The global HVACR equipment market is experiencing steady expansion, driven by rising demand for climate control solutions across residential, commercial, and industrial sectors. According to a report by Mordor Intelligence, the global HVAC market was valued at USD 131.78 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2024 to 2029. A critical component within this ecosystem is the 410A refrigerant pressure gauge, essential for safe and efficient servicing of air conditioning systems using R-410A refrigerant—a popular, environmentally compliant alternative to older refrigerants. As environmental regulations tighten and the adoption of high-efficiency HVAC systems increases, the demand for reliable 410A gauges continues to rise. With North America and Asia-Pacific leading in HVAC installations, key manufacturers are innovating to meet precision, durability, and smart connectivity demands. This growing market momentum underscores the importance of identifying the top 5 manufacturers leading in quality, performance, and technological advancement in 410A AC gauge production.

Top 5 410 Ac Gauges Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

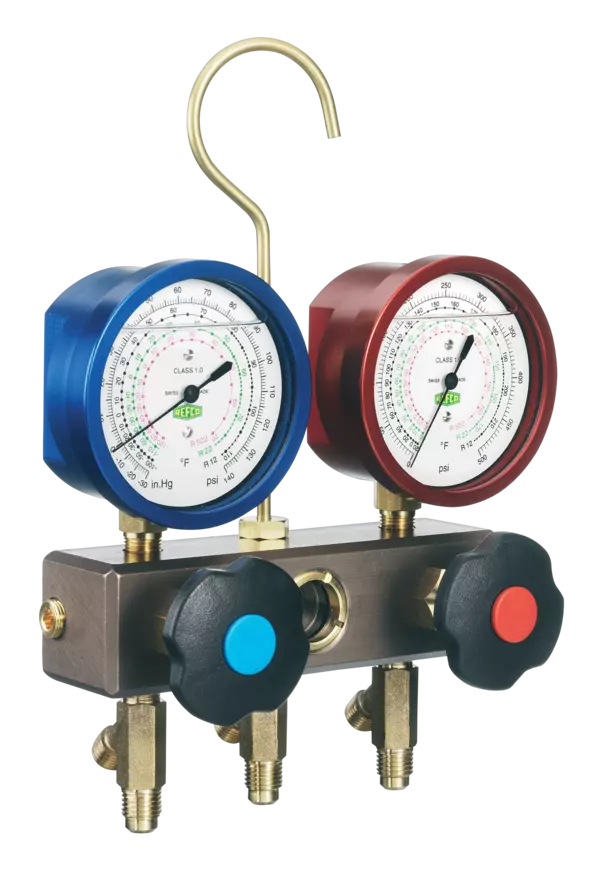

#1 M2-500-F-R410A

Domain Est. 2001

Website: refcoswiss.com

Key Highlights: M2-500-F-R410A · Class 1.6 accuracy · Zero point adjustable · Pulse free · Gauge internals are all brass, no plastic ……

#2 Manifold Gauge Sets, Air Conditioning & Refrigeration Tools

Domain Est. 2003

Website: imperialsupplies.com

Key Highlights: Free delivery over $400 365-day returnsLooking for Manifold Gauge Sets? Imperial Supplies has a large selection on hand, at incredible prices. Shop now to stock up and save….

#3 Manifold Gauges and Hoses

Domain Est. 2009

Website: hilmor.com

Key Highlights: Discover hilmor HVAC manifold gauges for accurate system pressure readings. Durable, precise, and built for reliable performance in HVAC applications….

#4 Elitech DMG

Domain Est. 2015

Website: elitechus.com

Key Highlights: Key Features: Professional Design: 3-Ways Air conditioning diagnostic manifold gauge set for R134A R12 R22 and R410A refrigerants. Designed for AC charging, ……

#5 Aprvtio AMF

Domain Est. 2017

Website: thermelc.com

Key Highlights: 6–10 day deliveryThe ac manifold gauge set has various functions such as dual pressure test, Evaporation(EV) & Condensation(CO) temperature display, vacuum pressure test, ……

Expert Sourcing Insights for 410 Ac Gauges

H2: 2026 Market Trends for 410A AC Gauges

The market for R-410A air conditioning (AC) gauges is undergoing significant transformation as the industry shifts toward more environmentally sustainable refrigerants and advanced diagnostic technologies. While R-410A has been a dominant refrigerant in residential and commercial HVAC systems for over two decades, upcoming regulatory changes and technological innovations are shaping the demand and functionality of R-410A-compatible gauges through 2026.

1. Declining Use of R-410A Refrigerant

By 2026, the use of R-410A is expected to continue its gradual phase-down in many regions, particularly in the United States and the European Union, due to its high Global Warming Potential (GWP). The Environmental Protection Agency (EPA) and international agreements such as the Kigali Amendment to the Montreal Protocol are accelerating the transition to lower-GWP alternatives like R-32 and R-454B. As a result, the long-term demand for R-410A-specific tools, including gauges, may plateau or decline after 2026, especially in new installations.

