The global connector market, including audio components such as 4mm banana plugs, is experiencing steady expansion driven by increasing demand in consumer electronics, automotive, and industrial applications. According to Grand View Research, the global electrical connector market was valued at USD 78.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by rising adoption of high-fidelity audio equipment, advancements in speaker and amplifier technology, and the proliferation of home automation systems—all of which rely on reliable, high-quality connections. Banana plugs, particularly the 4mm variety, have become standard in premium audio setups due to their secure fit and superior conductivity. As demand for performance-oriented audio accessories rises, a cadre of manufacturers has emerged to lead in precision engineering, durability, and electrical efficiency. Based on production scale, market presence, product innovation, and customer reviews, here are the top 9 manufacturers producing 4mm banana plugs that are shaping the industry landscape.

Top 9 4Mm Banana Plug Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CX

Domain Est. 2019

Website: bituoelec.com

Key Highlights: CX-03 is 4mm Connector. This connector is 4mm which widely using at electric connecting. Bituoelec offering various colors for this item. OEM/ODM is available ……

#2 Banana Plugs 4mm & 2mm Connectors

Domain Est. 1999

Website: warwickts.com

Key Highlights: 8-day delivery 14-day returnsExplore the wide range of 4mm and 2mm Banana Plugs from Electro-PJP, Pomona and EZ Hook, all leading manufacturers in the market….

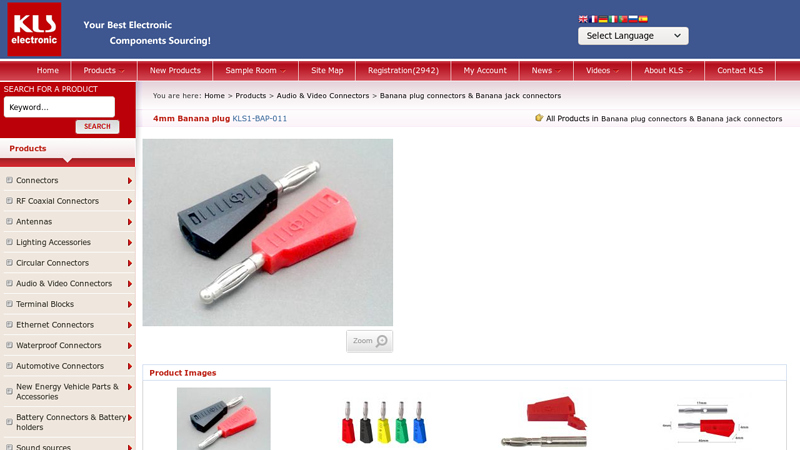

#3 4mm Banana plug manufacturer & supplier

Domain Est. 2012

Website: klsele.com

Key Highlights: We are a manufacturer of KLS1-BAP-011 , exporter of KLS1-BAP-011 made in China, get more KLS1-BAP-011 suppliers, factories, wholesalers, distributors, ……

#4 Banana Plugs & Jacks

Domain Est. 1994

Website: newark.com

Key Highlights: Free delivery over $150 · 60-day returnsBanana Test Connector, 4mm, Jack, Panel Mount, 36 A, 1 kV, Nickel Plated Contacts, Red MULTICOMP PRO Order Code 01AC7896…

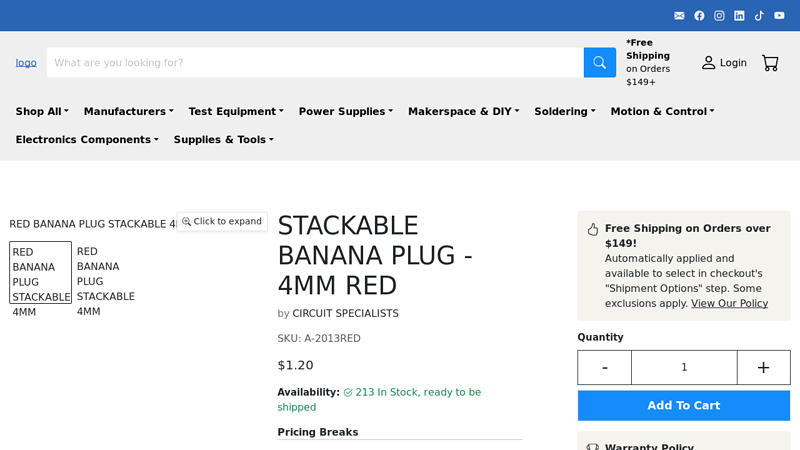

#5 Stackable Banana Plug

Domain Est. 1996

Website: circuitspecialists.com

Key Highlights: In stock Rating 4.7 (7,860) These rugged 4mm banana plugs are machined from brass with a moveable multi-lam contact cage spring for tight fit. The connectors are nickel-plated….

