The market for septic tanks is experiencing steady growth, driven by increasing demand for decentralized wastewater treatment solutions in both residential and commercial sectors. According to Grand View Research, the global septic tank market was valued at USD 7.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, fueled by urbanization in emerging economies and infrastructure development in rural areas. Mordor Intelligence projects similar momentum, noting rising construction activities and stringent environmental regulations around wastewater management as key drivers. Amid this growth, 5000-gallon septic tanks have become a preferred choice for larger households, small communities, and commercial facilities due to their high capacity and long-term efficiency. As demand escalates, selecting reliable manufacturers becomes critical. Below are the top six manufacturers leading innovation, durability, and market share in the 5000-gallon septic tank segment.

Top 6 5000 Gallon Septic Tank Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Septic

Domain Est. 2002

Website: phoenixprecast.com

Key Highlights: Phoenix Precast is one of the largest manufacturers of precast septic products in New Hampshire, we can provide you with a vast product selection….

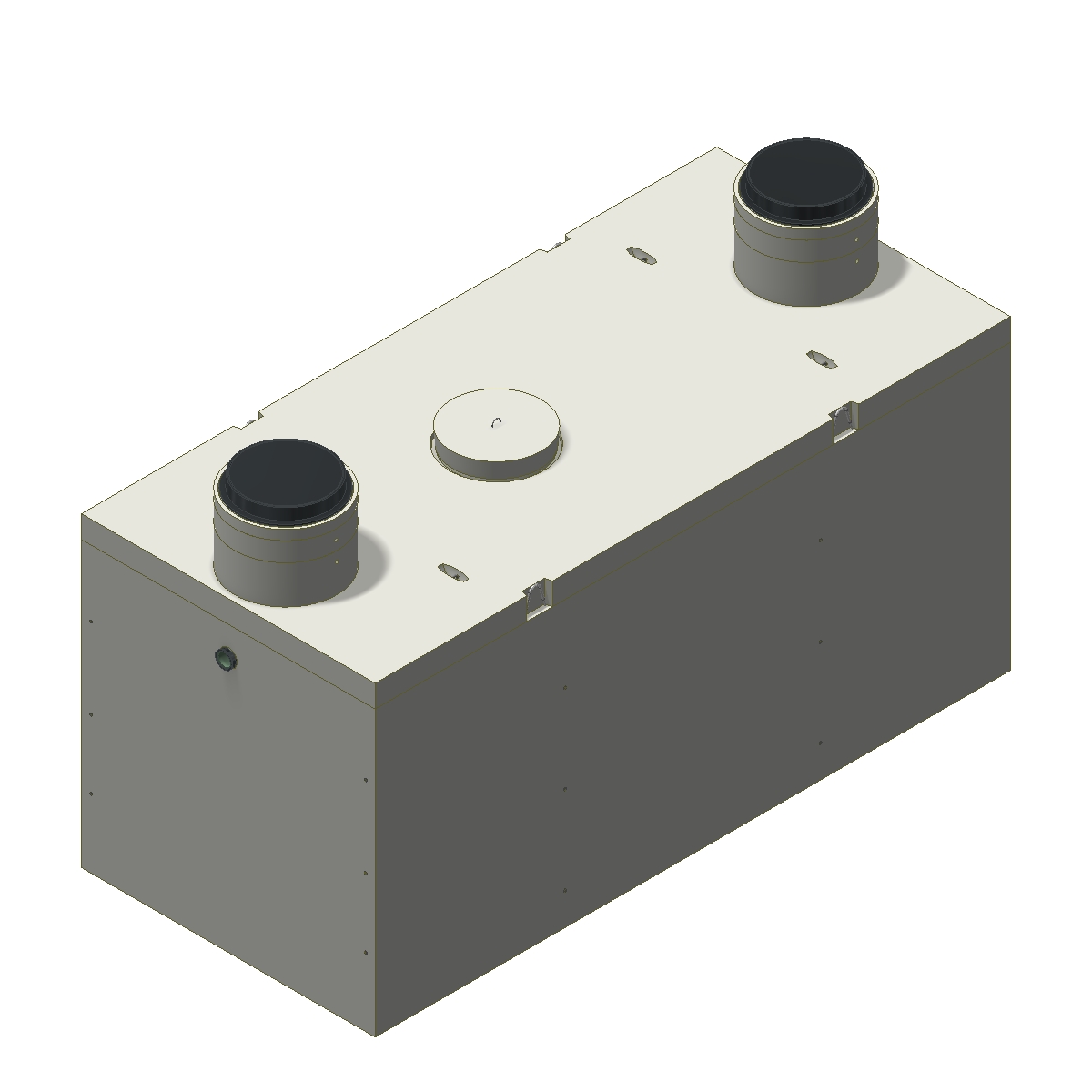

#2 Traffic Rated Septic Tank

Domain Est. 1996

Website: jensenprecast.com

Key Highlights: Upgrade to the JS 5000 gal. traffic-rated septic tank, featuring dual 24″ inlets/outlets and a central 24″B outlet. Fits 4″ and 6″ pipes. Buy today!…

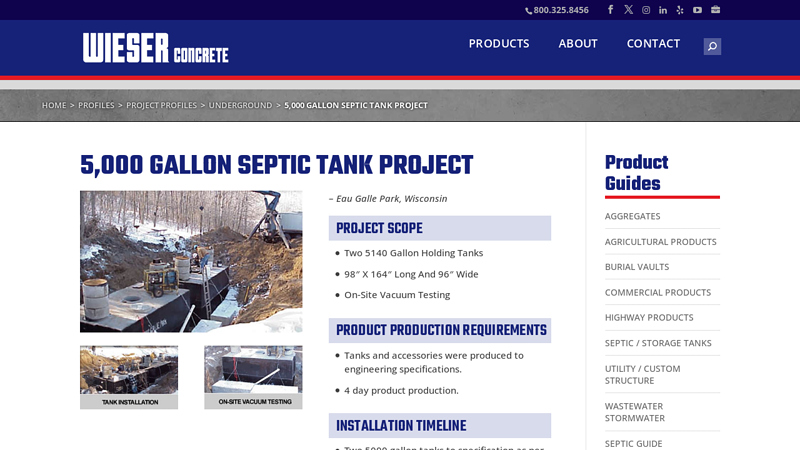

#3 5000 GALLON SEPTIC TANK PROJECT

Domain Est. 1998

Website: wieserconcrete.com

Key Highlights: 5,000 GALLON SEPTIC TANK PROJECT ; PROJECT SCOPE. Two 5140 Gallon Holding Tanks; 98″ X 164″ Long And 96″ Wide; On-Site Vacuum Testing ; PRODUCT PRODUCTION ……

#4 Xerxes ® tanks

Domain Est. 1998

Website: xerxes.com

Key Highlights: Our underground fuel and water tanks, and stormwater management products are designed and manufactured to meet – and exceed – industry standards….

#5 Norwesco 5000 Gallon Liquid Storage Tank

Domain Est. 1999

Website: tank-depot.com

Key Highlights: In stock $899 deliveryThe Norwesco 5000 Gallon Vertical Liquid Storage Tank (Mfg. Part #40164) sets the standard for reliable, large-volume liquid containment. Engineered for ……