2. Sustained Demand for Retrofit and Service Applications

Despite the phase-down, millions of R-410A-based HVAC systems will remain in operation through 2026 and beyond. This creates sustained demand for service, maintenance, and repair tools—particularly R-410A AC gauges. HVAC technicians will continue to require accurate, durable gauges compatible with R-410A’s high operating pressures (up to 600 psi), ensuring that the market remains active in the service and aftermarket sectors.

3. Integration of Digital and Smart Technologies

A key trend in 2026 is the increasing adoption of digital manifold gauges and smart diagnostic tools. Modern 410A AC gauges are integrating Bluetooth connectivity, mobile app integration, real-time data logging, and automatic pressure-to-temperature conversion. These smart gauges improve accuracy, reduce human error, and streamline diagnostics. Brands like Fieldpiece, Inficon, and Fluke are leading innovation in this space, offering hybrid tools compatible with both R-410A and next-generation refrigerants.

4. Emphasis on Precision and Safety

With R-410A operating at higher pressures than older refrigerants like R-22, safety and precision are paramount. In 2026, manufacturers are focusing on ruggedized designs, overpressure protection, and improved hose durability. Gauges are being built with larger, backlit LCDs for better readability and ergonomic designs to reduce technician fatigue during prolonged use.

5. Training and Certification Influence

As the industry transitions, HVAC training programs are placing greater emphasis on proper tool use, refrigerant handling, and environmental compliance. This is increasing demand for educational-grade 410A gauges and kits that support hands-on learning for next-generation technicians, even as they prepare for newer refrigerants.

6. Regional Market Variations

In developing markets, where R-410A systems are still being widely installed, demand for compatible gauges remains strong. Conversely, in mature markets like North America and Western Europe, the focus is shifting toward multi-refrigerant gauges that support both R-410A and newer alternatives, reducing the need for technicians to carry multiple tool sets.

Conclusion

While the long-term future of R-410A is limited due to environmental regulations, the 2026 market for 410A AC gauges remains robust in the service and repair segment. The trend is shifting from basic analog tools to advanced digital systems that offer compatibility, precision, and connectivity. Manufacturers who adapt by offering multi-refrigerant support and smart features are likely to maintain a competitive edge as the HVAC industry evolves.

Common Pitfalls When Sourcing 410A AC Gauges (Quality, IP)

Sourcing reliable 410A AC manifold gauges is critical for HVAC technicians to ensure accurate system diagnostics, safety, and compliance. However, several common pitfalls related to quality and incorrect refrigerant identification (IP—Incorrect Product) can compromise performance and safety.

Poor Build Quality and Material Defects

Many low-cost 410A gauges on the market use substandard materials such as brittle plastics, thin brass, or poorly machined valves. These components are prone to cracking, leaking, or failing under the high operating pressures of R-410A systems (which can exceed 500 psi). Poor seals and O-rings degrade quickly, leading to refrigerant leaks and inaccurate pressure readings.

Consequence: Risk of equipment damage, inaccurate diagnostics, safety hazards, and increased long-term costs due to frequent replacements.

Inaccurate Pressure Readings and Calibration Issues

Low-quality gauges often lack proper factory calibration or drift over time without recalibration features. Units may not be rated for the high pressures of R-410A or may display inconsistent readings across multiple uses.

Consequence: Misdiagnosis of system performance, incorrect charging, and potential compressor damage due to over- or under-pressurization.

Confusion with R-22 Gauges (IP – Incorrect Product)

One of the most dangerous pitfalls is accidentally sourcing or using R-22 (blue/yellow) gauges for R-410A systems. R-22 gauges are typically rated for lower pressures (up to 500 psi) and may not safely handle R-410A’s higher operating pressures. Additionally, color-coding mix-ups (e.g., blue for suction, red for discharge) can lead to cross-contamination if hoses are misconnected.

Consequence: Catastrophic gauge failure, refrigerant leaks, personal injury, and system contamination due to mixing refrigerants or lubricants.

Lack of Proper High-Pressure Safety Features

Some inferior gauges lack essential safety mechanisms such as over-pressure relief valves or reinforced hose braiding. R-410A systems operate at significantly higher pressures than older refrigerants, requiring robust design to prevent hose bursts or valve blowouts.

Consequence: Increased risk of injury from sudden pressure release and damage to service equipment.

Non-Compliance with Industry Standards

Not all gauges meet current HVAC standards (e.g., ASHRAE, SAE J2744). Gauges that lack proper certification may not be compatible with modern refrigerants or approved for use in regulated environments.

Consequence: Voided warranties, non-compliance with local regulations, and liability issues during inspections or insurance claims.

How to Avoid These Pitfalls

- Verify Pressure Ratings: Ensure gauges are specifically rated for R-410A (typically 800 psi or higher on the high side).

- Check Color Coding: Confirm red (high-side) and blue (low-side) hoses and gauges are correctly labeled and matched to R-410A.

- Purchase from Reputable Suppliers: Buy from trusted HVAC equipment brands (e.g., Fieldpiece, Yellow Jacket, Mastercool) with verifiable quality control.

