The global laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly and precision-based surface treatment solutions across industries such as automotive, aerospace, and manufacturing. According to a 2023 report by Mordor Intelligence, the global laser cleaning market was valued at approximately USD 390 million in 2022 and is projected to grow at a CAGR of over 22% during the forecast period from 2023 to 2028. This expansion is primarily fueled by the shift away from traditional abrasive and chemical cleaning methods toward more sustainable, efficient, and non-destructive alternatives. As industries prioritize automation and regulatory compliance, 500W pulse laser cleaning machines have emerged as a preferred solution, offering high-power performance for heavy-duty applications while maintaining precision and minimal substrate damage.

With rising adoption in industrial maintenance, mold cleaning, rust removal, and restoration processes, the demand for reliable, high-performance laser systems has intensified. Key factors influencing buyer preference include pulse energy stability, maintenance costs, beam quality, and integration capabilities with robotic systems. This growing market landscape has led to an increase in specialized manufacturers, particularly in Asia-Pacific, Europe, and North America. Based on market presence, technological innovation, customer reviews, and output capacity, the following seven manufacturers have distinguished themselves as leaders in developing and supplying 500W pulse laser cleaning machines, meeting the evolving needs of modern industrial operations.

Top 7 500W Pulse Laser Cleaning Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

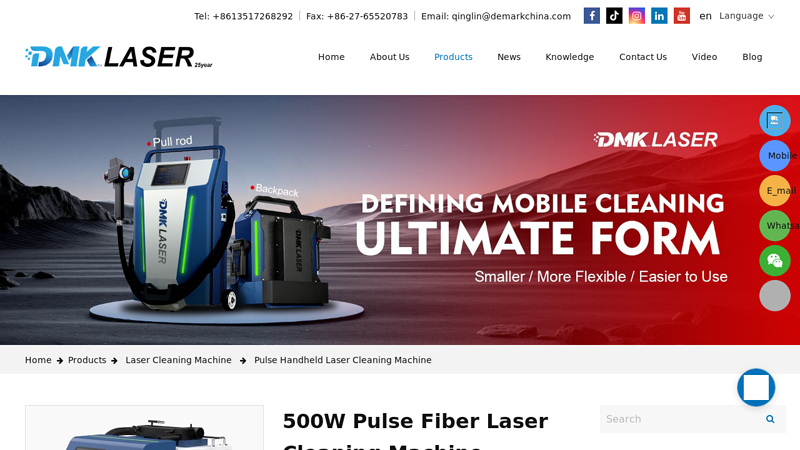

#1 500W Pulse Fiber Laser Cleaning Machine

Website: demarkchina.cn

Key Highlights: Demark (Wuhan) Technology Co., Ltd. is one of the leading manufacturers and suppliers of 500w pulse fiber laser cleaning machine in China. Please rest assured ……

#2 500W Pulse Wave Laser Cleaning Machine

Website: nuwavelaser.com

Key Highlights: The 500W Pulse Wave Laser Cleaning Machine delivers advanced industrial cleaning with unmatched precision and safety. Designed for a wide range of applications ……

#3 Laser Cleaning Machine

Website: baikeopto.com

Key Highlights: BAIKEOPTO laser cleaning machines include 100W, 200W, 300W, 500W pulse laser cleaning … © 2025 BAIKEOPTO LASER GLOBAL OFFICIAL WEBSITE. Copy right Wuhan ……

