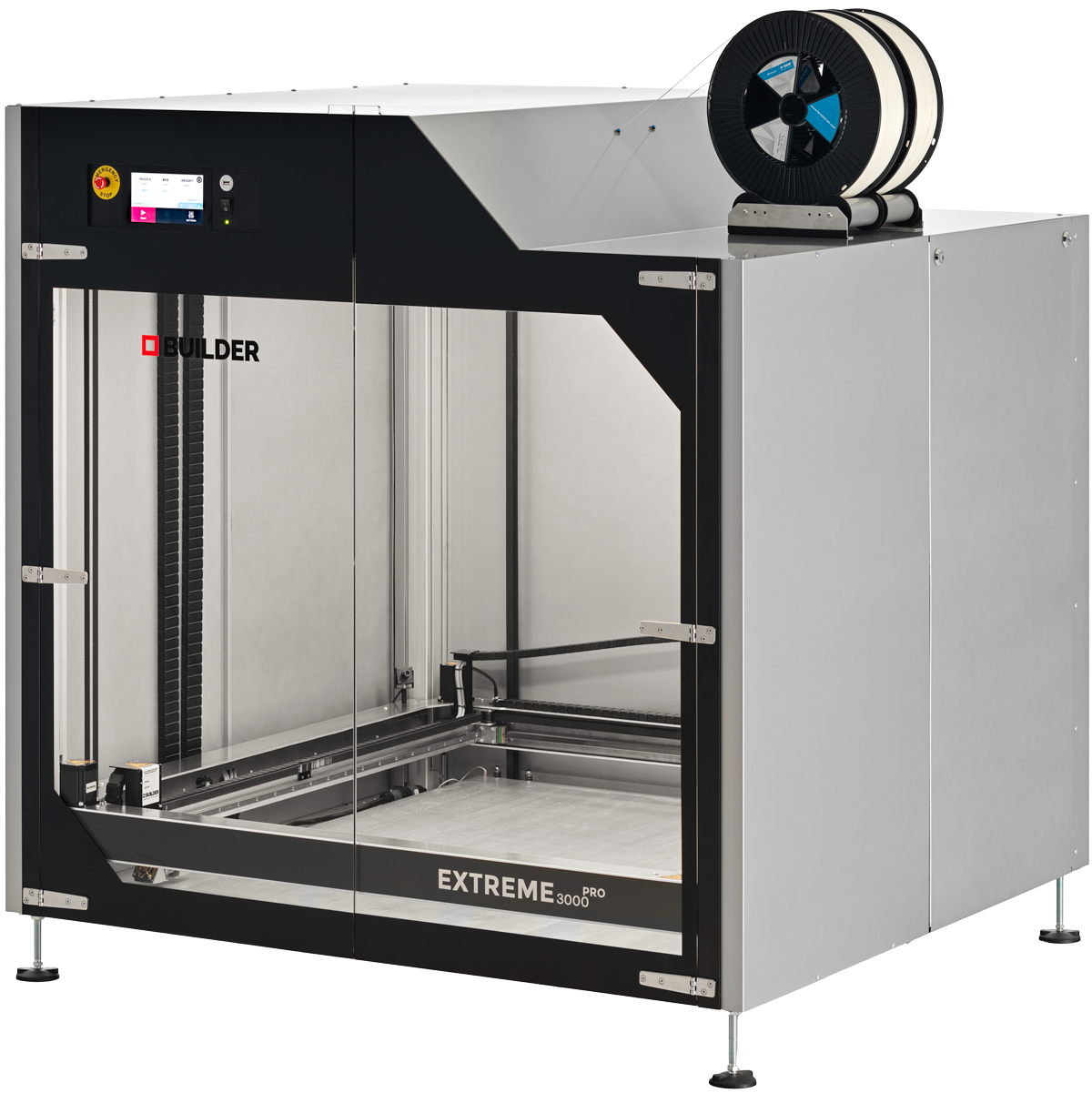

#2 Builder 3D Printers

Domain Est. 2014

Website: builder3dprinters.com

Key Highlights: Large Scale 3D Printers from the Netherlands. The Builder Extreme range is one of the biggest industrial FDM 3D printer. Affordable Large Scale 3D Printing….

