The global pressure washer market is experiencing robust growth, driven by rising demand across residential, commercial, and industrial sectors. According to a report by Grand View Research, the global pressure washer market was valued at USD 4.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. Factors such as increasing infrastructure development, expanding automotive maintenance services, and growing emphasis on cleaning efficiency are accelerating adoption. As high-pressure cleaning becomes essential in industries ranging from construction to agriculture, 5000 PSI models—known for their superior cleaning power and versatility—are gaining prominence. This demand surge has spurred innovation and competition among manufacturers. Based on market presence, technological capability, product reliability, and global distribution, we’ve identified the top 10 manufacturers leading the 5000 PSI pressure washer segment.

Top 10 5000 Psi Pressure Washer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Alkota

Domain Est. 1996

Website: alkota.com

Key Highlights: Commercial pressure washers for industrial cleaning applications, Alkota cleaning systems handle the toughest jobs from animal enclosures to oil rigs….

#2 Washing Equipment of Texas

Domain Est. 1996

Website: wet-inc.com

Key Highlights: Our wide selection of hot and cold pressure washers boast cleaning power of up to 10 gallons per minute or 5000 PSI. Extra Control. Our industrial cleaning ……

#3 Industrial Pressure Washers

Domain Est. 2006

Website: simpsoncleaning.com

Key Highlights: SIMPSON’s line of industrial pressure washers delivers high performance and durability for professional use. Click here to browse our selection….

