The global 3D printing market is experiencing robust expansion, driven by increasing adoption across industries such as healthcare, automotive, aerospace, and consumer goods. According to Grand View Research, the market size was valued at USD 13.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 20.8% from 2023 to 2030. Similarly, Mordor Intelligence estimates a CAGR of over 21% during the forecast period of 2023–2028, fueled by advancements in materials, rising demand for rapid prototyping, and the growing shift toward decentralized manufacturing. As innovation accelerates and industrial applications broaden, a select group of manufacturers are leading the charge in technology development, production scalability, and global market reach. Here’s a data-backed look at the top 10 3D printer manufacturers shaping the future of additive manufacturing.

Top 10 3D Printer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Markforged

Domain Est. 2013

Website: markforged.com

Key Highlights: Industrial 3D printers built for the factory floor. A complete line of machines with the precision and reliability manufacturing requires….

#2 Stratasys 3D Printers

Domain Est. 1993

Website: stratasys.com

Key Highlights: We provide industrial-grade additive 3D printers all along the production cycle, from design and prototyping to production and end-use parts….

#3 3D Systems

Domain Est. 1996

Website: 3dsystems.com

Key Highlights: 3D Systems provides comprehensive products and services, including 3D printers, print materials, software, on-demand manufacturing services, and healthcare ……

#4 Creality

Domain Est. 2000

Website: creality.com

Key Highlights: The Creality Ender 3 V3 SE sets a new baseline for cheap 3D printing, blending a familiar form with the beginner-friendly fully automatic bed leveling and self- ……

#5 Formlabs

Domain Est. 2009

Website: formlabs.com

Key Highlights: Formlabs is the largest supplier of professional stereolithography (SLA) and selective laser sintering (SLS) 3D printers in the world….

#6 LulzBot®

Domain Est. 2011

Website: lulzbot.com

Key Highlights: Our legendary 3D printers are making their mark, from elementary classrooms to cutting-edge space labs. Discover your LulzBot’s perfect role today!…

#7 Original Prusa 3D printers directly from Josef Prusa

Domain Est. 2013

Website: prusa3d.com

Key Highlights: Experience High-Performance 3D Printing with Prusa PRO Line. Master high-performance & engineering materials. Achieve unparalleled manufacturing speed and high ……

#8 – Velo3D

Domain Est. 2014

Website: velo3d.com

Key Highlights: Our unique process pushes the limits of what’s possible in metal additive manufacturing, ensuring you get parts with unmatched precision and durability….

#9 Professional 3D Printers Made in Italy

Domain Est. 2017

Website: 3dwasp.com

Key Highlights: Discover our 3D Printers solutions. Wasp is a company leader in 3D printing, we produce and sell printers totally made in Italy. Robotic arm 3D printing….

#10 EOS GmbH: Professional 3D Printing Solutions

Website: eos.info

Key Highlights: EOS is the world’s leading provider of 3D printing solutions, offering professional 3D printers, materials and software from a single source….

Expert Sourcing Insights for 3D Printer

H2: 2026 Market Trends for 3D Printers

The global 3D printing market is poised for transformative growth and innovation by 2026, driven by advancements in technology, expanding industrial applications, and increasing adoption across diverse sectors. Several key trends are expected to shape the market landscape during this period.

1. Industrial Adoption and Mass Customization

By 2026, industries such as aerospace, automotive, healthcare, and consumer goods are anticipated to significantly increase their reliance on 3D printing for both prototyping and end-part production. The shift toward mass customization—especially in medical devices (e.g., prosthetics, dental implants) and personalized consumer products—will drive demand for scalable, high-precision 3D printing solutions. Manufacturers are investing in additive manufacturing (AM) to streamline supply chains, reduce waste, and enable on-demand production.

2. Advancements in Materials and Multi-Material Printing

Material innovation remains a critical growth driver. The development of high-performance polymers, metal alloys, and composite materials will expand the range of viable applications. By 2026, multi-material and multi-color 3D printing technologies are expected to become more accessible, enabling complex, functional parts to be printed in a single run. Bio-inks and sustainable, recyclable materials will also gain traction, especially in healthcare and eco-conscious manufacturing.

3. Integration with AI and Digital Twins

Artificial intelligence (AI) and machine learning will play an increasingly central role in optimizing print processes, predicting failures, and improving design efficiency. Coupled with digital twin technology, 3D printing systems will enable real-time monitoring, simulation, and iterative improvements in product development cycles. This integration will enhance precision, reduce material waste, and lower production costs.