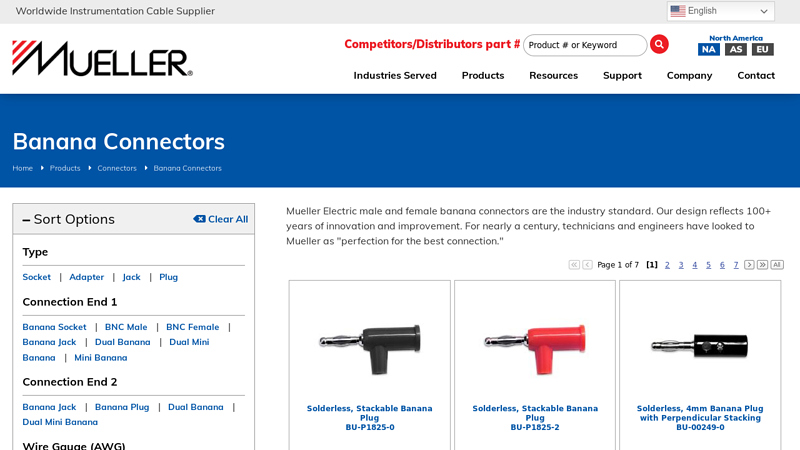

#6 Banana Connectors – Female and Male

Domain Est. 1997

Website: muellerelectric.com

Key Highlights: Mueller Electric male and female banana connectors are the industry standard. Our design reflects 100+ years of innovation and improvement….

#7 Banana Plugs And Jacks

Domain Est. 1998

Website: pomonaelectronics.com

Key Highlights: 4mm Safety Banana Jack To 2mm Banana Plug Adapter. Model 72914. 4mm Banana Plug To 2mm Banana Jack Adapter. Model ……

#8 Chord ChorAlloy Ohmic 4mm Banana Plug

Domain Est. 2017

Website: expressiveaudio.com

Key Highlights: 30-day returnsChordOhmic ChorAlloy™ plated spade loudspeaker connectors are designed to bring electrical and sonic benefits to speaker cables everywhere….

#9 Sources for 4mm banana plugs and sockets

Domain Est. 2021

Website: modwiggler.com

Key Highlights: Sources for 4mm banana plugs and sockets. From circuitbending to homebrew stompboxes & synths, keep the DIY spirit alive! 11 posts • Page 1 of 1….

Expert Sourcing Insights for 4Mm Banana Plug

H2: Projected 2026 Market Trends for 4mm Banana Plugs

The global market for 4mm banana plugs is expected to experience steady growth by 2026, driven by increasing demand in test and measurement, audio equipment, educational laboratories, and renewable energy sectors. As a standard in electrical connectivity for temporary or semi-permanent setups, 4mm banana plugs remain essential in both industrial and consumer electronics applications. Key trends shaping the 2026 landscape include technological advancements, regional market dynamics, and evolving industry standards.

-

Rising Demand in Test and Measurement Equipment

The expansion of R&D activities in electronics, telecommunications, and automotive industries is fueling the need for reliable, high-precision test connections. 4mm banana plugs are widely used in multimeters, oscilloscopes, and power supplies due to their ease of use and secure fit. With the growing complexity of electronic systems, demand for high-quality, low-noise banana plugs with enhanced safety features (e.g., shrouded designs, high current ratings) is expected to rise. -

Growth in Educational and Laboratory Applications

Universities, technical schools, and research institutions continue to adopt modular and reconfigurable lab setups. The 4mm standard is prevalent in educational electronics kits and training systems. As STEM education expands globally—especially in emerging economies—the need for durable, affordable, and safe banana plugs will support market growth through 2026. -

Advancements in Audio and High-Fidelity Equipment

In the consumer audio segment, high-end audio systems increasingly use 4mm banana plugs for speaker connections due to their superior conductivity and secure locking mechanisms. The trend toward premium home audio and professional sound systems supports sustained demand, particularly for gold-plated, low-resistance variants that minimize signal loss. -

