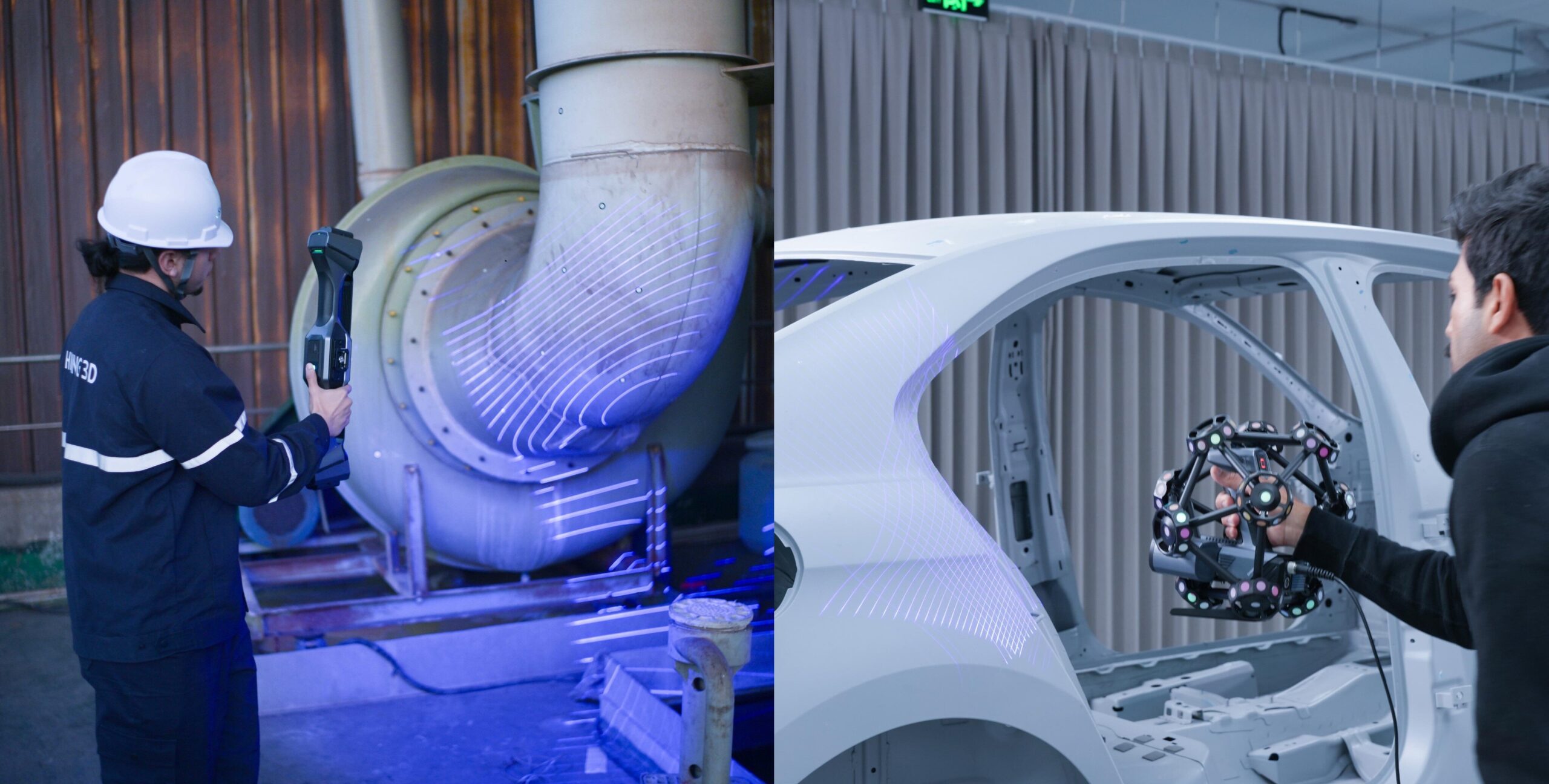

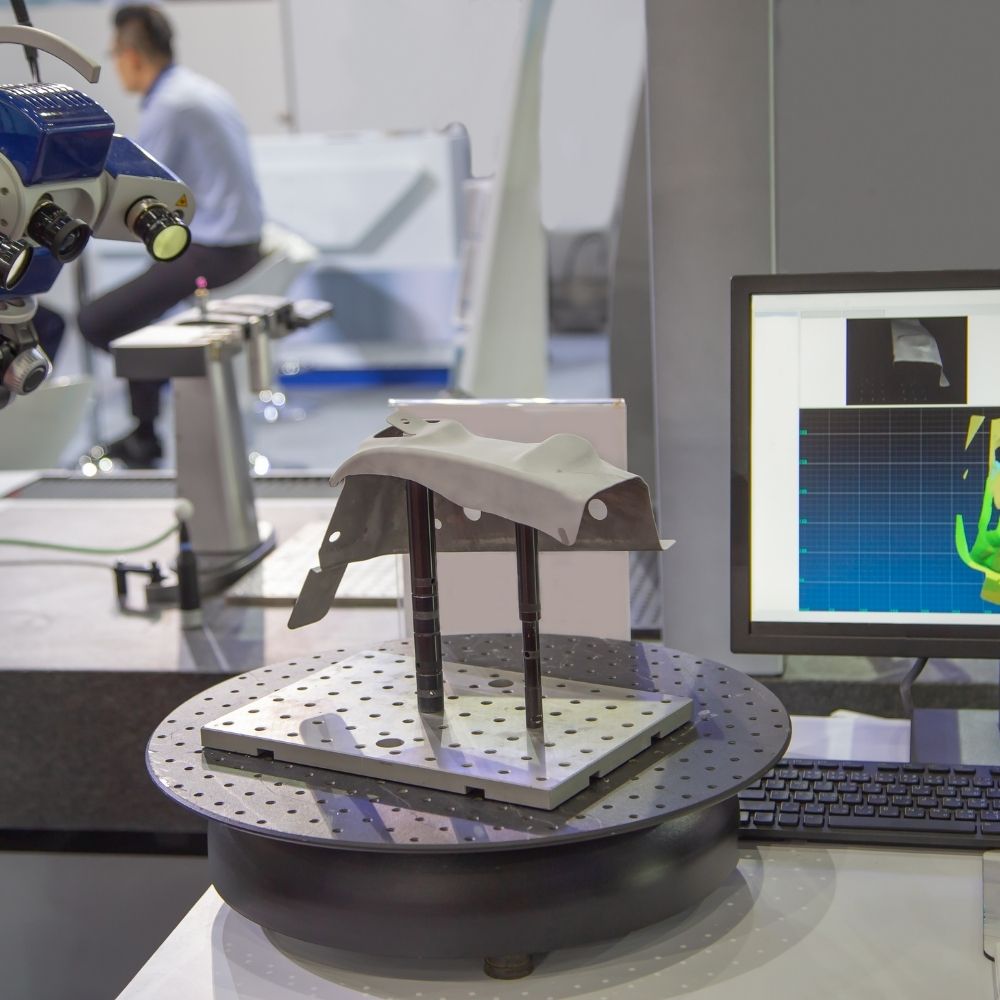

The global 3D scanning market is experiencing robust growth, driven by increasing demand for precision imaging in industries such as manufacturing, healthcare, archaeology, and e-commerce. According to Grand View Research, the global 3D scanning market size was valued at USD 7.68 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.5% from 2023 to 2030. This expansion is fueled by advancements in automation, rising adoption of quality control systems in production environments, and the integration of 3D scanning with AI and cloud-based platforms. A key enabler of accurate and repeatable 3D captures is the use of motorized turntables, which allow for full 360-degree object rotation during scanning. As demand for turnkey 3D scanning solutions grows, so does the need for reliable, high-precision turntable systems. In response, a competitive landscape of manufacturers has emerged, offering varying levels of accuracy, load capacity, and software integration. The following analysis highlights the top 8 3D scanner turntable manufacturers shaping this evolving ecosystem.

Top 8 3D Scanner Turntable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Thor3D – Manufacturer of Handheld 3D Scanners

Domain Est. 2015 | Founded: 2015

Website: thor3dscanner.com

Key Highlights: Thor3D has been creating unique 3D scanning technologies since 2015. · Professional & affordable · Built-in touchscreen · Simple editing software….

