The global trailer wiring market is experiencing steady growth, driven by rising demand for commercial vehicles, advancements in trailer safety technology, and increasing adoption of electric and intelligent towing systems. According to Grand View Research, the global trailer hitch and towing systems market size was valued at USD 11.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030—growth that encompasses critical components like 4-prong trailer wiring systems. As connectivity and safety standards evolve, manufacturers specializing in reliable, durable wiring solutions are gaining momentum. With millions of vehicles on the road requiring compatible, code-compliant electrical connections, 4-prong connectors remain a standard for light-duty towing applications. This growing demand has intensified competition among suppliers to deliver high-performance, weather-resistant, and easy-to-install wiring harnesses. In this landscape, nine manufacturers have distinguished themselves through innovation, quality assurance, and broad market reach—setting the benchmark for performance in the 4-prong trailer wiring segment.

Top 9 4 Prong Trailer Wiring Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 TRAILER PLUGS AND SOCKETS

Domain Est. 1999

Website: roadmasterinc.com

Key Highlights: Roadmaster offers the industry’s most commonly used trailer plugs and sockets. The plugs mate with the sockets in order to connect the electrical circuits….

#2 Trailer Harnesses

Domain Est. 2008

Website: wiring-harness-manufacturer.com

Key Highlights: Our complete wiring harnesses and connectors include 7 Way Molded Connectors and Breakaway Kits with or without a charging system….

#3 Trailer Products

Domain Est. 2009

Website: wiringdepot.com

Key Highlights: Free delivery over $49 10-day returnsWiring Depot can help. We have adapters to connect many common trailer plugs, we offer complete wiring kits to get your vehicle or trailer read…

#4 Peterson: A World

Domain Est. 2021

Website: petersonlightsandharness.com

Key Highlights: Peterson Manufacturing innovates vehicle safety lighting and wiring harness systems that improve performance and reduce operational costs….

#5 4 WAY TRAILER WIRING HARNESS

Domain Est. 1996

#6 4-Way Flat Connectors

Domain Est. 1997

Website: curtmfg.com

Key Highlights: CURT 4-flat wiring connectors feature an industry-standard design, plugging into virtually any universal 4-way flat. We offer male and female plugs and sockets….

#7 Vehicle / Trailer Wiring

Domain Est. 1998

Website: wesbar.com

Key Highlights: Wesbar is a Registered Brand of First Brands Group. Address: 3255 West Hamlin Road Rochester Hills, MI, 48309 800-632-3290…

#8 4 Pin Trailer Harness

Domain Est. 2002

#9 The Ultimate Guide to 4

Domain Est. 2004

Website: ariesautomotive.com

Key Highlights: Learn how to easily install and maintain a 4-wire trailer connector with our comprehensive guide. Perfect for boat, ATV, and utility trailers, this guide ……

Expert Sourcing Insights for 4 Prong Trailer Wiring

H2: 2026 Market Trends for 4 Prong Trailer Wiring

The 4 prong trailer wiring market is expected to experience steady growth and transformation by 2026, driven by increasing demand in the automotive, recreational vehicle (RV), and light-duty towing sectors. This analysis explores key trends shaping the market landscape over the next few years.

1. Rising Demand in Consumer and Commercial Towing

The growing popularity of recreational activities such as camping, boating, and off-roading continues to fuel consumer demand for trailers and compatible towing solutions. Parallel to this, small businesses in construction, landscaping, and agriculture are increasingly relying on light-duty trailers, boosting the need for reliable 4 prong wiring systems. As pickup trucks and SUVs with factory-installed towing packages become more common, the standardization of 4 prong connectors remains critical.

2. Emphasis on Safety and Regulatory Compliance

Regulatory bodies and safety organizations are placing greater focus on trailer lighting and electrical safety. By 2026, stricter enforcement of lighting standards in North America and Europe is expected to drive upgrades in wiring systems, including corrosion-resistant connectors and improved wiring insulation. The 4 prong system—responsible for brake lights, turn signals, and ground—will remain essential for compliance with FMVSS 108 and similar regulations.

3. Integration with Smart Towing Technologies

While 7 prong connectors support additional functions like auxiliary power and reverse lights, the 4 prong system is evolving to integrate with vehicle-based smart towing systems. Automakers are incorporating diagnostics and trailer detection features that rely on the basic 4 prong interface. This trend is expected to increase the demand for high-quality, OEM-compatible 4 prong wiring kits that support data communication between the tow vehicle and trailer.