- Inspect Build Quality: Look for all-metal construction, durable hoses with reinforced braiding, and smooth, leak-free valve operation.

- Calibration Certification: Choose gauges that come with calibration certificates or are field-calibratable.

Avoiding these common pitfalls ensures reliable, safe, and accurate servicing of R-410A systems, protecting both technicians and equipment.

Logistics & Compliance Guide for 410A AC Gauges

This guide outlines the essential logistics considerations and compliance requirements for handling, transporting, and using 410A AC gauges—tools specifically designed for measuring pressures in HVAC systems utilizing R-410A refrigerant. Adherence to these guidelines ensures safety, regulatory compliance, and equipment longevity.

Regulatory Compliance Requirements

Compliance with environmental, safety, and industry regulations is mandatory when working with R-410A refrigerant and associated tools like AC gauges. Key compliance areas include:

-

EPA Section 608 Regulations (U.S.): Technicians must be certified under EPA Section 608 to handle appliances containing R-410A. While the gauges themselves don’t require certification, their use in systems containing regulated refrigerants means only certified personnel should operate them. Proper recovery and leak prevention practices are required during gauge attachment and removal.

-

Refrigerant Handling Standards (ASHRAE 15 & ISO 5149): AC gauges used with R-410A must meet pressure and material compatibility standards defined in ASHRAE 15 and ISO 5149. Gauges should be rated for high-pressure applications (R-410A operates at approximately 50–70% higher pressures than R-22) and designed to prevent cross-contamination with other refrigerants.

-

Pressure Equipment Directive (PED) – EU Compliance: In European markets, AC gauges may fall under the Pressure Equipment Directive (2014/68/EU) if they are part of a pressurized system. Manufacturers must CE mark compliant gauges and provide technical documentation demonstrating conformity.

-

RoHS and REACH Compliance: Gauges containing electronic components or certain materials must comply with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, particularly for export to the EU.

Transportation & Handling Logistics

Proper logistics planning ensures that 410A AC gauges remain accurate, safe, and undamaged during shipping and field use.

-

Packaging Standards: Gauges should be shipped in rugged, shock-resistant cases with custom foam inserts to prevent movement. Include desiccant packs to control moisture, especially for analog gauges with brass internals susceptible to corrosion.

-

Temperature and Humidity Control: Avoid exposing gauges to extreme temperatures (below -20°C or above 60°C) or high humidity during transport and storage. Prolonged exposure can damage internal mechanisms and calibration.

-

Hazardous Materials Considerations: While the gauges themselves are not classified as hazardous, any attached hoses containing residual refrigerant may be subject to hazardous material (hazmat) shipping regulations. Always evacuate and purge hoses before transport.

-

Import/Export Documentation: For international shipments, ensure compliance with local customs regulations. Required documentation may include commercial invoices, packing lists, and certificates of conformity (e.g., CE, RoHS). Verify tariff codes (HS codes) for pressure measurement instruments (e.g., 9026.20 for pressure gauges).

Calibration & Maintenance Compliance

Regular calibration and maintenance are critical for accurate readings and regulatory adherence.

-

Calibration Frequency: Calibrate 410A AC gauges at least annually or per manufacturer recommendations. More frequent calibration may be required in high-use or harsh environments. Maintain a calibration log for audit purposes.

-

Traceable Certification: Use accredited calibration services that provide NIST-traceable certificates. This documentation is often required for compliance audits and quality assurance programs.

-

Leak Testing: Periodically inspect gauge sets and hoses for leaks using electronic leak detectors or soap solutions. Leaks compromise system integrity and may violate environmental regulations.

-

Refrigerant Separation: Never use the same gauge set for R-410A and other refrigerants (e.g., R-22 or R-134a). Cross-contamination can damage equipment and systems. Label gauges clearly and use dedicated sets.

Training & Documentation

Personnel must be properly trained, and records must be maintained to demonstrate compliance.

-

Technician Certification: Ensure all users hold valid EPA 608 Type II or Universal certification (in the U.S.) or equivalent local credentials.

-

Equipment Logs: Maintain records for each gauge set, including purchase date, calibration history, repair logs, and assigned technician.

-

Safety Data & Manuals: Provide access to Safety Data Sheets (SDS) for any cleaning agents used on gauges and retain manufacturer operation manuals for reference.

By following this logistics and compliance guide, organizations can ensure the safe, legal, and efficient use of 410A AC gauges across HVAC operations.

In conclusion, sourcing 410A AC pressure gauges requires careful consideration of accuracy, durability, compatibility, and compliance with industry standards. It is essential to select gauges specifically calibrated for R-410A refrigerant due to its higher operating pressures compared to other refrigerants. Opting for high-quality, reliable brands ensures accurate readings, enhances technician safety, and supports efficient system maintenance and troubleshooting. Additionally, considering features such as dual pressure measurement (PSI and bar), ergonomic design, and durable hoses can improve usability and longevity. Whether purchasing new or sourcing used equipment, verifying calibration and functionality is crucial. Overall, investing in the right 410A AC gauges contributes to professional service quality, regulatory compliance, and long-term cost savings in HVAC operations.