The global air compressor market is experiencing robust expansion, driven by increasing industrial automation, growing demand in manufacturing, automotive, and construction sectors, and a shift toward energy-efficient systems. According to Mordor Intelligence, the air compressor market was valued at USD 28.9 billion in 2023 and is projected to reach USD 38.7 billion by 2029, growing at a CAGR of approximately 5.1% during the forecast period. This growth reflects heightened demand for compact, reliable, and efficient units—such as 5 HP air compressors—across small to mid-sized industrial and commercial operations. With reliability, duty cycle, and energy efficiency serving as key buying criteria, manufacturers are innovating to deliver high-performance solutions tailored to diverse operational needs. As competition intensifies, several companies have emerged as leaders in engineering and delivering top-tier 5 HP air compressors, combining advanced technology with market-driven design. The following list highlights the top 10 manufacturers shaping this segment, based on product innovation, market presence, customer reviews, and operational performance metrics.

Top 10 5 Hp Air Compressor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 5 HP Screw Compressors

Domain Est. 1994

Website: compressors.cp.com

Key Highlights: The QRS 5.5 is the leading rotary screw compressor for light industrial applications. Ideal for tire shops, maintenance shops, vehicle body shops, paint shops, ……

#2 Bauer Compressors: High

Domain Est. 1997

Website: bauercomp.com

Key Highlights: Bauer Compressors manufactures a broad range of compressor systems for various breathing-air and industrial applications….

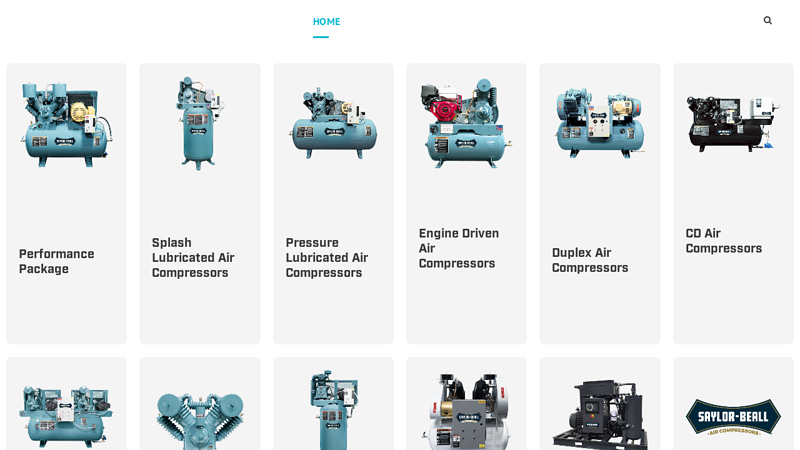

#3 Saylor

Domain Est. 1997 | Founded: 1915

Website: saylor-beall.com

Key Highlights: Since 1915, Saylor-Beall has been a trusted name in the manufacturing of industrial-quality, two-stage air compressors….

#4 US Air Compressor

Domain Est. 2003

Website: usaircompressor.com

Key Highlights: Purchase a high-quality industrial air compressor and experience our 10-Year Bumper-to-Bumper Warranty, ensuring zero downtime and predictable costs….

#5 High Quality 5 HP Air Compressors For Sale

Domain Est. 2014

Website: compressorpros.com

Key Highlights: Free delivery · 7-day returnsThe 5 HP air compressors available at CompressorPros.com are expertly designed to meet the high demands of industrial and commercial applications….

#6 Quincy Air Compressor Products

Domain Est. 1997

Website: quincycompressor.com

Key Highlights: Quincy Compressor products are known for their reliability, high quality & premium performance. Check out our product line & find a dealer near you!…

#7 2

Domain Est. 2001

Website: ingersollrand.com

Key Highlights: The Ingersoll Rand 60 gallon, electric-driven two-stage air compressor has the flexibility to provide both intermittent and continuous power….

#8 FS

Domain Est. 2008

Website: us.fscurtis.com

Key Highlights: Since 1854, we have manufactured rugged rotary screw and reciprocating air compressors in the USA, built for long-lasting power and reliability….

#9 Products

Domain Est. 2017

Website: championcompressor.net

Key Highlights: Products · CA Series ES Oil-Free Compressor · Champion Scroll Compressor Bare Air End · CRH Refrigerated Air Dryer · DRS Series Variable Speed Rotary Screw ……

#10

Domain Est. 2021

Website: kobelco-compressors.com

Key Highlights: KOBELCO COMPRESSORS is a global compressed air solution provider from Japan, having over 100 years history….