#2 Creaform® Manual 3D Scanning Turntable

Domain Est. 1998

#3 3D scanning turntable

Domain Est. 2002

Website: store.creaform3d.com

Key Highlights: Manual turntable to facilitate the scanning of small objects. Offers an alternative to applying positioning targets on the part itself (optional)….

#4 SHINING 3D

Domain Est. 2008

Website: shining3d.com

Key Highlights: SHINING 3D develops high-accuracy 3D scanners for a wide range of applications. Our solutions are ideal for use in high-precision metrology, digital dentistry, ……

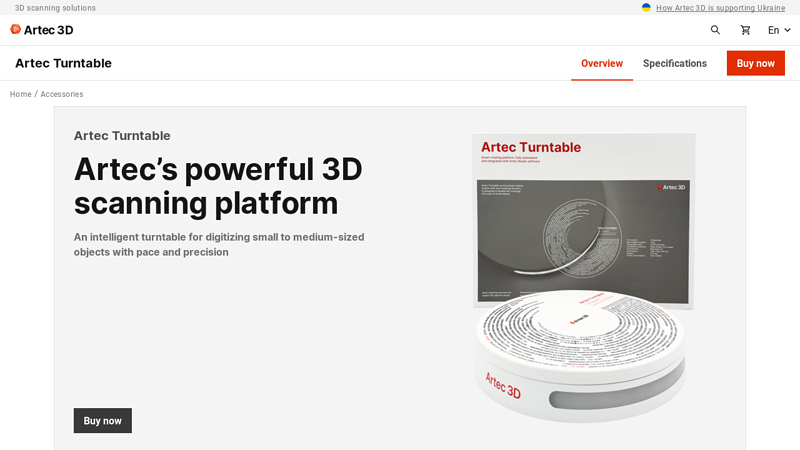

#5 Artec Turntable

Domain Est. 2009

Website: artec3d.com

Key Highlights: The Artec Turntable is designed to smoothly, consistently rotate small to medium-sized objects for faster, more complete 3D scans with less manual adjustment….

#6 3D Scanning Turntable

Domain Est. 2016

Website: titansofcnc.com

Key Highlights: 3D Scanning Turntable … This is the perfect solution for scanning small to medium-sized parts and offers an alternative to putting scanning targets on the part….

#7 Revopoint MINI 2: Blue Light High

Domain Est. 2019

Website: revopoint3d.com

Key Highlights: Revopoint MINI 2 is a high-accuracy blue light 3D scanner for capturing every detail on small objects for jewelry design, miniature 3D model making, ……

#8 Basic Turntable

Domain Est. 2022

Expert Sourcing Insights for 3D Scanner Turntable

H2: Projected 2026 Market Trends for 3D Scanner Turntables

The 3D scanner turntable market is poised for significant evolution by 2026, driven by technological advancements, expanding applications, and shifting industry demands. Key trends shaping this market include:

1. Integration of AI and Automation (H2 Focus):

By 2026, artificial intelligence will be deeply embedded in turntable systems. AI-powered software will enable automatic object recognition, optimal scanning path calculation, and real-time error correction during rotation. This “smart turntable” trend reduces user dependency on technical expertise, streamlines workflows, and enhances scan consistency—especially critical in quality control and reverse engineering.

2. Rise of Plug-and-Play, Consumer-Grade Solutions:

Demand from small businesses, educators, and hobbyists will drive the proliferation of affordable, easy-to-use turntables. These models will prioritize seamless integration with popular desktop 3D scanners and software (e.g., via USB or Bluetooth), intuitive mobile apps, and pre-calibrated setups. Expect widespread adoption in education, e-commerce (product digitization), and creative industries.

3. Enhanced Precision and Load Capacity for Industrial Use:

Industrial sectors (automotive, aerospace, manufacturing) will demand turntables with higher load capacities (up to 100+ kg), micron-level rotational accuracy, and ruggedized designs. Integration with metrology-grade scanners and compatibility with automated production lines will be essential. Turntables with programmable multi-axis movement (e.g., tilt-rotate) will gain traction for complex part scanning.

4. Expansion in Healthcare and Cultural Heritage Applications:

Custom prosthetics, orthotics, and dental modeling will increasingly rely on precise turntable-based scanning. Similarly, museums and archaeology projects will adopt portable, high-resolution turntable systems for artifact digitization and preservation. This growth will fuel demand for gentle, non-slip rotation mechanisms and non-reflective surface handling capabilities.

