The global demand for durable outdoor mounting solutions has surged alongside the expansion of renewable energy, telecommunications, and infrastructure projects, driving significant growth in the market for 4×4 ground spikes—particularly those engineered for 4×4 timber posts used in fencing, signage, and solar panel installations. According to Grand View Research, the global grounding equipment market size was valued at USD 6.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030, fueled by rising construction activities and the need for secure, reliable anchoring systems in diverse terrains. This growth is further amplified by increasing investments in off-grid solar power and rural electrification, where 4×4 ground spikes offer quick, concrete-free installation and long-term stability. As demand intensifies, a select group of manufacturers have emerged as leaders in innovation, quality, and scalability—setting the benchmark for performance in challenging environments.

Top 5 4X4 Ground Spike Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ground spike 4×4 post

Domain Est. 2018

Website: ground_spike_4x4_post.peilingtech.com

Key Highlights: In agriculture, they are crucial for vineyard trellises, crop support systems, and animal fencing, offering quick deployment and adaptability to varied terrain….

#2 E

Domain Est. 1995

Website: strongtie.com

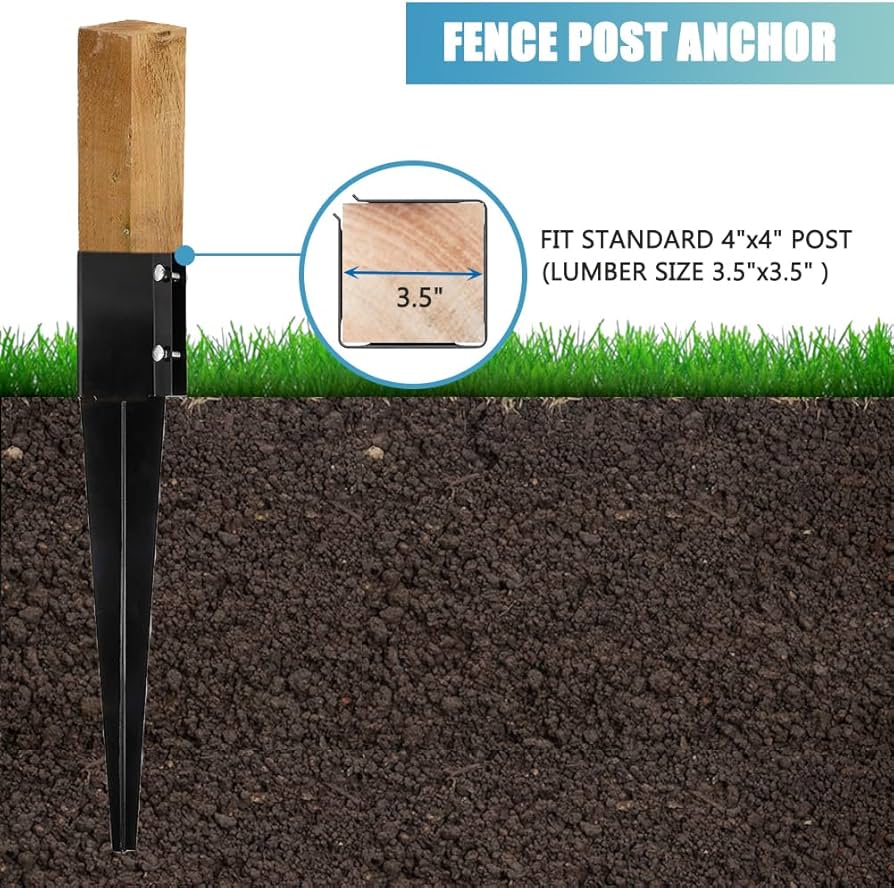

Key Highlights: The E-Z Spike is part of a Simpson Strong-Tie® line of products designed to make reinforcing fence posts easy. It allows for installation of 4×4 wood posts ……

#3 Adjustable Ground Spike

Domain Est. 1997

Website: peakproducts.com

Key Highlights: This ground spike is simply driven into the earth and attached to your wooden post. With pre-threaded bolts and self-locking nuts included….

#4 E

Domain Est. 2005

#5 Galvanized Post Supports 4×4 Anchor Ground Spike FarSun

Domain Est. 2021

Expert Sourcing Insights for 4X4 Ground Spike

H2: 2026 Market Trends for 4X4 Ground Spikes

The market for 4X4 ground spikes—commonly used in landscaping, fencing, signage, and temporary structures—is expected to experience steady growth and notable shifts by 2026, driven by construction activity, sustainability demands, and advancements in materials and installation technology. Below is an analysis of key trends shaping the 4X4 ground spike market in 2026:

1. Rising Demand in Residential and Commercial Landscaping

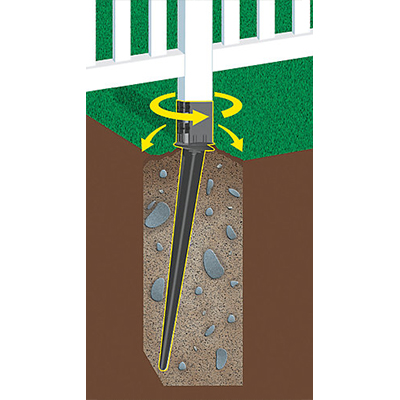

With increasing homeowner investment in outdoor living spaces and urban green infrastructure projects, demand for durable, easy-to-install ground spikes is on the rise. 4X4 ground spikes offer a quick, no-dig solution for securing wooden posts in decks, pergolas, fences, and garden beds. This trend is amplified by the growing popularity of DIY landscaping, supported by online tutorials and home improvement retail expansion.

