The global fiber laser market is experiencing robust growth, driven by increasing demand across industrial manufacturing, automotive, aerospace, and electronics sectors. According to Grand View Research, the market was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.6% from 2023 to 2030. This growth is fueled by the rising adoption of high-efficiency, low-maintenance fiber lasers for precision cutting, welding, and marking applications. With 50-watt fiber lasers occupying a sweet spot between performance and cost-effectiveness for small to medium-scale operations, manufacturers are focusing on improving beam quality, energy efficiency, and integration capabilities. As competition intensifies, several key players have emerged as leaders in innovation, reliability, and market reach—shaping the landscape of industrial laser technology. Here’s a data-driven look at the top 9 manufacturers of 50-watt fiber lasers leveraging this expanding market opportunity.

Top 9 50 Watt Fiber Laser Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Universal Laser Systems

Domain Est. 1996

Website: ulsinc.com

Key Highlights: Solve Material Processing Challenges. Overcome your most demanding and complex applications. ULS helps companies evaluate the feasibility of laser technology….

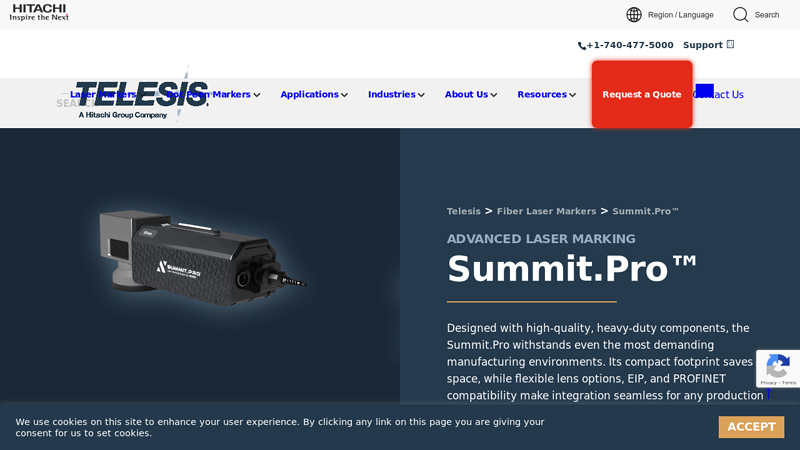

#2 Summit.Pro Industrial Fiber Laser

Domain Est. 1996

Website: telesis.com

Key Highlights: Designed with high-quality, heavy-duty components, the Summit.Pro withstands even the most demanding manufacturing environments. Its compact footprint saves ……

#3 Bodor

Domain Est. 2003

Website: bodor.com

Key Highlights: Bodor laser is a fiber laser cutting machine manufacturer specialized in cnc fiber laser cutting machine equipment with integrating development, production, ……

#4 Beamer Laser Marking Systems

Domain Est. 2007

Website: beamerlasermarking.com

Key Highlights: Beamer is an American manufacturer of IR fiber laser marking systems. … Power Lasers. 20 Watt IR Fiber 50 Watt IR Fiber 100 Watt IR Fiber Variable Pulse…

#5 Wuhan Raycus Fiber Laser Technologies Co., Ltd.

Domain Est. 2008

Website: en.raycuslaser.com

Key Highlights: High efficiency of electro-optic conversion · Resistance to high resistance · Efficient sheet cutting · Output fiber length can be customized · Maintenance free ……

#6 IPG Photonics

Domain Est. 1999

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#7 FIBER Laser

Domain Est. 2007

Website: gravotech.us

Key Highlights: This deep laser marking machine is available in several powers; 20W, 30W and 50W. 20W is adapted for most applications for surface marking, 30W is the solution ……

#8 Full Spectrum Laser

Domain Est. 2010

Website: fslaser.com

Key Highlights: 7–15 day delivery 30-day returnsFull Spectrum Laser is a US based company that designs, manufactures, and sells powerful and affordable laser cutting & laser engraving products….

