The global 3D printing market is undergoing rapid transformation, with the jewelry sector emerging as a key adopter of additive manufacturing technologies. According to Grand View Research, the global 3D printing in jewelry market size was valued at USD 1.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 16.4% from 2023 to 2030. This surge is driven by increasing demand for customization, reduced production lead times, and the rising adoption of lost-wax casting techniques enabled by high-resolution 3D printers. As jewelry manufacturers seek to enhance design precision and operational efficiency, investment in industrial-grade and desktop 3D printing solutions has intensified. In fact, Mordor Intelligence projects the overall 3D printing market to grow at a CAGR of over 23% during the forecast period (2023–2028), with specialized applications in fine jewelry playing a pivotal role. Against this backdrop, selecting the right 3D printer—balancing accuracy, material compatibility, surface finish, and throughput—has become critical for manufacturers aiming to maintain a competitive edge. Here, we present the top 9 3D printers shaping the future of jewelry production.

Top 9 3D Printer For Jewelry Industry Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

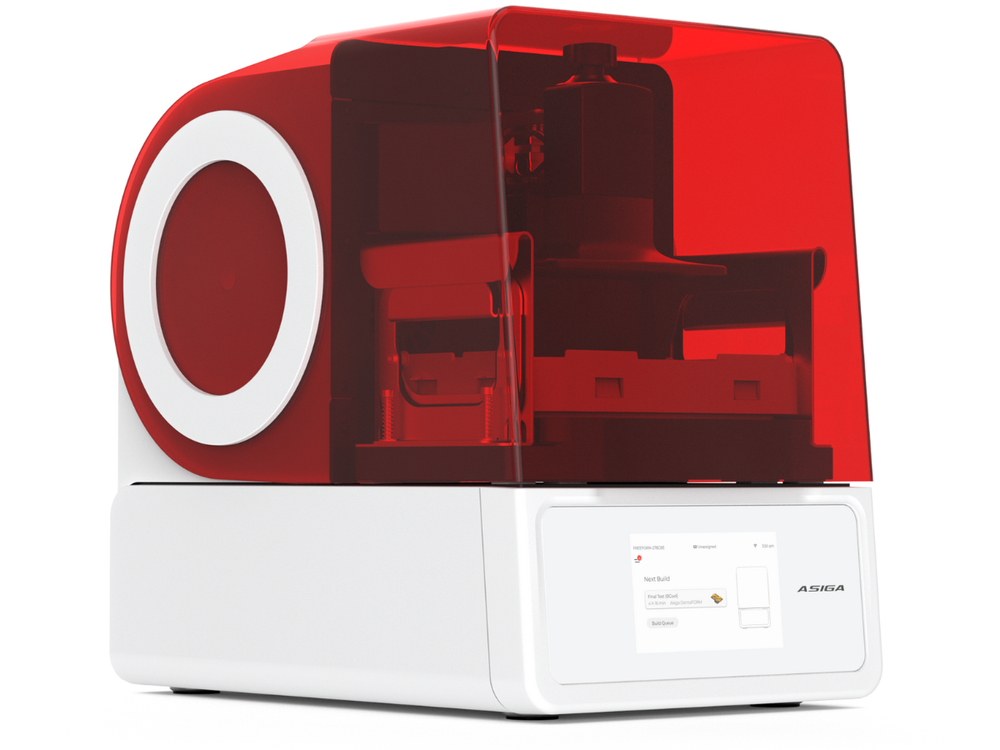

#1 Asiga

Domain Est. 2005

Website: asiga.com

Key Highlights: Precision 3D printers and materials. Manufacture end-use medical devices, industrial prototypes, fine jewellery and more….