Expansion in Renewable Energy and Electric Vehicle (EV) Testing

The proliferation of EVs and battery testing infrastructure is creating new applications for 4mm banana connectors in prototyping and quality assurance. EV battery test benches and power electronics validation setups often use banana plugs for quick probe connections. This industrial use case is expected to grow steadily, contributing to higher volumes in industrial-grade connector sales. -

Regional Market Developments

Asia-Pacific is anticipated to be the fastest-growing region due to expanding electronics manufacturing in China, India, and Southeast Asia. Local production of test equipment and consumer electronics is increasing the regional demand for banana plugs. Meanwhile, North America and Europe maintain strong demand supported by advanced R&D ecosystems and stringent safety regulations favoring insulated and compliant connector designs. -

Material and Design Innovations

By 2026, manufacturers are expected to focus on eco-friendly materials, improved durability, and compatibility with automated test systems. Innovations such as color-coded housings, spring-loaded contacts, and hybrid banana-banana or banana-BNC adapters will enhance usability and integration across platforms. -

Competitive Landscape and Pricing Pressure

While established brands (e.g., Keithley, Amphenol, Pomona) dominate the high-performance segment, low-cost alternatives from Asian suppliers are increasing competition. This dynamic may drive price optimization and consolidation, pushing manufacturers to differentiate through reliability, certifications (e.g., CE, RoHS), and customization.

In summary, the 4mm banana plug market in 2026 will be shaped by technological refinement, sector-specific adoption, and geographic expansion. Despite the emergence of newer connector types, the 4mm banana plug remains a resilient standard due to its versatility, cost-effectiveness, and widespread compatibility—ensuring continued relevance across multiple industries.

Common Pitfalls When Sourcing 4mm Banana Plugs (Quality and IP Considerations)

Sourcing 4mm banana plugs may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to performance issues, safety risks, or legal complications. Below are common pitfalls to avoid:

Quality-Related Pitfalls

1. Poor Material Construction

Low-cost banana plugs often use substandard materials such as brass with low conductivity or inadequate plating (e.g., thin nickel or no gold plating). This leads to increased resistance, overheating, and premature wear. Always verify material specifications and demand compliance with standards like IEC 61010.

2. Inconsistent Dimensional Tolerances

Inaccurate pin diameter or housing dimensions can result in loose connections or difficulty mating with jacks. Poor tolerances may cause intermittent signals or arcing. Ensure suppliers provide dimensional drawings and conduct first-article inspections.

3. Lack of Insulation and Safety Certification

Non-insulated or poorly insulated banana plugs pose electrical shock risks. Sourcing plugs without recognized safety certifications (e.g., UL, CE, VDE) increases liability. Always confirm compliance with relevant safety standards for the target application.

4. Inadequate Mechanical Durability

Plugs with weak spring mechanisms or brittle housings degrade quickly after repeated insertions. This is especially problematic in test environments requiring frequent connections. Request durability test data (e.g., mating cycle ratings) before procurement.

5. Misleading IP (Ingress Protection) Ratings

Some suppliers claim IP ratings (e.g., IP67) without proper testing or certification. A true IP-rated banana plug must be dust-tight and water-resistant when mated. Verify third-party test reports and ensure the rating applies to the mated pair, not just the plug alone.

IP (Intellectual Property)-Related Pitfalls

1. Copying Patented Designs

Major brands (e.g., Pomona, Amphenol, Keithley) hold patents on specific banana plug designs, including safety shrouds or locking mechanisms. Sourcing counterfeit or cloned versions can lead to IP infringement claims, especially in commercial or export markets.

2. Trademark and Brand Imitation

Suppliers may produce look-alike products with branding that mimics well-known manufacturers. Even if technically legal, this raises ethical concerns and risks damaging your brand reputation if discovered by customers or regulators.

3. Lack of Transparency in Design Ownership

Some OEMs fail to disclose whether their designs are proprietary or licensed. Without proper documentation, buyers may unknowingly distribute infringing products. Always require IP indemnification clauses in supplier agreements.

4. Use of Open-Source or Public Domain Misconceptions

Assuming that because a connector type is widely used, its design is free to replicate, is incorrect. While the 4mm banana plug form factor is standardized, specific enhancements (ergonomic housings, safety features) may still be protected.

