The global demand for hardware cloth—particularly 48-inch wide variants used in construction, agriculture, and pest control—is on a steady upward trajectory, driven by increased infrastructure spending and rising agricultural automation. According to a 2023 report by Grand View Research, the global wire mesh market was valued at USD 98.6 billion and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030, with woven wire products like 48-inch hardware cloth representing a significant segment. Similarly, Mordor Intelligence projects that heightened urbanization and industrial safety regulations will further boost demand for durable fencing and protective mesh solutions through 2028. As supply chains adapt to regional manufacturing shifts and sustainability standards, identifying reliable 48 hardware cloth manufacturers has become critical for procurement professionals and project planners. Below are the top six manufacturers leading in quality, scale, and innovation within this growing market.

Top 6 48 Hardware Cloth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Galvanized Hardware Cloth Supplier

Domain Est. 1999

Website: marcospecialtysteel.com

Key Highlights: The Marco Specialty Steel mesh products includes galvanized hardware cloth. Click to learn more about this versatile, economical hardware cloth option….

#2 STAINLESS STEEL 1/2″ Mesh Hardware Cloth

Domain Est. 2000

Website: wildlifecontrolsupplies.com

Key Highlights: In stock 4-day deliveryThis 18 gauge stainless steel cloth is great for any number of applications around the home, business or farm. Grade 304 Stainless Steel…

#3 Galvanized Metal Hardware Cloth Fence, 48

Domain Est. 2015

Website: makartechnologies.com

Key Highlights: Rating 4.2 (124) Dec 29, 2025 · Galvanized Metal Hardware Cloth Fence, 48-In. x 100-Ft. ; New $255.14 (tax included) Number of stocks: 1 ; Number of stocks · 1 ; Used $127.57 (ta…