#3 Tronxy Veho 500 Pro Fast 3D Printer 500x500mm

Domain Est. 2022

Website: tronxy3dprinter.com

Key Highlights: In stock Free deliveryExperience high-speed 3D printing with the Tronxy Veho 500 Pro. Enjoy a large print size of 500x500x500mm and upgraded Klipper technology….

#4 Professional 3D Printers

Domain Est. 2004

Website: bigrep.com

Key Highlights: Enclosed 250 Liters Build Chamber: 1000 x 500 x 500 mm build volume for large 3D prints from a machine that easily fits in most work spaces….

#5 3D printers

Domain Est. 2010

Website: omni3d.com

Key Highlights: Omni PRO HT ; Build size, 500 × 500 × 500 mm ; MAX. HEAD TEMPERATURE, 500°C ; Max Chamber temperature, 220 °C (ACTIVELY HEATED) ; BUILT-IN FILAMENT DRYER, YES ……

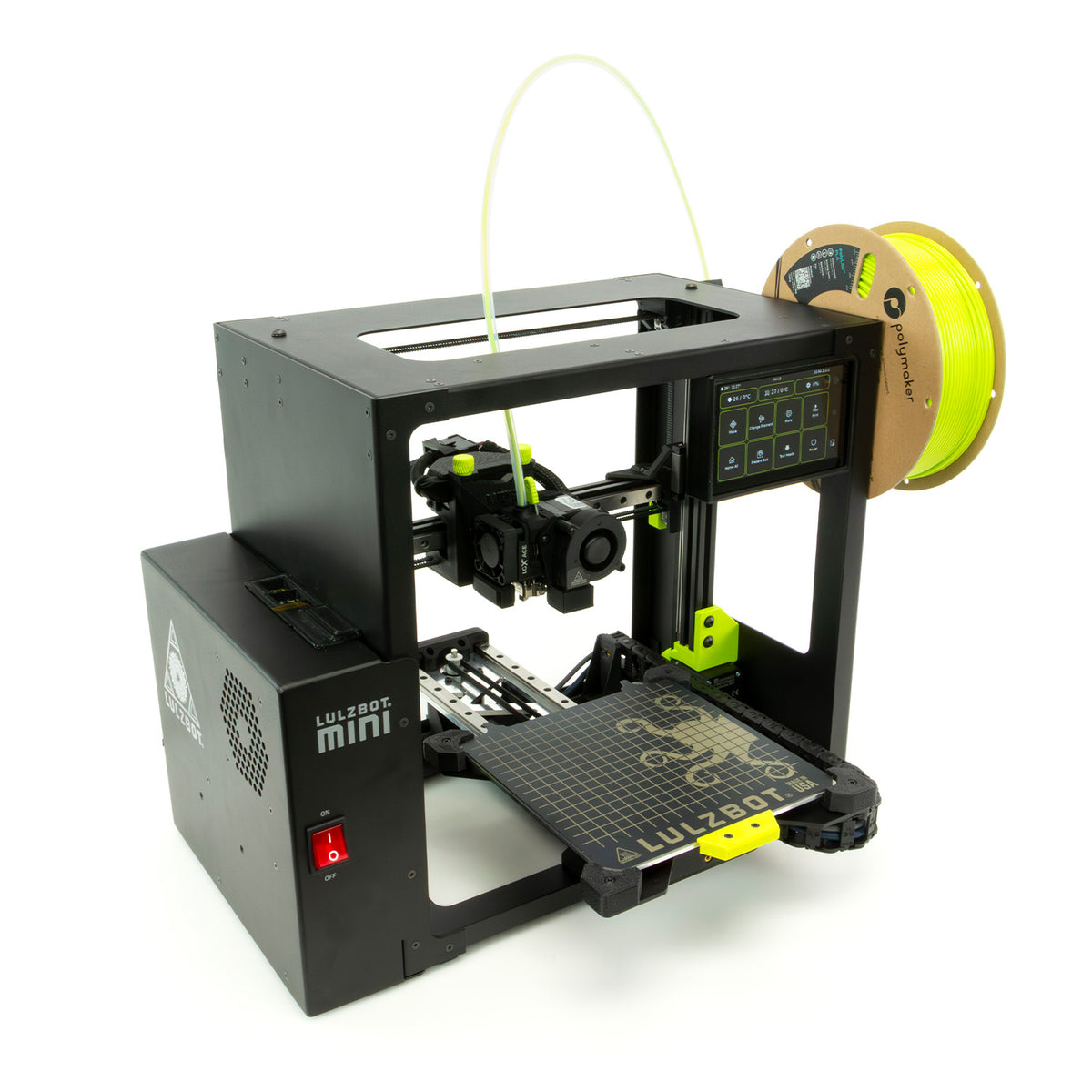

#6 LulzBot®

Domain Est. 2011

Website: lulzbot.com

Key Highlights: Our legendary 3D printers are making their mark, from elementary classrooms to cutting-edge space labs. Discover your LulzBot’s perfect role today!…

#7 SLS 3D Printer

Domain Est. 2014

Website: eplus3d.com

Key Highlights: Eplus3D offers SLS 3D Printer for sale that optimizes polymer nylon material in additive manufacturing. The SLS printer is a flexible machine that has high ……

#8 Massive Dimension

Domain Est. 2015

Website: massivedimension.com

Key Highlights: Explore our complete line of large-format 3D printing products from high-performance pellet extruder 3D printers to advanced material feeding systems….

#9 AML3D

Domain Est. 2019

Website: aml3d.com

Key Highlights: AML3D has the world’s largest, open-air, production-ready, metal 3D printers commercially available on the market….

Expert Sourcing Insights for 500X500 3D Printer

Market Trends for 500×500 mm 3D Printers in 2026

The 3D printing industry is undergoing rapid transformation, driven by advancements in materials, automation, and industrial adoption. In 2026, large-format 3D printers—particularly those with a 500×500 mm build volume—are expected to play a pivotal role across multiple sectors. This analysis explores key market trends shaping the demand, innovation, and competitive landscape for 500×500 mm 3D printers in 2026.