#9 MOPA Fiber Lasers

Domain Est. 2016

Website: en.jptoe.com

Key Highlights: JPT develops advanced MOPA fiber lasers with high peak power, adjustable pulse width, and excellent beam quality. Widely used in precision marking, ……

Expert Sourcing Insights for 50 Watt Fiber Laser

2026 Market Trends for 50 Watt Fiber Lasers

The 50-watt fiber laser market is poised for significant evolution by 2026, driven by technological advancements, expanding applications, and shifting industrial demands. While larger lasers dominate heavy cutting and welding, the 50W segment occupies a crucial niche, particularly in precision processing and cost-sensitive automation. Key trends shaping this market include:

1. Increased Adoption in Precision Micromachining & Fine Marking

By 2026, demand for high-precision manufacturing in electronics, medical devices, and semiconductors will drive the use of 50W fiber lasers. Their ability to deliver focused, stable beams enables fine engraving, micro-cutting of thin materials (e.g., stents, flex circuits), and high-contrast permanent marking on sensitive components. Advancements in beam quality (M² < 1.1) and pulse control will further enhance their suitability for intricate tasks where thermal damage must be minimized.

2. Growth in Automated Integration and Smart Manufacturing

The integration of 50W fiber lasers into automated production lines—especially with robotics and Industry 4.0 systems—will accelerate. Manufacturers will increasingly demand plug-and-play laser modules with IoT connectivity, real-time monitoring, and predictive maintenance capabilities. By 2026, 50W systems with built-in sensors and compatibility with CNC and robotic controllers will become standard, boosting productivity and enabling lights-out manufacturing in sectors like automotive and consumer electronics.

3. Cost Optimization and Market Democratization

Intense competition, particularly from Chinese manufacturers, will continue to drive down prices and improve cost-performance ratios. By 2026, more affordable, reliable 50W fiber lasers will become accessible to small and medium-sized enterprises (SMEs), expanding their use in niche fabrication, prototyping, and localized manufacturing. This democratization will fuel market growth, especially in emerging economies.

4. Advancements in Pulsed and Modulated Operation

While CW 50W lasers remain common, pulsed and modulated variants will gain traction for applications requiring controlled heat input. Innovations in Q-switching and burst-mode pulsing will allow 50W lasers to perform tasks previously requiring higher peak powers, such as selective ablation, surface texturing, and cold marking on plastics. This versatility will broaden their industrial applicability.

5. Sustainability and Energy Efficiency Focus

As sustainability becomes a key corporate priority, the inherently energy-efficient nature of fiber lasers—converting over 30% of electrical input into laser light—will be a significant selling point. By 2026, manufacturers will emphasize low power consumption, reduced cooling requirements, and longer component lifespans, aligning with green manufacturing initiatives and lowering total cost of ownership.

6. Competitive Pressure and Consolidation

The market will face continued pressure from low-cost suppliers, pushing established players to innovate in reliability, software integration, and service support. Consolidation among mid-tier manufacturers is likely as companies seek scale and R&D capabilities. The result will be a more segmented market: high-end 50W lasers with advanced features for precision industries, and standardized, cost-effective units for general marking and cutting.

In conclusion, the 50-watt fiber laser market in 2026 will be characterized by smarter, more integrated systems serving high-precision and automated environments. While not the most powerful option, its balance of performance, cost, and efficiency ensures it remains a vital tool in modern manufacturing, particularly as industries demand finer control and scalable automation solutions.

Common Pitfalls When Sourcing a 50 Watt Fiber Laser (Quality & IP)

Sourcing a 50-watt fiber laser involves navigating significant risks related to product quality and intellectual property (IP) protection. Being aware of these common pitfalls is crucial to making a sound investment and avoiding costly setbacks.

Quality-Related Pitfalls

Overstated Power Output and Performance Claims

Many suppliers advertise lasers as delivering a full 50 watts of output power, but actual delivered power may be significantly lower due to inefficiencies or misleading testing conditions. Some manufacturers test under ideal lab conditions rather than real-world operational settings, leading to performance gaps once the system is deployed.