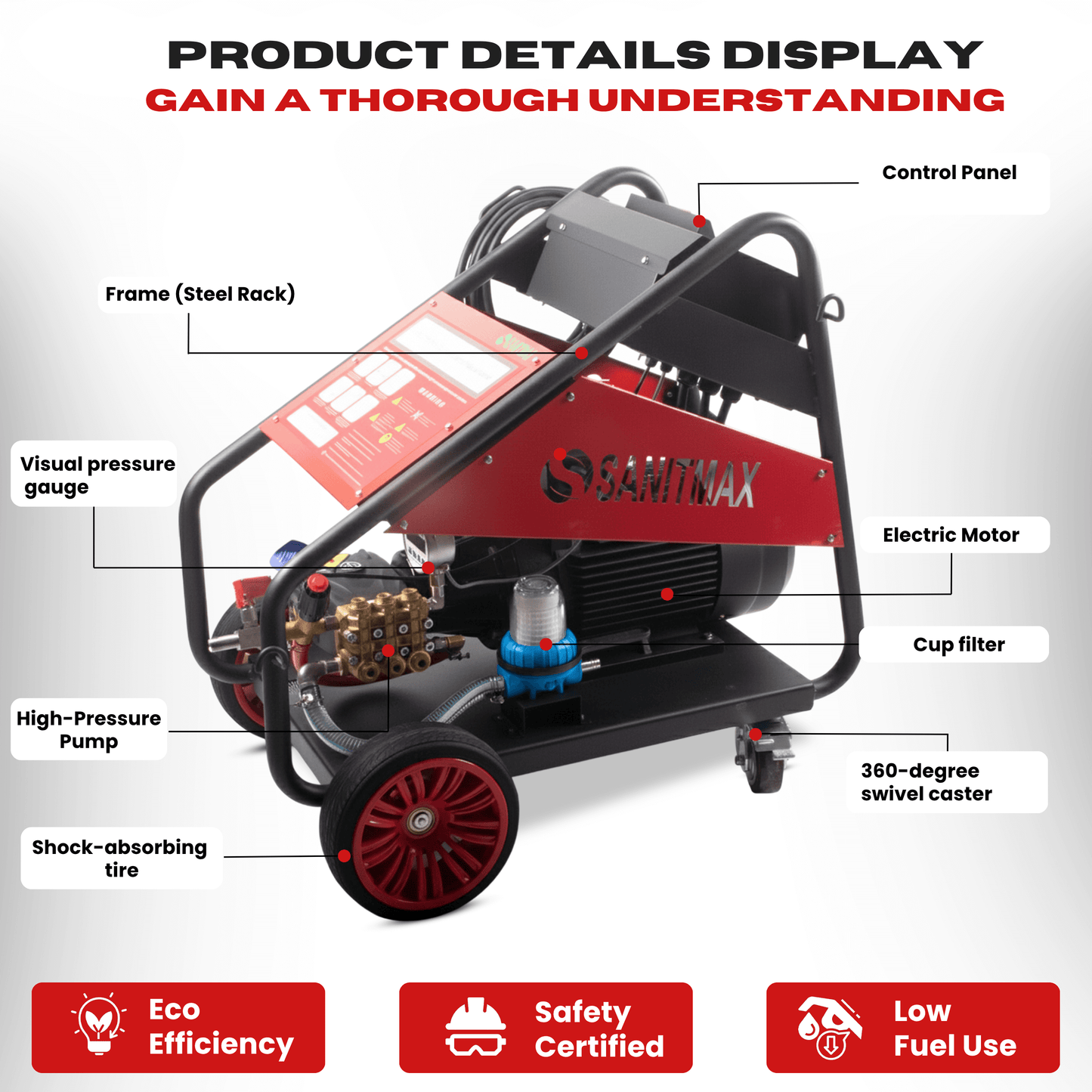

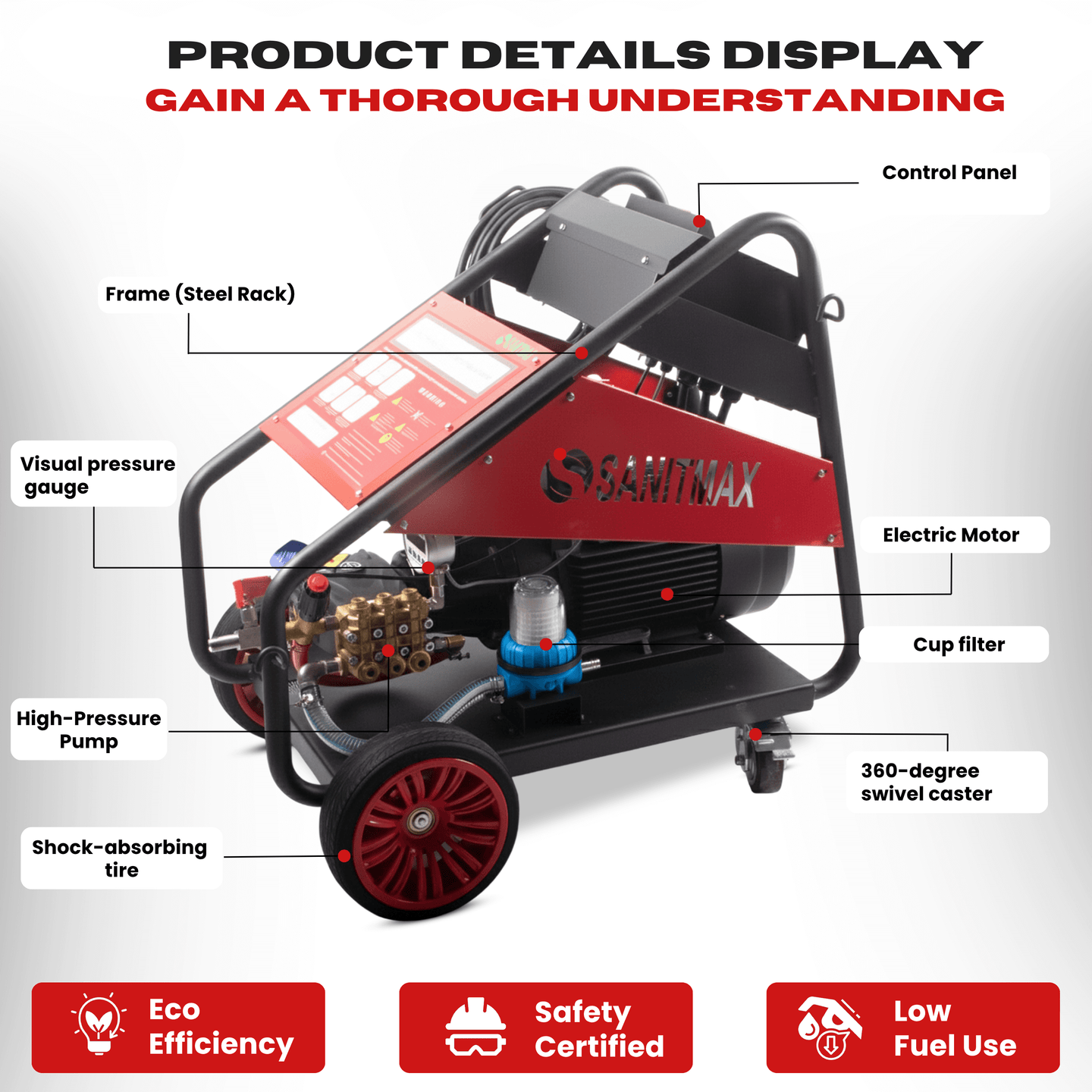

#4 Industrial Electric Pressure Washer 5000 PSI

Domain Est. 2021

Website: sanitmax.com

Key Highlights: In stock Free deliveryIndustrial cold water electric pressure washer delivering 5000 PSI at 5.5 GPM. 20 HP, 460V 3-phase system designed for heavy-duty industrial cleaning ……

#5 Landa Commercial Pressure Washer Products

Domain Est. 1994

Website: landa.com

Key Highlights: For caked-on dirt and debris, a cold water pressure washer is your most efficient solution, delivering cleaning power up to 5 GPM at 5000 PSI at a more ……

#6 Pressure Washing Equipment, Supplies and Accessories

Domain Est. 1996

Website: hotsy.com

Key Highlights: BDE Series. The BDE Series is a portable, electric cold water pressure washer, offering a Hotsy belt-drive, triplex pump and cleaning power of 5000 PSI….

#7 5000HXR Portable Cold Water Power Washer

Domain Est. 1997

Website: camspray.com

Key Highlights: Rating 4.2 (5) Model Number: 5000HXR P00680. The Cart mounted 5000HXR model is designed to be mobile on the job site and hooked to a standard garden hose for water supply….

#8 Pressure Washers Direct

Domain Est. 2002

Website: pressurewashersdirect.com

Key Highlights: Pressure Washers Direct – Shop huge selection of quality pressure washers from top name brands. Buy power washers direct. Free Shipping. Expert Advice….

#9 5000 PSI Pressure Washer

Domain Est. 2002

Website: skyworksllc.com

Key Highlights: The 5000 PSI Cold Pressure Washer delivers a powerful water output of 5000 PSI, efficiently tackling stubborn dirt, grime, and debris….

#10 BE Power Equipment

Domain Est. 2016

Website: bepowerequipment.com