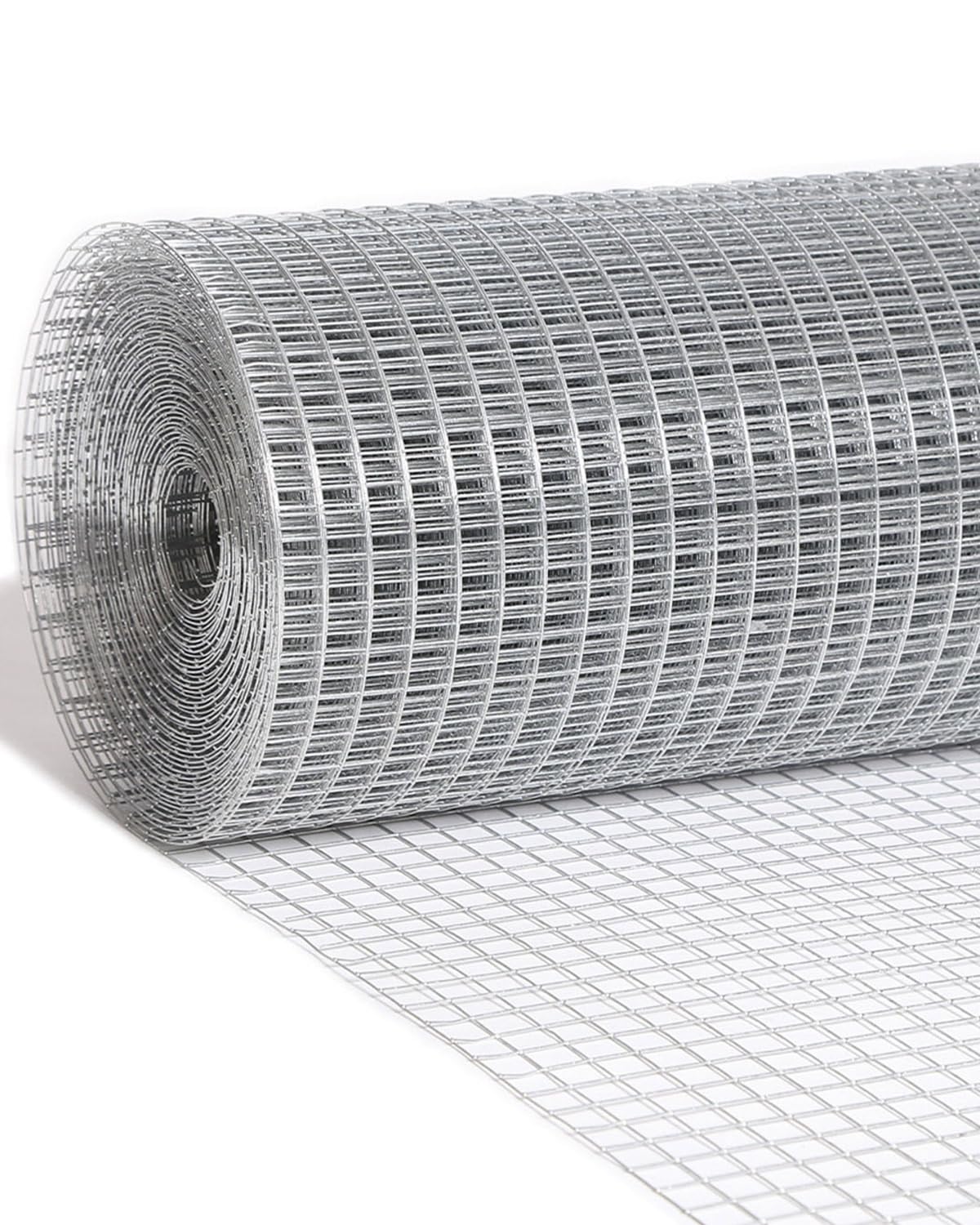

#4 Nueve Deer 1/2 inch Hardware Cloth 48×50 19

Domain Est. 2020

Website: rapiroy.com

Key Highlights: In stock Rating 4.6 (24) Product details · Premium Galvanized Construction – Made with 1/2 inch x 1/2 inch mesh, 48 inches x 50 feet (1.22m x 15.3m), from galvanized annealed ste…

#5 Garden Craft 48 in. W X 25 ft. L Silver Steel Hardware Cloth

Domain Est. 2021

Website: goldenwingsfishandchicken.com

Key Highlights: In stock Rating 4.1 (56) 8 days ago · 48in x 25ft 23 gauge galvanized hardware cloth features a 1/4in square mesh weave and is both lightweight and durable….

#6 Seboss Hardware Cloth Store

Domain Est. 2022

Website: sebossfence.com

Key Highlights: … SEBOSS 1/2 inch Openings 48in x100 ft Black Hardware Cloth Vinyl Coated Wire Mesh Roll. Sale. SEBOSS ……

Expert Sourcing Insights for 48 Hardware Cloth

H2: Projected 2026 Market Trends for 48-Inch Hardware Cloth

The market for 48-inch hardware cloth—a galvanized or stainless steel mesh commonly used in construction, agriculture, pest control, and DIY projects—is expected to experience steady growth and notable shifts by 2026, driven by evolving industry demands, material innovations, and regional economic developments.

1. Increased Demand in Residential and Agricultural Sectors

By 2026, the demand for 48-inch hardware cloth is projected to rise significantly in both residential and agricultural applications. In the U.S. and other developed markets, the surge in home improvement and backyard farming trends—accelerated by pandemic-era lifestyle changes—will sustain demand for durable fencing and animal enclosures. The standardized 48-inch width is particularly favored for chicken coops, garden protection, and rodent barriers, making it a staple in hardware stores and e-commerce platforms like Amazon and Home Depot.

2. Growth in E-Commerce and Direct-to-Consumer Sales

Online sales channels are expected to dominate hardware cloth distribution by 2026. Manufacturers and distributors are increasingly leveraging digital platforms to reach DIY consumers and small contractors. Customizable roll lengths, bundled kits (e.g., with staples or tools), and enhanced product descriptions with installation guides will improve customer experience and drive conversion rates.

3. Material and Sustainability Innovations

Environmental concerns and regulatory pressures will push manufacturers toward more sustainable production methods. By 2026, expect broader availability of hardware cloth made from recycled steel or with improved galvanization techniques that extend lifespan and reduce maintenance. Some producers may introduce bio-based protective coatings or explore alternative materials that mimic steel’s strength with lower carbon footprints.

4. Regional Market Expansion

Emerging markets in Latin America, Southeast Asia, and Africa will contribute to global growth in hardware cloth demand. Urbanization, infrastructure development, and rising awareness of pest control in agriculture will increase the need for cost-effective mesh solutions. The 48-inch size, compatible with standard building materials, will be well-positioned for adoption in these regions.