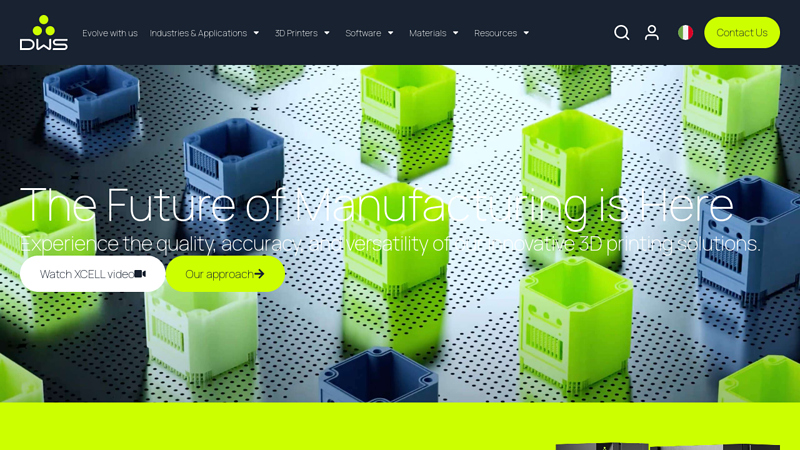

#2 Industrial 3D Printers

Domain Est. 2008

Website: dwssystems.com

Key Highlights: We will introduce the new XCell line and new materials dedicated to jewelry making. Make 3D printing for jewelry easier than ever: try Fusia Digital Wax and ……

#3 IFUN 3D Printing Solutions for Jewelry and Dental

Domain Est. 2018

Website: ifun3d.com

Key Highlights: IFUN is a Chinese manufacturer of photopolymer 3D printers and resins — providing complete printing and casting solutions for jewelry and dental industries….

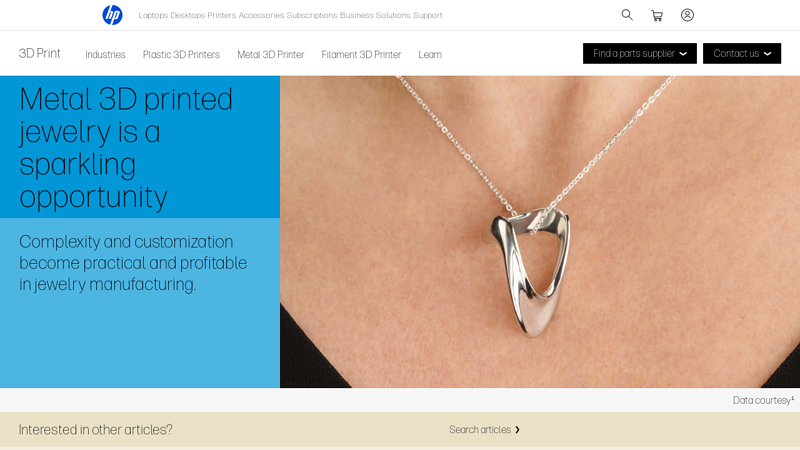

#4 Metal 3D printed jewelry is a sparkling opportunity

Domain Est. 1986

Website: hp.com

Key Highlights: See how metal 3D printed jewelry is helping complexity and customization become practical and profitable in jewelry manufacturing….

#5 3D Jewelry Manufacturing

Domain Est. 1995

Website: riogrande.com

Key Highlights: Free delivery over $250 30-day returnsThe 3D printers we have are designed for jewelry applications and deliver crisp, clean edges with exact details. The prints have smooth surfac…

#6 3D Systems

Domain Est. 1996

Website: 3dsystems.com

Key Highlights: 3D Systems provides comprehensive products and services, including 3D printers, print materials, software, on-demand manufacturing services, and healthcare ……

#7 Formlabs

Domain Est. 2009

Website: formlabs.com

Key Highlights: Formlabs is the largest supplier of professional stereolithography (SLA) and selective laser sintering (SLS) 3D printers in the world….

#8 Zortrax

Domain Est. 2012

Website: zortrax.com

Key Highlights: Zortrax offers 3D Printing products, award-winning FDM 3D printers, filaments, and software solutions with worldwide customer support services….

