The recreational vehicle (RV) market is experiencing robust expansion, driven by rising consumer demand for flexible travel options and outdoor experiences. According to Grand View Research, the global RV market size was valued at USD 45.1 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This surge in RV adoption has directly fueled demand for reliable electrical infrastructure, particularly 50-amp distribution panels—one of the most common power configurations in modern RVs. As electrical systems become more sophisticated with increased power loads from appliances and smart technology, the importance of high-quality distribution panels has grown significantly. In this context, a select group of manufacturers has emerged as leaders in performance, durability, and innovation. Based on market presence, product reliability, and technical specifications, the following are the top four manufacturers of 50-amp RV distribution panels shaping the industry today.

Top 4 50 Amp Rv Distribution Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 RV Distribution Panels

Domain Est. 1996

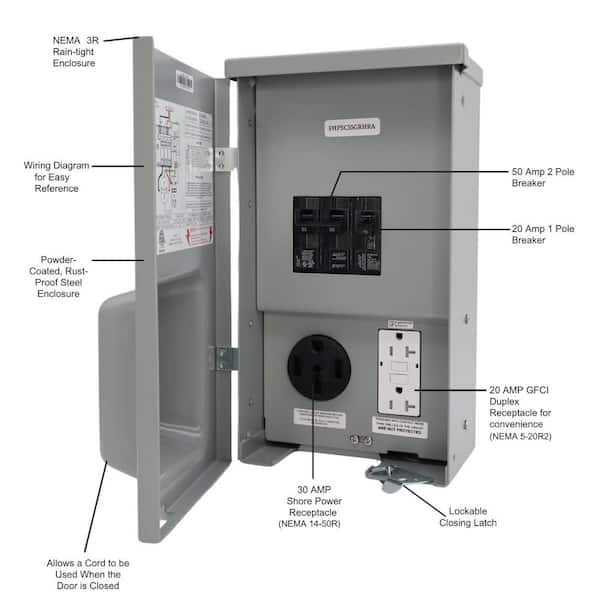

#2 Midwest Electric Products

Domain Est. 1997

Website: midwestelectric.com

Key Highlights: Midwest Electric Products is an industry leader in manufacturing quality weatherproof electrical equipment. Our product portfolio is focused on commercial and ……

#3 Progressive Dynamics

Domain Est. 1998

Website: progressivedyn.com

Key Highlights: Progressive DynamicsI produces a full line of Electrical products for the RV, marine and specialty industries … PD6000-DC-Distribution-Panel · PD5000-AC-DC- ……

#4 WF

Domain Est. 2023

Expert Sourcing Insights for 50 Amp Rv Distribution Panel

H2: 2026 Market Trends for 50 Amp RV Distribution Panels

The market for 50 Amp RV distribution panels is poised for significant evolution by 2026, driven by advancements in technology, shifting consumer preferences, and the broader growth of the recreational vehicle (RV) industry. As more consumers embrace outdoor lifestyles and remote work, the demand for reliable, efficient, and smart electrical systems in RVs continues to rise. Here are the key market trends expected to shape the 50 Amp RV distribution panel segment in 2026:

-

Increased Demand for Smart and Integrated Panels

By 2026, smart RV electrical systems are expected to dominate the market. 50 Amp distribution panels are increasingly being integrated with IoT (Internet of Things) capabilities, allowing users to monitor and control power usage via smartphone apps. Features such as real-time energy tracking, remote circuit shutdown, and overload alerts enhance safety and convenience, making smart panels a preferred choice among tech-savvy RV owners. -

Growth in Premium and Luxury RV Segments

The surge in high-end and luxury RV models—equipped with advanced appliances, HVAC systems, and entertainment setups—necessitates robust electrical infrastructure. The 50 Amp service, which provides 12,000 watts of power, remains the standard for larger RVs, ensuring continued demand for high-capacity distribution panels that can manage heavy electrical loads efficiently and safely. -

Emphasis on Energy Efficiency and Sustainability

As environmental consciousness grows, manufacturers are focusing on energy-efficient designs and compatibility with renewable energy sources. 50 Amp distribution panels are being engineered to seamlessly integrate with solar power systems, battery inverters, and energy management systems. This trend aligns with the broader movement toward off-grid and eco-friendly RV travel. -

Advancements in Panel Design and Safety Features

In 2026, distribution panels are expected to feature improved safety mechanisms such as arc-fault and ground-fault circuit interrupters (AFCI/GFCI), enhanced surge protection, and modular circuit breakers. Compact, space-saving designs with clear labeling and user-friendly interfaces are also becoming standard, improving accessibility and maintenance for RV owners. -