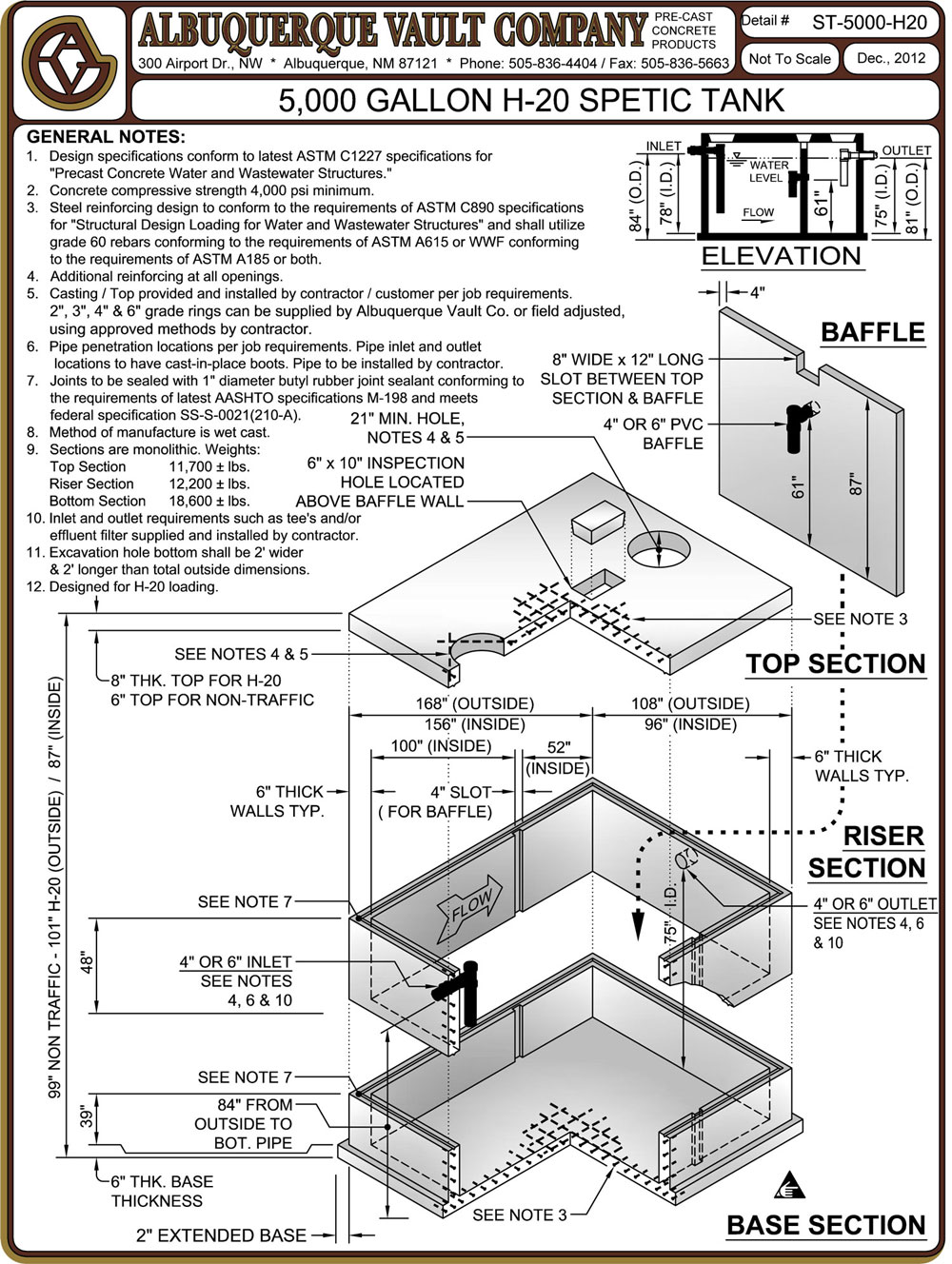

#6 Cut Sheets

Domain Est. 2009

Website: albuqvault.com

Key Highlights: The 5,000 Gallon H-20 Septic Tank from Albuquerque Vault Company is engineered for large-scale wastewater management applications, meeting ASTM ……

Expert Sourcing Insights for 5000 Gallon Septic Tank

H2: 2026 Market Trends for 5000-Gallon Septic Tanks

The market for 5000-gallon septic tanks is poised for notable shifts by 2026, driven by evolving regulatory standards, increased demand for sustainable wastewater solutions, and growth in rural and commercial infrastructure. As decentralized wastewater treatment becomes more critical—especially in areas lacking access to municipal sewer systems—the 5000-gallon septic tank, typically used for larger residential complexes, small businesses, and rural developments, is expected to experience steady demand.