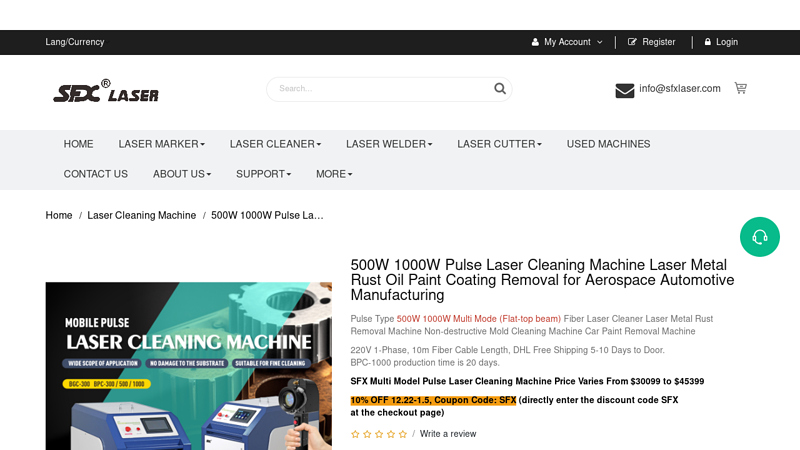

#4 500W 1000W Pulse Laser Cleaning Machine Laser Metal Rust Oil …

Website: sfxlaser.com

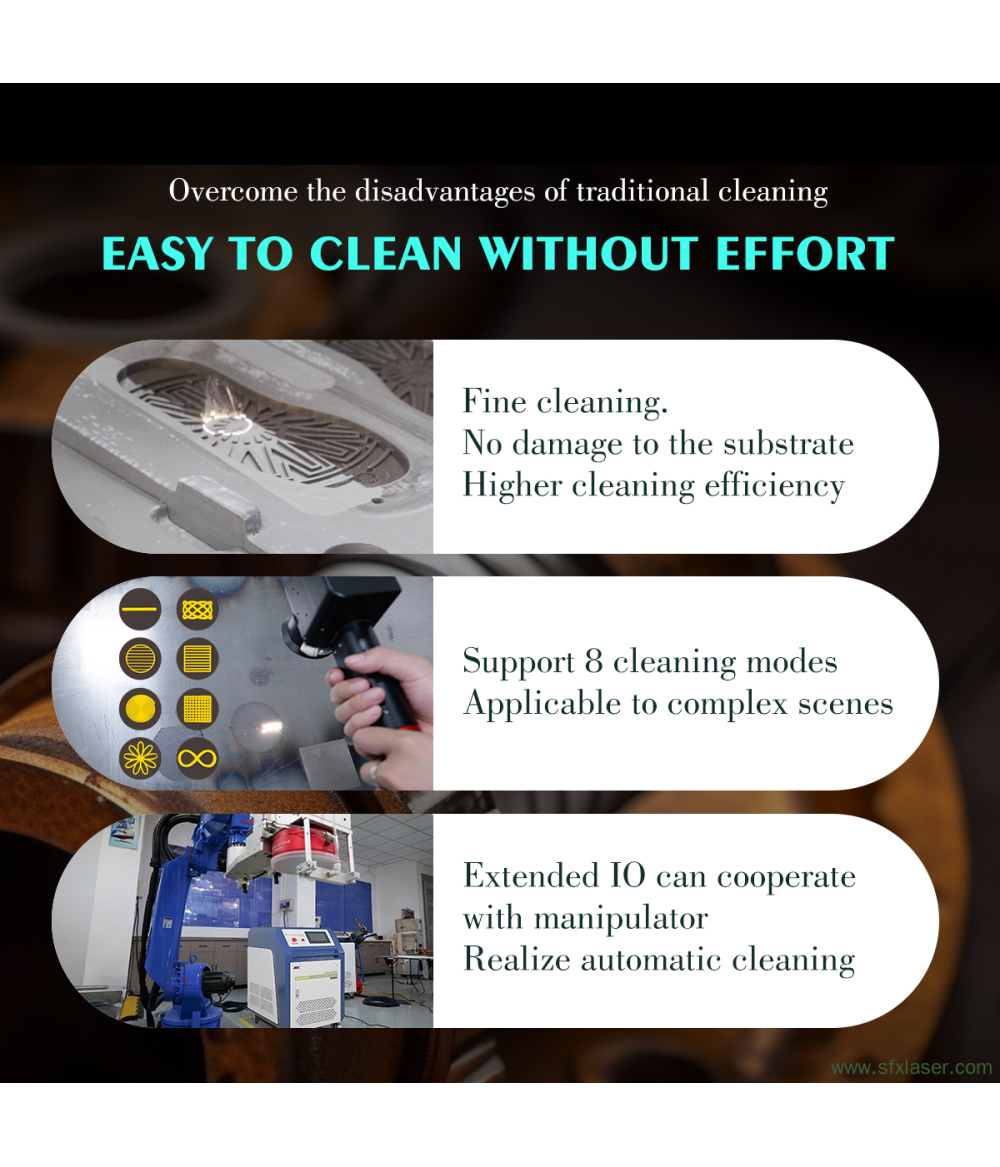

Key Highlights: In stock Free deliverySFX 500w 1000w pulse laser cleaning machine is suitable for rust, oil, paint, coating, mold cleaning, adhesive layer removal, cultural relic restoration, etc….