5. Cloud Connectivity and Workflow Integration:

By 2026, many turntables will offer cloud-based data management, allowing remote monitoring, scan data storage, and collaborative processing. Integration with digital twin platforms and PLM (Product Lifecycle Management) systems will streamline design-to-manufacturing workflows, especially in smart factories.

In summary, the 2026 3D scanner turntable market will be characterized by intelligent automation, broader accessibility, and deeper specialization—catering to both high-precision industrial needs and growing consumer and creative applications.

Common Pitfalls When Sourcing a 3D Scanner Turntable (Quality & IP)

Sourcing a 3D scanner turntable involves more than just finding a rotating platform—it requires careful evaluation of build quality, compatibility, and intellectual property concerns. Overlooking these aspects can lead to subpar scan results, integration challenges, or legal risks. Here are key pitfalls to avoid:

Poor Mechanical Build Quality and Precision

One of the most significant pitfalls is selecting a turntable with inferior mechanical components. Low-quality motors, bearings, or structural materials can result in wobbling, inconsistent rotation, or positioning inaccuracies. These flaws directly impact scan quality by introducing motion artifacts, misalignment between scan slices, or incomplete data capture. Always verify specifications such as rotational accuracy (e.g., ±0.1°), load capacity, and repeatability, and prioritize turntables constructed with rigid, non-reflective materials like anodized aluminum or composite plastics.

Incompatibility with 3D Scanning Software or Hardware

Many off-the-shelf turntables are not designed to integrate seamlessly with specific 3D scanning systems. A lack of proper communication protocols (e.g., USB, RS-232, or API support) or software triggers can prevent synchronized scanning, forcing manual operation and increasing human error. Before purchasing, confirm compatibility with your scanner’s ecosystem—whether it’s Artec, Shining 3D, or open-source platforms like MeshLab or ScanStudio. Look for models offering SDKs or documented APIs for automation and control.

Lack of Calibration and Repeatability Features

A high-quality turntable must offer repeatable positioning and support calibration routines. Without precise zero-point referencing or angular calibration, repeated scans of the same object may not align properly, undermining efforts to create consistent digital twins. Avoid turntables that don’t include calibration tools or documentation. Ideally, the system should support full 360° indexing with micro-step resolution and provide feedback mechanisms (e.g., encoder integration) for closed-loop control.

Intellectual Property (IP) Risks with Custom or Clone Designs

Sourcing low-cost turntables—especially from generic manufacturers—can expose buyers to IP infringement risks. Some budget models replicate patented designs or incorporate unlicensed firmware from established brands. Using such equipment may lead to legal liability, particularly in commercial or industrial applications. To mitigate this, purchase from reputable suppliers with transparent product origins, and request documentation confirming IP compliance. Avoid obscure vendors offering “compatible” or “OEM” versions of well-known turntables without clear licensing.

Inadequate Load Capacity and Size Constraints

Underestimating the size or weight of objects to be scanned is a frequent oversight. A turntable that cannot support the object’s weight or dimensions may stall, tilt, or damage the motor. Always assess maximum load capacity and platform diameter relative to your typical scanning use cases. Additionally, ensure the turntable’s height and clearance allow for unobstructed scanner access from multiple angles—especially with structured light or photogrammetry systems.

Overlooking Environmental and Operational Factors

Operating conditions such as vibration, ambient lighting, or surface reflectivity can influence turntable performance. A poorly isolated motor may transmit vibrations to the scanner, degrading resolution. Similarly, a reflective turntable surface can create scan artifacts by interfering with laser or projected light patterns. Choose models with anti-vibration feet, matte non-reflective surfaces, and shielding where necessary to maintain scan fidelity in real-world environments.

By addressing these pitfalls proactively—focusing on build quality, compatibility, calibration, IP safety, and operational fit—you can ensure reliable, high-precision scanning results and avoid costly rework or legal complications.

Logistics & Compliance Guide for 3D Scanner Turntable

Product Classification and HS Code

The 3D scanner turntable is typically classified under the Harmonized System (HS) code 8479.89, which covers “Machines of a kind used solely or principally for civil engineering, for raising or moving goods or persons, for handling materials, or for other specified industrial uses, not elsewhere specified or included.” However, classification may vary by country. It is essential to verify the correct HS code with local customs authorities or a licensed customs broker to ensure accurate tariff application and compliance.