4. Material and Design Innovation

Manufacturers are investing in durable, weather-resistant materials such as thermoplastic elastomers and UV-stabilized PVC to extend the lifespan of 4 prong wiring harnesses. Plug-and-play designs, modular connectors, and anti-rust coatings are becoming standard features. By 2026, product differentiation will increasingly hinge on reliability, ease of installation, and resistance to environmental stressors.

5. E-Commerce and Aftermarket Expansion

The aftermarket segment is poised for significant growth, supported by online retail platforms and DIY culture. Consumers are increasingly purchasing 4 prong wiring kits directly online, favoring brands that offer clear installation guides, video tutorials, and compatibility tools. This shift is encouraging manufacturers to enhance customer education and provide value-added services alongside their products.

6. Sustainability and Environmental Considerations

Environmental regulations are pushing manufacturers to adopt recyclable materials and reduce hazardous substances in wiring components. By 2026, eco-conscious design principles—such as lead-free soldering and RoHS-compliant insulation—will become industry benchmarks, particularly in Europe and North America.

Conclusion

The 4 prong trailer wiring market in 2026 will be characterized by sustained demand, technological integration, and a focus on durability and safety. While newer, more advanced connectors exist, the 4 prong system remains a cost-effective and reliable solution for basic lighting needs. Companies that innovate in materials, user experience, and compliance will gain a competitive edge in this mature yet evolving segment.

Common Pitfalls When Sourcing 4 Prong Trailer Wiring (Quality & IP Ratings)

When sourcing 4 prong trailer wiring, overlooking key quality and Ingress Protection (IP) factors can lead to poor performance, safety hazards, and premature failure. Here are the most common pitfalls to avoid:

Overlooking IP Rating for Environmental Exposure

One of the most frequent mistakes is selecting wiring or connectors without verifying the appropriate Ingress Protection (IP) rating. Trailers are exposed to rain, road spray, dust, and mud. A low or unspecified IP rating (e.g., less than IP67) may result in water intrusion, causing short circuits, corrosion, and brake or light failures. Always confirm that both the connector and wiring harness are rated for outdoor use—ideally IP67 or higher—to ensure protection against dust and temporary water immersion.

Prioritizing Price Over Build Quality

Choosing the cheapest available 4 prong wiring often means sacrificing durability. Low-cost harnesses may use thin gauge wires, substandard copper, or weak insulation that cracks in extreme temperatures. Poor soldering or crimping in connectors can lead to intermittent connections. Investing in higher-quality wiring with robust strain relief, UV-resistant jacketing, and corrosion-resistant terminals ensures longer service life and safer operation.

Ignoring Compatibility and Pin Configuration

Not all 4 prong connectors follow the same wiring standard (e.g., North American vs. European color codes or pin assignments). Using an incompatible harness can result in incorrect signal routing—such as brake lights activating turn signals. Always verify that the wiring matches your vehicle’s and trailer’s pinout configuration to prevent malfunctions and potential safety issues.

Using Non-Marine or Non-UV-Resistant Components

Standard automotive wiring is often not designed for the harsh conditions trailers face. Without UV-resistant insulation, wires degrade quickly under sunlight, becoming brittle and prone to cracking. Similarly, non-marine-grade connectors corrode faster when exposed to moisture and road salts. Opt for components specifically rated for trailer or marine use to enhance longevity.

Skipping Strain Relief and Secure Mounting

Poor installation practices undermine even high-quality wiring. Failing to use strain relief at connection points puts stress on solder joints and terminals, leading to wire fatigue and breakage. Additionally, not securing the harness along the trailer frame allows it to swing freely, increasing wear and risk of damage. Always use proper clips, grommets, and strain relief boots during installation.

Assuming “Waterproof” Without Verification

Many products are marketed as “waterproof” without meeting standardized IP ratings. This misleading claim can result in inadequate protection. Always look for independently tested and clearly labeled IP ratings rather than relying on promotional language.

Avoiding these pitfalls ensures your 4 prong trailer wiring delivers reliable, safe performance in real-world conditions. Prioritize certified IP ratings, robust construction, and correct compatibility to protect your investment and maintain road safety.

4 Prong Trailer Wiring: Logistics & Compliance Guide

Understanding the logistics and compliance requirements for 4 prong trailer wiring is essential for safe and legal towing operations. This guide outlines the key considerations for proper installation, maintenance, and regulatory adherence.