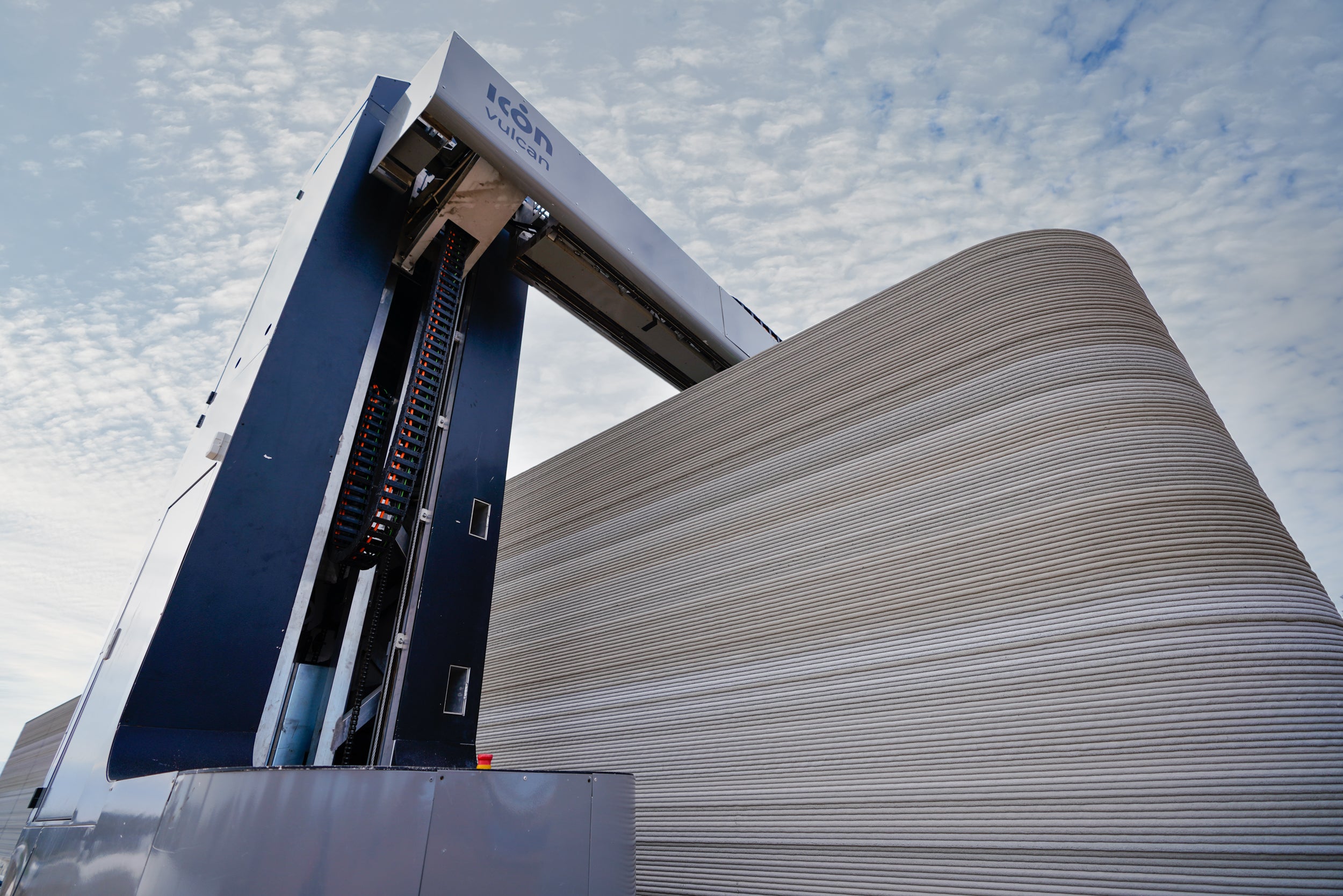

Expanding Industrial Adoption

One of the most significant trends in 2026 is the accelerated integration of 500×500 mm 3D printers into industrial manufacturing. Industries such as aerospace, automotive, and construction are increasingly using large-format printers for prototyping, tooling, and end-use part production. The ability to print large components in a single piece reduces assembly time, improves structural integrity, and cuts production costs. Companies are investing in scalable additive manufacturing solutions, favoring 500 mm-class printers for their balance between size, precision, and cost-efficiency.

Advancements in Printing Technologies

By 2026, core 3D printing technologies like Fused Filament Fabrication (FFF), Selective Laser Sintering (SLS), and Continuous Liquid Interface Production (CLIP) have evolved to better support large build volumes. Enhanced motion systems, improved thermal management, and AI-driven calibration are standard in new 500×500 mm models. These upgrades result in higher print accuracy, reduced warping, and faster print speeds—critical factors for industrial throughput. Additionally, multi-material capabilities and closed-loop feedback systems are becoming more prevalent, enabling complex, high-performance parts.

Growth in Customization and On-Demand Manufacturing

