The global carburetor market is witnessing steady demand, particularly in off-road vehicles, small engines, and legacy engine applications, despite the broader shift toward fuel injection systems. According to Grand View Research, the global carburetor market was valued at approximately USD 3.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 3.4% from 2023 to 2030, driven by ongoing use in motorcycles, lawn equipment, and agricultural machinery. Complementing this, Mordor Intelligence forecasts sustained regional demand in Asia-Pacific and Latin America, where cost-effective engine solutions remain pivotal across two-wheelers and small-displacement engines. Amid this landscape, the 400Ex carburetor—a popular choice for high-performance ATV and motorcycle modifications—has carved a niche segment characterized by precision tuning, aftermarket demand, and compatibility with performance upgrades. As consumer preference shifts toward reliable, high-output aftermarket components, a select group of manufacturers have emerged as leaders in engineering, scalability, and product consistency. Based on market presence, customer reviews, technical innovation, and distribution reach, the following six companies represent the top manufacturers of 400Ex carburetors shaping the performance small-engine ecosystem today.

Top 6 400Ex Carburetor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 carburetor

Domain Est. 2000

Website: motosport.com

Key Highlights: Free delivery over $79 · 90-day returnsEnjoy our everyday low prices on 2007 Honda TRX400EX OEM ATV parts. Buy with MotoSport and save up to 40% and get free shipping on orders ov…

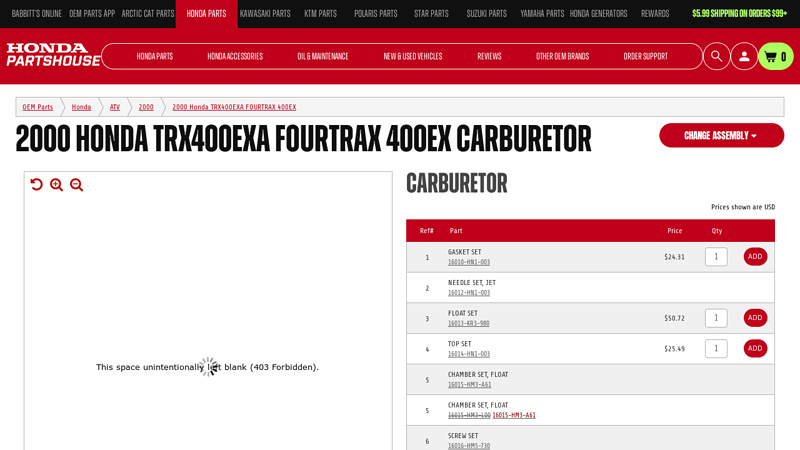

#2 2000 Honda TRX400EXA FOURTRAX 400EX Carburetor

Domain Est. 2007

Website: hondapartshouse.com

Key Highlights: Shop online for OEM Carburetor parts that fit your 2000 Honda TRX400EXA FOURTRAX 400EX, search all our OEM Parts or call at (231)737-4542….

