The global fasteners market continues to expand, driven by growing demand from industries such as automotive, electronics, aerospace, and consumer goods. According to Grand View Research, the global fasteners market size was valued at USD 109.1 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key segment within this market is small-diameter screws, including 4-40 screws—commonly used in precision applications ranging from electronic device assembly to medical instruments. The rising production of compact electronic devices and miniaturized equipment has significantly increased demand for these standardized fasteners. As industries prioritize reliability, thread precision, and material consistency, selecting the right 4-40 screw manufacturer has become a critical factor in ensuring product performance and supply chain efficiency. Based on production capabilities, global reach, quality certifications, and innovation in materials and coatings, the following eight manufacturers have emerged as leaders in the 4-40 screw segment.

Top 8 4-40 Screws Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM Walbro 96

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: Screw 4 – 40 X .19 In 96-156-7. Manufactured by: Walbro. ERP Number: ERP10035834. Part Number: 96-156-7. Original Equipment Manufacturer ? $4.13. In Stock….

#2 #4

Domain Est. 1994

Website: grainger.com

Key Highlights: When it comes to #4-40 Bolts & Screws, you can count on Grainger. Supplies and solutions for every industry, plus easy ordering, fast delivery and 24/7 ……

#3 4

Domain Est. 2004

Website: mfsupply.com

Key Highlights: MF Supply is a leading supplier of 4-40X1/2 Slotted Round Machine Screw Fully Threaded Zinc. Buy online or request a custom quote today!…

#4 4-40 x 7/8 Phil Pan Machine Screws Zinc

Domain Est. 2008

Website: aftfasteners.com

Key Highlights: In stock Free delivery over $200#4-40 x 7/8″ (Fully Threaded) Machine Screws Pan Head Phillips Zinc Cr+3 (100/Pkg.) ; Manufacturer Part #:: 587077 ; Package Quantity: 100 ; Diamete…

#5 NAS517

Domain Est. 2013

Website: military-fasteners.com

Key Highlights: In stock Free delivery over $150Call 1 (904) 543-6395 ; Description: Fastener Length: 2-63/64″, Thread: 1/4-28, Thread Length: 1/2″, ; * Manufacturer certifications are shipped wit…

#6 4-40 Machine Screws

Domain Est. 1994

Website: newark.com

Key Highlights: Free delivery over $150 · 60-day returnsFind a huge range of 4-40 Machine Screws at Newark Electronics. We stock a wide range of Machine Screws, such as 4-40, 6-32, 8-32 & #10-32 …

#7 4

Domain Est. 1995

Website: mouser.com

Key Highlights: $4.99 delivery4-40 Screws & Fasteners are available at Mouser Electronics. Mouser offers inventory, pricing, & datasheets for 4-40 Screws & Fasteners….

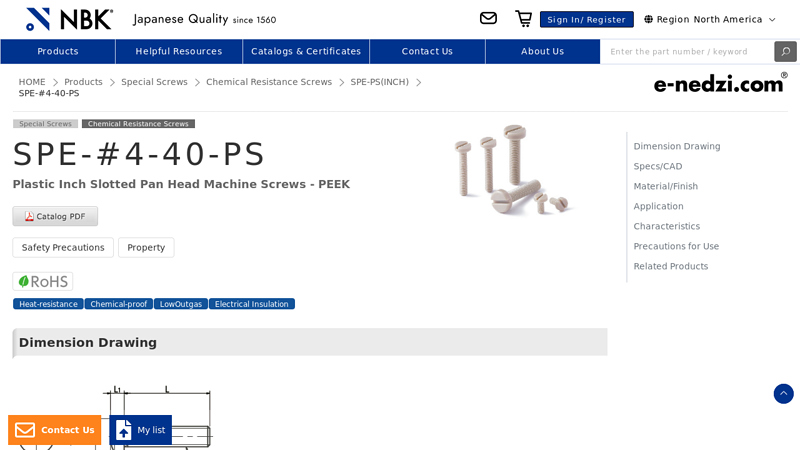

#8 SPE-#4-40-PS

Domain Est. 2000

Website: nbk1560.com

Key Highlights: PEEK slotted pan head machine screws. · Inch screw type. · PEEK is a thermoplastic super engineering plastic superior in physical and chemical properties….