The demand for customized, low-volume production is fueling the popularity of large-format 3D printers. In sectors like architecture, healthcare (e.g., prosthetics and orthotics), and consumer goods, businesses leverage 500×500 mm printers to deliver bespoke solutions rapidly. The shift toward localized, on-demand manufacturing reduces supply chain dependencies and inventory costs—trends amplified by geopolitical uncertainties and sustainability goals. By 2026, cloud-connected 500 mm printers enable distributed manufacturing networks, allowing designers to send files globally for local production.

Material Innovation and Sustainability

Material science is a key driver in the 500×500 mm 3D printer market. In 2026, manufacturers are offering broader material compatibility, including high-strength polymers (e.g., PEEK, PEKK), composite filaments (carbon fiber-reinforced), and recyclable bioplastics. Sustainability initiatives are pushing companies to adopt eco-friendly materials and closed-loop recycling systems. Printers are increasingly designed for energy efficiency and material reuse, aligning with ESG (Environmental, Social, and Governance) standards.

Competitive Landscape and Pricing Trends

The market for 500×500 mm 3D printers is becoming more competitive, with established players like Stratasys, Ultimaker, and Creality expanding their large-format offerings, while startups introduce cost-effective, open-source alternatives. Price points are decreasing due to economies of scale and improved component sourcing, making these printers accessible to small and medium enterprises (SMEs). However, premium models with advanced features—such as dual extrusion, HEPA filtration, and industrial-grade reliability—command higher margins and dominate enterprise sales.