Use of Low-Grade or Counterfeit Components

To reduce costs, some manufacturers use substandard optical components (e.g., pump diodes, collimators, fiber splices) or recycled parts. This compromises beam quality, stability, and mean time between failures (MTBF). Poor component selection often results in frequent maintenance, reduced cutting/engraving precision, and shorter laser lifespan.

Inadequate Thermal and Mechanical Design

A 50W laser generates substantial heat. Systems lacking effective thermal management (e.g., insufficient cooling or poor heatsink design) suffer from thermal drift, power instability, and accelerated degradation. Similarly, flimsy mechanical housings increase sensitivity to vibration and misalignment, affecting long-term reliability.

Lack of Proper Certification and Testing

Reputable lasers should come with certifications such as CE, FDA, or IEC 60825 for laser safety. Suppliers skipping these certifications may not adhere to international safety or performance standards. Absence of independent test reports (e.g., beam profile, power stability over time) is a red flag for quality control.

Intellectual Property (IP) Pitfalls

Infringement of Core Laser Technology IP

Fiber laser technology is heavily patented, particularly in areas like oscillator design, pump coupling, and mode control. Some low-cost manufacturers reverse-engineer or copy designs from leading brands (e.g., IPG, SPI), potentially infringing on protected IP. Purchasing such systems could expose your business to legal risks, especially if used in export markets with strict IP enforcement.

Lack of Transparency in Technology Origin

Suppliers may obscure the origin of core components or firmware. A laser advertised as “designed in [Country X]” might actually use a cloned control board or resonator from a third party. This opacity makes it difficult to assess IP compliance and support long-term innovation or customization needs.

Risk of Firmware and Software Licensing Violations

Control software and embedded firmware in laser systems may incorporate licensed or open-source code used without proper authorization. If discovered, this can lead to software takedowns, compliance audits, or liability—especially if your application involves integration into larger commercial systems.

Limited Ability to Customize or Innovate

Off-the-shelf 50W lasers from IP-infringing sources often come with locked-down interfaces and proprietary protocols. This restricts your ability to modify, upgrade, or integrate the laser into automated systems—hurting product differentiation and scalability.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: verify power output with third-party testing, inspect component quality, demand compliance certifications, and investigate the supplier’s IP practices. Consider partnering with reputable manufacturers who provide transparent technical documentation and respect intellectual property rights. This ensures both equipment reliability and legal safety in your operations.

H2: Logistics & Compliance Guide for 50-Watt Fiber Laser

1. H2: Safety & Regulatory Compliance

- Laser Safety (IEC 60825-1 / ANSI Z136.1):

- Classification: A 50W continuous-wave (CW) fiber laser is Class 4 (high power). This is the highest hazard class.

- Mandatory Controls: Strict engineering controls (interlocked enclosures, beam shutters, key-controlled operation), administrative procedures (training, SOPs), and personal protective equipment (PPE – certified laser safety eyewear specific to the laser wavelength, e.g., 1064nm) are required.

- Laser Safety Officer (LSO): Designation of an LSO is strongly recommended or mandated by regulations in many jurisdictions.

- Labeling: The laser and its enclosure must display the appropriate Class 4 warning labels (diamond symbol, wavelength, max output).

- Interlocks: The system must have safety interlocks on access panels and doors that disable the laser emission when opened.

- Electrical Safety (e.g., UL/CSA 61010-1, IEC 61010-1):

- The laser source and power supply must comply with relevant electrical safety standards for laboratory/industrial equipment (e.g., UL/CSA 61010-1, IEC 61010-1).

- Ensure proper grounding and use of a dedicated circuit if required by the manufacturer.

- Fumes & Particulates (OSHA/NIOSH, Local Regulations):

- Ventilation: Mandatory local exhaust ventilation (LEV) or fume extraction system is required to capture hazardous fumes and particulates generated during material processing (e.g., metal fumes, plastic decomposition products).

