The global fastener market, including precision components such as 5-32 screws, is experiencing steady expansion driven by rising demand across automotive, aerospace, electronics, and construction industries. According to Grand View Research, the global fastener market size was valued at USD 105.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. This growth is fueled by increasing industrial automation, lightweight material adoption in vehicle manufacturing, and the proliferation of consumer electronics—applications where 5-32 screws are commonly specified due to their optimal size and thread compatibility. With North America and Asia-Pacific leading in production and consumption, the competitive landscape for screw manufacturers has intensified, emphasizing precision engineering, material innovation, and compliance with ISO and ASME standards. As demand for high-reliability fasteners rises, identifying top-tier manufacturers capable of consistent quality and scalable output becomes critical for OEMs and supply chain managers alike.

Top 10 5 32 Screw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pro-Dec – Manufacturer of Screw Covers & Bolt Caps

Domain Est. 1997

Website: pro-dec.com

Key Highlights: Free delivery over $35 30-day returnsPro-Dec is the world’s largest manufacturer of many types of screw covers and bolt covers to conceal and protect screws and bolts, both indoors…

#2 Thread cutting screw

Domain Est. 2007

Website: katsuhana.com.tw

Key Highlights: Katsuhana Fasteners Corp, Taiwan professional screw manufacturer, provides High Stable Quality of Drywall Screw, SDS screw, Painted Screw, Tapping Screw, ……

#3 Global Leader in Fastening Technology

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: As the world’s #1 fastening systems provider, Stanley® Engineered Fastening builds on over 100 years of experience and the strength of legacy brands like Nelson ……

#4 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

#5 Full

Domain Est. 1995

Website: thk.com

Key Highlights: For THK precision ball screws, a wide array of precision-ground screw shafts and ball screw nuts are available as standard to meet diversified applications….

#6 Machine Screw

Domain Est. 1996

Website: minerallac.com

Key Highlights: Machine screws form a fastening that is superior in strength to spaced thread screws. For use with a pre-tapped hole or with a nut. Material, Steel. Size, 10-32 ……

#7 Wholesale Stainless Steel Products

Domain Est. 1998

Website: starstainless.com

Key Highlights: Star Stainless is a wholesale distributor specializing in Stainless Steel products. For over 70 years our STAR Service, Off-the-Shelf Inventory Programs and ……

#8 Efficient and Effective Lead Screws

Domain Est. 2012

Website: helixlinear.com

Key Highlights: $20 delivery 30-day returnsLead screws are available in both metric and imperial sizes, with diameters ranging from 2mm to 25mm. Crafted from high-quality stainless steel or durabl…

#9 MS24694C6 Screw

Domain Est. 2013

Website: military-fasteners.com

Key Highlights: In stock Free delivery over $150Military Standard Machine Screw. Description: length: 19/32″, grip: 5/32″, thread: 8-32, countersunk, flat head, structural, corrosion resistant ste…

#10 Screw Size Charts: Basic Screw & Thread Terms

Domain Est. 2017

Website: mwcomponents.com

Key Highlights: Here you’ll find screw size charts, and a list of standard terminology for screws and threading associated with screw products….

Expert Sourcing Insights for 5 32 Screw

H2: 2026 Market Trends for #5 32 Screw

The global market for #5 32 screws—commonly used in electronics, HVAC systems, cabinetry, and light industrial applications—is expected to experience moderate but steady growth by 2026, driven by advancements in manufacturing, rising demand in key end-use sectors, and regional industrial expansion. Below is an analysis of the major trends shaping the #5 32 screw market in 2026:

-

Increased Demand in Electronics and Consumer Devices

The proliferation of compact electronic devices—such as smartphones, wearables, and IoT-enabled gadgets—continues to drive demand for precision fasteners like the #5 32 screw. These screws are favored for their balance of strength and small form factor. As consumer electronics manufacturers focus on miniaturization and modular design, the need for reliable, standardized screws remains strong. -

Growth in Residential and Commercial Construction

The construction sector, particularly in North America and parts of Asia-Pacific, is rebounding post-pandemic with increased spending on residential and commercial infrastructure. #5 32 screws are widely used in drywall installation, cabinetry, and light framing. With green building standards and DIY culture gaining traction, demand for versatile, corrosion-resistant screws is rising. -