Software and Ecosystem Integration

In 2026, seamless software integration is a differentiator. Leading 500×500 mm printers come with comprehensive ecosystems, including slicing software, remote monitoring, predictive maintenance, and compatibility with CAD/PLM systems. AI-powered optimization tools help users reduce material waste and improve print success rates. Interoperability with Industry 4.0 platforms allows real-time data tracking and integration into smart factory environments.

Regional Market Dynamics

North America and Europe lead in adoption due to strong industrial bases and R&D investments. Meanwhile, Asia-Pacific—especially China and India—is experiencing rapid growth, driven by government support for advanced manufacturing and rising domestic demand. Localized production hubs and regional supply chains are boosting the deployment of large-format 3D printers in emerging markets.

Conclusion

By 2026, the 500×500 mm 3D printer market is characterized by technological maturity, industrial integration, and expanding applications. As these printers become more reliable, affordable, and sustainable, their role in reshaping manufacturing will continue to grow. Businesses that adopt this technology early will gain significant advantages in agility, cost-efficiency, and innovation.

Common Pitfalls When Sourcing a 500×500 3D Printer (Quality & IP)

When sourcing a large-format 500×500 mm 3D printer, buyers often encounter significant challenges related to print quality consistency and intellectual property (IP) risks. Being aware of these pitfalls is crucial for making a sound investment.

Poor Structural Rigidity Leading to Print Quality Issues

Many budget or poorly engineered 500×500 printers use lightweight frames or inadequate support structures, resulting in frame flex during high-speed printing. This lack of rigidity causes layer misalignment, dimensional inaccuracies, and failed prints—especially with large models. Buyers should verify the printer’s frame material (e.g., steel vs. aluminum extrusions) and look for designs with reinforced corner brackets or welded sections to ensure long-term stability.

Inconsistent Bed Leveling and Z-Axis Wobble

Due to the large build area, even minor deviations in bed flatness or Z-axis alignment can cause failed first layers or warping. Printers with single Z-axis motors or unsupported lead screws are prone to tilt and wobble. Look for dual or triple Z-axis lead screws with synchronized motors and precision linear rails to maintain consistent layer height across the entire 500×500 platform.

Overheating and Poor Thermal Management

Extended print times for large parts generate significant heat, especially in enclosed environments. Inadequate cooling for the stepper drivers, mainboard, or extruder can lead to thermal shutdowns or component failure. Ensure the printer includes active cooling systems, high-quality power supplies rated for continuous operation, and thermally stable hotends designed for prolonged use.

Use of Open-Source Designs Without Proper Licensing (IP Risk)

Some manufacturers sell 500×500 printers based on open-source designs (e.g., derivatives of the Creality CR-10 or Prusa i3) but fail to comply with licensing terms like the GNU General Public License (GPL) or specific Creative Commons licenses. This can expose buyers to legal risks if the seller is distributing modified firmware or design files without proper attribution or source code availability. Always verify that the manufacturer complies with open-source licensing and provides documented firmware sources if applicable.

Lack of Firmware Transparency and Customization

Many low-cost printers use proprietary or heavily modified firmware without providing access to source code or configuration files. This limits the ability to troubleshoot, upgrade, or ensure security. It also raises red flags about potential IP infringement. Prioritize suppliers who offer open, documented firmware (e.g., Marlin or Klipper) and allow user access for inspection and modification.

Counterfeit or Unbranded Components

To cut costs, some manufacturers use counterfeit stepper motors, fake name-brand hotends (e.g., “E3D-style”), or uncertified power supplies. These components degrade print quality, pose safety hazards, and may void warranties. Request detailed specifications and certifications (e.g., UL, CE) for critical components, and favor suppliers who transparently list genuine part brands.

Avoiding these pitfalls requires due diligence: request test print samples, verify design and firmware licenses, inspect build quality in person if possible, and choose reputable suppliers with clear documentation and support.

Logistics & Compliance Guide for 500×500 3D Printer

Shipping & Packaging Requirements

Ensure the 500×500 3D printer is securely packaged using a rigid double-walled cardboard box with internal foam inserts or custom molded supports to immobilize the print bed, gantry, and electronics. Include corner protectors and bubble wrap around exposed components such as the display screen and extruder. Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Use a shipping weight and dimensional calculation that accounts for the printer (typically 25–40 kg) plus packaging materials, and select a freight or parcel carrier experienced in handling sensitive machinery. For international shipments, provide a detailed packing list and commercial invoice.

