The global air compressor market is experiencing robust growth, driven by rising industrial automation, increasing demand in manufacturing, and expanding applications in sectors such as automotive, construction, and oil & gas. According to Mordor Intelligence, the air compressor market was valued at USD 28.2 billion in 2023 and is projected to reach USD 39.6 billion by 2029, growing at a CAGR of approximately 5.8% during the forecast period. This expansion is further fueled by technological advancements and a shift toward energy-efficient solutions. Within this landscape, 5 HP air compressor motors represent a critical segment—offering an optimal balance of power, portability, and efficiency for small to medium-scale operations. As demand for reliable and high-performance compressors rises, identifying leading motor manufacturers becomes essential for OEMs and end-users alike. Based on production capacity, innovation, energy efficiency ratings, and global market presence, the following nine companies have emerged as top manufacturers of 5 HP air compressor motors.

Top 9 5 Hp Air Compressor Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Baldor.com

Domain Est. 1995

Website: baldor.com

Key Highlights: ABB is the world’s number-one manufacturer of NEMA motors, and we’re proud to support you locally with the Baldor-Reliance product brand….

#2 Bauer Compressors: High

Domain Est. 1997

Website: bauercomp.com

Key Highlights: Bauer Compressors manufactures a broad range of compressor systems for various breathing-air and industrial applications….

