The global industrial manufacturing sector continues to expand, driven by rising demand for high-performance materials in automotive, aerospace, and energy applications. According to Grand View Research, the global stainless steel market was valued at USD 134.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. A key segment within this landscape is the production of 440/12 stainless steel—an ultra-high-carbon variant prized for its exceptional hardness, wear resistance, and moderate corrosion resistance, commonly used in cutlery, bearings, and precision components.

As demand for durable and high-precision steel increases, especially in Asia-Pacific and North America, manufacturers capable of consistently delivering high-quality 440/12 alloys are gaining strategic importance. Advances in processing technologies, along with increased investments in R&D, are enabling leading producers to enhance product consistency and performance. With tightening supply chains and a growing focus on material traceability and sustainability, identifying reliable 440/12 manufacturers has become a strategic priority for buyers across industries. Based on production capacity, global reach, quality certifications, and customer reviews, the following nine companies have emerged as top manufacturers in the 440/12 stainless steel space.

Top 9 440/12 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SOS

Domain Est. 1996

Website: dbroberts.com

Key Highlights: Standoffs. Manufacturer: Penn Engineering. Manufacturer Part Number: Penn Engineering SOS-440-12. Thread Size: 4-40. Material: 300 Series Stainless Steel….

#2 SOS

Domain Est. 1996

Website: swaco.com

Key Highlights: Manufacturer, Penn Engineering. Manufacturer’s Part No. SOS-440-12. Description, SOS-440-12 Through-Hole Threaded Standoff. Type, SOS. Thread Size, #4-40….

#3 Hazet 440

Domain Est. 2010

Website: hockeysushi.ca

Key Highlights: Rating 4.6 (79) Dec 26, 2025 · General Information Manufacturer Hazet Part Number 440-12 Product Type Open Ended Wrenches California Residents Proposition 65 Warning….

#4 SOS-440-12 PEM

Domain Est. 1995

Website: mouser.com

Key Highlights: In stock $4.99 deliveryProduct: Standoffs. Type: Round. Thread Size: 4-40. Length: 0.375 in. Material: Stainless Steel. Outside Diameter: 0.187 in. Gender: Female / Female….

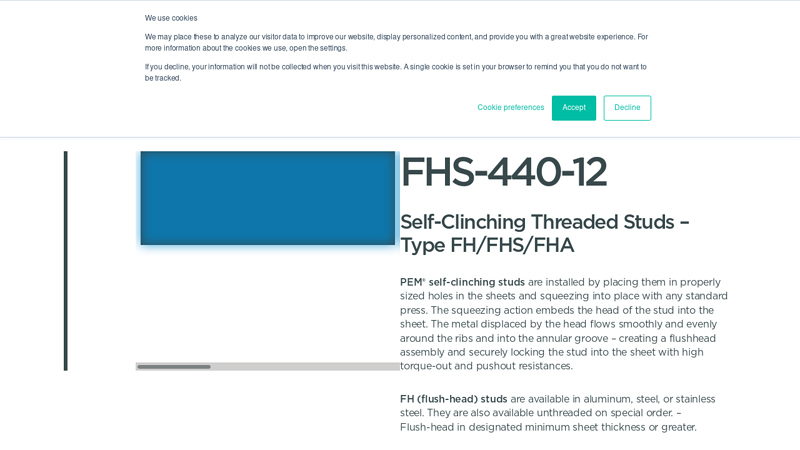

#5 FHS

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM self-clinching studs are installed by placing them in properly sized holes in the sheets and squeezing into place with any standard press….