Expert Sourcing Insights for 4-40 Screws

H2: Projected 2026 Market Trends for 4-40 Screws

The global market for 4-40 screws—a standard #4 diameter screw with 40 threads per inch commonly used in electronics, aerospace, medical devices, and precision machinery—is expected to experience steady growth and notable shifts by 2026. Driven by advancements in manufacturing technologies, evolving regulatory standards, and increasing demand across high-tech industries, several key trends are shaping the market landscape.

-

Rising Demand from Electronics and Consumer Devices

The proliferation of compact electronic devices such as smartphones, wearables, IoT sensors, and miniaturized medical equipment is fueling demand for small, reliable fasteners like 4-40 screws. As product designs emphasize slimmer profiles and modular construction, the need for precision screws with consistent thread integrity will continue to grow. The Asia-Pacific region, particularly China, South Korea, and Vietnam, remains a manufacturing hub driving this demand. -

Increased Adoption of Automation and Robotics

Automation in assembly lines—especially in electronics and automotive sectors—requires highly standardized and machine-compatible fasteners. The 4-40 screw’s uniform dimensions make it ideal for robotic screwdriving systems. By 2026, integration with Industry 4.0 practices will push suppliers to offer traceable, defect-free screws with tighter tolerances and improved surface coatings to prevent jamming or corrosion during automated handling. -

Growth in Aerospace and Defense Applications

The aerospace industry’s shift toward lightweight, high-strength materials (such as titanium and advanced composites) necessitates compatible fastening solutions. 4-40 screws made from stainless steel, titanium, or nickel alloys are increasingly specified for avionics, instrumentation panels, and UAVs. Stringent quality certifications (e.g., AS9100, NAS standards) will become more critical, favoring suppliers with aerospace-grade manufacturing capabilities. -

Sustainability and Material Innovation

Environmental regulations and corporate sustainability goals are prompting a shift toward recyclable materials and low-impact surface treatments. By 2026, expect increased use of trivalent chromium passivation (RoHS and REACH compliant) over traditional hexavalent coatings. Additionally, biodegradable or composite fasteners remain in early R&D stages but may begin niche application trials in non-structural roles. -

Supply Chain Resilience and Regionalization

Ongoing geopolitical tensions and supply chain disruptions have led OEMs to diversify sourcing. Nearshoring and regional production hubs in North America and Europe are gaining traction. This trend may benefit local fastener manufacturers who can offer short lead times, customization, and compliance with regional standards, potentially reducing reliance on Asian imports. -

Price Volatility and Raw Material Costs

Fluctuations in the prices of stainless steel, aluminum, and specialty alloys may impact 4-40 screw pricing through 2026. Producers are likely to adopt hedging strategies or long-term supply contracts to stabilize costs. Smaller manufacturers may consolidate or form strategic partnerships to maintain competitiveness. -

Digitalization and Smart Inventory Management

E-commerce platforms and digital procurement tools are transforming how 4-40 screws are sourced. By 2026, B2B platforms with real-time inventory tracking, AI-driven demand forecasting, and just-in-time delivery options will dominate. Customization portals allowing engineers to specify length, drive type, coating, and packaging will gain popularity.

Conclusion

The 4-40 screw market in 2026 will be shaped by technological precision, sustainability demands, and supply chain agility. While the product remains a commodity in many contexts, differentiation through quality, compliance, and service will separate leading suppliers. Companies that invest in automation, material science, and digital integration will be best positioned to capture value in this specialized fastener segment.