Expert Sourcing Insights for 5 Hp Air Compressor

H2: 2026 Market Trends for 5 HP Air Compressors

The global market for 5 HP air compressors is poised for steady growth and transformation by 2026, driven by industrial expansion, technological advancements, and shifting demands across key end-use sectors. This analysis explores the major trends shaping the 5 HP air compressor landscape through 2026.

-

Increasing Demand from Small and Medium Enterprises (SMEs)

SMEs in manufacturing, automotive repair, construction, and woodworking are increasingly adopting 5 HP air compressors due to their optimal balance of power, efficiency, and cost. As these sectors recover and expand post-pandemic—especially in emerging economies like India, Brazil, and Southeast Asia—the demand for mid-capacity compressors is rising. The 5 HP model is ideal for workshops needing reliable performance without the high energy costs of larger units. -

Shift Toward Energy-Efficient and Smart Compressors

Energy efficiency regulations are tightening globally, prompting manufacturers to innovate in compressor design. By 2026, a growing share of 5 HP units will feature variable speed drives (VSD), advanced cooling systems, and IoT-enabled monitoring. These smart compressors optimize energy use based on real-time demand, reducing operational costs and carbon emissions. Adoption is particularly strong in Europe and North America, where sustainability standards are more stringent. -

Growth in Oil-Free and Low-Maintenance Models

Industries such as food and beverage, pharmaceuticals, and electronics require clean, oil-free compressed air. As a result, oil-free 5 HP compressors are gaining traction. Technological improvements have enhanced the durability and performance of oil-free systems, making them more competitive with traditional oil-lubricated models. These units also appeal to users seeking lower maintenance and longer service intervals. -

Regional Market Diversification

Asia-Pacific is expected to dominate the 5 HP air compressor market by 2026, fueled by rapid industrialization, infrastructure development, and government initiatives like “Make in India” and “Smart Cities.” Meanwhile, North America and Europe will see steady demand due to equipment replacement cycles and a focus on upgrading to energy-efficient models. Latin America and Africa present emerging opportunities, particularly in construction and mining applications. -

E-Commerce and Direct-to-Consumer Sales Growth

Online platforms are becoming a major distribution channel for 5 HP air compressors. Industrial equipment retailers and manufacturers are expanding their digital presence, offering detailed product comparisons, financing options, and direct delivery. This trend is especially notable among DIY users, small workshops, and independent contractors seeking convenience and competitive pricing. -

Integration with Renewable Energy Systems

As industries aim for carbon neutrality, there is growing interest in integrating air compressors with solar and wind power systems. By 2026, some manufacturers will offer 5 HP compressors designed for compatibility with renewable energy sources, including DC-powered models and hybrid systems. This trend is still in early stages but is expected to gain momentum in off-grid and remote operations.

Conclusion

By 2026, the 5 HP air compressor market will be characterized by innovation, sustainability, and accessibility. Energy efficiency, smart technology, and regional industrial growth will be key drivers. Companies that invest in R&D, digital distribution, and environmentally responsible designs will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing a 5 HP Air Compressor (Quality and IP Considerations)

Sourcing a 5 HP air compressor requires careful evaluation to ensure reliable performance, longevity, and suitability for your specific application. Two critical aspects—quality and Ingress Protection (IP) rating—are often misunderstood or overlooked, leading to poor purchasing decisions. Below are common pitfalls associated with each.

1. Overlooking Build Quality and Component Materials

One of the most frequent mistakes is prioritizing price over build quality. A low-cost 5 HP compressor may use substandard materials, such as aluminum rotors, thin steel tanks, or low-grade seals and gaskets, which compromise durability.

- Pitfall: Compressors with poorly machined pumps or inadequate cooling systems may overheat quickly, reducing lifespan.

- Solution: Inspect the pump type (e.g., reciprocating vs. rotary screw), material of critical components (cast iron is preferred), and brand reputation. Look for units with thermal overload protection and robust motor insulation.

2. Misunderstanding Continuous Duty vs. Intermittent Use

Many buyers assume that a 5 HP compressor can run continuously at full load, but cheaper models are often designed for intermittent use only.