Key Highlights: BE Power Equipment is the premier power equipment brand supplying Pressure Washers, Generators, Inverters, Air Compressors, and Pumps….

Expert Sourcing Insights for 5000 Psi Pressure Washer

H2: 2026 Market Trends for 5000 PSI Pressure Washers

The market for 5000 PSI pressure washers is expected to experience notable shifts by 2026, driven by technological advancements, growing consumer demand for heavy-duty cleaning solutions, and evolving environmental regulations. As one of the highest-pressure categories available for commercial and industrial use, 5000 PSI models are increasingly favored for their efficiency in demanding applications such as construction cleanup, fleet maintenance, and large-scale agricultural operations.

A key trend shaping the 2026 market is the integration of smart technology and IoT-enabled features. Leading manufacturers are incorporating wireless connectivity, remote monitoring, and performance tracking into high-PSI units. These innovations allow users to optimize pressure settings, monitor maintenance schedules, and improve operational efficiency—particularly valuable in commercial settings where uptime and equipment longevity are critical.

Another significant trend is the shift toward more sustainable and eco-friendly designs. While 5000 PSI pressure washers traditionally rely on gas-powered engines, the industry is witnessing increased investment in electric and hybrid models. By 2026, electric high-pressure washers—especially those powered by lithium-ion batteries or connected to renewable energy sources—are expected to gain market share, driven by stricter emissions standards in regions like the EU and California.