#9 Phrozen

Domain Est. 2017

Website: phrozen3d.com

Key Highlights: Explore Phrozen’s high-precision resin and FDM 3D printers and accesories for personal, dental, and professional use. Shop now!…

Expert Sourcing Insights for 3D Printer For Jewelry Industry

H2: 2026 Market Trends for 3D Printers in the Jewelry Industry

As we approach 2026, the integration of 3D printing technology into the jewelry industry continues to accelerate, reshaping traditional manufacturing processes and enabling new levels of customization, efficiency, and design innovation. Driven by advancements in materials, software, and printing precision, 3D printers are becoming indispensable tools for both artisanal jewelers and large-scale manufacturers. The following trends are expected to define the 2026 market landscape for 3D printers in the jewelry sector:

-

Increased Adoption of High-Resolution Resin Printers

By 2026, high-resolution resin-based 3D printers—particularly those utilizing DLP (Digital Light Processing) and LCD/MSLA (Masked Stereolithography) technologies—are projected to dominate the jewelry market. These systems offer micron-level accuracy (as fine as 10–25 microns), essential for capturing intricate designs, delicate filigree, and fine stone settings. Manufacturers like Formlabs, EnvisionTEC (now part of Desktop Metal), and Anycubic are expected to continue innovating with improved build volumes and faster print speeds, making high-detail prototyping and production more accessible. -

Growth in Direct Metal 3D Printing

While indirect casting via 3D-printed wax or resin patterns remains prevalent, direct metal 3D printing (DMP/SLM) is gaining traction for high-end and bespoke jewelry. By 2026, advancements in selective laser melting (SLM) and binder jetting technologies will make metal printing more cost-effective and precise. Companies such as EOS, 3D Systems, and SLM Solutions are developing systems capable of printing in precious metals like gold, platinum, and silver with minimal post-processing. This trend is particularly appealing to luxury brands seeking to offer unique, one-of-a-kind pieces with complex internal geometries unachievable through traditional methods. -

Expansion of Sustainable and Eco-Friendly Practices

Sustainability will be a major market driver in 2026. Jewelry consumers are increasingly demanding ethically sourced materials and low-impact production. 3D printing supports this shift by minimizing material waste—often reducing metal usage by up to 90% compared to traditional methods. Additionally, recyclable resins and closed-loop systems for metal powders are emerging, aligning with ESG (Environmental, Social, and Governance) goals. Jewelry brands are expected to leverage their use of 3D printing as a green differentiator in marketing and branding. -

Rise of Mass Customization and On-Demand Manufacturing

Enabled by digital design and rapid prototyping, 3D printing allows for efficient mass customization. In 2026, more jewelry retailers and e-commerce platforms will adopt made-to-order models, using 3D printing to produce personalized pieces—custom engravings, tailored ring sizes, or AI-generated designs—without inventory overhead. This shift reduces overproduction and enhances customer engagement, with platforms integrating 3D design configurators directly into online shopping experiences. -

Integration with AI and Generative Design Software

Artificial intelligence and machine learning tools are poised to transform jewelry design workflows by 2026. AI-powered software can generate thousands of design variations based on aesthetic preferences, ergonomics, or cultural motifs, which can then be 3D printed for rapid iteration. Generative design algorithms optimize structures for strength and material efficiency, particularly beneficial for lightweight yet durable pieces. This synergy between AI and 3D printing will empower designers to push creative boundaries while maintaining manufacturability. -

Democratization of Access through Cloud-Based and Desktop Solutions

Affordable desktop 3D printers and cloud-based printing services will continue to lower entry barriers for small studios and independent designers. By 2026, plug-and-play systems with automated calibration and cloud-connected design libraries will be commonplace, enabling even non-technical users to produce professional-quality models. Subscription-based models for printers, materials, and software are expected to grow, offering scalability for businesses of all sizes. -

Standardization and Certification of 3D-Printed Jewelry

As 3D-printed jewelry becomes more prevalent in luxury and fine jewelry markets, industry standards and certifications for print quality, material purity, and durability will gain importance. By 2026, organizations like the Responsible Jewellery Council (RJC) and assay offices are likely to establish formal guidelines for 3D-printed pieces, ensuring consumer trust and facilitating wider acceptance in high-value segments.

In conclusion, the 2026 market for 3D printers in the jewelry industry will be characterized by technological sophistication, sustainability, and a shift toward digital craftsmanship. As the lines between design, manufacturing, and retail blur, 3D printing will not only enhance production efficiency but also redefine how jewelry is conceived, created, and consumed.