Import Regulations & Documentation

Verify import regulations in the destination country, as 3D printers may fall under HS Code 8477.30 (machines for additive manufacturing). Prepare required documentation including a Commercial Invoice, Bill of Lading/Air Waybill, Packing List, and Certificate of Origin. Some regions (e.g., EU, UK, Canada) require additional declarations regarding voltage compatibility, electromagnetic compliance, and product safety. Confirm whether the 500×500 model requires a pre-shipment inspection or import permit, especially when shipping to regulated markets.

Electrical & Safety Compliance

Ensure the 3D printer complies with regional electrical safety standards:

– North America: UL/CSA 60950-1 or UL/CSA 62368-1

– European Union: CE marking per Low Voltage Directive (LVD), Electromagnetic Compatibility (EMC) Directive, and RoHS

– UK: UKCA marking with adherence to UKCA LVD and EMC requirements

– Australia/New Zealand: RCM mark per AS/NZS standards

Verify voltage compatibility (typically 100–240V AC, 50/60 Hz) and include region-specific power cords or adapters. Over-temperature protection, emergency stop function, and proper grounding must be validated.

Environmental & Material Regulations

Confirm that all materials used in the printer (e.g., plastics, wiring, circuit boards) comply with environmental directives:

– EU RoHS Directive 2011/65/EU: Restriction of Hazardous Substances

– REACH Regulation (EC 1907/2006): Registration, Evaluation, Authorization, and Restriction of Chemicals

– WEEE Directive 2012/19/EU: Proper labeling for end-of-life disposal (apply the crossed-out wheelie bin symbol)

Maintain documentation of substance declarations and ensure suppliers provide SVHC (Substances of Very High Concern) compliance.

Software & Cybersecurity Compliance

If the 500×500 printer includes embedded software, wireless connectivity (Wi-Fi, Bluetooth), or cloud integration, comply with:

– Cybersecurity regulations (e.g., EU Cyber Resilience Act for products placed on the market after 2027)

– Data privacy laws such as GDPR (EU) or CCPA (California) if user data is collected

Implement secure boot, firmware update validation, and disable unused network services. Provide users with clear privacy notices and data handling policies.

User Documentation & Labeling

Include multilingual user manuals covering assembly, operation, maintenance, and safety warnings. Manuals must meet local language requirements (e.g., French in Canada, German in Austria). Safety labels on the device must be durable, legible, and include warnings for hot surfaces, moving parts, and electrical hazards. Provide compliance labels indicating certifications (e.g., CE, FCC, UKCA) in visible locations on the printer housing.

After-Sales & Warranty Logistics

Establish a warranty fulfillment process compliant with consumer laws in the destination market (e.g., EU’s 2-year legal warranty, Australia’s consumer guarantees). Offer spare parts logistics and technical support in local languages. For returns or repairs, ensure compliance with import regulations for returned goods (e.g., Temporary Admission or warranty return provisions) to avoid duties and taxes on repaired units.

Conclusion for Sourcing a 500x500mm 3D Printer:

After a thorough evaluation of market options, technical specifications, pricing, and reliability, sourcing a 500x500mm 3D printer presents a strategic opportunity to enhance large-format additive manufacturing capabilities. Models from reputable manufacturers such as Creality (e.g., K1 series), Bambu Lab (X1C or X2 with modifications), Sovol, and Anycubic offer competitive features including high-speed printing, dual extrusion, auto-bed leveling, and excellent build quality.

The 500x500mm build volume strikes an optimal balance between scalability and workspace efficiency, making it ideal for prototyping, custom manufacturing, architectural models, and industrial tooling. When selecting a supplier, considerations such as after-sales support, availability of spare parts, ease of maintenance, and community/software ecosystem are crucial for long-term operational success.

In conclusion, investing in a 500x500mm 3D printer from a trusted brand with strong technical support and upgrade potential ensures scalability, reliability, and a solid return on investment for both prototyping and production needs. Final selection should align with specific application requirements, budget constraints, and integration capabilities within existing workflows.