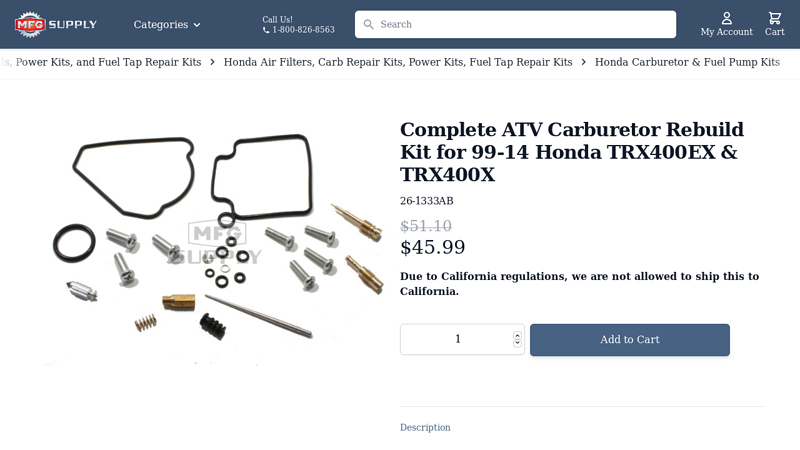

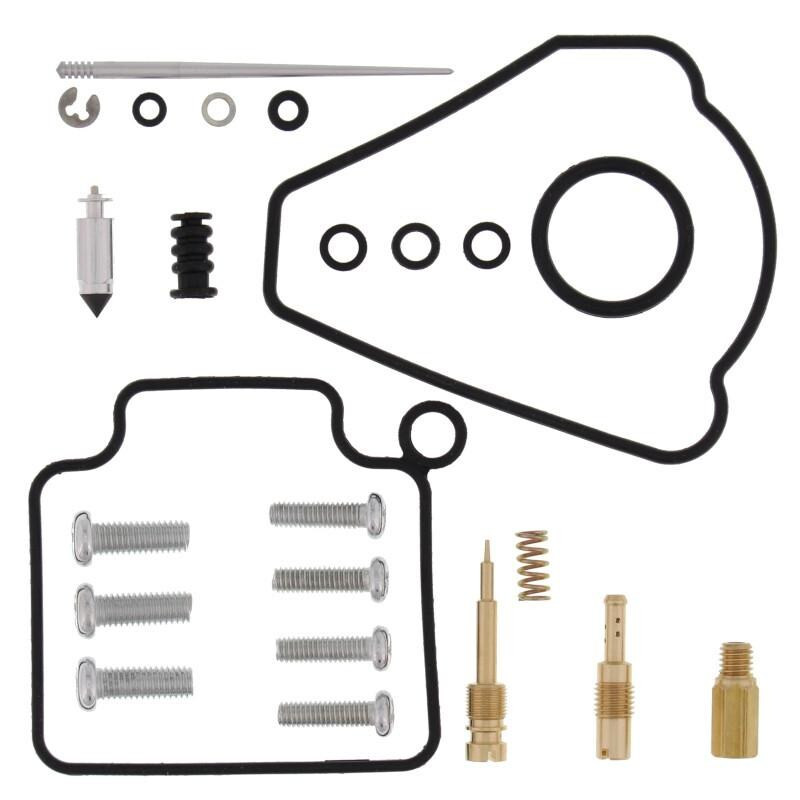

#3 Complete ATV Carburetor Rebuild Kit for 99

Domain Est. 1996

Website: mfgsupply.com

Key Highlights: In stock Rating 4.4 287 Complete ATV Carburetor Rebuild Kit for 99-14 Honda TRX400EX & TRX400X. 26-1333AB. $51.10 $45.99. Due to California regulations, we are not allowed to shi…

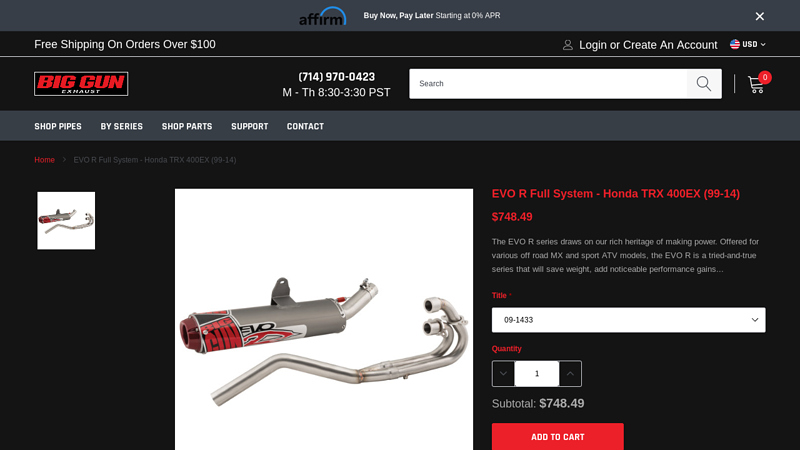

#4 EVO R Full System

Domain Est. 1998

Website: biggunexhaust.com

Key Highlights: The EVO R is a tried-and-true series that will save weight, add noticeable performance gains and sound tremendously better than stock….