Understanding the 4 Prong Trailer Wiring System

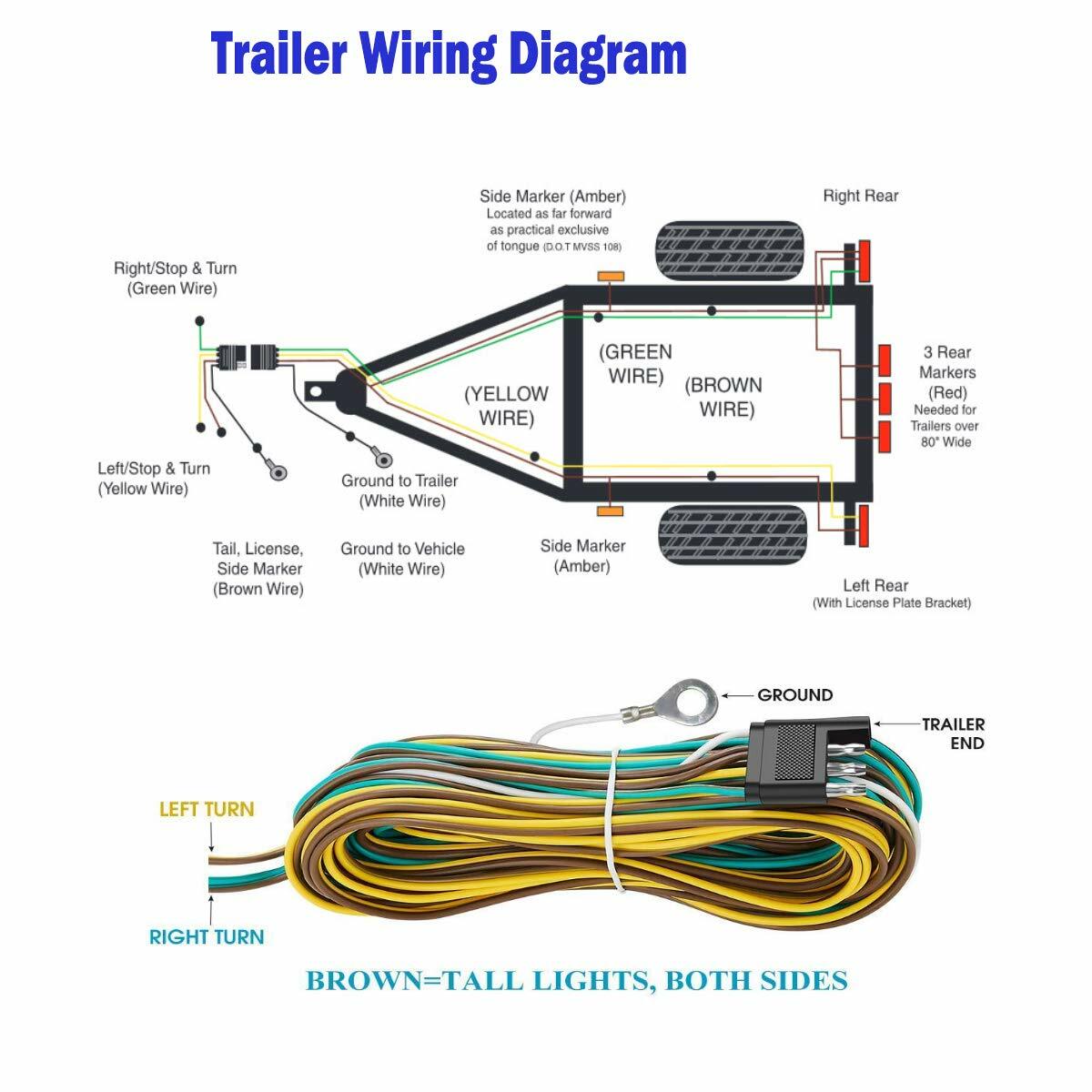

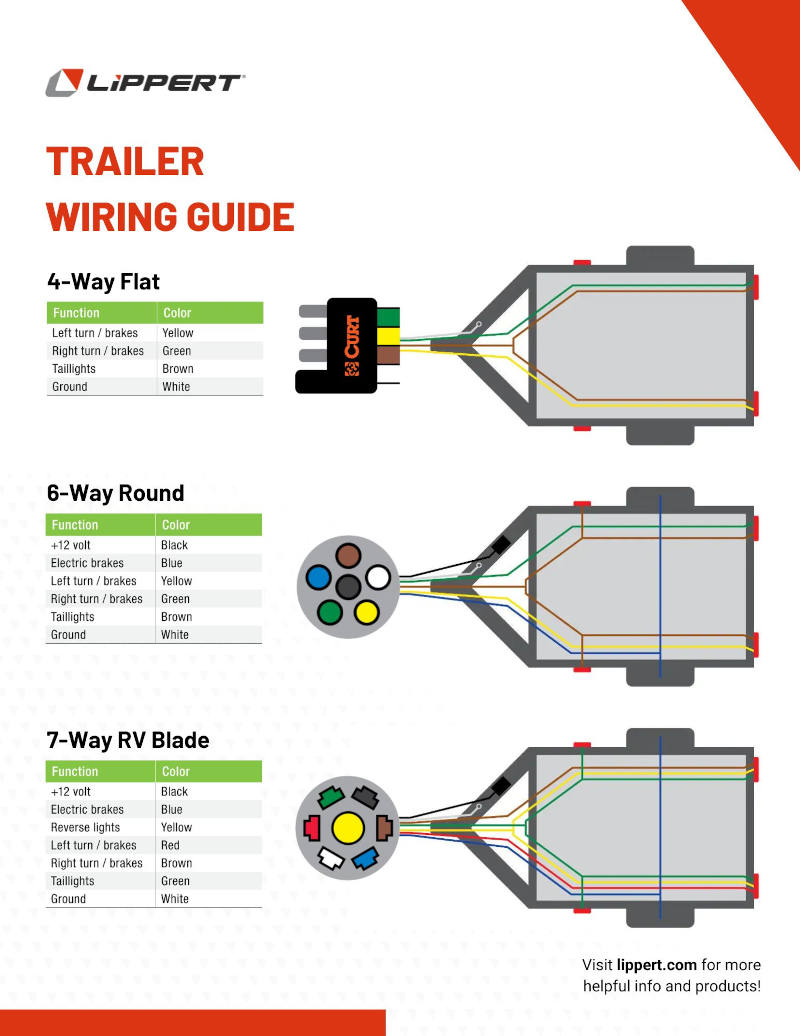

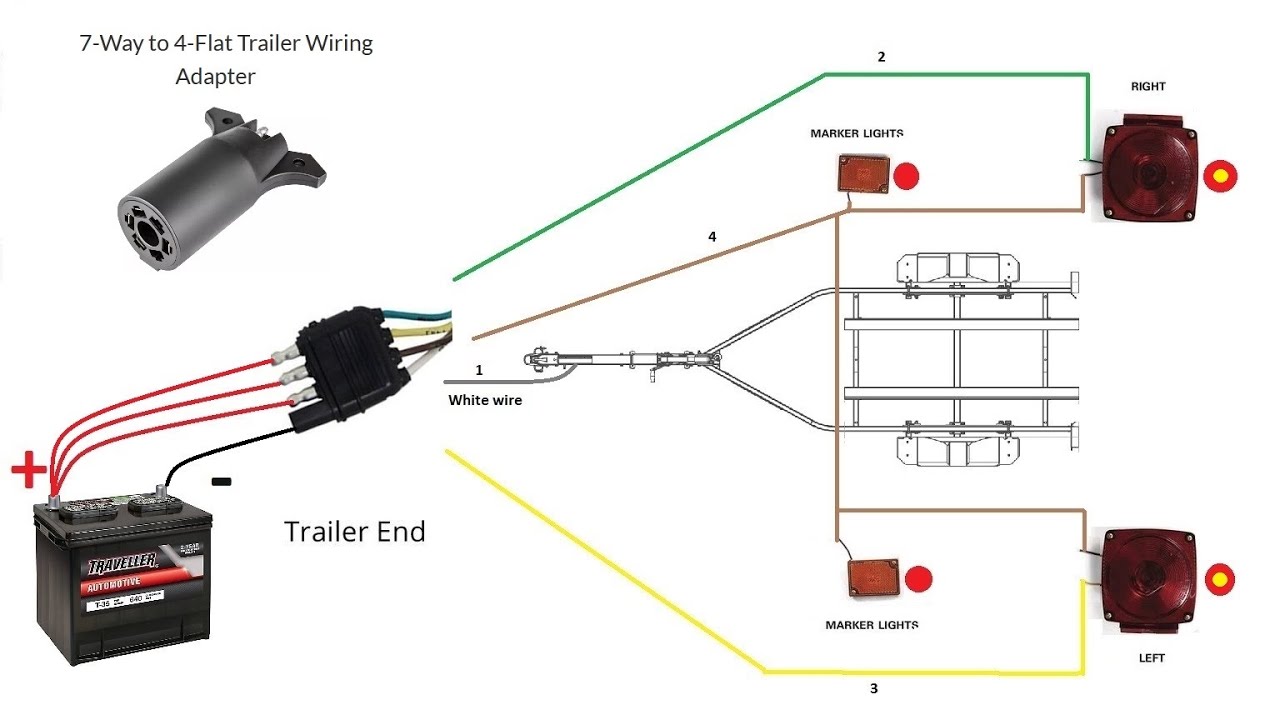

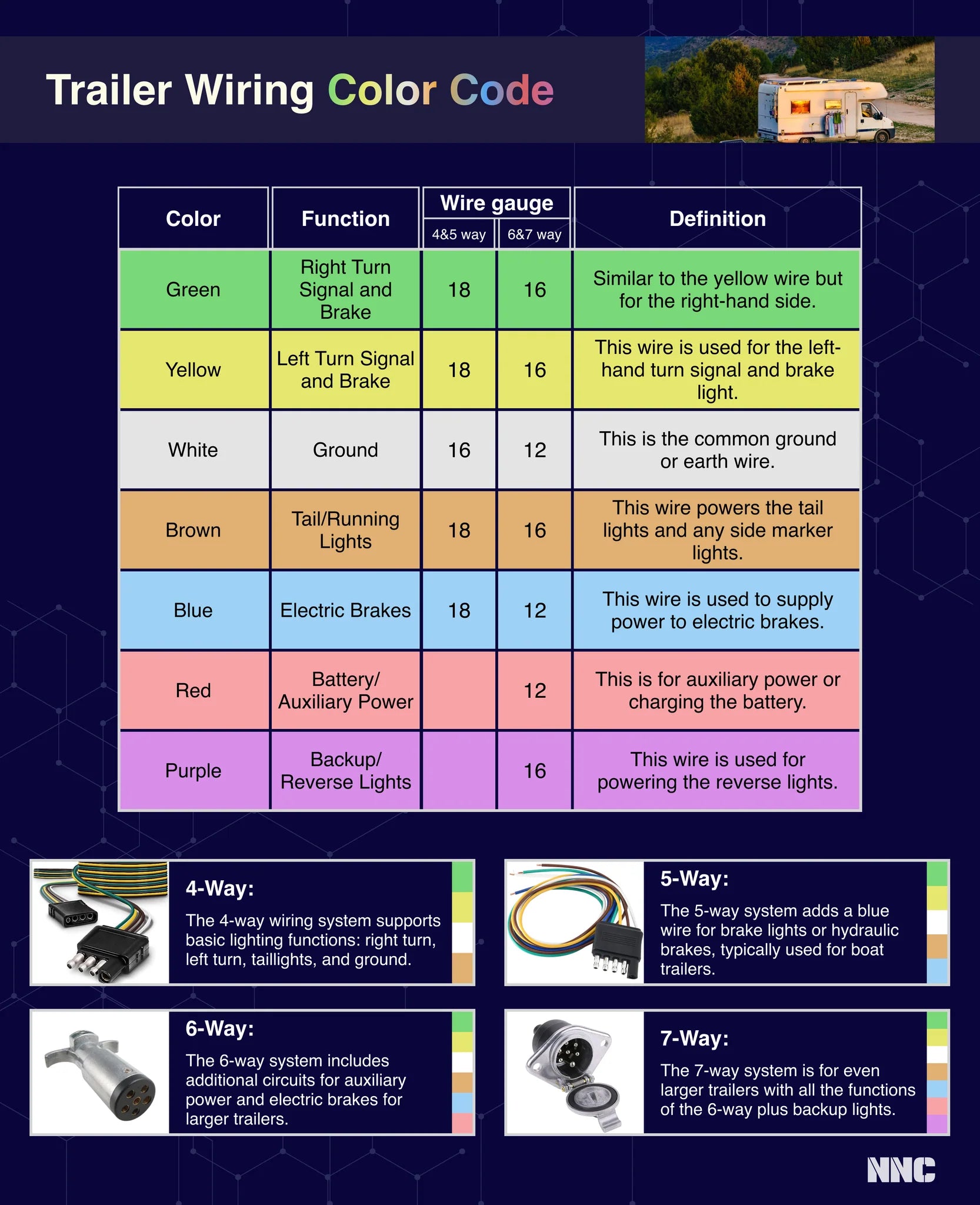

A 4 prong trailer wiring harness is the most common electrical connection used for small to medium-sized trailers. It provides basic lighting functions necessary for road safety and regulatory compliance. The four wires (typically color-coded) are responsible for:

- Brown: Tail/running lights

- Green: Right turn signal and brake lights

- Yellow: Left turn signal and brake lights

- White: Ground (common return path)

This system uses a shared circuit for brake and turn signals, which is acceptable for trailers under certain weight limits as defined by transportation authorities.