4. Growth of Desktop and Prosumer 3D Printing

The prosumer and desktop 3D printer segment will continue to grow, fueled by decreasing hardware costs, user-friendly software, and open-source communities. By 2026, these printers will offer higher resolution, faster print speeds, and improved reliability, making them attractive for small businesses, education, and hobbyists. Plug-and-play features and cloud-based platforms will further simplify usage and broaden market access.

5. Sustainability and Circular Economy Initiatives

Environmental considerations will influence 3D printing trends, with a focus on energy-efficient printers and recyclable materials. The ability of 3D printing to minimize material waste compared to traditional subtractive methods aligns with global sustainability goals. Companies will increasingly adopt circular manufacturing models, using recycled feedstock and designing for disassembly and reuse.

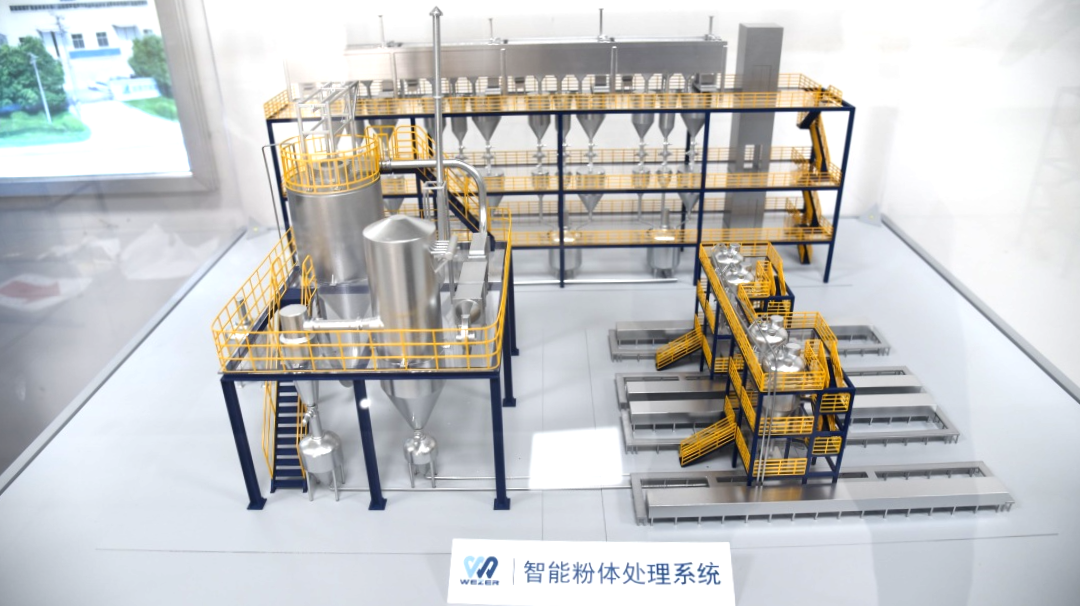

6. Regional Market Expansion

While North America and Europe remain leaders in 3D printing innovation and adoption, Asia-Pacific—particularly China, India, and South Korea—is expected to experience rapid market growth by 2026. Government support, rising R&D investments, and expanding manufacturing bases will drive regional expansion. Localized production hubs will emerge, reducing dependency on global supply chains.

7. Regulatory and Standardization Developments

As 3D printing moves into regulated industries like aerospace and healthcare, standardization of materials, processes, and quality control will become critical. By 2026, regulatory frameworks are expected to mature, enabling wider certification of 3D-printed components and fostering trust in AM-produced parts.

In summary, the 3D printing market in 2026 will be characterized by technological convergence, industrial integration, and a strong emphasis on customization and sustainability. Companies that leverage these trends through innovation and strategic partnerships will be well-positioned to lead in the next era of manufacturing.

Common Pitfalls When Sourcing 3D Printers: Quality and Intellectual Property Risks

Quality-Related Pitfalls

Inconsistent Print Accuracy and Reliability

Many low-cost or poorly manufactured 3D printers suffer from inconsistent dimensional accuracy, warping, layer misalignment, or mechanical failures. Buyers may receive units that fail to meet advertised specifications, resulting in wasted materials, time, and reduced productivity. Without standardized testing or certifications, evaluating true performance before purchase can be difficult.