- Pitfall: Selecting a compressor without a true continuous-duty rating leads to overheating, premature motor failure, and downtime.

- Solution: Verify duty cycle specifications. For industrial use, opt for compressors with 100% duty cycle ratings and adequate CFM (cubic feet per minute) output at your required PSI.

3. Ignoring the Actual Horsepower vs. “Peak” Horsepower

Manufacturers often advertise inflated “peak” or “developed” horsepower rather than true running (rated) horsepower.

- Pitfall: A unit advertised as 5 HP may only deliver 3–4 HP under continuous operation, leading to underperformance.

- Solution: Focus on brake horsepower (BHP) or rated horsepower and cross-check with motor specifications (e.g., voltage, amps, service factor). Reputable brands provide transparent performance data.

4. Neglecting IP (Ingress Protection) Rating for the Operating Environment

The IP rating indicates how well the compressor is protected against dust and moisture—critical for safety and performance.

- Pitfall: Using a compressor with insufficient IP rating (e.g., IP20) in dusty or damp environments can lead to electrical failures, motor corrosion, or safety hazards.

- Solution: Match the IP rating to your environment:

- IP21: Basic drip protection—suitable for dry indoor use.

- IP54: Dust-protected and splash-resistant—ideal for workshops or light industrial settings.

- IP55 or higher: Recommended for outdoor or harsh environments.

5. Assuming All 5 HP Compressors Deliver Equal Air Output

Horsepower alone doesn’t determine airflow. Efficiency varies widely based on pump design, motor efficiency, and drive system.

- Pitfall: A poorly designed 5 HP unit may deliver less CFM than a well-designed 3 HP model.

- Solution: Prioritize CFM at operating PSI (e.g., 90–100 PSI) over HP. Compare performance data under real-world conditions, and consider volumetric efficiency.

6. Skipping Compliance and Certification Checks

Industrial compressors must meet safety and electrical standards, especially in regulated environments.

- Pitfall: Sourcing non-certified units (e.g., lacking CE, UL, or ISO marks) can violate safety regulations and void warranties.

- Solution: Ensure the compressor complies with regional standards (e.g., OSHA in the US, CE in Europe) and includes proper documentation.

Conclusion

Avoiding these pitfalls requires due diligence in evaluating both the quality of construction and the IP rating appropriate for your environment. Investing in a well-built, correctly specified 5 HP air compressor ensures reliability, safety, and long-term cost savings—far outweighing the initial price difference. Always request technical specifications, verify claims with trusted suppliers, and consider total cost of ownership, not just upfront cost.

H2: Logistics & Compliance Guide for 5 HP Air Compressor

This guide outlines key logistics and compliance considerations for the transportation, handling, and regulatory adherence of a 5 HP (horsepower) air compressor. These guidelines apply to manufacturers, distributors, importers, and end-users involved in the movement and operation of industrial air compressors.

1. Transportation & Handling

a. Packaging Requirements

- Ensure the air compressor is securely packaged in a moisture-resistant, impact-protected container.

- Use wooden pallets or skids for stability during transit.

- Include corner protectors and shrink-wrapping to prevent shifting and damage.

- Clearly label packages with:

- “Fragile”

- “This Side Up”

- Weight and center of gravity indicators

b. Weight & Dimensions

- Typical 5 HP air compressors weigh between 150–300 lbs (68–136 kg).

- Dimensions vary by model; measure length, width, and height for accurate freight classification.

- Confirm ground clearance and forklift entry points for safe loading/unloading.

c. Mode of Transport

- Ground Freight (LTL/FTL): Most common for domestic shipments. Use lift gates if delivery site lacks loading docks.

- Air Freight: Rare due to weight and cost; only for urgent international delivery.

- Sea Freight: Common for international shipments; comply with IMDG Code if applicable (e.g., lubricants on board).

d. Storage Conditions

- Store in dry, temperature-controlled environments (ideally 40–100°F / 4–38°C).

- Keep away from corrosive chemicals, moisture, and direct sunlight.

- Elevate on pallets to prevent floor moisture absorption.

2. Regulatory Compliance

a. Safety Standards

- OSHA (Occupational Safety and Health Administration – USA):

- Comply with 29 CFR 1910.169 (Safety Standard for Compressed Air Equipment).

- Pressure vessels must have certified pressure relief valves and undergo periodic inspections.