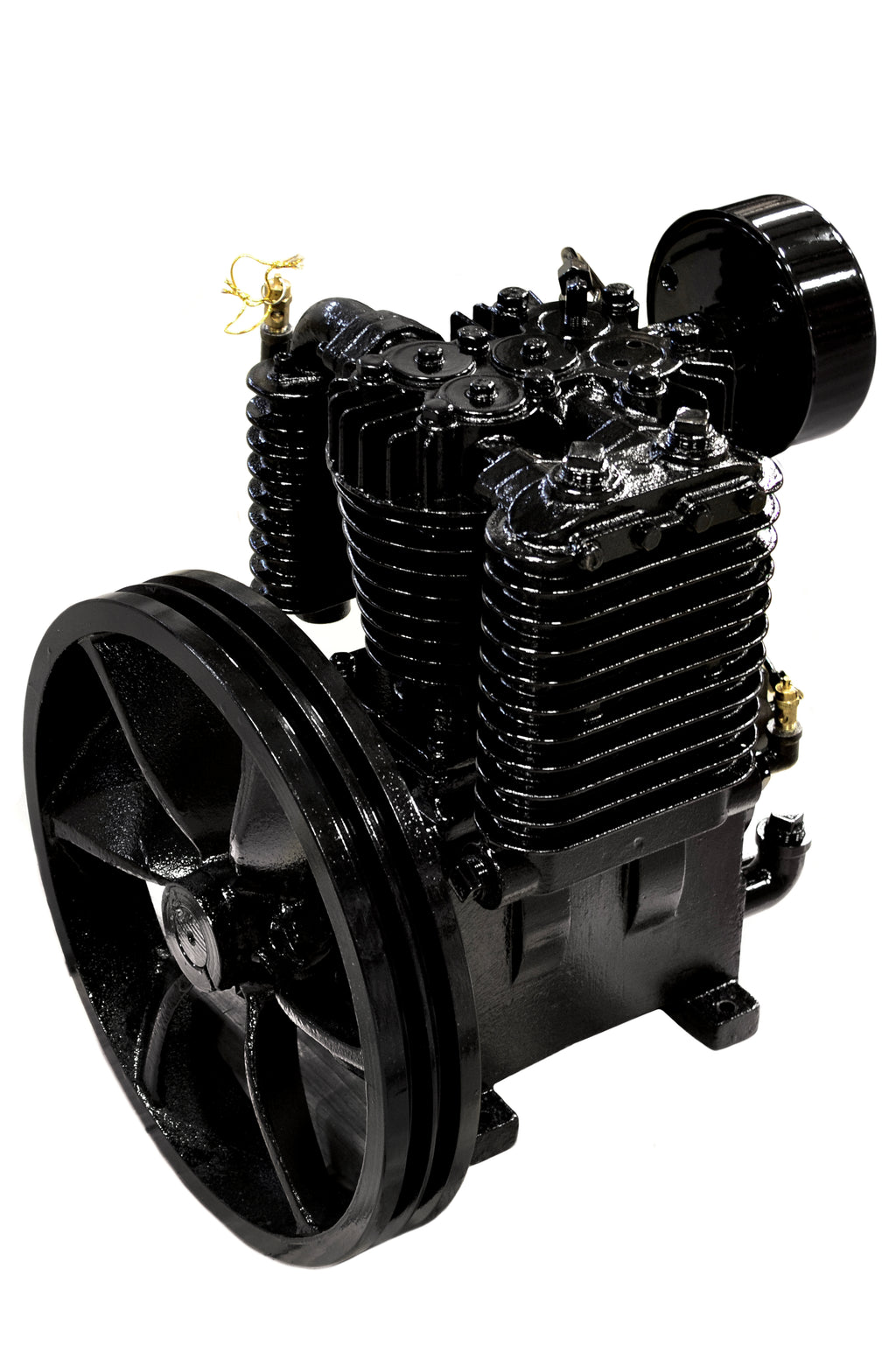

#3 Saylor

Domain Est. 1997 | Founded: 1915

Website: saylor-beall.com

Key Highlights: Since 1915, Saylor-Beall has been a trusted name in the manufacturing of industrial-quality, two-stage air compressors….

#4 US Air Compressor

Domain Est. 2003

Website: usaircompressor.com

Key Highlights: Purchase a high-quality industrial air compressor and experience our 10-Year Bumper-to-Bumper Warranty, ensuring zero downtime and predictable costs….

#5 High Quality 5 HP Air Compressors For Sale

Domain Est. 2014

Website: compressorpros.com

Key Highlights: Free delivery · 7-day returnsThe 5 HP air compressors available at CompressorPros.com are expertly designed to meet the high demands of industrial and commercial applications….

#6 Advantage Oil-Lubricated Reciprocating Compressor

Domain Est. 1996

Website: championpneumatic.com

Key Highlights: Two Stage, Splash Lubricated (5-25 HP) Reciprocating Air Compressor. The Advantage Series units come fully packaged with pre-installed accessories….

#7 Quincy Air Compressor Products

Domain Est. 1997

Website: quincycompressor.com

Key Highlights: Quincy Compressor products are known for their reliability, high quality & premium performance. Check out our product line & find a dealer near you!…

#8 2

Domain Est. 2001

Website: ingersollrand.com

Key Highlights: The Ingersoll Rand 60 gallon, electric-driven two-stage air compressor has the flexibility to provide both intermittent and continuous power….

#9 Products

Domain Est. 2017

Website: championcompressor.net

Key Highlights: Products · CA Series ES Oil-Free Compressor · Champion Scroll Compressor Bare Air End · CRH Refrigerated Air Dryer · DRS Series Variable Speed Rotary Screw ……

Expert Sourcing Insights for 5 Hp Air Compressor Motor

H2: Market Trends for 5 HP Air Compressor Motors in 2026

By 2026, the market for 5 HP air compressor motors is expected to reflect significant shifts driven by technological innovation, energy efficiency regulations, industrial automation, and evolving end-user demands. This analysis outlines key trends shaping the landscape of 5 HP air compressor motors over the next few years.

-

Increased Demand for Energy-Efficient Motors

A primary driver in the 5 HP air compressor motor market is the global push toward energy efficiency. Governments and regulatory bodies, particularly in North America, Europe, and parts of Asia, are enforcing stricter energy performance standards (e.g., IE4 and upcoming IE5 efficiency classes under IEC 60034-30-1). As a result, manufacturers are increasingly adopting premium-efficiency and ultra-premium-efficiency motors in 5 HP models, enhancing lifecycle cost savings for industrial users and supporting sustainability goals. -

Growth in Industrial Automation and Smart Manufacturing

The integration of Industry 4.0 technologies is transforming compressed air systems. By 2026, 5 HP air compressor motors are increasingly being equipped with smart sensors, IoT connectivity, and variable speed drives (VSDs). These features allow for real-time monitoring of motor performance, predictive maintenance, and adaptive load management—improving operational efficiency and reducing downtime. Demand is rising in sectors such as automotive, food and beverage, and pharmaceuticals, where process reliability and energy optimization are critical. -

Expansion of Variable Speed Drive (VSD) Adoption

Fixed-speed motors are gradually being replaced by VSD-enabled 5 HP models, which adjust motor speed based on air demand. This reduces energy waste during partial-load operations—a common scenario in many industrial applications. By 2026, VSD-integrated 5 HP air compressor motors are projected to capture over 40% of the mid-power compressor market, driven by ROI benefits and payback periods under three years in high-usage environments. -

Regional Market Dynamics and Industrial Growth

Asia-Pacific, especially India and Southeast Asia, is expected to be the fastest-growing region for 5 HP air compressor motors due to rapid industrialization, infrastructure development, and rising small-to-medium enterprise (SME) investments. In contrast, North America and Western Europe will focus more on retrofitting existing systems with high-efficiency motors to comply with environmental regulations and reduce carbon footprints. -