A key trend shaping the 2026 market is stricter environmental regulations. Governments at both federal and state levels are tightening effluent discharge standards to protect groundwater quality. This is driving adoption of advanced treatment systems, including aerobic treatment units (ATUs) and prefabricated tanks with enhanced filtration, often in the 5000-gallon capacity range. As a result, manufacturers are focusing on innovation in materials (such as durable polyethylene and fiberglass) and integration with smart monitoring technologies for leak detection and maintenance alerts.

Another influential factor is the expansion of rural housing and eco-resorts, particularly in the U.S., Canada, and parts of Europe and Asia. With remote work trends persisting beyond 2023, more people are relocating to rural areas, boosting construction of off-grid homes and community developments that require large-capacity septic systems. The 5000-gallon tank offers an optimal balance between cost, size, and functionality for these applications.

Additionally, sustainability initiatives are pushing demand for greener solutions. Biodegradable additives, rainwater harvesting integration, and greywater recycling systems are being paired with large septic tanks to improve efficiency and reduce environmental impact. By 2026, such hybrid systems are expected to represent a growing segment of the market.

Finally, supply chain resilience and local manufacturing are gaining importance. Post-pandemic disruptions have led companies to regionalize production and stock inventory more strategically. This is expected to reduce lead times and increase market responsiveness, benefiting both installers and end-users.

In summary, the 2026 market for 5000-gallon septic tanks will be shaped by regulatory pressures, technological innovation, rural development, and a growing emphasis on sustainability—positioning the sector for moderate but steady growth with increasing value-added features.

Common Pitfalls When Sourcing a 5000-Gallon Septic Tank (Quality & Intellectual Property)

Sourcing a 5000-gallon septic tank involves significant investment and long-term implications for system performance and regulatory compliance. Avoiding key pitfalls related to quality and intellectual property (IP) is essential to ensure durability, functionality, and legal safety.

Poor Material Quality and Construction Standards

One of the most critical risks is selecting a tank made from substandard materials or poor manufacturing practices. Low-quality polyethylene, fiberglass, or concrete can lead to premature cracking, warping, or structural failure under soil and hydrostatic pressure. Buyers may encounter tanks with inconsistent wall thickness, inadequate UV protection (for plastic tanks), or improper reinforcement (in concrete or fiberglass units), compromising longevity. Always verify compliance with ASTM, NSF, or local regulatory standards and request third-party test certifications.

Lack of Design Certification and Engineering Validation

A major quality concern is sourcing tanks without proper engineering approval or site-specific design validation. Some suppliers offer “off-the-shelf” tanks not suited for local soil, water table, or load-bearing conditions. Using an uncertified design can void warranties, fail inspections, and result in costly repairs. Ensure the tank design is stamped by a licensed professional engineer and tailored to the installation environment.

Counterfeit or Unlicensed Replicas of Proprietary Designs

Intellectual property violations are increasingly common in the septic tank market. Some manufacturers produce unauthorized replicas of patented tank designs, incorporating protected features such as baffle configurations, inlet/outlet systems, or structural geometries. Purchasing such products exposes buyers to legal liability and may result in performance issues due to inferior execution of the original design. Always verify that the manufacturer holds legitimate rights to the design or has proper licensing agreements.

Inadequate Documentation of IP Rights and Manufacturing Origin

Failure to obtain clear documentation on design ownership, manufacturing origin, and IP compliance can lead to disputes, especially in public or commercial projects. Suppliers may obscure the source of their designs or provide incomplete technical records. Request proof of patents, trademarks, or licensing agreements, and audit the manufacturer’s credentials to mitigate risk.

Overlooking Warranty and Liability Coverage

Low-cost tanks often come with limited or ambiguous warranties that exclude failures due to design or material defects. Worse, counterfeit or IP-infringing products typically offer no enforceable warranty or liability protection. Ensure the warranty explicitly covers structural integrity, material degradation, and design performance over time—and that the manufacturer is legally accountable.