- Fume Extractor: Use a HEPA-filtered fume extractor designed for laser processing. Filters must be changed regularly according to manufacturer guidelines and exposure assessments.

- Risk Assessment: Conduct a hazard assessment for the specific materials being processed. Consult Safety Data Sheets (SDS).

- Fire Safety:

- Class 4 lasers pose a significant fire hazard. Flammable materials (solvents, packaging, dust) must be kept away from the beam path and processing area.

- Fire Extinguisher: A Class ABC fire extinguisher must be readily accessible near the laser workstation.

- Supervision: Never leave an operating Class 4 laser unattended.

- Noise: While generally not a primary hazard for the laser source itself, associated components (cooling fans, extractors, motion systems) may require noise assessment if levels exceed local limits (e.g., OSHA PEL).

- Documentation:

- Maintain the manufacturer’s User Manual, Safety Manual, and Declaration of Conformity (DoC).

- Keep records of LSO duties, safety training, maintenance, and fume extractor filter changes.

2. H2: Import/Export & Trade Compliance

- Export Controls (Critical):

- ECCN (Export Control Classification Number): 50W fiber lasers typically fall under ECCN 6A003.b.4 (Lasers, other than those specified in 6A002.b.4, having all of the following: a) Average output power exceeding 500 mW; AND b) A minimum achievable spot diameter less than 500 µm). Confirm the specific ECCN with the manufacturer/supplier.

- License Requirement: Exporting a 50W fiber laser to many countries (especially restricted destinations or entities) requires an export license from the relevant authority (e.g., BIS in the USA, SPIRE in the UK, Export Control Authority in the EU).

- Deemed Exports: Providing technical data or access to the laser to foreign nationals within your own country may also require a license (“deemed export”).

- ITAR: Generally, commercial fiber lasers are not ITAR-controlled (US Munitions List), but always verify with the manufacturer.

- Import Regulations:

- Customs Tariff Codes (HS Codes): Identify the correct Harmonized System (HS) code for import (e.g., 9013.20.xx – Lasers, other than laser diodes). This determines import duties and taxes.

- Import Licenses: Some countries may require specific import permits for laser equipment.

- Conformity Assessment: Ensure the laser meets the safety and EMC requirements of the destination country (e.g., CE Marking for EU/UK, KC Mark for South Korea, CCC Mark for China). The manufacturer’s DoC is crucial.

- Required Documentation for Shipment:

- Commercial Invoice (detailing value, description, ECCN/HS code)

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Export License (if required)

- Certificate of Origin

- Manufacturer’s Declaration of Conformity (DoC)

- Safety Data Sheet (SDS – for any hazardous components like batteries in controllers, though often minimal for the laser itself)

3. H2: Packaging & Shipping

- Original Manufacturer Packaging (STRONGLY Recommended):

- Use the original foam-in-box packaging designed by the manufacturer. This provides optimal protection for the sensitive optics and electronics.

- Ensure all internal foam inserts are present and undamaged.

- Robust Outer Shipping Container:

- Use a new, high-quality, double-walled corrugated cardboard box or a sturdy wooden crate.

- The outer box/crate must be significantly larger than the inner packaged unit to accommodate ample cushioning.

- Cushioning & Immobilization:

- Fill all voids between the inner package and the outer box/crate with high-density foam blocks, bubble wrap, or air pillows. The unit must not move inside the box.

- Critical: Protect the output fiber connector and any other delicate ports with protective caps and additional cushioning.

- Hazard Labels:

- Affix “Fragile” and “This Side Up” labels prominently on the outer packaging.

- DO NOT label the package as “Laser” or “Dangerous Goods” unless it contains hazardous batteries/components requiring specific UN labeling (rare for standard 50W units). Mislabeling can cause significant delays. The commercial invoice declares the contents.

- Carrier Selection:

- Use a reputable freight forwarder experienced in handling high-value, sensitive industrial equipment.