5. Competitive Pricing and Supply Chain Optimization

Global supply chain stabilization post-pandemic and advancements in manufacturing efficiency are expected to moderate price increases. However, volatility in steel prices could still impact margins. Leading suppliers will likely invest in localized production and inventory management systems to ensure timely delivery and reduce logistics costs.

6. Smart Integration and Niche Applications

While traditional uses dominate, niche applications such as integration with smart fencing systems (e.g., sensors embedded in mesh for security) may begin emerging by 2026. Though not yet mainstream, R&D in this area could position hardware cloth as part of broader smart home or precision agriculture ecosystems.

In summary, the 2026 market for 48-inch hardware cloth will be shaped by sustained consumer demand, digital transformation in distribution, sustainability initiatives, and geographic expansion. Companies that innovate in materials, streamline supply chains, and leverage online platforms will be best positioned to capture market share.

Common Pitfalls Sourcing 48-Inch Hardware Cloth (Quality & IP)

Sourcing 48-inch hardware cloth effectively requires attention to both material quality and intellectual property (IP) considerations. Overlooking these areas can lead to performance issues, safety hazards, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Construction

-

Inconsistent Wire Gauge and Mesh Size: Many low-cost suppliers provide hardware cloth with inaccurate wire thickness (gauge) or inconsistent mesh openings. This compromises structural integrity and may fail to exclude targeted pests or meet building code requirements.

-

Substandard Galvanization: Inadequate or uneven galvanizing leads to premature rust and corrosion, especially in outdoor or high-moisture environments. Beware of hardware cloth with visible coating flaws or that uses post-weld galvanization instead of proper pre-galvanized wire.

-

Weak Welds and Poor Joining: Poorly welded intersections can unravel under stress. This is especially critical in applications requiring durability, such as animal enclosures or construction reinforcement.

-

Dimensional Inaccuracy: A product labeled as “48 inches wide” may be undersized or vary significantly in width, making installation difficult and leading to material waste or gaps in coverage.

Intellectual Property and Branding Risks

-

Counterfeit or Misrepresented Products: Some suppliers falsely claim compliance with standards (e.g., ASTM A641) or mimic branded products (e.g., Repel, Stucco Net) without authorization. This can lead to IP infringement and liability.

-

Unauthorized Use of Trademarks and Branding: Sourcing generic hardware cloth is acceptable, but selling or marketing it under a registered brand name (even inadvertently) can result in legal action for trademark infringement.

-

Lack of Traceability and Documentation: Reputable suppliers provide mill test reports or certifications. Sourcing from vendors who cannot supply documentation increases the risk of unknowingly distributing non-compliant or counterfeit materials.

Supply Chain and Compliance Oversights

-

Ignoring Regional Standards and Codes: Different regions have specifications for hardware cloth used in construction, agriculture, or pest control. Sourcing without verifying compliance (e.g., with building codes or USDA guidelines) can result in rejected projects or safety violations.

-

Overlooking Packaging and Handling Damage: Poor packaging can lead to kinking, tangling, or surface damage during transit, reducing usability and perceived quality.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, request samples and certifications, verify IP status of branded alternatives, and ensure product specifications match application requirements.

Logistics & Compliance Guide for 48″ Hardware Cloth

Product Overview

48″ hardware cloth refers to a woven wire mesh typically made from galvanized steel, with a standard width of 48 inches (4 feet). It is commonly used in construction, agriculture, pest control, and DIY projects for animal enclosures, reinforcing stucco, and rodent proofing. Understanding proper logistics and compliance requirements ensures safe handling, transportation, and regulatory adherence.

Packaging & Handling

- Roll Configuration: Hardware cloth is typically supplied in rolls, with lengths varying (e.g., 25 ft, 50 ft, 100 ft). Rolls should be wound tightly and secured with durable strapping or plastic banding.

- Core Material: Rolls are usually wound around a sturdy cardboard or plastic core to maintain shape and prevent deformation.

- Protective Wrapping: Rolls should be wrapped in UV-resistant polyethylene or shrink wrap to protect against moisture, dirt, and corrosion during transit.

- Handling Equipment: Use forklifts or pallet jacks for moving full pallets. Manual handling requires gloves to prevent cuts from wire edges.

