The global 3D UV resin printer market is experiencing robust expansion, driven by increasing demand for high-resolution, rapid prototyping in industries such as healthcare, dental, jewelry, and consumer electronics. According to Grand View Research, the global resin 3D printing market size was valued at USD 1.38 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 18.2% from 2023 to 2030. This surge is fueled by advancements in photopolymer materials, rising adoption of digitalization in manufacturing, and the proliferation of desktop-level resin printers in small-to-medium enterprises and hobbyist communities. Additionally, Mordor Intelligence projects the 3D printing market to expand at a CAGR of over 23% during the forecast period (2023–2028), with Asia-Pacific emerging as a key growth region due to industrial modernization and government support for additive manufacturing. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining innovation, precision engineering, and scalable production to meet the expanding global demand for reliable and high-performance UV resin 3D printers.

Top 10 3D Uv Resin Printer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stratasys 3D Printers

Domain Est. 1993

Website: stratasys.com

Key Highlights: We provide industrial-grade additive 3D printers all along the production cycle, from design and prototyping to production and end-use parts….

#2 Photocentric

Domain Est. 2014

Website: photocentricgroup.com

Key Highlights: We have been world leaders in the manufacture of clear photopolymer stamps and craft products, for over 20 years….

#3 Creality Resin 3D Printers

Domain Est. 2000

Website: store.creality.com

Key Highlights: 3–4 day delivery · 14-day returnsCreality Resin 3D Printers include 14K HALOT-MAGE S and 8K models. High-speed, high-precision printing with washing/curing options….

#4 Formlabs

Domain Est. 2009

Website: formlabs.com

Key Highlights: Formlabs is the largest supplier of professional stereolithography (SLA) and selective laser sintering (SLS) 3D printers in the world….

#5 Zortrax

Domain Est. 2012

Website: zortrax.com

Key Highlights: Zortrax offers 3D Printing products, award-winning FDM 3D printers, filaments, and software solutions with worldwide customer support services….

#6 Tethon 3D

Domain Est. 2013

Website: tethon3d.com

Key Highlights: Bison 1000 DLP Printer $22950.00 Add to cart Zirconia Resin (5Y) 385-405 nm (New formula)- 1 Liter $1500.00 Select options This product has multiple ……

#7 Anycubic 3D Printer

Domain Est. 2014

Website: anycubic.com

Key Highlights: Discover the best Resin and FDM 3D printers, filaments, accessories and software on Anycubic. Elevate your printing projects with top-quality materials….

#8 Premium 3D Printer Resin

Domain Est. 2016

Website: us.elegoo.com

Key Highlights: Free delivery over $50Step into the future of 3D printing with our premium selection of 3D printer resins, designed to bring your ideas to life with precision and clarity….

#9 Wide Selection of Materials for All Your 3D Printing Needs

Domain Est. 2017

Website: phrozen3d.com

Key Highlights: Phrozen Materials We offer a wide variety of durable resins in different colors that are designed for low-shrinkage, high-precision printing….

#10 Siraya Tech 3D Printing UV Resin for Elegoo,Anycubic & SLA 3d …

Domain Est. 2019

Expert Sourcing Insights for 3D Uv Resin Printer

H2: Projected 2026 Market Trends for 3D UV Resin Printers

By 2026, the 3D UV resin printer market is expected to undergo significant transformation driven by technological innovation, expanding applications, and evolving consumer and industrial demands. Key trends shaping the market include advancements in print speed and resolution, increased adoption across industries, integration of AI and automation, sustainability initiatives, and the expansion of entry-level and professional-grade product segments.