By focusing on certified quality, verified engineering, and legitimate intellectual property, purchasers can avoid costly failures and ensure a reliable, compliant septic solution.

Logistics & Compliance Guide for 5000 Gallon Septic Tank

Site Assessment and Permitting

Before installation, a thorough site assessment must be conducted by a licensed professional. This includes evaluating soil composition, percolation rates, groundwater levels, and proximity to water bodies, property lines, and structures. Local health departments or environmental agencies typically require a percolation (perc) test to determine soil absorption capacity. Based on the assessment, an installation permit must be obtained. Requirements vary by jurisdiction, but generally include engineered site plans, septic design specifications, and compliance with local zoning ordinances.

Tank Selection and Delivery Logistics

Select a 5000-gallon septic tank constructed from durable, code-compliant materials—typically precast concrete, fiberglass, or high-density polyethylene (HDPE). Confirm that the tank meets ASTM or equivalent standards. Coordinate delivery with the supplier, ensuring the delivery vehicle can access the installation site. A 5000-gallon tank is heavy (approximately 10,000–15,000 lbs empty) and requires a large flatbed truck or lowboy trailer. Plan for clear access roads, sufficient turning radius, and ground stability to prevent accidents during offloading.

Installation Requirements and Best Practices

Installation must follow manufacturer guidelines and local regulations. The excavation must be level and large enough to allow for proper backfilling and berming around the tank. Use a crane or heavy lift equipment to set the tank, ensuring it is placed on a firm, level base (typically 4–6 inches of compacted gravel). Maintain proper slope for inlet and outlet pipes (usually 1/4 inch per foot) and verify tank orientation. Backfill carefully with approved material (e.g., native soil free of rocks), compacting in layers to prevent shifting. Install risers and lids securely and ensure all baffles and tees are correctly positioned.

Regulatory Compliance and Inspections

Compliance with federal, state, and local regulations is mandatory. In the U.S., systems are generally regulated at the state and county level under authority of the Clean Water Act. Key compliance points include adherence to setback requirements (e.g., 50–100 feet from wells, streams, or property lines), proper leach field design, and overflow protection. A licensed inspector must approve the tank placement, piping, and drain field before backfilling is completed and again upon final cover. Maintain all permits, inspection reports, and as-built drawings for future reference.

Maintenance and Long-Term Compliance

Schedule regular maintenance to ensure system longevity and regulatory compliance. Pump the tank every 3–5 years, depending on usage, to prevent solids from clogging the drain field. Avoid flushing non-biodegradable materials or harsh chemicals. Conduct periodic inspections to check for leaks, cracks, or system failures. Many jurisdictions require maintenance contracts for large-capacity systems like 5000-gallon tanks, especially in environmentally sensitive areas. Keep detailed records of pumping, repairs, and inspections to demonstrate compliance during audits or property transfers.

Conclusion: Sourcing a 5000-Gallon Septic Tank

Sourcing a 5000-gallon septic tank requires careful consideration of multiple factors, including material type (concrete, fiberglass, or polyethylene), local regulations, site conditions, installation requirements, and long-term maintenance needs. After evaluating suppliers, product quality, delivery logistics, and cost-effectiveness, it is essential to select a reputable manufacturer and installer who comply with environmental and health standards.

A 5000-gallon capacity is typically suited for large residential properties, commercial facilities, or multi-unit developments, making durability and proper system design critical. While higher initial costs may be associated with premium materials and professional installation, these investments often lead to reduced maintenance expenses and extended system lifespan.

In conclusion, sourcing the right 5000-gallon septic tank involves balancing upfront costs with long-term performance and regulatory compliance. By conducting thorough research, obtaining multiple quotes, and consulting with local authorities and licensed contractors, you can ensure a reliable, code-compliant septic solution that meets your specific needs for years to come.