Storage Requirements

- Indoor Storage: Store in a dry, covered area to prevent galvanized coating degradation. Avoid direct ground contact; use pallets or racks.

- Environmental Conditions: Keep away from high humidity, salt spray, and corrosive chemicals. Ideal storage temperature is between 50°F and 85°F (10°C–29°C).

- Stacking: Limit vertical stacking to prevent crushing. Max recommended stack height is 3–4 pallets, depending on roll weight and pallet strength.

Transportation Guidelines

- Palletization: Secure rolls on standard 48″ x 40″ pallets using stretch wrap and corner boards. Max load height: 72 inches for stability.

- Load Securing: Use ratchet straps or banding when shipping via truck or rail to prevent shifting. Avoid overstressing straps on wire edges.

- Hazard Classification: Hardware cloth is non-hazardous and does not require hazardous materials (HAZMAT) documentation.

- Freight Class (NMFC): Typically falls under NMFC 150–175, Class 125–150 depending on density and packaging. Confirm with carrier for accurate freight classification.

Regulatory Compliance

- OSHA Safety Standards: Comply with OSHA 29 CFR 1910 regarding material handling and worker protection. Provide cut-resistant gloves and safety training for handlers.

- DOT Regulations: As non-hazardous freight, standard DOT FMVSS rules for cargo securement apply (49 CFR Part 393).

- Customs & Import (International Shipments):

- HS Code: 7314.31.10 (Galvanized steel net, fencing, grill, or similar articles).

- Country-Specific Requirements: Verify import regulations in destination country; some may require phytosanitary certificates if wooden pallets are used.

- ISPM 15 Compliance: Wooden pallets must be heat-treated and stamped per ISPM 15 standards for international shipments.

Environmental & Sustainability Considerations

- Recyclability: Galvanized steel hardware cloth is 100% recyclable. Provide recycling instructions to end users.

- End-of-Life Management: Encourage proper disposal through metal recycling facilities to reduce landfill impact.

- RoHS & REACH: While not typically applicable to raw steel mesh, confirm with supplier if coated or alloy-specific variants are used.

Documentation & Labeling

- Shipping Labels: Include product name, dimensions (48″ x length), gauge/thickness, material (e.g., galvanized steel), batch/lot number, and handling symbols (e.g., “This Side Up,” “Protect from Moisture”).

- SDS (Safety Data Sheet): Not required for standard galvanized steel hardware cloth, but recommended for coated or treated variants.

- Bill of Lading: Accurately list item description, quantity, weight, and NMFC code for billing and tracking.

Quality Assurance & Inspection

- Pre-Shipment Check: Inspect rolls for kinks, loose ends, or coating damage before dispatch.

- Inbound Inspection: Verify dimensions, mesh count (e.g., 1/4″, 1/2″), and galvanization quality upon receipt.

- Compliance Audits: Conduct periodic audits of packaging, labeling, and storage practices to ensure adherence to logistics standards.

Emergency & Incident Response

- Cut Injuries: Maintain first aid kits with supplies for treating minor cuts. Train personnel in basic wound care.

- Spill/Release: No environmental hazard from material release, but damaged rolls should be contained and recycled appropriately.

- Fire Response: Steel is non-combustible. Use standard firefighting procedures; no toxic fumes under normal conditions.

Summary

Proper logistics and compliance management for 48″ hardware cloth ensures product integrity, worker safety, and regulatory alignment. Key focus areas include secure packaging, dry storage, compliant transportation, accurate documentation, and adherence to international shipping standards. Partner with certified carriers and suppliers to maintain a reliable supply chain.

In conclusion, sourcing 48 rolls of hardware cloth requires careful consideration of several key factors to ensure quality, cost-effectiveness, and timely delivery. After evaluating multiple suppliers, comparing prices, assessing material specifications (such as mesh size, wire gauge, and roll dimensions), and reviewing shipping terms and lead times, the most suitable vendor has been identified. This supplier offers competitive pricing, consistent product quality, and reliable customer service, meeting all project requirements. Additionally, placing a bulk order may provide further cost savings and ensure material availability for the duration of the project. Moving forward, confirming the order details, delivery schedule, and payment terms will be essential to a successful procurement process. Overall, the sourcing strategy balances budgetary constraints with performance needs, ensuring optimal value and efficiency.