#5 All Balls Racing 99

Domain Est. 2009

Website: utvsource.com

Key Highlights: In stock Rating 4.4 287 Revitalize your Honda TRX400EX carburetor with the All Balls Racing Carburetor Rebuild Kit (26-1333). Comprehensive and expertly crafted for peak ATV ……

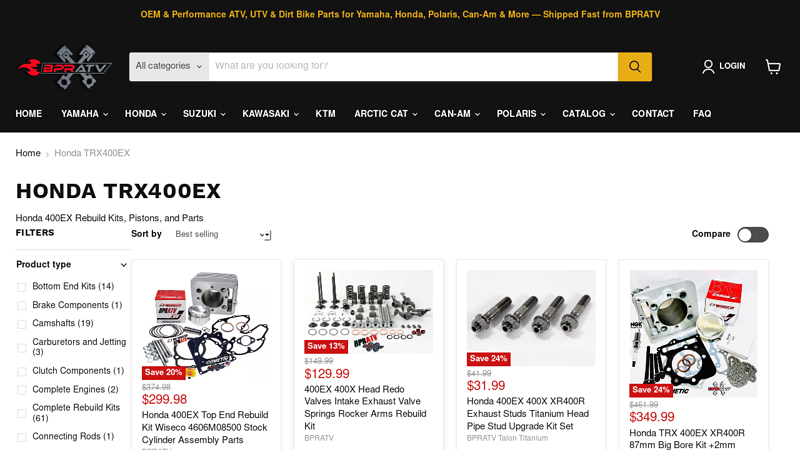

#6 Honda TRX400EX

Domain Est. 2019

Website: bpratv.com

Key Highlights: 6–7 day delivery 30-day returnsHonda 400EX Stock Carb Kit 400X Replacement Carburetor Set Intake Filter Cable · BPRATV….

Expert Sourcing Insights for 400Ex Carburetor

H2: 2026 Market Trends for 400EX Carburetor

As the powersports and off-road vehicle market evolves toward electrification and stricter emissions regulations, the demand for traditional carbureted components like the 400EX carburetor is undergoing a strategic shift. However, the 400EX carburetor—originally designed for the Honda 400EX ATV—remains relevant in 2026 due to several key market dynamics.

1. Niche Aftermarket Demand Remains Strong

Despite declining OEM use of carburetors, the 400EX carburetor continues to see robust demand in the aftermarket sector. Enthusiasts restoring or maintaining older Honda 400EX ATVs (produced from 1999–2009) rely on replacement and performance carburetors. In 2026, this classic ATV maintains a loyal following, particularly in trail riding, racing, and DIY modification communities, ensuring steady aftermarket sales.

2. Performance Upgrades and Customization

The 400EX carburetor is frequently modified or replaced with high-performance alternatives (e.g., Keihin or aftermarket billet carburetors) to improve throttle response, fuel delivery, and power output. In 2026, the trend toward ATV customization—especially in youth and intermediate off-road racing—drives demand for tuned carburetion systems. Vendors are responding with pre-jetted, plug-and-play carburetor kits tailored for modified engines.

3. Global Regional Disparities in Demand

In North America and Europe, emissions regulations have largely phased out carbureted vehicles in new models, limiting growth. However, in emerging markets across Latin America, Southeast Asia, and Africa, carbureted ATVs remain popular due to lower costs and easier maintenance. This sustains international demand for 400EX-compatible carburetors, especially in rural utility and agricultural applications.

4. Competition from Fuel Injection Retrofits

A notable trend in 2026 is the rise of fuel injection (EFI) conversion kits for carbureted ATVs. These systems offer better fuel efficiency, cold-start reliability, and emissions compliance. While this poses a threat to carburetor sales, it also creates a hybrid market where users experiment with both systems—temporarily sustaining carburetor demand during transition periods.

5. Supply Chain and Obsolescence Challenges

Original OEM parts for the 400EX carburetor are increasingly scarce. In response, third-party manufacturers and specialty suppliers dominate the market with compatible replacements. In 2026, these suppliers leverage CNC machining and improved materials to offer durable, drop-in replacements, often with enhanced adjustability.