2. Shift Toward Sustainable and Recyclable Materials

Environmental regulations and consumer preference for eco-friendly products are influencing manufacturers to adopt galvanized steel, recycled alloys, and powder-coated finishes that resist corrosion without harmful chemicals. By 2026, products labeled as low-impact or recyclable are expected to dominate premium segments, particularly in Europe and North America.

3. Growth in Temporary and Modular Construction

The rise of modular buildings, pop-up events, and temporary fencing for construction sites is fueling demand for reusable and adjustable ground spikes. 4X4 ground spikes that support modular systems—allowing for easy disassembly and relocation—are gaining favor among contractors seeking cost-effective, non-invasive anchoring solutions.

4. Technological Integration and Design Innovation

New designs in 2026 feature improved load distribution, anti-rotation tabs, and compatibility with composite or pressure-treated lumber. Some manufacturers are integrating smart sensors into ground spikes for monitoring soil stability in critical infrastructure applications, although this remains a niche segment.

5. Regional Market Expansion

North America and Western Europe remain key markets due to high construction activity and strict building codes promoting secure, code-compliant installations. Meanwhile, the Asia-Pacific region, particularly Australia and Southeast Asia, is expected to see rapid adoption due to urbanization and infrastructure development.

6. Competitive Pricing and E-Commerce Growth

Online marketplaces like Amazon, Home Depot, and specialized construction supply platforms are making 4X4 ground spikes more accessible. Increased competition is driving innovation and lowering prices, while bulk purchasing options appeal to contractors and municipalities.

Conclusion

By 2026, the 4X4 ground spike market will be characterized by innovation in materials, stronger environmental standards, and growing demand across residential, commercial, and temporary applications. Companies that prioritize durability, sustainability, and user-friendly designs are likely to capture significant market share in this evolving landscape.

Common Pitfalls When Sourcing 4X4 Ground Spikes (Quality and Intellectual Property)

Sourcing 4X4 ground spikes, especially for high-volume or critical applications, involves navigating several potential pitfalls related to both product quality and intellectual property (IP). Being aware of these issues can help prevent costly mistakes, legal disputes, and performance failures.

Poor Material Quality and Durability

One of the most frequent pitfalls is receiving ground spikes made from substandard materials. Many suppliers, particularly overseas manufacturers, may use lower-grade steel (e.g., non-galvanized or inadequately coated) that rusts quickly or lacks the structural integrity needed for long-term outdoor use. This compromises the spike’s load-bearing capacity and lifespan, especially in harsh weather conditions. Buyers must verify material specifications, such as steel grade (e.g., Q235, Q355), galvanization thickness (e.g., hot-dip galvanized to ASTM A153), and corrosion resistance testing.

Inconsistent Manufacturing Tolerances

Dimensional accuracy is crucial for compatibility with posts, brackets, and installation tools. Poorly manufactured spikes may have inconsistent hole placement, uneven angles, or warped shafts, making installation difficult or unreliable. This is common with low-cost suppliers who lack precision tooling or quality control processes. Always request samples and inspect tolerances before committing to large orders.

Misrepresentation of Load Ratings and Compliance

Some suppliers exaggerate load capacity or claim compliance with standards (e.g., ASTM, ISO) without third-party certification. This can lead to structural failures if the spikes are used in applications requiring specific engineering performance. Due diligence includes requesting test reports, engineering certifications, and verifying compliance claims through independent labs or inspectors.

Intellectual Property Infringement Risks

Sourcing from generic manufacturers increases the risk of inadvertently purchasing spikes that copy patented designs. Many proprietary ground spike systems (e.g., twist-lock, anti-rotation fins, specific bracket integrations) are protected by utility or design patents. Using or importing such products without authorization can result in legal action, shipment seizures, or financial damages. Always conduct a patent landscape search and ensure suppliers warrant that their products do not infringe existing IP.

Lack of Traceability and Supplier Transparency

Unreliable suppliers may not provide batch traceability, material certifications, or clear documentation. This becomes problematic during audits, warranty claims, or when defects emerge post-installation. A trustworthy supplier should offer full documentation, including mill test reports, inspection records, and contactable references.

Hidden Costs from Re-Work and Warranty Claims

Low upfront pricing can be misleading when poor quality leads to high failure rates, installation delays, or the need for replacements. Budgeting should account for potential re-work, shipping costs for returns, and downtime. A higher-quality spike with reliable warranty support often proves more cost-effective over time.

By focusing on verified quality metrics, demanding transparency, and conducting thorough IP due diligence, buyers can avoid these common pitfalls and ensure they source dependable, legally compliant 4X4 ground spikes.