Common Pitfalls When Sourcing 4-40 Screws (Quality, IP)

Sourcing 4-40 screws—small yet critical fasteners commonly used in electronics, aerospace, and precision equipment—can present several challenges, especially when quality and intellectual property (IP) concerns are involved. Below are key pitfalls to watch for:

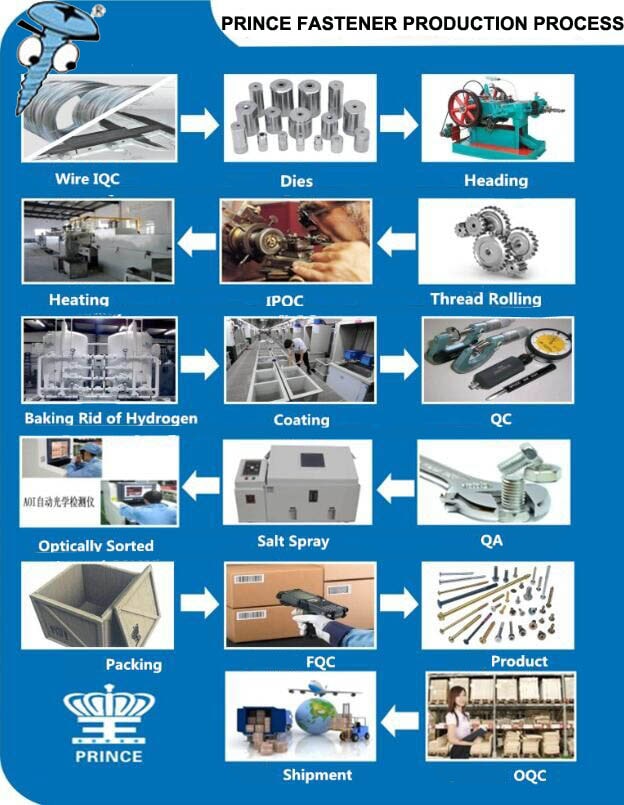

Poor Material and Manufacturing Quality

One of the most frequent issues is receiving screws made from substandard materials or with inconsistent manufacturing tolerances. Low-quality 4-40 screws may use incorrect alloys (e.g., non-stainless or low-grade steel), leading to corrosion, stripping, or thread failure. Additionally, poor thread rolling or head forming can result in galling, weak drive engagement, or dimensional inaccuracies that compromise fit and function.

Mitigation: Specify material standards (e.g., 303 or 304 stainless steel per ASTM), request certification (e.g., RoHS, REACH), and conduct incoming inspections or third-party testing.

Inconsistent Thread Accuracy and Fit

The 4-40 thread (0.112” major diameter, 40 threads per inch) requires precise threading to ensure reliable mating with nuts or tapped holes. Sourcing from unreliable suppliers often results in out-of-spec threads, leading to cross-threading, binding, or loosening under vibration.

Mitigation: Require compliance with ASME B1.1 or ISO standards and use thread gauges for quality checks during procurement.

Lack of Traceability and Certification

Many suppliers, especially in the gray market or from unverified overseas sources, fail to provide proper documentation. This lack of traceability increases the risk of counterfeit or non-conforming parts, which can jeopardize product reliability and regulatory compliance.

Mitigation: Source from authorized distributors or certified manufacturers and insist on mill test reports and lot traceability.

Intellectual Property (IP) Risks

When sourcing proprietary or custom-designed 4-40 screws (e.g., with unique head styles, coatings, or markings), IP infringement is a serious concern. Unauthorized replication by suppliers—especially in regions with lax IP enforcement—can lead to counterfeit parts entering the supply chain or even reverse engineering of your designs.

Mitigation: Use non-disclosure agreements (NDAs), work with trusted partners in IP-protected jurisdictions, and consider patent or trademark protection for unique features.

Coating and Surface Finish Deficiencies

Many applications require specific finishes (e.g., passivation, black oxide, or PTFE coating) for corrosion resistance or reduced friction. Poorly applied or omitted coatings can degrade performance and lead to field failures.

Mitigation: Clearly specify finish requirements (e.g., ASTM A967 for passivation), and verify through sample testing.

Supply Chain and Lead Time Instability

Due to their small size and high volume use, 4-40 screws are often sourced from multiple low-cost suppliers, increasing exposure to supply disruptions, long lead times, or quality drift between batches.

Mitigation: Diversify suppliers carefully, maintain safety stock for critical applications, and conduct regular supplier audits.

Avoiding these pitfalls requires due diligence in supplier selection, clear technical specifications, and ongoing quality control—especially when performance, safety, or IP protection is at stake.

Logistics & Compliance Guide for 4-40 Screws

Overview

4-40 screws are a common type of machine screw with a #4 nominal diameter and 40 threads per inch. These screws are widely used in electronics, aerospace, and precision machinery. Proper logistics handling and regulatory compliance are essential to ensure product quality, safety, and seamless supply chain operations.