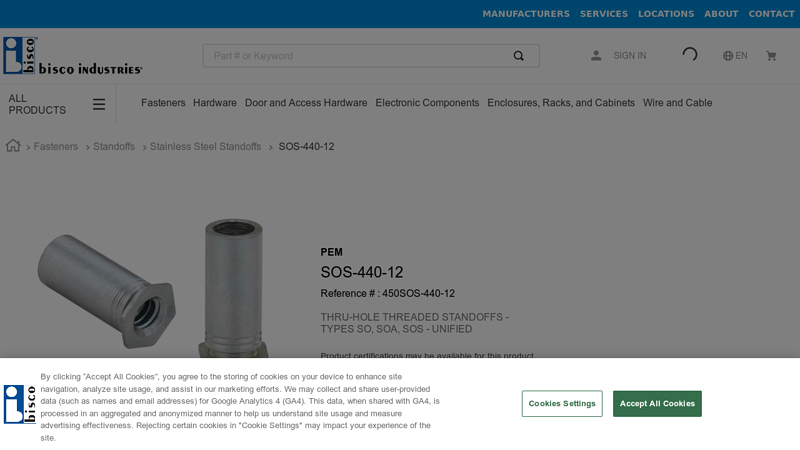

#6 SOS-440-12

Domain Est. 1996

Website: biscoind.com

Key Highlights: In stock $48.55 deliverySOS-440-12. Reference # : 450SOS-440-12. Product … *Non-stock pricing and lead time may be subject to change based on manufacturing availability….

#7 PEM SOS

Domain Est. 2000

Website: appianfasteners.com

Key Highlights: Type SO through hole, threaded self-clinching standoffs are used for the attachment and spacing of panels, boards or components where a flush open end is ……

#8 UA 440

Domain Est. 2002

Website: ualocal440.org

Key Highlights: The Plumbers, Steamfitters & HVACR Service Technicians Local 440 J.A.T.C. is now accepting applications to their Apprenticeship Program on a Year-Round Basis….

#9 Town of Grand Chute, WI Sewers

Domain Est. 2008

Website: ecode360.com

Key Highlights: § 440-12 Sewer main assessment procedure. § 440-13 Reimbursement to Sanitary District for ……

Expert Sourcing Insights for 440/12

H2: 2026 Market Trends for 440/12

As of 2026, the market for 440/12 — commonly interpreted as a steel grade (AISI 440C) in a 12% chromium configuration or potentially a product code in niche industrial sectors — reflects evolving demand driven by advancements in material science, manufacturing efficiency, and sector-specific applications. Below is an analysis of key trends shaping the 440/12 market landscape in 2026:

-

Increased Demand in Precision Engineering

The high hardness and wear resistance of 440C stainless steel (often referenced in 440/12 contexts) continue to make it a preferred material in precision bearings, valve components, and cutting tools. In 2026, demand is rising in aerospace, medical devices, and high-performance automotive applications, where reliability under stress and corrosion resistance are critical. -

Growth in Medical and Surgical Instrumentation

The 440/12 designation is frequently associated with high-carbon martensitic stainless steels used in surgical tools and dental instruments. With global healthcare modernization and increased elective procedures post-pandemic, the medical sector is a key growth driver. Manufacturers are investing in cleaner melting processes and tighter tolerance controls to meet ISO and FDA standards. -

Shift Toward Sustainable and Recyclable Materials

Environmental regulations in Europe and North America are pushing producers to adopt greener production methods. The 440/12 steel market is responding with increased use of electric arc furnaces (EAFs) and recycled scrap inputs. In 2026, certifications like EPD (Environmental Product Declarations) are becoming standard, influencing procurement decisions. -

Competition from Alternative Alloys

While 440C remains popular, newer high-performance alloys such as 440V, CPM-20CV, and ceramic composites are gaining ground, especially in consumer knives and high-end industrial tools. These materials offer superior edge retention and toughness, pressuring traditional 440/12 producers to innovate or specialize. -

Geopolitical and Supply Chain Dynamics

China remains a dominant producer of stainless steel, including 440-series grades. However, in 2026, trade policies, export tariffs, and raw material (chromium, molybdenum) availability are creating volatility. Companies are diversifying sourcing to India, South Korea, and Southeast Asia to mitigate risks. -

Digitalization and Smart Manufacturing Integration

Industry 4.0 technologies are optimizing the production and quality control of 440/12 components. Predictive maintenance, AI-driven metallurgical analysis, and real-time monitoring of heat treatment processes are improving yield rates and consistency, reducing waste and costs. -

Emerging Markets Driving Volume Growth

In regions like Southeast Asia, India, and Latin America, expanding industrialization and infrastructure projects are increasing demand for durable, cost-effective tool steels. While high-end applications still favor Western or Japanese steel, mid-tier 440/12 products are seeing strong adoption in machinery and automotive repair sectors.