Shift Toward Oil-Free and Low-Maintenance Designs

With growing emphasis on air quality in sensitive applications (e.g., medical, electronics, and food processing), demand for oil-free 5 HP compressor motors is increasing. These systems use advanced motor and bearing technologies that require less maintenance and offer longer service life. Motor designs are evolving to support continuous operation in harsh environments while maintaining peak efficiency. -

Impact of Supply Chain and Material Innovation

By 2026, manufacturers are adopting advanced materials such as high-grade silicon steel, rare-earth magnets (in permanent magnet motors), and improved insulation systems to boost motor efficiency and durability. However, supply chain volatility for critical raw materials may influence pricing and production timelines, prompting companies to localize manufacturing or develop alternative motor designs. -

Rise in Rental and Service-Based Models

An emerging trend is the shift from outright equipment purchases to rental, leasing, and performance-based service agreements. Compressor-as-a-Service (CaaS) models are gaining traction, especially among SMEs seeking to minimize upfront capital expenditure. These models often include energy-efficient 5 HP motors with remote monitoring, aligning with broader trends in servitization and digital service platforms.

Conclusion

The 5 HP air compressor motor market in 2026 will be characterized by a strong focus on energy efficiency, digital integration, and sustainability. Key players are expected to differentiate through smart motor technologies, compliance with global standards, and flexible service offerings. Companies that invest in R&D for compact, intelligent, and eco-friendly motor solutions will be best positioned to capture growing demand across diverse industrial sectors.

H2: Common Pitfalls When Sourcing a 5 HP Air Compressor Motor (Quality and IP Rating)

Sourcing a 5 HP air compressor motor requires careful consideration of both quality and Ingress Protection (IP) rating to ensure reliability, safety, and longevity. However, several common pitfalls can compromise performance and lead to costly downtime or repairs. Below are key issues to watch for:

1. Compromising on Motor Quality for Lower Cost

Opting for cheaper, low-quality motors may seem cost-effective initially but often leads to premature failure, inefficient operation, and higher maintenance costs. Poor-quality windings, substandard bearings, and inadequate insulation reduce motor lifespan and increase the risk of overheating.

2. Ignoring IP (Ingress Protection) Rating

The IP rating indicates a motor’s resistance to dust and moisture. Using a motor with an insufficient IP rating (e.g., IP21 instead of IP55) in harsh environments can lead to contamination, corrosion, and electrical failure. For industrial or outdoor applications, an IP55 or higher is typically recommended.

3. Mismatched Duty Cycle and Application Needs

Some motors are rated for intermittent use but are installed in continuous-duty compressors. This mismatch causes overheating and shortens motor life. Ensure the motor is rated for continuous duty (S1) if the compressor runs for extended periods.

4. Poor Thermal Protection

Motors lacking proper thermal overload protection are prone to burnout during voltage fluctuations or high ambient temperatures. Always verify the presence of built-in thermal protection (e.g., PTC sensors or thermal cut-offs).

5. Inadequate Voltage and Phase Compatibility

Using a motor with incorrect voltage (e.g., 208V vs. 230V) or phase (single-phase vs. three-phase) can result in poor performance, excessive current draw, and premature failure. Confirm electrical specifications match your power supply.

6. Overlooking Certification and Compliance

Motors without recognized certifications (e.g., CE, UL, or ISO) may not meet safety or efficiency standards. This poses safety risks and could void warranties or insurance in industrial settings.

7. Inconsistent Brand Reputation and After-Sales Support

Sourcing from unknown or unverified suppliers increases the risk of counterfeit or reconditioned motors. Lack of technical support and spare parts availability can lead to extended downtime.

8. Misinterpreting Horsepower Ratings

Some manufacturers inflate HP ratings. A true 5 HP motor should deliver consistent output under load. Always check nameplate data and efficiency ratings (e.g., NEMA Premium) to verify actual performance.

By avoiding these pitfalls—prioritizing quality construction, appropriate IP rating, correct specifications, and reputable suppliers—you ensure reliable operation and maximize the return on your 5 HP air compressor motor investment.

H2: Logistics & Compliance Guide for 5 HP Air Compressor Motor

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient transportation, handling, and operation of a 5 HP air compressor motor. Adhering to these guidelines ensures regulatory compliance, operational safety, and product longevity.

1. Regulatory Compliance

a. Electrical Standards

– Ensure the motor complies with regional electrical standards:

– North America: UL 1004 (Motors), CSA C22.2 No. 100 (Canada)

– European Union: CE marking per Machinery Directive 2006/42/EC, Low Voltage Directive (LVD), and EMC Directive

– Other Regions: Check local certifications (e.g., CCC in China, PSE in Japan, RCM in Australia)

– Voltage and frequency must match local supply (e.g., 230V/60Hz in the U.S., 400V/50Hz in EU).

b. Environmental Regulations

– Verify compliance with RoHS (Restriction of Hazardous Substances) and REACH (EU) if applicable.