Common Pitfalls When Sourcing 3D Printers for the Jewelry Industry (Quality, IP)

Poor Print Quality Leading to Defective Castings

One of the most critical pitfalls is selecting a 3D printer that lacks the resolution and precision required for fine jewelry details. Low-quality prints with surface roughness, layer misalignment, or dimensional inaccuracies can result in flawed wax patterns, leading to casting defects such as porosity, flash, or incomplete details. This not only increases post-processing time but also wastes precious materials and labor. Sourcing printers without verifying micron-level accuracy (typically 10–50 microns) and consistent repeatability across print runs can severely impact product quality and customer satisfaction.

Inadequate Material Compatibility for Jewelry Applications

Not all 3D printers support high-resolution castable resins specifically engineered for jewelry investment casting. Using incompatible or generic resins can lead to incomplete burnout, ash residue, or poor surface finish in the final metal casting. Sourcing a printer without confirming compatibility with industry-standard, low-ash, high-detail castable materials risks production failures and increased rejection rates.

Intellectual Property (IP) Risks from Unsecured Data and Software

Jewelry designs are highly valuable intellectual property. Sourcing 3D printers from vendors with weak cybersecurity measures—such as unencrypted file transfers, cloud-based slicing software, or shared network access—can expose proprietary designs to theft or unauthorized replication. This is especially risky when working with third-party service providers or networked printers in shared workspaces. Failing to audit a printer’s data handling protocols and local processing capabilities can lead to significant IP loss.

Lack of Vendor Support and Long-Term Resin Availability

Many low-cost or generic 3D printers lack dedicated support for the jewelry sector. This includes insufficient technical assistance, slow response times, or discontinued resin formulations. Sourcing equipment without ensuring long-term resin availability and strong vendor support can halt production, especially when specific material properties are required for reliable casting performance.

Overlooking Post-Processing Requirements

High-quality jewelry printing demands meticulous post-processing—including washing, curing, and support removal. Sourcing a printer without considering integrated or compatible post-processing solutions can lead to inconsistent results and damage delicate features. Underestimating these requirements often results in increased labor costs and reduced throughput.

Choosing Based on Price Alone Without Total Cost of Ownership Analysis

Focusing solely on the initial purchase price can be misleading. Low-cost printers may have higher failure rates, consume more expensive proprietary resins, or require frequent maintenance. Ignoring the total cost of ownership—including material costs, downtime, waste, and labor—can lead to higher long-term expenses and reduced profitability.

Logistics & Compliance Guide for 3D Printers in the Jewelry Industry

Overview of 3D Printing in Jewelry Manufacturing

3D printing has revolutionized the jewelry industry by enabling rapid prototyping, intricate design capabilities, and efficient production of wax patterns or direct metal prints. However, the integration of 3D printers into jewelry manufacturing requires careful attention to logistics and compliance. This guide outlines key considerations to ensure seamless operations, regulatory adherence, and supply chain efficiency.

Regulatory Compliance Requirements

International Standards and Certifications

Ensure that your 3D printer and related materials meet international standards such as ISO 9001 (Quality Management), ISO 13485 (if producing medical jewelry), and IEC 60601 (for electrical safety). For resin-based printers, compliance with REACH and RoHS directives is essential to restrict hazardous substances.

Material Safety and Handling

Jewelry 3D printers often use photopolymer resins or metal powders. These materials may be classified as hazardous under OSHA (U.S.) or CLP (EU) regulations. Maintain Safety Data Sheets (SDS) for all consumables, implement proper labeling, and train staff on safe handling, storage, and disposal procedures.

Intellectual Property and Design Protection

Jewelry designs are often protected by copyright, trademark, or design patents. Implement digital rights management (DRM) for 3D design files and secure your data network to prevent unauthorized access or duplication. Ensure that CAD files used are either original or properly licensed.

Import and Export Regulations

Customs Documentation and Tariff Classification

When importing or exporting 3D printers, properly classify equipment under the Harmonized System (HS) code—typically 8477.30 for industrial 3D printers. Provide accurate commercial invoices, packing lists, and certificates of origin. Include detailed specifications to avoid customs delays.