Conclusion:

By 2026, the 440/12 market is characterized by steady, specialized demand rather than explosive growth. Success hinges on differentiation through quality, sustainability, and application-specific engineering. Producers who adapt to regulatory shifts, embrace digital manufacturing, and target high-value niches are best positioned to thrive.

Common Pitfalls When Sourcing 440/12 (Quality, IP)

Sourcing materials like 440/12—a designation that may refer to a specific grade or specification in industries such as steel, textiles, or composites—can present significant challenges, especially concerning quality assurance and intellectual property (IP) protection. Failing to address these pitfalls can result in substandard products, legal disputes, or supply chain disruptions.

Poor Quality Control and Inconsistent Specifications

One of the most frequent issues when sourcing 440/12 is variability in material quality. Suppliers may claim compliance with the specification, but actual batches can deviate in critical properties such as tensile strength, chemical composition, or surface finish. This inconsistency often arises from lack of standardized manufacturing processes, inadequate testing, or use of subpar raw materials. Without rigorous third-party certification or on-site audits, buyers risk receiving non-conforming products that compromise end-product performance.

Misrepresentation of Material Certification

Suppliers may provide falsified or inaccurate mill test certificates (MTCs) or material compliance documents. This misrepresentation can make it appear that the 440/12 material meets required standards when it does not. Relying solely on paperwork without independent verification—such as spectrographic analysis or mechanical testing—can expose companies to safety risks and regulatory non-compliance, particularly in highly regulated sectors like aerospace or medical devices.

Lack of Traceability and Supply Chain Opacity

Many sourcing channels, especially in global markets, lack full traceability from raw material to finished product. This opacity increases the risk of counterfeit or recycled materials being passed off as virgin 440/12. Without clear chain-of-custody documentation, it becomes difficult to validate authenticity or respond effectively to quality failures or recalls.

Intellectual Property Infringement Risks

When sourcing proprietary or patented materials designated as 440/12, there is a risk of inadvertently purchasing from unauthorized manufacturers or counterfeiters. Unauthorized production may violate IP rights held by the original developer or licensor. Buyers who integrate such materials into their products can face legal liability, product seizures, or reputational damage—even if unaware of the infringement.

Inadequate Supplier Due Diligence

Rushing the supplier selection process without thorough vetting increases exposure to both quality and IP risks. Many companies fail to assess a supplier’s manufacturing capabilities, compliance history, or legal standing. Without contractual safeguards—such as warranties, indemnification clauses, or audit rights—buyers have limited recourse when issues arise.

Insufficient Contractual Protections

Sourcing agreements that lack clear specifications, quality benchmarks, IP indemnification, or confidentiality clauses leave buyers vulnerable. Ambiguities in the contract can lead to disputes over material suitability or ownership of modifications. Ensuring that contracts explicitly define compliance with 440/12 standards and allocate IP responsibilities is essential for risk mitigation.

Geographic and Regulatory Compliance Gaps

Sourcing from regions with weak regulatory enforcement or differing standards may result in materials that do not meet international requirements (e.g., REACH, RoHS). Even if locally labeled as 440/12, the material might not satisfy the technical or environmental criteria expected in the buyer’s market, leading to import denials or compliance penalties.

Avoiding these pitfalls requires a proactive sourcing strategy that combines technical validation, legal diligence, and ongoing supplier management.

Logistics & Compliance Guide for 440/12

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and regulatory adherence related to product or material designated as 440/12. Specific details may vary depending on the nature of 440/12 (e.g., industrial component, chemical substance, electronic module); ensure alignment with your organization’s classification and applicable regulations.