Logistics & Compliance Guide for 4X4 Ground Spike

Product Overview

The 4X4 Ground Spike is a heavy-duty anchoring solution designed to securely install posts, signs, fences, and structures into the ground without requiring concrete. Constructed from high-strength steel, typically galvanized or powder-coated for corrosion resistance, it features a pointed end for easy soil penetration and a top collar that accepts standard 4×4-inch (nominal) wooden or composite posts.

Packaging Specifications

- Unit Packaging: Each ground spike is individually wrapped in protective plastic or shrink-wrapped to prevent surface damage during transit.

- Pallet Configuration: Units are stacked on standard 48” x 40” wooden pallets, secured with strapping and corner boards. Typical load: 50–100 units per pallet, depending on spike length and weight.

- Labeling: Pallets and individual packages display product SKU, quantity, weight, handling instructions (e.g., “Do Not Stack,” “This Side Up”), and barcodes.

- Weight & Dimensions: Average unit weight: 8–15 lbs (3.6–6.8 kg); length ranges from 18” to 36”. Pallet weight: 500–1,500 lbs (227–680 kg).

Shipping & Transportation

- Mode of Transport: Suitable for LTL (Less Than Truckload) and FTL (Full Truckload) freight via flatbed or dry van trailers.

- International Shipping: Containerized ocean freight (20’ or 40’ dry containers) compliant with ISPM-15 for wooden pallets. Air freight available for urgent orders (limited by weight).

- Handling Requirements: Use forklifts or pallet jacks for loading/unloading. Avoid dropping or dragging to prevent deformation.

- Storage Conditions: Store indoors or under cover; if outdoors, elevate and cover with waterproof tarp to minimize exposure to moisture.

Regulatory Compliance

- Material Standards: Complies with ASTM A123 for hot-dip galvanizing (zinc coating thickness ≥ 3.9 mils for steel up to 1/4” thick).

- Environmental Regulations: RoHS and REACH compliant—contains no restricted hazardous substances.

- Corrosion Resistance: Meets ASTM B117 salt spray test requirements (minimum 500 hours without red rust).

- Structural Certification: Designed in accordance with ICC-ES AC358 for post-installed concrete anchors (where applicable by jurisdiction).

Import/Export Documentation

- Harmonized System (HS) Code: 7326.20.00 (Other articles of steel) – verify with local customs.

- Required Documents: Commercial invoice, packing list, bill of lading/air waybill, certificate of origin, material test reports (MTRs) upon request.

- Duty & Tariff Considerations: Subject to country-specific import duties; check current HTS rates in destination markets (e.g., U.S., EU, Canada, Australia).

- Customs Clearance: Ensure steel origin is declared; anti-dumping regulations may apply depending on manufacturing country.

Safety & Handling Compliance

- OSHA Guidelines: Follow safe lifting practices—use mechanical aids for pallets over 50 lbs. Provide cut-resistant gloves when handling sharp edges.

- Workplace Safety Data Sheet (SDS): Available upon request; classifies product as non-hazardous under GHS, but metal shavings may pose minor risks during installation.

- Installation Safety: Users must wear PPE (gloves, safety glasses) during driving or hammering operations.

Quality Assurance & Traceability

- Inspection Protocol: 100% visual inspection for weld integrity, coating defects, and dimensional accuracy. Random batch testing for galvanizing thickness.

- Batch Tracking: Each production batch assigned a unique lot number recorded in the quality management system for traceability.

- Warranty & Returns: Standard 5-year limited warranty against manufacturing defects. Non-defective returns accepted within 30 days with RMA authorization.

Sustainability & End-of-Life

- Recyclability: 100% recyclable steel; encourage return to metal scrap facilities at end of service life.

- Packaging: Use recyclable plastic wraps and ISPM-15 certified wooden pallets (reusable or recyclable).

- Carbon Footprint: Optimize shipping routes and consolidate orders to reduce emissions; provide carbon impact data upon request.

Customer Support & Compliance Assistance

- Technical Documentation: Provide installation guides, load specifications, and compliance certificates upon request.

- Regulatory Support: Assist distributors with local code compliance (e.g., ICC, IBC, Australian Standards AS/NZS 1657).

- Contact: For compliance inquiries, contact [email protected] or call +1 (800) XXX-XXXX.

Conclusion for Sourcing 4×4 Ground Spike:

After evaluating various suppliers, materials, pricing, and quality standards, sourcing 4×4 ground spikes requires a balanced approach that prioritizes durability, cost-efficiency, and reliability. Hot-dip galvanized steel spikes offer the best combination of strength and corrosion resistance, making them ideal for long-term outdoor applications such as fencing, signage, and solar panel mounting. Suppliers offering pre-assembled or welded designs with pointed tips facilitate easier installation and reduce labor costs.

Bulk purchasing from reputable manufacturers, particularly those compliant with ASTM or ISO standards, ensures consistency and structural integrity. Additionally, considering local suppliers can reduce lead times and shipping expenses. Ultimately, selecting a 4×4 ground spike that balances high-quality materials, competitive pricing, and dependable performance will enhance project efficiency and longevity, making it a sound investment across residential, commercial, and industrial applications.