6. Online Retail and Community Influence

E-commerce platforms (e.g., Amazon, eBay, specialized ATV parts sites) remain the primary distribution channel. YouTube tutorials, forums (e.g., ATVConnection, ThumperTalk), and social media groups heavily influence purchasing decisions. Brands that engage with these communities—offering tech support, tuning guides, and user testimonials—gain competitive advantage.

Conclusion

While the 400EX carburetor is a legacy component in a modern era of fuel injection, its market in 2026 remains viable due to passionate enthusiast communities, global demand for affordable off-road transportation, and strong aftermarket support. Manufacturers and retailers who focus on performance, compatibility, and digital engagement will continue to thrive in this specialized segment.

Common Pitfalls Sourcing a 400EX Carburetor (Quality & Intellectual Property)

Sourcing a replacement carburetor for a Honda 400EX ATV can be fraught with challenges, particularly concerning component quality and intellectual property (IP) issues. Being aware of these pitfalls is crucial to avoid costly mistakes and performance problems.

1. Inferior Quality and Inconsistent Materials

One of the most significant risks when sourcing aftermarket 400EX carburetors is encountering subpar manufacturing quality. Many third-party manufacturers cut corners to offer lower prices, resulting in several performance and reliability issues:

- Poor Material Composition: Low-cost carburetors often use inferior metals or plastics that degrade quickly under heat, vibration, and exposure to fuel and ethanol blends. This can lead to warping, cracking, or internal corrosion.

- Imprecise Machining: Critical components like throttle bores, float bowls, and jet orifices require tight tolerances. Inexpensive units frequently suffer from inconsistent machining, leading to air/fuel mixture imbalances, poor idle, hesitation, or flooding.

- Inadequate Seals and Gaskets: Substandard rubber or composite materials in gaskets and O-rings dry out, harden, or leak prematurely, causing vacuum leaks or fuel seepage.

- Inconsistent Performance: Even within the same brand, quality control can vary drastically between production batches, making reliable performance unpredictable.

2. Intellectual Property (IP) and Design Infringement

Many aftermarket 400EX carburetors are direct copies or “clones” of the original Honda design, which raises serious IP concerns:

- Patent and Trademark Violations: Honda holds patents and trademarks on specific carburetor designs and components. Unauthorized replication infringes on these rights, potentially exposing both the seller and buyer to legal risk, especially in commercial or resale contexts.

- Misleading Branding: Some counterfeit units use logos or model names that closely resemble Honda’s to deceive buyers into believing they are purchasing OEM or licensed parts. This misrepresentation undermines consumer trust and can void warranties.

- Lack of Design Validation: Clone manufacturers often replicate the physical form without fully understanding or testing the engineering principles behind the original. This can result in poor tuning, reduced efficiency, and emissions non-compliance.

3. Compatibility and Calibration Issues

Even if a carburetor physically fits, discrepancies in internal design can cause operational problems:

- Jetting Mismatches: Aftermarket units may come with incorrect main jets, pilot jets, or needle settings, leading to lean or rich conditions that harm engine performance and longevity.

- Venting and Fuel Flow Differences: Variations in bowl vent design or internal passages can affect fuel delivery consistency, especially under different riding conditions or altitudes.

- Throttle Response and Idle Instability: Poorly calibrated linkages or idle circuits result in jerky throttle response or inability to maintain a steady idle.

4. Limited Support and Warranty

Low-cost carburetors often come with minimal or no technical support:

- No Manufacturer Support: If issues arise, clone manufacturers may be unreachable or unwilling to provide troubleshooting assistance.

- Short or Voided Warranties: Warranties may be non-existent or easily voided due to installation or tuning issues, leaving the buyer with no recourse.

Conclusion

When sourcing a 400EX carburetor, prioritize suppliers that offer OEM-certified parts, reputable aftermarket brands with proven quality control, or rebuilt OEM units from trusted sources. Avoid suspiciously cheap options that may compromise on materials or infringe on intellectual property. Investing in a high-quality, legally compliant carburetor ensures better performance, reliability, and long-term value.

H2: Logistics & Compliance Guide for 400Ex Carburetor

This guide outlines the essential logistics and compliance considerations for the shipment, handling, import/export, and regulatory adherence of the 400Ex Carburetor. Ensuring compliance across all stages of distribution is critical for avoiding delays, penalties, and safety issues.