- ASME (American Society of Mechanical Engineers):

- Air receiver tanks must be ASME-certified (Section VIII, Division 1).

- Stamp and documentation must be present.

- CE Marking (EU):

- Comply with Pressure Equipment Directive (PED) 2014/68/EU.

- Meet Machinery Directive 2006/42/EC and Electromagnetic Compatibility (EMC) Directive.

b. Electrical Compliance

- NRTL Certification (USA/Canada): UL, CSA, or ETL listing for electrical components.

- IEC Standards (International): IEC 60204-1 (Safety of machinery – Electrical equipment).

- Voltage and frequency must match destination country standards (e.g., 120V/60Hz in USA, 230V/50Hz in EU).

c. Environmental Regulations

- EPA (USA): Comply with noise emission standards where applicable (typically <80 dB at 3 ft).

- RoHS (EU): Restriction of Hazardous Substances in electrical components.

- REACH: Ensure no restricted chemical substances in materials.

d. Pressure Vessel Regulations

- In the U.S., DOT regulates transport of pressurized systems (empty and depressurized during shipping).

- In Canada, comply with CSA B51 Boiler, Pressure Vessel, and Pressure Piping Code.

- In EU, periodic inspection required under PED.

3. Documentation & Labeling

a. Required Documents

- Bill of Lading (BOL)

- Commercial Invoice (for international shipments)

- Packing List

- Certificate of Conformity (CE, UL, CSA, etc.)

- ASME Data Report (for pressure vessel)

- User Manual (multilingual if exported)

b. Labeling Requirements

- Permanent nameplate with:

- Manufacturer name and address

- Model and serial number

- HP rating (5 HP)

- Voltage, phase, and frequency

- Maximum working pressure (PSI or bar)

- ASME or PED certification mark

- Noise level (dB)

- Weight and fluid capacity

4. Import/Export Considerations

a. HS Code Classification

- Typical HS Code: 8414.80 (Air pumps, vacuum pumps, air or other gas compressors).

- Confirm local tariff codes to avoid customs delays.

b. Customs Compliance

- Declare accurate value, origin, and technical specs.

- Provide import permits if required (e.g., India, Brazil).

- Use Incoterms® 2020 clearly (e.g., FOB, CIF, DDP).

c. Country-Specific Requirements

- USA: No export license generally required for 5 HP compressors.

- Canada: Compressor must meet CSA C22.2 No. 72 (air compressors).

- EU: CE marking mandatory; notified body involvement may be required for higher risk categories.

- Australia: Comply with RCM (Regulatory Compliance Mark) under EMC and electrical safety laws.

5. End-Use Compliance & Safety

- Provide user training on safe operation and maintenance.

- Ensure proper ventilation in installation area.

- Follow lockout/tagout (LOTO) procedures during servicing.

- Conduct regular inspections of hoses, filters, and safety valves.

Conclusion

Proper logistics planning and compliance with regional and international standards are critical for the safe and legal distribution of 5 HP air compressors. Always verify local regulations and maintain complete documentation throughout the supply chain.

Note: Regulations may vary by jurisdiction. Consult legal or compliance experts for project-specific guidance.

Conclusion for Sourcing a 5 HP Air Compressor:

After thorough evaluation of technical specifications, performance requirements, supplier reliability, and cost considerations, sourcing a 5 HP air compressor should prioritize a balance between efficiency, durability, and total cost of ownership. A 5 HP compressor is well-suited for medium to heavy-duty industrial applications, offering sufficient airflow (typically 15–20 CFM at 90–100 PSI) to support multiple tools or continuous operations.

Key factors in the final sourcing decision include choosing between rotary screw and reciprocating types—rotary screw models offer smoother, continuous operation with lower noise and vibration, ideal for sustained use, while reciprocating compressors are more cost-effective for intermittent demand. Additionally, energy efficiency, maintenance requirements, warranty terms, and availability of after-sales service should strongly influence the supplier selection.

It is recommended to source from reputable manufacturers or certified distributors that comply with safety and environmental standards (e.g., CE, ISO). Investing in a slightly higher upfront cost for a quality unit can result in significant long-term savings through improved efficiency, reduced downtime, and extended equipment life.

In conclusion, the optimal 5 HP air compressor is one that aligns with the specific operational needs, offers reliable performance, and comes from a trusted supplier, ensuring long-term value and operational continuity.