Regulatory Compliance Standards

Compliance with national and regional safety standards is mandatory when installing and using 4 prong trailer wiring systems. Key regulatory bodies include:

- DOT (Department of Transportation) – United States: Requires functional lighting systems that meet FMVSS (Federal Motor Vehicle Safety Standards) No. 108. Trailers must have operational tail lights, brake lights, turn signals, and reflectors.

- Transport Canada: Enforces similar lighting requirements under the Motor Vehicle Safety Regulations (MVSR). 4 prong connectors are acceptable for trailers under 4,500 kg GVWR (Gross Vehicle Weight Rating).

- ADR (Australian Design Rules): In Australia, trailers must comply with ADR lighting standards, and 4 pin connectors are commonly used for lighter trailers.

Always verify local regulations, as requirements may vary by state, province, or country—especially regarding trailer weight thresholds and required lighting.

Wiring Installation and Logistics Best Practices

Proper installation is crucial to ensure reliable performance and compliance. Follow these logistics best practices:

- Use Quality Components: Select weather-resistant connectors and UV-rated wiring to prevent corrosion and degradation.

- Secure Wiring Routes: Mount wiring securely along the trailer frame using clips or conduit to prevent abrasion, snagging, or exposure to road debris.

- Ensure Solid Ground Connection: Connect the white (ground) wire directly to clean, unpainted metal on the trailer chassis. A poor ground is the most common cause of lighting issues.

- Waterproof Connections: Use dielectric grease and sealed connectors to protect against moisture, which can lead to short circuits or corrosion.

- Label Wires: Clearly label wires at both ends during installation to simplify troubleshooting and future maintenance.

Maintenance and Inspection Protocols

Regular maintenance ensures continued compliance and operational safety:

- Pre-Trip Checks: Inspect all lights (tail, brake, turn signals) before every trip. Verify that both sides function correctly.

- Clean Connectors: Periodically disconnect and clean both vehicle and trailer plugs to remove dirt, corrosion, or moisture.

- Check for Damage: Inspect wiring for cuts, fraying, or loose connections, especially after off-road use or long-distance towing.

- Replace Worn Components: Immediately replace damaged wires, connectors, or light housings to avoid failure during transit.

When to Upgrade from 4 Prong to 5, 6, or 7 Prong

The 4 prong system supports only basic lighting. If your trailer requires additional functions, compliance may necessitate an upgraded wiring system:

- Brake Control for Electric Brakes: Requires a 5th wire (blue) for brake controller signal—mandatory for trailers over a certain weight (e.g., over 3,000 lbs in the U.S.).

- Reverse Lights or Auxiliary Power: Additional circuits (6 or 7 prong) are needed and may be required depending on trailer configuration and local laws.

Always assess trailer specifications and legal requirements before towing to determine if a 4 prong system is sufficient.

Documentation and Compliance Records

Maintain records to demonstrate compliance during inspections or roadside checks:

- Keep receipts for wiring components and installation.

- Document inspection logs showing regular maintenance and light functionality tests.

- Retain user manuals and wiring schematics for reference.

These records support due diligence in the event of an audit or accident investigation.

Conclusion

The 4 prong trailer wiring system is a reliable and compliant solution for lightweight towing applications when installed and maintained correctly. Adhering to regulatory standards, following best practices for installation, and conducting routine inspections are essential for safety, legal compliance, and trouble-free towing operations. Always verify local regulations and upgrade wiring as needed for larger or more complex trailers.

In conclusion, sourcing a 4-prong trailer wiring harness is a practical and cost-effective solution for ensuring safe and reliable electrical connectivity between your vehicle and trailer. It enables essential lighting functions such as brake lights, turn signals, and running lights, which are critical for visibility and road safety. When selecting a 4-prong wiring kit, consider compatibility with your vehicle and trailer, durability of materials, ease of installation, and whether a hardwired or plug-and-play option best suits your needs. Purchasing from reputable suppliers or auto parts stores ensures quality and compliance with safety standards. Overall, investing time in sourcing the right 4-prong trailer wiring enhances towing safety, improves compliance with traffic regulations, and contributes to a smoother, more confident towing experience.