Expansion of E-Commerce and DIY Markets

Online retail platforms have made fasteners more accessible to both professionals and DIY enthusiasts. By 2026, e-commerce is expected to account for over 30% of fastener sales in developed markets. Pre-packaged kits containing #5 32 screws are increasingly popular, especially in home improvement and furniture assembly segments. -

Shift Toward Sustainable and High-Performance Materials

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt eco-friendly materials and coatings. Zinc-plated, stainless steel, and biodegradable-coated #5 32 screws are gaining preference. Additionally, improved thread designs and heat-treated alloys are enhancing durability and reducing failure rates in critical applications. -

Regional Market Dynamics and Supply Chain Adjustments

Asia-Pacific remains the largest producer and consumer of #5 32 screws, with China and India leading in volume. However, geopolitical tensions and supply chain disruptions have prompted companies to diversify sourcing. Nearshoring and automation in North American and European manufacturing are expected to increase regional production capacity by 2026, reducing dependency on imports.

In summary, the #5 32 screw market in 2026 will be shaped by technological precision, sustainability, and evolving end-user demands. While not a high-growth niche on its own, its integration into broader industrial and consumer trends ensures continued relevance and stable market performance.

Common Pitfalls When Sourcing 5/32 Screws (Quality and IP)

Sourcing small fasteners like 5/32-inch screws may seem straightforward, but overlooking key quality and Intellectual Property (IP) considerations can lead to significant issues in performance, compliance, and liability. Below are common pitfalls to avoid.

Quality-Related Pitfalls

Inconsistent Material Composition

One of the most frequent issues when sourcing 5/32 screws is variability in material quality. Suppliers—especially from low-cost regions—may use substandard alloys that do not meet specified tensile strength or corrosion resistance standards. This can result in premature failure, particularly in high-stress or corrosive environments.

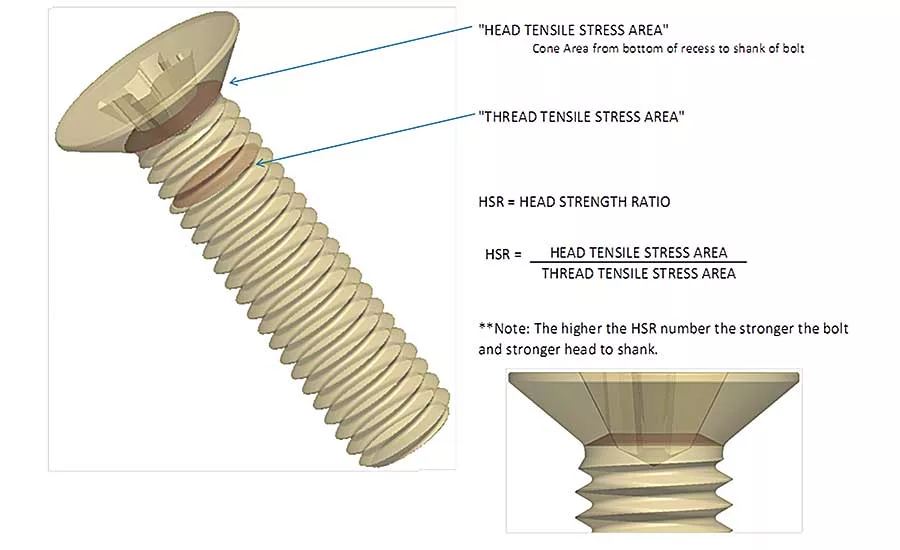

Poor Thread Accuracy and Tolerance Control

Due to their small size, 5/32 screws are highly sensitive to dimensional inaccuracies. Inadequate thread rolling or poor tooling can lead to stripped threads, misalignment, or difficulty in assembly. Without adherence to standards such as ASME B1.1 or ISO 68-1, functional reliability diminishes significantly.

Inadequate Surface Finish and Coating

Many applications require specific surface treatments (e.g., zinc plating, black oxide, or passivation) for corrosion resistance or aesthetics. Sourcing screws with inconsistent or poorly applied coatings can lead to rust, galvanic corrosion, or non-compliance with industry-specific requirements (e.g., medical or aerospace).