1. Product Classification & Regulatory Overview

- HS Code (Harmonized System Code): 8409.91 (Parts and accessories for engines, carburetors and parts thereof)

- UN Number: Not applicable (non-hazardous when dry and free of fuel residue)

- EPA Compliance: Carburetors must comply with U.S. Environmental Protection Agency (EPA) emission standards if intended for use in off-highway vehicles (e.g., ATVs). The 400Ex model must be certified under 40 CFR Part 85, Subpart D.

- CARB Compliance (California Air Resources Board): Required for sale in California. Verify that the carburetor meets CARB standards for small off-road engines (SORE).

2. Packaging & Handling Requirements

- Packaging: Use sealed, anti-static, and moisture-resistant packaging to prevent damage during transit. Include protective caps on fuel and air intakes.

- Labeling:

- Clearly mark contents as “400Ex Carburetor – Non-Hazardous When Empty”

- Include model number, manufacturer info, and compliance markings (e.g., EPA/CARB certification labels)

- Add handling icons (e.g., “Fragile,” “Do Not Invert”)

- Weight & Dimensions:

- Approximate weight: 1.2 kg (2.6 lbs)

- Packaging size: 20 x 15 x 10 cm (8 x 6 x 4 in)

3. Transportation & Shipping

- Mode of Transport: Suitable for air, sea, and ground freight (non-hazardous classification applies only if completely cleaned of fuel and oil)

- Documentation:

- Commercial Invoice

- Packing List

- Certificate of Origin

- EPA and/or CARB Compliance Certificate (if applicable)

- Export Controls: No ITAR or EAR restrictions apply; however, check destination country regulations for emissions or import restrictions on engine components.

- Incoterms: Recommended use of FOB (Free On Board) or DAP (Delivered At Place), depending on buyer agreement.

4. Import Compliance by Region

- United States:

- CBP (U.S. Customs and Border Protection) clearance required

- EPA Form 3520-1 may be needed for importers of motor vehicle parts

- European Union:

- Compliant with EU Regulation (EU) 2016/1628 for non-road mobile machinery (if applicable)

- CE marking not required for individual carburetor parts, but must fit CE-compliant systems

- Canada:

- Must meet Transport Canada and Environment and Climate Change Canada standards

- HS Code: 8409.91.00.10

5. Inventory & Storage

- Storage Conditions:

- Temperature: 10°C to 30°C (50°F to 86°F)

- Humidity: Below 60% to prevent corrosion

- Store upright and away from direct sunlight or chemical exposure

- Shelf Life: Indefinite if stored properly; inspect seals and gaskets before installation after long-term storage

6. Environmental & Disposal Compliance

- End-of-Life Handling:

- Recycle aluminum and brass components through certified metal recyclers

- Dispose of rubber/plastic parts per local waste regulations

- RoHS Compliance: Confirm that the 400Ex Carburetor meets EU RoHS directives (Restriction of Hazardous Substances) for lead, cadmium, and other restricted materials.

7. Quality Assurance & Traceability

- Each unit must carry a unique serial or batch number for traceability

- Maintain records of compliance testing, calibration, and shipping documentation for a minimum of 5 years

8. Recommended Best Practices

- Conduct pre-shipment inspections to verify cleanliness and packaging integrity

- Train logistics personnel on emissions compliance documentation

- Partner with freight forwarders experienced in automotive parts logistics

For further details on certification or regional import rules, contact your compliance officer or refer to the manufacturer’s technical dossier.

In conclusion, sourcing a carburetor for a 400EX requires careful consideration of compatibility, quality, and reliability. Whether opting for OEM parts, aftermarket alternatives, or used components, it’s essential to verify fitment with your specific model year and engine specifications. Reputable suppliers, positive customer reviews, and comprehensive product listings can help ensure you receive a functional and durable carburetor. Additionally, considering maintenance and tuning needs post-installation will contribute to optimal engine performance. Taking the time to research and select the right carburetor ultimately leads to improved reliability, smoother operation, and a more enjoyable riding experience with your 400EX.