Demand is also being fueled by the expansion of industries such as infrastructure development and outdoor equipment rental services. Emerging markets in Asia-Pacific and Latin America are projected to show rising adoption of high-performance cleaning equipment, contributing to global market growth. Additionally, the trend toward equipment-as-a-service (EaaS) models may increase access to premium 5000 PSI units, enabling small businesses and contractors to rent rather than purchase.

Finally, product differentiation through durability, portability, and ease of maintenance will be crucial. Brands that offer rugged construction, modular components, and comprehensive service networks are likely to capture greater market share. As safety standards become more stringent, enhanced safety features such as automatic shut-off, low-oil shutdown, and improved hose durability will become standard in 5000 PSI units by 2026.

In summary, the 2026 market for 5000 PSI pressure washers will be defined by innovation, sustainability, and expanding industrial applications, positioning these high-performance tools as essential assets in commercial and industrial cleaning ecosystems.

Common Pitfalls When Sourcing a 5000 PSI Pressure Washer (Quality & Intellectual Property)

Sourcing a 5000 PSI pressure washer, especially from international suppliers or lesser-known brands, comes with significant risks related to quality control and intellectual property (IP) infringement. Being aware of these pitfalls is crucial to avoid costly failures, safety hazards, and legal complications.

1. Inflated or Misleading PSI Claims (Quality Risk)

Many suppliers, particularly online or from certain regions, exaggerate pressure ratings. A unit advertised as 5000 PSI may deliver significantly less under actual operating conditions.

- Cause: “Peak PSI” or “burst pressure” may be listed instead of “operating PSI.” Poor pump design or low-quality motors cannot sustain claimed pressures.

- Consequences: Inadequate cleaning performance, inability to handle intended tasks (e.g., stripping paint, heavy industrial use), customer dissatisfaction.

- Mitigation: Request independent third-party test reports (e.g., from Intertek, SGS) verifying operating PSI. Look for reputable pump brands (e.g., AR Blue, CAT Pumps, Annovi Reverberi) and verify motor specifications (HP/kW, RPM).

2. Poor Build Quality and Component Durability (Quality Risk)

High-pressure systems endure extreme stress. Substandard materials and construction lead to rapid failure.

- Cause: Use of plastic instead of metal in critical components (pump housing, manifolds, fittings), thin-walled hoses, low-grade seals and valves, underpowered or inefficient motors.

- Consequences: Frequent breakdowns (pump seal leaks, hose bursts, motor burnout), high maintenance costs, safety hazards (e.g., flying debris from failed parts), short product lifespan.

- Mitigation: Conduct on-site factory audits to inspect materials and assembly processes. Demand detailed component specifications (e.g., stainless steel vs. brass fittings, triplex plunger pump). Request samples for destructive testing or long-duration run tests.

3. Inadequate Thermal Protection and Overheating (Quality Risk)

Continuous high-pressure operation generates significant heat. Poor thermal management damages the pump.

- Cause: Lack of effective thermal relief valves, insufficient cooling fins, inadequate duty cycle design, poor ventilation in the pump housing.

- Consequences: Premature pump failure due to overheating, seized plungers, destroyed seals, potential fire risk from overheated motors.

- Mitigation: Verify the presence and specifications of thermal relief valves. Check the manufacturer’s stated duty cycle (e.g., “50/50” means 5 minutes on, 5 minutes off). Ensure the pump design includes adequate cooling features.

4. Counterfeit or Replica Products (IP Risk)

Many unbranded or “look-alike” pressure washers directly copy the design, logos, and branding of established manufacturers (e.g., AR, Karcher, Simpson) without authorization.

- Cause: Suppliers replicate patented designs, trademarks, and trade dress to capitalize on brand reputation while cutting costs.

- Consequences: Legal liability for trademark/copyright infringement, seizure of goods by customs, damage to your brand reputation, potential fines or lawsuits from the IP holder. Counterfeit units often have the worst quality issues.

- Mitigation: Conduct thorough IP due diligence. Search trademark and patent databases (e.g., USPTO, EUIPO) for the design and brand names. Work with suppliers who provide proof of legitimate licensing or authorization. Avoid suppliers offering near-identical copies of well-known brands at suspiciously low prices.