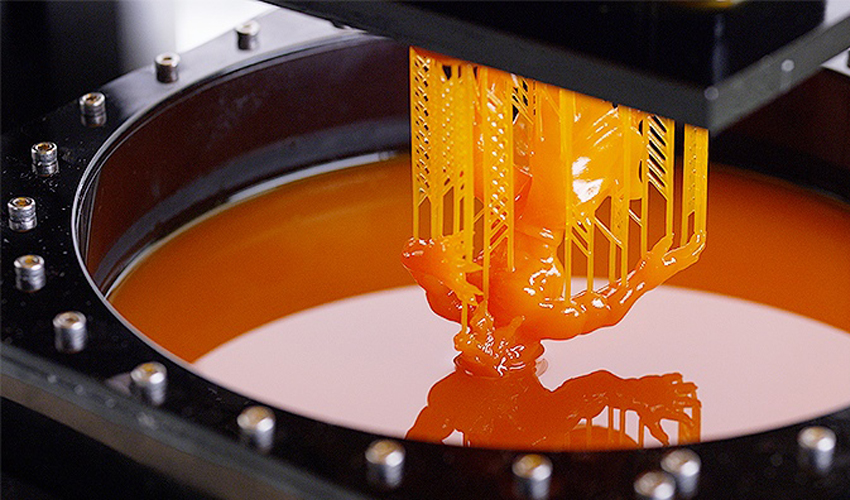

1. Technological Advancements Driving Performance

UV resin 3D printing technology will continue to benefit from improvements in light source efficiency, particularly with the widespread adoption of 405 nm LED and emerging LCD/MSLA (Masked Stereolithography) platforms. By 2026, printers are expected to achieve faster cure times and higher throughput, reducing production cycles for both prototyping and end-use parts. Innovations in resin formulation—such as faster-curing, low-odor, and biocompatible resins—will broaden material capabilities, meeting stringent requirements in healthcare, dentistry, and electronics.

2. Expansion into Industrial and Professional Applications

While initially popular in hobbyist and prototyping circles, UV resin printers are increasingly being adopted in industrial settings. By 2026, sectors such as dental labs, jewelry manufacturing, and medical device production will rely heavily on high-precision resin printing for mass customization. The integration of UV resin systems into digital workflows—such as CAD-to-print pipelines and digital dentistry platforms—will enhance scalability and repeatability, supporting Industry 4.0 initiatives.