#5 500W Pulse Laser Cleaning Machine

#6 Fortune Laser Pulses 500W Water Cooling Laser Cleaning Machine

Website: fortunelaser.com

Key Highlights: The Fortunelaser FL-HC500 pulse laser cleaning system can be used to clean various metal substrates, such as titanium alloy, aluminum alloy, high temperature ……

#7 ZAC 300W 500W G

Expert Sourcing Insights for 500W Pulse Laser Cleaning Machine

H2: Market Trends for 500W Pulse Laser Cleaning Machines in 2026

By 2026, the global market for 500W pulse laser cleaning machines is expected to experience robust growth, driven by increasing industrial automation, stringent environmental regulations, and the rising demand for precision, non-contact surface treatment technologies. These machines—utilizing high-intensity pulsed laser beams to remove contaminants such as rust, paint, oxides, and coatings without damaging substrates—are becoming integral in manufacturing, automotive, aerospace, and heritage conservation sectors.

Key market trends shaping the 500W pulse laser cleaning segment in 2026 include:

-

Industrial Adoption and Automation Integration

The integration of 500W pulse laser cleaning systems into automated production lines is accelerating. Manufacturers are increasingly adopting robotic arms equipped with 500W lasers for scalable, repeatable cleaning operations. This trend is particularly evident in the automotive and aerospace industries, where precision cleaning of engine components, molds, and turbine blades is critical. The 500W power output strikes an optimal balance between cleaning efficiency and operational safety, making it ideal for high-throughput environments. -

Environmental and Regulatory Drivers

Global environmental regulations are phasing out traditional cleaning methods involving chemical solvents and abrasive blasting due to their ecological and health hazards. Pulse laser cleaning offers a green alternative—generating no secondary waste and requiring no consumables. In 2026, compliance with directives such as REACH (EU) and EPA guidelines (USA) is expected to further incentivize the shift toward laser-based systems, particularly in environmentally conscious markets like Western Europe and North America. -

Technological Advancements and Cost Reduction

Advances in fiber laser technology have improved the efficiency, reliability, and portability of 500W pulse systems. Enhanced beam quality, longer diode lifespans, and intelligent control systems (e.g., AI-assisted parameter optimization) are increasing user adoption. Additionally, economies of scale and competitive manufacturing—especially in China—are driving down equipment costs. By 2026, entry-level 500W systems are expected to be 15–20% more affordable than in 2022, expanding accessibility for SMEs. -

Expansion into New Application Areas

Beyond industrial maintenance, 500W pulse lasers are penetrating niche markets such as nuclear decommissioning, art restoration, and marine engineering. The ability to selectively clean without surface abrasion makes these machines suitable for delicate tasks like removing corrosion from historical artifacts or radioactive particles from reactor components. This diversification is broadening the addressable market and stimulating R&D investments. -

Regional Market Growth

Asia-Pacific is projected to dominate the 500W pulse laser cleaning market by 2026, led by China, Japan, and South Korea, where rapid industrialization and government support for smart manufacturing (e.g., China’s Made in China 2025) are accelerating adoption. North America and Europe follow closely, driven by aerospace and defense applications and strong sustainability mandates. -

Competition and Market Consolidation

The market is becoming increasingly competitive, with established players like IPG Photonics, Trumpf, and Han’s Laser expanding their laser cleaning portfolios. At the same time, agile startups are introducing modular, user-friendly 500W systems with IoT connectivity. This competition is spurring innovation and leading to early signs of market consolidation through strategic partnerships and acquisitions.

In conclusion, by 2026, the 500W pulse laser cleaning machine market will be characterized by technological maturity, broader industrial integration, and strong growth momentum—positioning it as a cornerstone of sustainable and precision surface engineering.

Common Pitfalls When Sourcing a 500W Pulse Laser Cleaning Machine (Quality & IP)

Sourcing a 500W pulse laser cleaning machine requires careful due diligence to avoid significant risks related to product quality, performance, and intellectual property (IP). Here are the most common pitfalls to watch for:

1. Overstated or Misleading Power Specifications

- Pitfall: Suppliers may advertise “500W” based on peak pulse power, average power calculated under ideal lab conditions, or even theoretical maximums, rather than actual, sustained average output power during real-world cleaning.

- Impact: The machine performs significantly below expectations, leading to slow cleaning speeds, inability to remove tougher contaminants, and ultimately, project delays or failure.

- Mitigation: Demand verified, third-party test reports (e.g., from TÜV, SGS, or a reputable laser lab) showing actual average output power under continuous operation. Ask for detailed specifications (pulse energy, frequency, duration) and calculate expected average power yourself (Avg Power = Pulse Energy x Repetition Rate).

2. Compromised Core Components (Oscillator, Scanner, Cooling)

- Pitfall: To cut costs, some manufacturers use lower-grade laser sources (e.g., inferior fiber lasers with shorter lifespans, unstable output), low-quality galvanometer scanners (leading to slow speeds, positioning errors, or drift), or inadequate cooling systems.