Export Controls and Licensing

3D scanner turntables may be subject to export control regulations, particularly if they are capable of high-precision movement or integration with advanced scanning systems. Review regulations such as the U.S. Export Administration Regulations (EAR) or the EU Dual-Use Regulation. Most turntables fall under EAR99 (low concern), but confirm technical specifications do not exceed controlled thresholds. No export license is typically required for EAR99 items shipped to most destinations, but restricted end-users or embargoed countries (e.g., Iran, North Korea) may require licensing or be prohibited.

Packaging and Shipping Requirements

Ensure the turntable is securely packaged to prevent damage during transit. Use robust, shock-absorbent materials and secure internal bracing. Include anti-static protection if electronic components are present. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”). Use consistent branding and include product identifiers (model number, serial number if applicable). For international shipping, provide a detailed packing list and commercial invoice.

Import Duties and Taxes

Import duties vary by country and depend on the applicable HS code and trade agreements. Research duty rates in the destination country. Additionally, account for Value Added Tax (VAT), Goods and Services Tax (GST), or other local import taxes. Accurate product valuation on the commercial invoice is critical to avoid customs delays or penalties. Consider using Delivered Duty Paid (DDP) or Delivered at Place (DAP) Incoterms to clarify responsibility.

Electrical and Safety Compliance

Ensure the turntable complies with electrical safety standards in the target market. In the European Union, CE marking is required under directives such as the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. In the United States, adherence to UL or FCC standards may be necessary. Provide required documentation, including Declaration of Conformity (DoC), technical files, and test reports from accredited laboratories.

Documentation for Customs Clearance

Prepare the following documents for smooth customs clearance:

– Commercial Invoice (with value, currency, and terms of sale)

– Packing List (itemizing contents, weights, and dimensions)

– Bill of Lading or Air Waybill

– Certificate of Origin (if claiming preferential tariff under a trade agreement)

– Export Declaration (as required by exporting country)

– Compliance Certificates (e.g., CE, FCC, RoHS)

RoHS and Environmental Regulations

The 3D scanner turntable must comply with environmental directives such as the EU’s Restriction of Hazardous Substances (RoHS) Directive, which limits the use of lead, mercury, cadmium, and other hazardous materials. Ensure all components and sub-assemblies meet RoHS requirements. Provide a RoHS compliance statement or certificate upon request.

Warranty and After-Sales Support Logistics

Define warranty terms and service procedures for international customers. Clarify whether repairs will be handled locally or require return to the manufacturer. Establish partnerships with local service providers if feasible. Include multilingual user manuals and safety instructions. Ensure spare parts availability and efficient return logistics (RMA process) to support customer satisfaction and regulatory expectations.

Data Privacy and Connectivity (if applicable)

If the turntable includes embedded software or connectivity features (e.g., Bluetooth, Wi-Fi), ensure compliance with data privacy laws such as the EU’s General Data Protection Regulation (GDPR). Minimize data collection, implement security measures, and provide transparent privacy notices. Even if the device does not store personal data, connected functionality may trigger regulatory scrutiny.

Conclusion for Sourcing a 3D Scanner Turntable

After evaluating various options and requirements, sourcing a 3D scanner turntable is a crucial step in achieving high-quality, consistent, and efficient 3D captures. A reliable turntable enhances scanning precision by enabling automated, full-rotation imaging, reducing manual handling, and ensuring uniform lighting and alignment. Key factors such as rotational accuracy, load capacity, compatibility with existing 3D scanning software and hardware, and ease of integration must be carefully considered.

Both in-house manufacturing and third-party procurement offer distinct advantages depending on budget, customization needs, and technical capabilities. Commercial turntables provide plug-and-play convenience and technical support, while custom-built solutions allow for tailored specifications and potential long-term cost savings.

Ultimately, investing in a high-quality turntable significantly improves workflow efficiency and scan repeatability, making it a valuable addition to any 3D scanning setup. Proper sourcing ensures seamless integration, long-term reliability, and a strong return on investment through enhanced output quality and reduced processing time.