Lack of Certifications and Traceability

Reputable applications demand material certifications (e.g., RoHS, REACH, or ISO 9001). Failing to verify that suppliers provide batch traceability and test reports increases the risk of using non-compliant or counterfeit components.

IP-Related Pitfalls

Use of Proprietary or Patented Designs

Some 5/32 screws incorporate patented drive types (e.g., Torx, Robertson, or specialized tamper-proof designs). Sourcing generic versions that mimic these designs without proper licensing can expose companies to intellectual property infringement claims, especially in regulated or litigious markets.

Counterfeit or Grey-Market Components

Unverified suppliers may offer screws that appear identical to branded fasteners but are manufactured without authorization. These counterfeit products often lack quality control and can carry legal risks related to IP violations and product liability.

Inadequate Due Diligence on Supplier IP Compliance

Many sourcing teams focus solely on price and lead time, neglecting to audit whether suppliers have the right to manufacture and distribute specific screw designs. This oversight can result in supply chain disruptions or recalls if IP disputes arise post-purchase.

Conclusion

To avoid these pitfalls, procurement teams should vet suppliers rigorously, demand full certification and compliance documentation, and consult legal experts when sourcing fasteners with proprietary features. Prioritizing quality and IP diligence ensures long-term reliability and protects against legal and operational risks.

Logistics & Compliance Guide for #5 32 Screw

Product Overview

The #5 32 screw is a standard fastener with a nominal diameter of #5 and 32 threads per inch. It is commonly used in electronics, appliances, furniture, and light-duty assembly applications. This guide outlines logistics handling, packaging, shipping, and regulatory compliance requirements for domestic and international distribution.

Packaging Requirements

Use anti-static or moisture-resistant packaging for bulk shipments to prevent corrosion and electrostatic damage, especially if intended for electronic assembly. Individual screws should be sealed in poly bags or blister packs if retail-ready. Bulk quantities must be packed in labeled corrugated boxes with internal dividers to avoid movement during transit. Each package must include a label with part number, quantity, material type (e.g., zinc-plated steel), RoHS compliance status, and batch/lot number.

Shipping & Handling

Ensure proper stacking and weight distribution when palletizing screw packages. Use edge protectors and stretch wrap to secure loads. For air freight, verify total shipment weight and dimensions comply with carrier limits. Ground shipments must comply with DOT regulations if transporting hazardous materials—note that standard #5 32 screws are typically non-hazardous. Maintain dry, temperature-controlled storage environments to prevent rust and degradation.

Regulatory Compliance

Ensure screws meet applicable industry standards such as ASTM F548, ASME B18.6.3, or ISO 1580. Confirm compliance with environmental regulations including RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) for shipments to the EU. For U.S. imports, adhere to CBP regulations and provide accurate HTS code 7318.15.00 (screws, bolts, and nuts, of iron or steel). Conflict minerals reporting is not typically required for standard steel screws unless sourced from designated high-risk regions.

Documentation & Traceability

Maintain full supply chain documentation including certificates of conformance (CoC), material test reports, and compliance declarations. For international shipments, include commercial invoices, packing lists, and bills of lading with precise product descriptions. Implement lot tracking to enable rapid recall if quality issues arise. Retain records for a minimum of five years in accordance with ISO 9001 quality management standards.

Conclusion for Sourcing 5/32″ Screws:

After evaluating suppliers, material specifications, cost, availability, and quality standards, the most viable option for sourcing 5/32″ screws has been identified. The selected supplier offers the required size and thread type (e.g., machine or sheet metal), in the appropriate material (such as stainless steel, zinc-plated steel, or brass), meeting the necessary strength and corrosion resistance requirements. Pricing is competitive, with options for bulk ordering to reduce long-term costs. Delivery timelines are reliable, and quality certifications ensure compliance with industry standards.

In conclusion, proceeding with the recommended supplier will ensure consistent supply, product reliability, and cost-effectiveness for ongoing operations or project needs. It is advised to establish a backup supplier for risk mitigation and to periodically review performance and market alternatives.