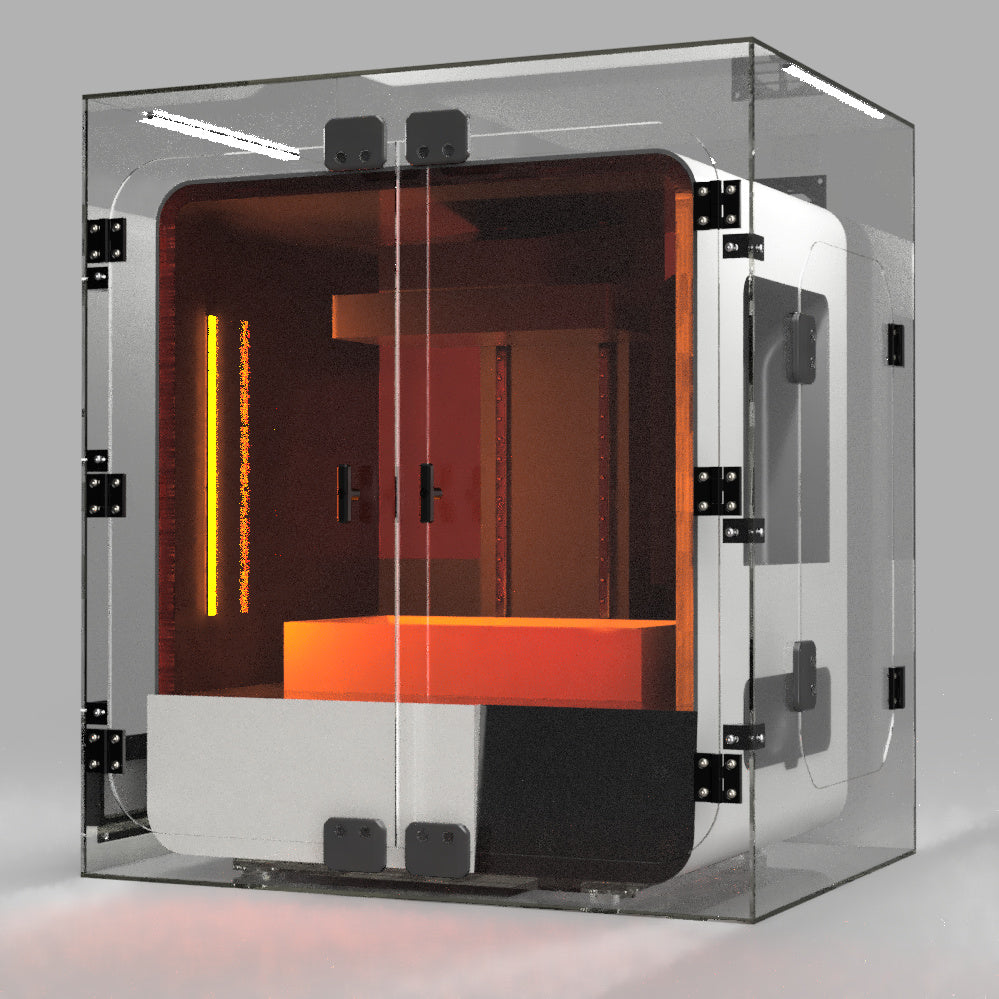

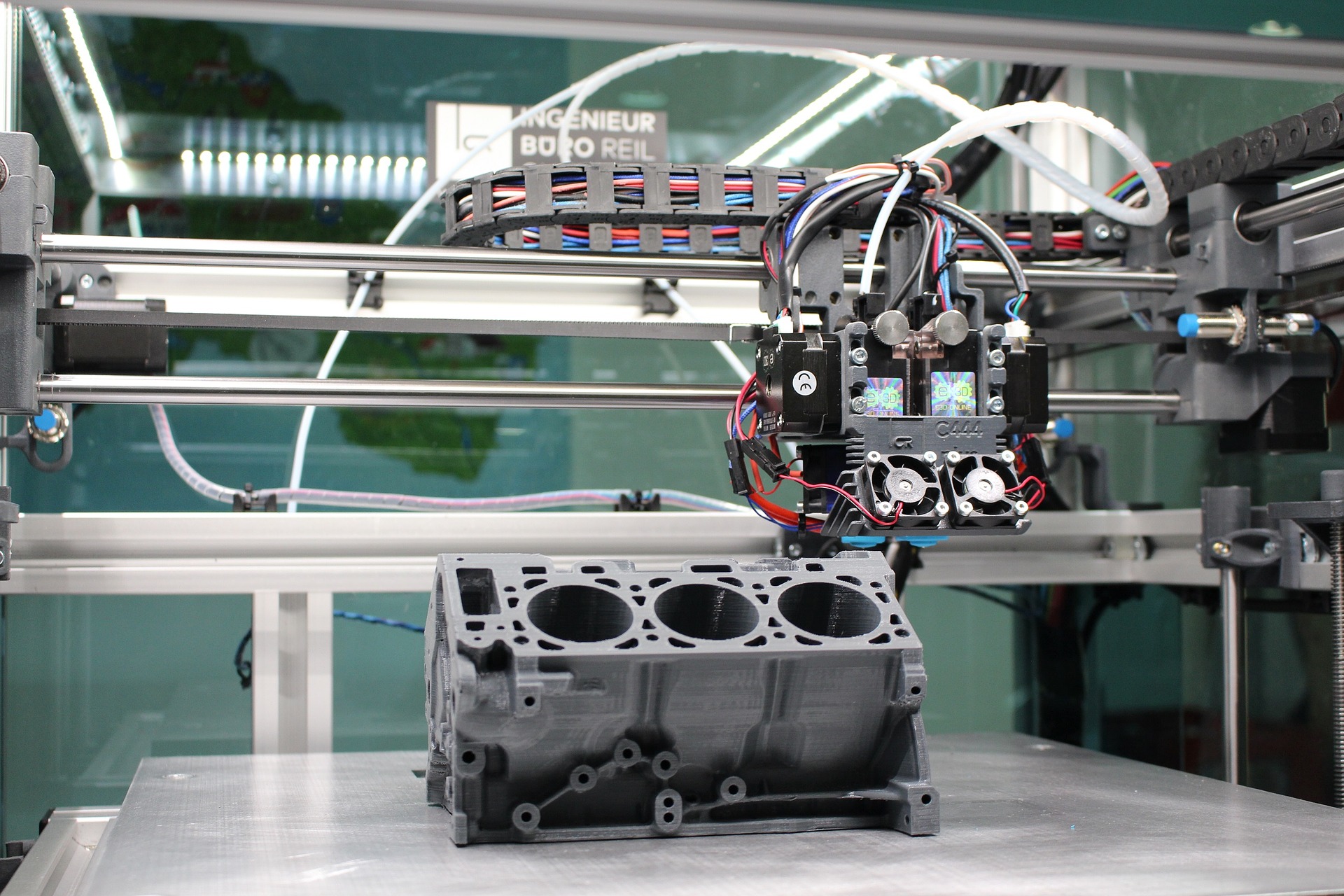

3. Growth of Affordable, High-Quality Desktop Printers

The consumer and prosumer segments will see continued innovation with cost-effective, user-friendly UV resin printers. Manufacturers will focus on improving safety features (e.g., enclosed build chambers, air filtration), ease of use (auto-levelling, touchscreen interfaces), and reliability. This democratization of high-resolution 3D printing will expand access for designers, educators, and small businesses.

4. AI and Software Integration

By 2026, AI-powered slicing software and predictive maintenance systems will be more prevalent in UV resin printing ecosystems. These tools will optimize print orientation, reduce support structures, and minimize failures—addressing key pain points like print warping and resin waste. Cloud-based platforms will allow remote monitoring and collaborative design workflows.

5. Sustainability and Material Innovation

Environmental concerns will push manufacturers to develop bio-based, recyclable, or compostable UV-curable resins. Regulatory pressures and consumer demand for greener alternatives will accelerate R&D in sustainable photopolymers. Additionally, closed-loop resin systems and improved waste management solutions will become standard features in next-generation printers.

6. Market Consolidation and Regional Growth

The competitive landscape will likely see consolidation among smaller brands, with major players expanding their portfolios through acquisitions. Meanwhile, Asia-Pacific—driven by China, Japan, and South Korea—will remain a key manufacturing and consumption hub. North America and Europe will lead in high-value applications, particularly in healthcare and aerospace.

In summary, the 2026 3D UV resin printer market will be defined by enhanced precision, broader industrial integration, smarter software ecosystems, and a growing emphasis on sustainability. These trends will position UV resin printing as a critical enabler of digital manufacturing across diverse sectors.

Common Pitfalls When Sourcing a 3D UV Resin Printer: Quality and Intellectual Property Concerns

Poor Print Quality Due to Low-Grade Components