Expansion of Aftermarket and Retrofit Solutions

With the growing number of older RVs being upgraded for modern use, the aftermarket for 50 Amp distribution panels is expanding. Retrofit kits that simplify the replacement of outdated panels with modern, code-compliant units are gaining popularity. This trend is supported by DIY culture and the availability of online installation guides and tutorials. -

Regulatory and Code Compliance Driving Innovation

Electrical safety standards, such as those from the National Electrical Code (NEC) and RV Industry Association (RVIA), are influencing panel designs. By 2026, compliance with updated codes—especially around fire prevention and energy efficiency—will be a key differentiator for manufacturers, pushing innovation in materials, circuit protection, and labeling. -

Supply Chain and Manufacturing Localization

Post-pandemic supply chain challenges have prompted a shift toward localized production, particularly in North America. This trend is expected to continue into 2026, reducing lead times and increasing availability of 50 Amp RV distribution panels. Regional manufacturing also allows for quicker adaptation to market-specific needs and regulations.

Conclusion:

By 2026, the 50 Amp RV distribution panel market will be characterized by smart integration, enhanced safety, and sustainability. As the RV lifestyle becomes more mainstream and technologically advanced, distribution panels will play a critical role in ensuring reliable and efficient power management. Manufacturers that prioritize innovation, user experience, and compliance will lead the market in this dynamic and growing sector.

Common Pitfalls When Sourcing a 50 Amp RV Distribution Panel (Quality & IP Rating)

Sourcing a reliable 50 Amp RV distribution panel is critical for safe and efficient power management in your recreational vehicle. However, several pitfalls related to quality and Ingress Protection (IP) ratings can compromise performance and safety. Being aware of these common issues helps ensure you select a durable, code-compliant, and weather-resistant solution.

Poor Build Quality and Substandard Components

One of the most frequent pitfalls is selecting a panel constructed with low-quality materials or inferior internal components. Cheaply made panels may use thin-gauge steel or plastic enclosures that are prone to cracking, warping, or corroding over time. Internally, substandard bus bars, breakers, or wiring terminals can overheat under load, posing fire hazards. Always verify that the panel uses UL-listed or ETL-certified components and is built to meet NEC (National Electrical Code) standards for RV applications.

Inadequate or Misrepresented IP Rating

The Ingress Protection (IP) rating indicates how well the panel resists dust and moisture. Many budget panels either lack a proper IP rating or falsely advertise one. For RV use—especially in outdoor or exposed locations—panels should have a minimum IP54 rating (dust protected and splash resistant). Panels rated below IP54 may allow moisture or debris to enter, leading to short circuits, corrosion, or component failure. Always confirm the IP rating with the manufacturer and look for third-party testing documentation.

Lack of Corrosion Resistance

RVs are often exposed to humid, salty, or wet environments, making corrosion a serious concern. Panels made with non-corrosion-resistant materials—such as untreated steel or low-grade plastics—will degrade quickly. Opt for enclosures made from UV-stabilized polycarbonate, marine-grade aluminum, or stainless steel, which offer better longevity in harsh conditions.

Improper Mounting and Enclosure Design

Some distribution panels are not designed with RV-specific mounting in mind. Panels that lack secure mounting points or vibration-resistant hardware can loosen over time due to road travel. Additionally, poorly designed enclosures may not allow for proper cable entry sealing or adequate internal space, leading to wire strain or overheating. Choose a panel with knockouts, strain relief options, and enough room for future upgrades.

Overlooking Temperature and Environmental Ratings

RVs experience extreme temperature fluctuations. Panels not rated for wide operating temperatures (typically -20°C to 60°C or better) may fail in cold winters or hot summers. Confirm the operating temperature range and ensure components are rated for continuous 50A service without derating in high-heat environments.

Skipping Compliance and Certification Verification

Avoid panels that lack clear certification marks from recognized testing laboratories (e.g., UL, CSA, ETL). Non-certified panels may not meet safety standards and could void insurance or fail inspection. Always request certification documentation before purchase, especially when sourcing from online marketplaces or lesser-known brands.

By paying close attention to build quality, IP rating accuracy, material durability, and compliance, you can avoid these common sourcing pitfalls and ensure your 50 Amp RV distribution panel delivers safe, reliable performance for years.

Logistics & Compliance Guide for 50 Amp RV Distribution Panel

This guide outlines key logistics considerations and compliance requirements for sourcing, handling, installing, and certifying a 50 Amp RV Distribution Panel. Adhering to these standards ensures safety, regulatory compliance, and proper functionality in recreational vehicles.