5. Unlicensed Use of Proprietary Pump Technology (IP Risk)

Reputable brands often use patented pump designs (e.g., specific valve configurations, crankshaft designs, seal technologies). Unauthorized copying is common.

- Cause: Suppliers reverse-engineer patented pumps and manufacture clones without licensing the technology.

- Consequences: Patent infringement lawsuits (which can target the importer/distributor, not just the manufacturer), product recalls, injunctions halting sales, significant legal fees.

- Mitigation: Identify the specific pump model used. Research its patent status. Source pumps from authorized distributors of known brands (e.g., AR, CAT). Require suppliers to warrant they have the right to use the technology and indemnify you against IP claims.

6. Lack of Safety Certifications (Quality & Regulatory Risk)

High-pressure equipment must meet rigorous safety standards (e.g., UL, CE, CSA, ETL). Non-compliant units are dangerous and illegal to sell in many markets.

- Cause: Suppliers skip costly certification processes or falsify documentation.

- Consequences: Equipment failure causing injury (high-pressure injection wounds are severe), product recalls, bans on import/sale, liability for damages, reputational damage.

- Mitigation: Demand valid, current certificates from accredited bodies for your target market. Verify certificates directly with the issuing body. Inspect units for genuine certification marks.

7. Inadequate After-Sales Support and Spare Parts (Quality Risk)

Even robust machines need maintenance. Sourcing spare parts for obscure brands can be impossible.

- Cause: Suppliers lack a global parts network or go out of business.

- Consequences: Long downtime for repairs, increased total cost of ownership, customer frustration, stranded inventory of unusable units.

- Mitigation: Negotiate clear terms for spare parts supply (minimum stock levels, minimum order quantities, lead times) in the contract. Verify the supplier’s track record and financial stability. Consider stocking critical spare parts yourself.

By proactively addressing these common pitfalls through rigorous due diligence, supplier vetting, contractual safeguards, and independent verification, you can significantly reduce the risks associated with sourcing high-pressure equipment and ensure you deliver a safe, reliable, and legally compliant product.

H2: Logistics & Compliance Guide for 5000 PSI Pressure Washer

This guide outlines key logistics and compliance considerations for the distribution, sale, and use of a 5000 PSI pressure washer. Adhering to these standards ensures product safety, regulatory compliance, and efficient supply chain operations.

- Regulatory Compliance

1.1. Electrical Safety (if electric-powered)

– Ensure compliance with:

– UL 1776 (Standard for Electric Motor-Operated Water Pumps) in the U.S.

– CSA C22.2 No. 195 in Canada.

– IEC 60335-2-79 for international markets (e.g., EU, UK, Australia).

– Units must be certified by a Nationally Recognized Testing Laboratory (NRTL) such as UL, ETL, or CSA.

1.2. Gasoline-Powered Units (if applicable)

– EPA and CARB Compliance:

– Meet U.S. Environmental Protection Agency (EPA) Phase 3 and California Air Resources Board (CARB) standards for small off-road engines (SORE).

– Engines must be labeled with EPA and/or CARB certification numbers.

– Include emissions compliance documentation with each unit.

1.3. Electrical and Cord Safety (for electric models)

– Power cord must comply with:

– UL 817 (Attachment Plugs and Receptacles)

– UL 62 (Standard for Flexible Cords and Cables)

– GFCI (Ground Fault Circuit Interrupter) protection required for outdoor use.

1.4. Noise Regulations

– Sound pressure levels must comply with:

– OSHA 29 CFR 1910.95 (workplace noise exposure)

– EU Directive 2000/14/EC (Outdoor Equipment Noise Emission)

– Label units with dB(A) levels at operator position.

1.5. Product Labeling & Documentation

– Required labels:

– Manufacturer name and address

– Model and serial number

– Voltage, frequency, amperage, or fuel type

– Maximum PSI and GPM ratings

– Warning labels (e.g., high pressure, electrical hazards, pinch points)

– EPA/CARB certification (if applicable)

– CE mark (for EU sales)

– UKCA mark (for UK sales)

- Include user manual in local language(s) with:

- Safety instructions

- Assembly and operation procedures

- Maintenance schedule

- Troubleshooting guide

-

Warranty information

-

Transportation & Logistics

2.1. Packaging Requirements

– Use durable, weather-resistant packaging to protect during transit.