Material and Finish Specifications

Ensure screws are manufactured from approved materials (e.g., stainless steel, zinc-plated steel, or alloy steel) per ASTM, ISO, or customer-specific standards. Finishes must comply with RoHS, REACH, and other environmental regulations where applicable. Documentation such as Certificates of Conformance (CoC) or Material Test Reports (MTRs) should accompany shipments.

Packaging Requirements

Package screws in sealed, moisture-resistant containers to prevent corrosion during transit and storage. Use anti-static packaging for electronic applications. Clearly label each package with part number (e.g., 4-40 x 1/2″), material type, finish, quantity, batch/lot number, and handling instructions. Barcodes or RFID tags are recommended for inventory tracking.

Storage Conditions

Store in a dry, temperature-controlled environment (10°C to 30°C) with relative humidity below 60%. Avoid direct contact with concrete floors; use pallets or shelving. Segregate different finishes or materials to prevent cross-contamination. Implement first-in, first-out (FIFO) inventory practices.

Transportation Guidelines

Use secure, enclosed vehicles to protect against moisture, dust, and physical damage. Avoid extreme temperatures during transit. For international shipments, comply with IMDG Code (if applicable) and ensure proper export documentation. Screws classified as non-hazardous typically fall under UN3082 (environmentally hazardous substance, solid, n.o.s.) only if packaging includes lubricants or coatings requiring declaration.

Regulatory Compliance

- RoHS (EU): Confirm absence of restricted substances (lead, cadmium, etc.) in plating or base materials.

- REACH (EU): Register or notify substances of very high concern (SVHCs) if present above threshold.

- ITAR/EAR (US): Verify if screws are subject to export controls based on application (e.g., defense or aerospace use).

- Customs Classification: Use correct HS Code (e.g., 7318.15 for threaded fasteners of iron/steel) to ensure accurate tariffs and import compliance.

Quality Control and Traceability

Implement quality checks per AS9100, ISO 9001, or customer-specific requirements. Maintain lot traceability throughout the supply chain. Perform periodic audits of suppliers and logistics partners to ensure ongoing compliance.

Documentation and Labeling

Include the following with each shipment:

– Packing list

– Commercial invoice

– Certificate of Compliance

– Safety Data Sheet (SDS), if required due to coatings or lubricants

– Export license (if applicable)

Labels must be durable, multilingual (as needed), and include handling symbols (e.g., “Fragile,” “Keep Dry”).

Disposal and Recycling

Follow local regulations for metal waste disposal. Encourage recycling programs for scrap or defective screws. Provide disposal guidance in SDS if chemical coatings are present.

Emergency Procedures

In case of spillage or damage during transit, contain loose screws to prevent injury or equipment damage. Report incidents per internal safety protocols and customer requirements. Maintain contact information for regulatory agencies and emergency response.

Conclusion for Sourcing 4-40 Screws:

After evaluating various suppliers, materials, finishes, and cost considerations, sourcing 4-40 screws can be efficiently achieved through a balanced approach that prioritizes quality, availability, and value. Standard 4-40 screws are widely available from reputable industrial suppliers such as McMaster-Carr, MSC Industrial Supply, and Fastenal, offering reliable specifications and quick turnaround times. For high-volume or specialized applications, partnering with manufacturers on platforms like Alibaba or ThomasNet may provide cost savings, especially when custom features such as specific coatings (e.g., zinc plating, black oxide) or materials (e.g., stainless steel, alloy steel) are required.

Critical factors in the sourcing decision include thread accuracy, material strength, corrosion resistance, and compliance with industry standards (e.g., ANSI, ASME B18.6.3). Additionally, lead times, minimum order quantities, and shipping costs should be assessed to ensure alignment with project timelines and budgets.

In conclusion, a dual-sourcing strategy—utilizing domestic suppliers for urgent or low-volume needs and international vendors for bulk procurement—offers optimal flexibility and cost-efficiency. Establishing relationships with trusted suppliers and maintaining a small safety stock can further ensure continuity in production and assembly operations.