Regulatory Compliance Standards

All 50 Amp RV Distribution Panels must comply with applicable national and industry-specific electrical standards. Key regulations include:

- National Electrical Code (NEC) – NFPA 70: Governs safe electrical installation practices. RV panels must adhere to relevant sections, particularly Article 551 (Recreational Vehicles).

- UL 489 – Molded-Case Circuit Breakers: Panels and breakers must be certified under UL 489 or UL 1077 (Supplementary Protectors) as applicable.

- RVIA Standards (Recreational Vehicle Industry Association): Mandatory for RVs manufactured in the U.S. RVIA requires compliance with ANSI A119.2, which references electrical system safety and installation protocols.

- CSA C22.2 No. 234 – Motor Homes and Recreational Vehicles (Canada): Required for units sold or operated in Canada.

- FMVSS No. 108 & 121 (DOT Regulations): While primarily for lighting and braking, electrical design can impact compliance with broader vehicle safety standards.

Ensure all components are labeled with appropriate certification marks (e.g., UL, CSA, ETL).

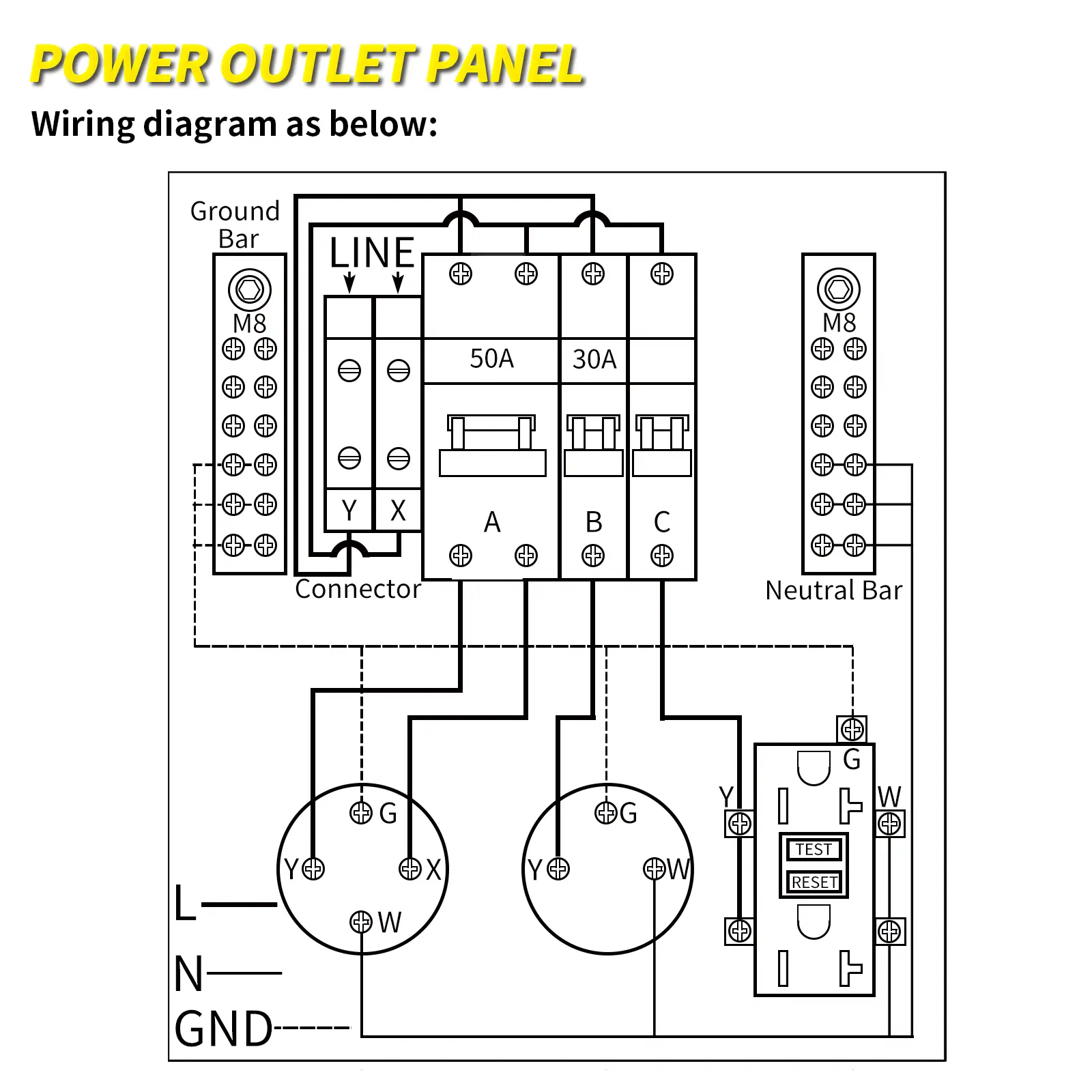

Panel Specifications and Load Management

The 50 Amp RV Distribution Panel is designed to handle a 120/240V AC split-phase supply (two 50A legs, neutral, and ground). Key technical compliance points include:

- Rated Current: 50 Amps per leg (12,000 watts total capacity when balanced).