Regulatory Classification and Documentation

Identify and confirm the official classification of item 440/12 under relevant regulatory frameworks. This includes determining its HTS (Harmonized Tariff Schedule) code for import/export, UN number (if applicable), and any hazardous material designation (e.g., under DOT, IATA, IMDG, or ADR). Maintain accurate shipping descriptions, safety data sheets (SDS), and compliance certifications. All documentation must reflect the correct nomenclature and specifications to avoid customs delays or penalties.

Packaging and Labeling Requirements

Ensure packaging for 440/12 complies with industry standards and transportation regulations. Use durable, sealed containers appropriate for the item’s weight, dimensions, and sensitivity. Apply required labels, including but not limited to: handling instructions (e.g., “Fragile,” “This Side Up”), hazard labels (if applicable), barcodes, and shipment identifiers. Labeling must be legible, weather-resistant, and affixed securely to each unit or pallet.

Transportation and Carrier Compliance

Select carriers certified to transport goods of this type, especially if 440/12 is subject to temperature control, shock sensitivity, or hazardous material rules. Confirm that carriers adhere to relevant transport regulations (e.g., IATA for air freight, FMCSA for U.S. road transport). Provide carriers with proper shipping papers, emergency response information, and advance notifications where required. Track shipments in real time and validate delivery against purchase orders or contracts.

Import/Export Controls and Duties

Verify that the shipment of 440/12 complies with export control regulations such as EAR (Export Administration Regulations) or ITAR, if applicable. Determine duty rates, eligibility for trade agreements (e.g., USMCA), and required import licenses. Submit accurate Electronic Export Information (EEI) via AES (Automated Export System) when required. Coordinate with customs brokers to ensure smooth clearance at destination ports.

Storage and Handling Protocols

Designate appropriate storage conditions for 440/12 based on environmental requirements (e.g., temperature, humidity, ventilation). Implement FIFO (First In, First Out) inventory practices where applicable. Train warehouse personnel on safe handling procedures, including use of PPE and material-specific precautions. Conduct regular audits to ensure compliance with internal SOPs and external safety standards.

Recordkeeping and Auditing

Maintain comprehensive records for a minimum of five years, including shipping manifests, customs documentation, SDS, compliance certificates, and audit trails. These records support regulatory audits and incident investigations. Conduct periodic internal compliance reviews to identify gaps and implement corrective actions promptly.

Incident Response and Non-Compliance Management

Establish a response plan for logistics incidents involving 440/12, such as spills, damage, or customs detention. Define roles, reporting procedures, and communication protocols with regulators and stakeholders. Document all incidents and implement preventive measures to reduce recurrence. Report violations to relevant authorities as required by law.

Training and Compliance Awareness

Provide regular training for logistics, procurement, and operations staff on the specific requirements related to 440/12. Include updates on regulatory changes, proper documentation practices, and emergency procedures. Maintain training records to demonstrate due diligence in compliance efforts.

Ensure this guide is reviewed and updated annually or whenever regulatory changes occur or operational processes are modified.

A conclusion for sourcing 440/12 (which commonly refers to a material specification such as AISI 440C stainless steel in a 12mm diameter bar or rod) could be structured as follows:

Conclusion:

After a comprehensive evaluation of potential suppliers and market availability, sourcing AISI 440C stainless steel in a 12mm diameter (440/12) is feasible from multiple reputable vendors specializing in high-performance alloy steels. The material meets the required specifications for high hardness, wear resistance, and moderate corrosion resistance, making it suitable for applications such as bearings, cutting tools, and surgical instruments. Key considerations in the sourcing decision include material certification (preferably with mill test reports), adherence to international standards (e.g., ASTM A276/A582), and supply chain reliability. While pricing varies across suppliers, local and regional vendors offer competitive lead times and logistical advantages. It is recommended to establish long-term agreements with qualified suppliers to ensure consistent quality and supply continuity. Future procurement strategies should include periodic audits and performance reviews to maintain material integrity and operational efficiency.