- Impact: Reduced machine lifespan, inconsistent cleaning results (striping, incomplete removal), frequent breakdowns, overheating shutdowns, and high maintenance costs. Scanner issues directly impact cleaning quality and speed.

- Mitigation: Insist on knowing the exact brand and model of the laser source (e.g., IPG, Raycus, JPT, Max Photonics), scanners (e.g., Raylase, Scanlab, CJ), and cooling unit. Research these components’ reputations. Request MTBF (Mean Time Between Failures) data for critical components.

3. Inadequate Beam Quality (M² Factor) and Stability

- Pitfall: Poor beam quality (high M²) means the laser spot cannot be focused tightly enough, reducing power density on the target. Unstable beam parameters (mode, pointing) lead to inconsistent cleaning results across the work area.

- Impact: Inability to effectively clean fine details or achieve uniform results. Reduced cleaning efficiency and potential damage to the substrate if power density varies uncontrollably.

- Mitigation: Require specification of the M² value (ideally ≤ 1.2 for high-quality industrial lasers) and beam pointing stability. Ask for beam profile measurements (e.g., via camera) demonstrating consistency over time and across the scan field.

4. Ignoring Intellectual Property (IP) Infringement Risks

- Pitfall: Sourcing from manufacturers who copy designs, software, or key technologies without proper licensing. This includes cloned control software, copied optical layouts, or unauthorized use of patented scanner technology.

- Impact: Severe legal liability if IP owners pursue action against you (as the user) or your supplier. Risk of machine seizure, fines, and reputational damage. No technical support or updates if the infringing supplier is shut down. Potential safety risks from untested cloned designs.

- Mitigation: Choose suppliers with a transparent track record and known brand reputation. Ask directly about IP ownership and compliance. Prefer suppliers who develop their own control software or use reputable, licensed software platforms. Be wary of prices significantly below market average, as this often indicates IP infringement or severe component cost-cutting.

5. Insufficient or Poorly Designed Safety Features

- Pitfall: Omitting critical safety interlocks (door switches, emergency stops), inadequate laser shielding, missing or ineffective fume extraction integration points, or non-compliant labeling (laser class, warning signs).

- Impact: Major safety hazard for operators (eye/skin injury, fire risk, inhalation of fumes). Non-compliance with local safety regulations (e.g., OSHA, CE, IEC 60825) leading to fines, work stoppages, or inability to use the machine.

- Mitigation: Verify the machine meets relevant safety standards (e.g., IEC 60825-1 for laser safety, applicable machine safety directives like ISO 13849). Inspect safety features physically or via detailed photos/videos. Ensure proper fume extraction compatibility is designed in.

6. Lack of Real-World Performance Validation & Support

- Pitfall: Suppliers cannot or will not demonstrate the machine cleaning your specific contaminants (e.g., rust, paint, oxide) on your specific materials (e.g., steel, aluminum, concrete) at the required speed and quality.

- Impact: The machine fails to meet your application needs despite meeting paper specifications. Difficulty getting effective technical support, spare parts, or repairs.

- Mitigation: Demand application testing. Send your representative samples to the supplier for cleaning trials. Get video evidence of the process and results. Scrutinize the supplier’s warranty terms, service network, spare parts availability, and technical support responsiveness before purchase. Avoid suppliers with vague or non-existent support promises.

By proactively identifying and mitigating these common pitfalls, you can significantly increase your chances of sourcing a reliable, high-performing, and legally compliant 500W pulse laser cleaning machine that delivers a strong return on investment.

H2: Logistics & Compliance Guide for 500W Pulse Laser Cleaning Machine

Proper logistics planning and regulatory compliance are essential when shipping, importing, and operating a 500W Pulse Laser Cleaning Machine. This guide outlines key considerations to ensure safe, legal, and efficient handling throughout the supply chain and end-use deployment.

1. International Shipping & Transportation

- Classification: The 500W Pulse Laser Cleaning Machine typically falls under machinery/electronic equipment for shipping purposes. Confirm with the Harmonized System (HS) code—commonly 8515.31 or 8479.89 (other electric welding or soldering machinery).

- Packaging: Use export-grade wooden crates with internal foam or shock-absorbing materials to protect sensitive optical and electronic components.

- Labeling: Clearly label packages with:

- “Fragile”

- “This Side Up”

- “Protect from Moisture”

- “Laser Radiation” warning (Class 4 laser product)

- Transport Modes:

- Air: Subject to IATA Dangerous Goods Regulations due to batteries (if included) and laser classification. A Shipper’s Declaration may be required.