Export Controls and Dual-Use Technologies

Certain high-resolution or metal 3D printers may be subject to export control regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation. Verify if your equipment requires an export license, especially when shipping to restricted countries or regions.

Supply Chain and Inventory Management

Sourcing of Consumables and Spare Parts

Establish reliable suppliers for resins, supports, filters, and replacement components. Maintain safety stock levels for critical items, especially specialized materials like casting-compatible resins (e.g., IC-200, Wax-like resins) to avoid production downtime.

Cold Chain and Sensitive Material Transport

Some photopolymer resins are sensitive to temperature and UV exposure. Use temperature-controlled shipping and opaque packaging when transporting or storing resins. Monitor shipment conditions using data loggers to ensure material integrity.

Workplace Safety and Environmental Compliance

Ventilation and Fume Extraction

Resin 3D printing emits volatile organic compounds (VOCs). Install proper ventilation systems or fume extractors with activated carbon filters. Conduct air quality testing to comply with local occupational health standards (e.g., OSHA PELs or EU Workplace Exposure Limits).

Waste Disposal and Recycling

Cured resin waste and used isopropyl alcohol (IPA) are considered hazardous waste in many jurisdictions. Partner with licensed waste disposal companies for compliant treatment. Explore resin recycling options and IPA distillation systems to reduce environmental impact.

Equipment Maintenance and Calibration

Scheduled Maintenance Protocols

Develop a maintenance schedule for critical components such as build plates, resin tanks, and galvanometers. Keep a log of servicing activities and use OEM-recommended parts to maintain warranty and performance.

Calibration and Quality Assurance

Regularly calibrate your 3D printer to ensure dimensional accuracy—critical for jewelry casting. Use standardized test prints and implement quality control checks before batch production. Document calibration procedures for audit readiness.

Cybersecurity and Data Logistics

Secure File Transfer and Storage

Jewelry design files are high-value digital assets. Use encrypted cloud storage and secure file transfer protocols (e.g., SFTP or HTTPS) when sharing CAD or STL files. Restrict access via role-based permissions and multi-factor authentication.

Backup and Disaster Recovery

Implement automated backup systems for design libraries and printer settings. Store backups offsite or in secure cloud environments. Test recovery procedures regularly to minimize data loss risks.

Conclusion

Successfully integrating 3D printing into the jewelry industry requires more than technical expertise—it demands a structured approach to logistics and compliance. By adhering to regulatory standards, managing supply chains effectively, and prioritizing safety and data security, jewelry manufacturers can leverage 3D printing technology sustainably and competitively. Regular audits and staff training are recommended to maintain compliance as regulations evolve.

Conclusion: Sourcing a 3D Printer for the Jewelry Industry

Sourcing the right 3D printer for the jewelry industry is a strategic decision that can significantly enhance design precision, production efficiency, and customization capabilities. Given the intricate nature of jewelry design, resin-based stereolithography (SLA) and digital light processing (DLP) printers are the most suitable technologies due to their high resolution, fine detail reproduction, and compatibility with casting processes using castable resins.

When evaluating 3D printers, key factors such as print resolution (typically 25–50 microns), build volume, material compatibility (especially for investment casting), reliability, and software integration must be carefully considered. Leading brands like Formlabs, EnvisionTEC (now part of Desktop Metal), and 3D Systems offer specialized solutions tailored to jewelry prototyping and production, ensuring professional-grade results.

Additionally, the total cost of ownership—including printer cost, materials, maintenance, and post-processing equipment—should be assessed alongside long-term benefits such as reduced material waste, faster turnaround times, and the ability to produce complex geometries unachievable through traditional methods.

Ultimately, investing in a high-quality 3D printer empowers jewelers to innovate, streamline workflows, and meet growing consumer demand for personalized, bespoke pieces. As digital manufacturing continues to transform the jewelry sector, early adoption of the right 3D printing technology positions businesses for sustained competitiveness and creative growth in a rapidly evolving market.