Many budget-friendly UV resin printers on the market use substandard components such as inaccurate linear rails, low-resolution LCD screens, or inconsistent UV light sources. These compromises often lead to failed prints, layer misalignment, and inconsistent curing, ultimately affecting the final product’s dimensional accuracy and surface finish. Buyers may find themselves investing in additional upgrades or replacements post-purchase to achieve acceptable print quality.

Inadequate Build Volume and Z-Axis Wobble

Some printers advertise large build volumes but fail to maintain structural rigidity, especially in taller models. This results in Z-axis wobble caused by flimsy lead screws or poorly designed motion systems, leading to visible banding or delamination in prints. It’s essential to verify real-world performance through user reviews or test samples before procurement.

Lack of Firmware and Software Support

Printers sourced from lesser-known manufacturers often come with outdated or closed-source firmware, limiting customization and long-term usability. Issues such as poor slicing algorithms, lack of automatic calibration, or absence of community support can hinder reliable operation. Additionally, proprietary software may not be compatible with common slicing tools, reducing workflow flexibility.

Intellectual Property (IP) Infringement Risks

A significant concern when sourcing UV resin printers—particularly from certain regions—is the potential use of cloned or reverse-engineered designs. Some manufacturers replicate popular open-source models without proper licensing or attribution, exposing buyers to legal risks, especially in regulated industries. Using such devices in commercial production may violate IP laws, leading to liability or supply chain disruptions.

Absence of Safety and Compliance Certifications

Many low-cost UV resin printers lack essential safety certifications (e.g., CE, FCC, RoHS). This raises concerns about electrical safety, UV radiation leakage, and off-gassing of harmful fumes during operation. Non-compliant devices may fail regulatory inspections, posing risks to users and creating obstacles for commercial deployment.

Limited Spare Parts and After-Sales Support

Sourcing printers from manufacturers with weak global support networks often results in prolonged downtime due to unavailable replacement parts—particularly critical components like LCD masks or VATs. Poor customer service and language barriers further complicate troubleshooting, increasing total cost of ownership over time.