- Choose a service offering tracking, insurance, and controlled handling (e.g., air freight for speed, specialized ground for cost).

- Insurance:

- Fully insure the shipment for its replacement value against loss or damage in transit.

4. H2: Receiving & Installation

- Pre-Install Check:

- Inspect the outer packaging for severe damage before signing the delivery receipt. Note any damage on the delivery note.

- Open the package in a clean, dry, static-safe environment.

- Verify contents against the packing list. Check for physical damage to the unit and components.

- Site Preparation:

- Location: Choose a stable, level surface with adequate clearance (especially rear for ventilation/connections). Ensure proximity to required power (voltage, phase, grounding) and exhaust/ventilation ducts.

- Environment: Maintain within specified temperature (typically 15-35°C) and humidity (e.g., 30-70% non-condensing) ranges. Minimize dust, vibration, and direct sunlight.

- Utilities: Prepare dedicated power circuit (if required), compressed air (if needed for cooling or assist gas), and fume extraction connection.

- Installation:

- Follow the manufacturer’s installation manual precisely.

- Ensure proper grounding of the laser source and all connected equipment.

- Connect cooling (chiller), power, control signals (Ethernet/USB), and exhaust ducting as specified.

- Carefully connect the output fiber to the processing head, ensuring cleanliness and avoiding tight bends (respect minimum bend radius, e.g., >10cm).

- Post-Installation:

- Perform initial power-up and system checks per the manual.

- Conduct beam alignment and safety system verification (interlocks, emergency stop).

- Complete safety training for all operators before first use.

5. H2: Ongoing Compliance & Maintenance

- Regular Maintenance:

- Follow the manufacturer’s preventive maintenance schedule (cleaning optics, checking connections, inspecting fiber, replacing filters in chiller/extractor).

- Keep detailed maintenance logs.

- Safety Audits:

- Periodically audit the installation to ensure safety controls (interlocks, enclosures, signage, PPE availability) remain functional and effective.

- Review and update SOPs and risk assessments.

- Training:

- Provide initial and recurrent laser safety training for all personnel working with or near the laser.

- Regulatory Updates:

- Stay informed about changes in laser safety regulations, export control lists, and environmental regulations (e.g., responsible disposal of used filters).

Key Reminders:

- Class 4 Laser = High Risk: Treat safety with the utmost seriousness.

- Export Controls are Complex: Always verify the ECCN and license requirements before shipping internationally. Consult legal/compliance experts if unsure.

- Original Packaging is Best: Never ship without proper manufacturer-specific packaging or equivalent protection.

- Document Everything: Maintain records of compliance, training, maintenance, and safety inspections.

- Consult Experts: When in doubt, consult the laser manufacturer, a Laser Safety Officer (LSO), or a trade compliance specialist.

Conclusion for Sourcing a 50-Watt Fiber Laser

After a thorough evaluation of market options, technical requirements, and supplier capabilities, sourcing a 50-watt fiber laser presents a cost-effective and efficient solution for precision marking, engraving, and light cutting applications across various industries such as automotive, electronics, and medical devices. This power range strikes an optimal balance between performance and operational cost, offering sufficient power for most industrial marking needs without the higher maintenance and energy demands of more powerful systems.

Key advantages of the 50-watt fiber laser include high reliability, low maintenance, long operational life, and excellent beam quality, ensuring consistent and durable markings on metals and certain plastics. Additionally, the integration of such systems into automated production lines is streamlined due to compact design and compatibility with standard industrial controls.

When sourcing, it is essential to consider factors such as brand reputation, after-sales support, warranty terms, software compatibility, and local service availability. Opting for reputable suppliers with proven track records ensures long-term reliability and minimizes downtime.

In conclusion, investing in a 50-watt fiber laser is a strategic decision that enhances manufacturing capabilities, improves product traceability, and supports scalability. With careful vendor selection and proper integration planning, this technology provides a strong return on investment and positions the business for greater efficiency and competitiveness in the market.