– Ensure no use of restricted materials (e.g., lead, mercury, certain phthalates).

c. Noise Emissions

– Confirm noise levels (measured in dB) comply with local regulations (e.g., EU Directive 2000/14/EC for outdoor equipment).

– Typical 5 HP compressor noise: 70–80 dB; provide operator hearing protection if required.

d. Energy Efficiency

– Check for compliance with energy standards:

– U.S.: DOE 10 CFR Part 431 – Electric Motors

– EU: IE3 efficiency minimum per Regulation (EU) 2019/1781 (Ecodesign for Energy-Related Products)

2. Packaging & Handling

a. Packaging Requirements

– Use robust, weather-resistant packaging with internal foam or bracing to prevent vibration damage.

– Clearly label with:

– “Fragile”

– “Do Not Invert”

– “Keep Dry”

– Product ID, model number, and net weight (~25–40 kg typical for 5 HP motor)

b. Handling Instructions

– Lift using forklifts or pallet jacks; avoid dragging.

– Use proper PPE (gloves, safety shoes) during unloading.

– Store in dry, level, indoor area with temperature between 5°C and 40°C.

3. Transportation Logistics

a. Domestic Shipping (e.g., U.S., EU)

– Motor can be shipped via standard freight (LTL or full truckload).

– Secure on pallet with stretch wrap or straps; center load to prevent shifting.

– Ensure carrier provides lift-gate service if delivery location lacks a dock.

b. International Shipping

– Use sea freight (FCL/LCL) or air freight for urgent deliveries.

– Complete export documentation:

– Commercial Invoice

– Packing List

– Certificate of Origin

– Bill of Lading (B/L) or Air Waybill (AWB)

– Classify under correct HS Code:

– 8501.10 (Motors of an output ≤ 750 W) or 8501.31 (>750 W, AC single-phase)

– Note: 5 HP ≈ 3730 W → likely HS 8501.32 (AC multi-phase motors)

– Comply with export controls (e.g., EAR in the U.S. – verify if license is required).

c. Import Compliance

– Verify import duties and taxes (varies by country).

– Provide technical specifications and compliance certificates to customs.

4. Installation & Operational Compliance

a. Electrical Installation

– Must be performed by a licensed electrician.

– Follow NEC (U.S.) or IEC 60364 (International) wiring standards.

– Ensure proper grounding and overcurrent protection (e.g., 30–40A circuit breaker for 5 HP motor).

b. Ventilation & Clearance

– Maintain minimum clearance (30–50 cm) around motor for cooling.

– Avoid installation in explosive or corrosive environments unless rated for such use (e.g., ATEX/IECEx).

c. Safety Devices

– Install thermal overload protection and pressure relief valve per ISO 5393 and OSHA/ANSI standards.

5. Documentation & Recordkeeping

- Retain copies of:

- Compliance certificates (UL, CE, etc.)

- Test reports (efficiency, insulation resistance)

- Warranty and user manual

- Shipping and customs documents for 5+ years (audit purposes)

6. Disposal & End-of-Life

- Follow WEEE (EU) or local e-waste regulations for motor disposal.

- Recycle copper windings, steel housing, and electronic components appropriately.

Summary Checklist

✅ Verify electrical and safety certifications

✅ Use compliant packaging and labeling

✅ Complete accurate shipping documentation

✅ Confirm import/export requirements

✅ Ensure proper installation by qualified personnel

✅ Maintain compliance records

By following this H2-level guide, stakeholders can ensure the 5 HP air compressor motor meets all logistical and regulatory requirements across its lifecycle.

Conclusion for Sourcing a 5 HP Air Compressor Motor:

After evaluating various suppliers, technical specifications, cost considerations, and performance requirements, sourcing a 5 HP air compressor motor requires a balanced approach that prioritizes reliability, energy efficiency, and long-term operational cost savings. Motors from reputable manufacturers offering IE3 or IE4 efficiency ratings provide optimal performance and reduced energy consumption, leading to lower total cost of ownership. Compatibility with existing compressor systems, duty cycle requirements, and environmental conditions (such as ambient temperature and dust exposure) are critical factors to ensure durability and safety.

Additionally, considering warranties, availability of technical support, and ease of maintenance will enhance operational continuity. Sourcing from certified suppliers with a proven track record of quality control and timely delivery minimizes downtime risks. Ultimately, selecting a 5 HP motor that meets or exceeds industry standards (such as NEMA or IEC) while aligning with budgetary constraints ensures a reliable, efficient, and cost-effective solution for industrial or commercial compressed air applications.