- Sea: Standard FCL/LCL container shipping; ensure moisture protection and secure stowage.

- Ground: Use padded, climate-controlled trucks for domestic transport to prevent vibration or temperature damage.

2. Export & Import Compliance

- Export Controls:

- Check if the laser system falls under dual-use regulations (e.g., EU Dual-Use Regulation or U.S. EAR – Export Administration Regulations).

- A 500W pulsed laser may require an export license depending on destination country and end-use.

- Verify country-specific restrictions (e.g., sanctions against certain regions).

- Import Requirements:

- Provide commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

- Import duties and VAT/GST apply based on local tariff schedules.

- Some countries require pre-shipment inspection (e.g., in Africa or the Middle East).

3. Laser Safety & Regulatory Standards

- Laser Classification: The 500W pulse laser is a Class 4 laser product—capable of causing skin burns, eye injury, and fire hazards.

- Compliance Standards:

- IEC 60825-1: Safety of laser products (emission limits, labeling, user instructions).

- FDA/CDRH (U.S.): Requires laser product registration, certification, and compliance with 21 CFR 1040.10/1040.11.

- CE Marking (EU): Compliance with the Machinery Directive (2006/42/EC), EMC Directive (2014/30/EU), and Laser Products Standard (EN 60825-1).

- RoHS & REACH: Ensure materials used comply with hazardous substance restrictions.

- Required Documentation:

- Declaration of Conformity (DoC)

- User manual with safety warnings in local language

- Technical construction file (for CE)

- FDA Accession Number (for U.S. market)

4. Installation & Operational Compliance

- Workplace Safety:

- Install in a controlled access area with interlocks and warning signs.

- Use appropriate laser safety eyewear (OD-rated for pulse wavelength, typically 1064 nm for fiber lasers).

- Implement fume extraction systems to manage particulate byproducts.

- Training: Operators must be trained in laser safety (e.g., ANSI Z136.1 in the U.S. or IEC 60825 standards).

- Regulatory Inspections: Maintain logs for safety audits and ensure compliance with OSHA (U.S.) or equivalent national occupational health and safety bodies.

5. After-Sales & Service Logistics

- Spare Parts: Maintain an inventory of critical components (laser source, nozzles, filters) for quick turnaround.

- Technician Certification: Service personnel should be trained and certified to handle high-power laser systems.

- Warranty & Returns: Define clear return procedures, especially for cross-border warranty claims (consider repair-in-country options to avoid re-import duties).

6. Environmental & Disposal Compliance

- End-of-Life Disposal:

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU.

- Lasers may contain hazardous materials—dispose of optics and electronic boards via certified e-waste handlers.

- Battery Handling (if applicable): Comply with UN38.3 testing and shipping requirements for lithium batteries.

Best Practices Summary:

- Conduct a pre-shipment compliance review for destination country.

- Partner with freight forwarders experienced in high-tech industrial equipment.

- Maintain all certifications and update documentation for regulatory changes.

- Provide multilingual safety and operation manuals.

Adhering to this logistics and compliance framework ensures safe delivery, legal market access, and responsible operation of the 500W Pulse Laser Cleaning Machine worldwide.

Conclusion for Sourcing a 500W Pulse Laser Cleaning Machine

After a thorough evaluation of technical specifications, supplier reliability, cost-efficiency, and long-term operational benefits, sourcing a 500W pulse laser cleaning machine presents a strategic and future-ready investment for industrial cleaning applications. This power class offers an optimal balance between effective contaminant removal—such as rust, paint, oxides, and oil—and minimal substrate damage, making it suitable for precision tasks across automotive, aerospace, mold maintenance, and heritage restoration industries.

Pulsed fiber laser technology ensures high peak power with controlled thermal input, improving cleaning precision and material selectivity. The non-abrasive, chemical-free cleaning process aligns with environmental and safety standards, reducing hazardous waste and worker exposure. Additionally, the reduction in downtime and media consumption translates to long-term cost savings despite a higher initial investment.

When sourcing, priority should be given to reputable manufacturers with proven track records, comprehensive after-sales support, training, and warranty options. Compatibility with automation systems and ease of integration into existing production lines further enhance ROI.

In conclusion, acquiring a 500W pulse laser cleaning machine represents a smart, sustainable, and scalable solution that enhances cleaning efficiency, supports eco-friendly operations, and improves overall production quality. It is a justified investment for any organization aiming to modernize its maintenance and surface preparation processes.