Conclusion

To avoid these pitfalls, conduct thorough due diligence on suppliers, request material and test certifications, verify IP status, and prioritize long-term reliability over short-term cost savings. Engaging with reputable manufacturers and legal counsel when in doubt can prevent costly quality failures or legal disputes.

Logistics & Compliance Guide for 4mm Banana Plug

Product Classification & Identification

The 4mm banana plug is categorized as an electrical connector used in test and measurement, audio, and power applications. Proper identification includes confirming the plug’s gender (male/female), material composition (typically brass, copper, or nickel-plated), insulation type (if shrouded), and voltage/current ratings. Accurate product codes (such as SKU or part number) and harmonized system (HS) codes (commonly 8536.69 or 8536.90 depending on function) must be assigned for international shipping and customs clearance.

Regulatory Compliance Standards

4mm banana plugs must comply with relevant regional and international safety and performance standards. Key certifications include:

– CE Marking (EU): Compliance with Low Voltage Directive (LVD) and RoHS (Restriction of Hazardous Substances).

– UL/CSA Recognition (North America): Listed under UL 61010-1 for electrical safety in laboratory equipment.

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals—ensure restricted substances are below permissible limits.

– RoHS 2 (2011/65/EU): Confirms lead, cadmium, mercury, and other hazardous materials are within allowable thresholds.

Manufacturers and distributors must maintain technical documentation and conformity declarations for audit purposes.

Packaging & Labeling Requirements

Use anti-static, durable packaging to prevent damage during transit. Each package must include:

– Product name and model number

– Manufacturer/importer details

– Compliance markings (CE, UL, RoHS)

– Safety warnings (e.g., “For Use in Low-Voltage Applications Only”)

– Batch/lot number and date of manufacture

– Country of origin

Labels must be legible, permanent, and compliant with destination country language requirements (e.g., French labeling in Canada, Spanish in parts of Latin America).

Shipping & Transportation Logistics

Banana plugs are generally non-hazardous and may be shipped via standard courier or freight services. However:

– Avoid extreme temperatures and moisture during storage and transit.

– Use ESD-safe containers if intended for sensitive electronic testing environments.

– For air freight, ensure compliance with IATA regulations—no special handling required unless combined with batteries or hazardous components.

– Declare accurate weight, dimensions, and declared value for customs processing.

Import/Export Documentation

Prepare the following for international shipments:

– Commercial Invoice (with itemized description, unit price, total value)

– Packing List

– Certificate of Origin

– Safety Compliance Certificates (CE, UL, RoHS)

– Import licenses (if required by destination country)

Verify tariff classifications and potential import duties using the destination country’s customs database.

Environmental & Disposal Compliance

At end-of-life, banana plugs should be recycled as electronic waste (e-waste). Comply with:

– WEEE Directive (EU): Producers must support take-back and recycling programs.

– Local e-waste regulations (e.g., EPA guidelines in the U.S.)

Ensure disposal partners are certified recyclers to avoid environmental liability.

Quality Assurance & Traceability

Maintain lot traceability through the supply chain. Conduct regular quality audits and electrical performance testing (e.g., contact resistance, insulation integrity). Record test results and retain them for minimum of 5 years to support compliance claims and warranty services.

Conclusion:

After evaluating various suppliers and options for sourcing 4mm banana plugs, it is clear that a balance between quality, cost, and reliability must be prioritized. Multiple suppliers offer competitive pricing and product specifications suitable for different applications—be it educational, industrial, or laboratory use. Key considerations such as material quality (e.g., copper alloy conductivity, insulation type), plating (nickel or gold for corrosion resistance), and current rating should guide the final selection.

Based on comparative analysis, sourcing from reputable suppliers—whether local distributors or global platforms like Digi-Key, Mouser, or RS Components—ensures compliance with safety standards and consistent performance. While lower-cost options from general marketplaces may appear attractive, they often compromise on durability and electrical integrity.

In conclusion, the recommended approach is to source 4mm banana plugs from trusted electronics component suppliers that provide detailed specifications, certifications, and technical support. This ensures long-term reliability, safety, and compatibility within your test and measurement systems. Establishing a relationship with a dependable supplier will also support future scalability and consistent product quality.