– Include internal cushioning to prevent damage to hoses, nozzles, and motor components.

– Clearly label packages with:

– “Fragile”

– “This Side Up”

– Hazard symbols (if applicable, e.g., electrical components)

2.2. Hazardous Materials Considerations

– Gasoline-powered units:

– Engines must be shipped with empty fuel tanks to comply with DOT 49 CFR and IATA/IMDG regulations.

– Include fuel instructions and safety warnings.

– Battery-powered models:

– Lithium-ion batteries must comply with UN 38.3 testing.

– Packages must display proper Class 9 lithium battery labels if shipped by air.

2.3. Domestic Shipping (U.S. & Canada)

– Classify under proper HTS codes (e.g., 8424.81.00 for power washers).

– Follow FMCSA and DOT guidelines for ground transport.

– Ensure carriers are aware of any weight or size restrictions.

2.4. International Shipping

– Prepare complete export documentation:

– Commercial invoice

– Packing list

– Certificate of Origin

– Bill of Lading or Air Waybill

– Verify import regulations in target country (e.g., CE certification in EU, RCM mark in Australia).

– Consider customs duties, tariffs, and import taxes.

- Storage & Handling

3.1. Warehouse Storage

– Store in dry, temperature-controlled environments to prevent motor or pump damage.

– Protect from moisture, especially for electric models.

– Stack units according to manufacturer guidelines to avoid crushing.

3.2. Handling Procedures

– Use proper lifting equipment for units over 50 lbs.

– Avoid dragging or dropping units to prevent hose and pump damage.

– Keep accessories (nozzles, hoses, wands) organized and secure.

- End-User Compliance & Safety

4.1. Operator Safety

– Recommend use of PPE:

– Safety goggles

– Gloves

– Hearing protection

– Sturdy footwear

– Warn against direct spray on skin or electrical outlets.

4.2. Environmental Compliance

– Encourage proper wastewater disposal, especially when using detergents.

– Avoid runoff into storm drains (violates U.S. Clean Water Act in many cases).

– Recommend use of closed-loop systems or water reclamation in commercial settings.

- Warranty & Service

5.1. Warranty Registration

– Provide online or mail-in registration to track units and comply with consumer protection laws.

– Clearly state warranty terms (e.g., 2-year residential, 90-day commercial).

5.2. Service & Repair

– Maintain a network of authorized service centers.

– Train technicians on safety and compliance protocols.

– Keep records of repairs for traceability.

-

Recall Preparedness

-

Establish a product recall plan compliant with:

- U.S. Consumer Product Safety Commission (CPSC) guidelines

- Health Canada for Canadian market

- EU RAPEX system

- Maintain traceability via serial numbers and batch tracking.

Conclusion

Ensuring compliance and efficient logistics for a 5000 PSI pressure washer involves adherence to electrical, environmental, transportation, and safety regulations across all stages—from manufacturing to end-user operation. Proactive planning and documentation are essential for legal compliance, customer safety, and smooth global distribution.

In conclusion, sourcing a 5000 psi pressure washer requires careful consideration of several key factors to ensure optimal performance, durability, and value for the intended application. High-pressure washers in this range are ideal for heavy-duty cleaning tasks such as industrial equipment, large vehicles, concrete surfaces, and commercial facilities. When sourcing, it is essential to evaluate the machine’s build quality, whether it features a direct-drive or belt-drive pump, and the reliability of the engine (gas or electric). Additionally, prioritize reputable manufacturers known for robust customer support and parts availability. Consider portability, ease of maintenance, safety features, and warranty coverage to maximize long-term efficiency and reduce downtime.

Sourcing from authorized dealers or trusted suppliers ensures authenticity, proper servicing, and compliance with safety standards. While upfront cost may be higher for commercial-grade models, the investment pays off through increased durability and reduced operational costs over time. Ultimately, selecting the right 5000 psi pressure washer involves aligning technical specifications with specific cleaning needs, ensuring a powerful, reliable solution that enhances productivity and delivers exceptional cleaning results.