Logistics & Compliance Guide for 3D UV Resin Printers

Regulatory Classification and Import Requirements

3D UV resin printers are generally classified under the Harmonized System (HS) Code 8477.30 (Machines for additive manufacturing). Import regulations vary by country, but common requirements include:

- CE Marking (EU): Required for all electronic equipment. Ensures compliance with EU health, safety, and environmental protection standards.

- FCC Certification (USA): Mandatory for devices emitting radio frequencies. Applies to the printer’s electronic components.

- RoHS Compliance (Global): Restricts the use of hazardous substances such as lead, mercury, and cadmium in electrical equipment.

- REACH (EU): Regulates chemicals, including UV-curable resins. Users must ensure resin formulations comply with SVHC (Substances of Very High Concern) requirements.

Always verify local regulations before shipping to ensure compliance with electrical safety, electromagnetic compatibility (EMC), and chemical handling standards.

Safe Handling and Transportation of Resins

UV-curable resins are classified as hazardous materials due to their chemical reactivity and potential health hazards (skin/eye irritant, sensitization). Key logistics considerations:

- UN Number: Resins often fall under UN 1866 (Acrylic resin, flammable, liquid) or UN 3082 (Environmentally hazardous substance, liquid, n.o.s.), depending on composition.

- Packaging: Use UN-certified, leak-proof containers with secondary containment. Label with GHS pictograms (flammable, health hazard, environmental hazard).

- Transportation: Subject to IATA (air), IMDG (sea), or ADR (road) regulations when shipped in quantities exceeding thresholds. Small quantities (<1 L) may qualify for limited exceptions.

- Documentation: Provide Safety Data Sheets (SDS) with each shipment. Declare hazardous content on commercial invoices.

Ensure resins are stored and transported away from UV light and high temperatures to prevent premature curing.

Workplace Safety and Operational Compliance

Operating a 3D UV resin printer requires adherence to occupational health and safety standards:

- Ventilation: Use in well-ventilated areas or with fume extraction (preferably with activated carbon filters) to reduce inhalation of volatile organic compounds (VOCs).

- Personal Protective Equipment (PPE): Operators must wear nitrile gloves, safety goggles, and lab coats to prevent skin and eye contact.

- Curing and Post-Processing: Use UV light sources in enclosed areas; avoid direct exposure to skin or eyes. Isopropyl alcohol (IPA) used for cleaning is flammable and requires proper storage and disposal.

- Waste Disposal: Uncured resin and contaminated IPA are hazardous waste. Follow local regulations for disposal (e.g., EPA in the US, WEEE in EU). Never pour down the drain.

Environmental and End-of-Life Compliance

- Recycling: Some resins and printer components (e.g., LCD screens, electronics) may be recyclable. Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU.

- Spill Management: Have spill kits (absorbents, neutralizers) on hand. Clean spills immediately using appropriate procedures to minimize environmental impact.

- Sustainability: Choose biodegradable or low-toxicity resins where possible to reduce environmental footprint.

Documentation and Record-Keeping

Maintain records for compliance audits:

– Safety Data Sheets (SDS) for all resins and chemicals

– Certifications (CE, FCC, RoHS)

– Training logs for personnel on safe handling

– Waste disposal manifests

– Maintenance and calibration logs for equipment

Adhering to this guide ensures legal compliance, minimizes risk, and promotes safe, sustainable use of 3D UV resin printers across the supply chain.

In conclusion, sourcing a 3D UV resin printer requires careful consideration of several key factors including print quality, build volume, reliability, post-processing requirements, and overall cost of ownership. UV resin printers offer exceptional detail and precision, making them ideal for applications in prototyping, jewelry design, dentistry, and miniatures. When selecting a supplier or model, it’s essential to evaluate compatibility with different resins, customer support, software user-friendliness, and safety features such as UV shielding and ventilation.

Additionally, sourcing from reputable manufacturers or distributors ensures access to reliable technical support, firmware updates, and genuine replacement parts. It’s also beneficial to review user feedback, conduct sample testing if possible, and compare warranty and service terms. By thoroughly assessing these aspects, you can make an informed decision that aligns with your specific application needs and achieves long-term value and performance from your 3D UV resin printer investment.