- Voltage Rating: 120/240V AC, 60 Hz.

- Circuit Protection: Must include dual-pole main breaker (50A) and individual branch circuit breakers sized per connected loads (e.g., 15A or 20A for outlets, dedicated circuits for AC units or water heaters).

- Neutral and Ground Separation: Ground and neutral bus bars must be isolated unless the panel is the first disconnect point (typically only at the pedestal). In the RV, neutrals and grounds are typically bonded at the inverter or converter output but separated in the main distribution panel.

- Load Balancing: Design must distribute loads evenly across both 120V legs to prevent overloading a single phase.

Shipping and Handling Logistics

Proper logistics handling ensures product integrity and safety:

- Packaging: Panels must be shipped in robust, ESD-safe packaging with foam inserts to prevent damage during transit.

- Labeling: Clearly label packages with “Fragile,” “This Side Up,” and include compliance and voltage rating information.

- Storage Conditions: Store in dry, temperature-controlled environments (ideally 32°F to 104°F / 0°C to 40°C) to avoid condensation and component degradation.

- Inventory Management: Track stock using lot numbers and expiration dates (if applicable to components like breakers or surge protectors).

Installation and Field Compliance

Installation must follow manufacturer instructions and industry best practices:

- Mounting Location: Install in a dry, ventilated, accessible compartment. Avoid areas exposed to moisture, fuel lines, or excessive heat.

- Wiring: Use stranded copper wire sized per ampacity requirements (e.g., #4 AWG for 50A feeder lines). All connections must be torqued to manufacturer specifications.

- Bonding and Grounding: Bond the panel enclosure to the RV chassis ground. Verify continuity and grounding resistance per NEC and RVIA standards.

- Labeling: The panel must have a clearly legible load schedule and circuit directory. Warning labels (e.g., “Danger: High Voltage”) are required.

Inspection and Certification

Prior to delivery or use, the distribution panel must undergo:

- Factory Testing: Dielectric withstand test, continuity check, and operational verification of all breakers.

- Third-Party Certification: Panels should be pre-certified by a Nationally Recognized Testing Laboratory (NRTL) such as UL or ETL.

- Final RV Inspection: Conducted by an RVIA-certified technician to ensure compliance with ANSI A119.2 and proper system integration.

Maintenance and Documentation

For ongoing compliance and safety:

- Keep Records: Maintain logs of installation, inspections, modifications, and maintenance.

- User Manual: Provide end users with a detailed operations and safety guide.

- Recall Monitoring: Register products with manufacturers to receive safety alerts or recall notices.

Adhering to this logistics and compliance guide ensures that 50 Amp RV Distribution Panels perform safely and meet all regulatory requirements across North America.

Conclusion: Sourcing a 50 Amp RV Distribution Panel

After evaluating various factors such as reliability, functionality, cost, and availability, sourcing a 50 amp RV distribution panel requires careful consideration of both product specifications and supplier credibility. A high-quality distribution panel is essential for safely managing electrical loads in a recreational vehicle, particularly when operating multiple high-demand appliances simultaneously. Panels should meet or exceed NEC and RVIA standards, feature corrosion-resistant materials, include adequate circuit protection (such as dual-pole breakers), and offer ample space for future expansion.

Reputable suppliers—such as major RV parts retailers, certified electrical equipment distributors, and OEM manufacturers like Progressive Industries, Balmar, or WFCO—provide reliable options that ensure durability and compliance. While cost is a factor, prioritizing safety, warranty support, and proper amperage rating (120/240V split-phase for 50-amp service) is crucial. Additionally, integrating surge protection and monitoring features can enhance long-term performance and user peace of mind.

In conclusion, sourcing a 50 amp RV distribution panel should focus on quality, safety compliance, and compatibility with the RV’s electrical system. Investing in a well-designed panel from a trusted supplier ensures reliable power distribution, protects valuable appliances, and supports safe, efficient off-grid or campground living.