Substandard Component Quality

Sourcing from unreliable suppliers often means receiving printers built with inferior components—such as low-grade stepper motors, unstable print beds, or poorly calibrated extruders. These issues lead to frequent maintenance, premature breakdowns, and inconsistent output, undermining long-term operational efficiency.

Lack of After-Sales Support and Spare Parts

Cheaper or unknown brands may lack reliable customer service, technical documentation, or availability of replacement parts. This can result in prolonged downtime when issues arise, especially for businesses dependent on continuous printing operations.

Inadequate Software and Firmware

Some sourced printers come with outdated, poorly supported, or non-upgradable firmware and slicing software. This can limit functionality, create compatibility issues, and introduce security vulnerabilities, affecting both print quality and user experience.

Intellectual Property (IP) Risks

Counterfeit or Cloned Devices

Many 3D printers, especially from certain regions, are unauthorized copies of established designs. Sourcing such products exposes buyers to legal liability, particularly if the counterfeit technology infringes on patented mechanisms, electronics, or firmware.

Use of Unlicensed Firmware or Software

Some manufacturers use open-source firmware (e.g., Marlin, Klipper) but fail to comply with licensing requirements (e.g., GPL). Purchasing such devices may indirectly involve your organization in IP violations, especially in regulated industries or when reselling printed products.

Risk of Embedding Infringing Designs

When sourcing printers capable of producing complex parts, there’s a risk that the device or its default design library includes IP-infringing models (e.g., trademarked characters, patented functional parts). Using such designs—even unknowingly—can lead to legal exposure.

Lack of IP Warranty or Indemnification

Most generic suppliers do not provide intellectual property warranties or indemnification clauses. If a third party claims infringement related to the printer’s design or operation, the buyer may bear full legal and financial responsibility.

Logistics & Compliance Guide for 3D Printers

Import Regulations and Documentation

When importing a 3D printer, ensure compliance with destination country regulations. Required documentation typically includes a commercial invoice, bill of lading or airway bill, packing list, and certificate of origin. Some countries may require additional permits or pre-shipment inspections. Verify whether the printer falls under specific import restrictions or requires declaration due to its electrical components, laser systems (in laser-based printers), or dual-use potential.

Customs Classification (HS Code)

Classify the 3D printer using the appropriate Harmonized System (HS) Code to determine duties and taxes. Common classifications include:

– 8477.30: Machines for 3D printing (additive manufacturing) of plastics

– 8479.89: Other machines not elsewhere specified, including metal 3D printers

– 8517.62: If classified as a digital communication device (in specific cases)

Confirm the correct code with local customs authorities, as misclassification can lead to delays and penalties.

Electrical and Safety Standards

Ensure the 3D printer meets the electrical safety standards of the destination market. Key certifications include:

– CE Marking (European Union): Compliance with Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive

– FCC Certification (USA): For electromagnetic interference (EMI) compliance

– UKCA Marking (United Kingdom): Post-Brexit equivalent to CE

– PSE Mark (Japan): Required for electrical safety

– RCM Mark (Australia/New Zealand): For electrical and electromagnetic compliance

Environmental and Chemical Compliance

Adhere to regulations governing hazardous substances in electronic equipment:

– RoHS (EU): Restricts use of lead, mercury, cadmium, and other hazardous materials

– REACH (EU): Requires declaration of Substances of Very High Concern (SVHC)

– WEEE Directive (EU): Mandates proper disposal and recycling of electronic waste; producers may need to register and contribute to recycling schemes

Ensure printed materials (filaments, resins) also comply with relevant chemical safety regulations (e.g., SDS availability, TSCA in the U.S.).

Shipping and Packaging Requirements

Use secure, anti-static packaging to protect sensitive electronic components during transit. Clearly label packages with:

– Handling instructions (e.g., “Fragile,” “This Side Up”)

– Weight, dimensions, and contents

– Manufacturer and importer contact information

Consider temperature and humidity controls if shipping through extreme climates, especially for resin-based printers.

Software and Intellectual Property Considerations

Ensure firmware and control software comply with local laws regarding:

– Export controls (e.g., U.S. EAR regulations may apply to advanced 3D printing technology)

– Open-source licensing (if applicable)

– Digital rights management (DRM) requirements

Avoid pre-loading unauthorized or pirated software on printer control boards.

End-Use and Export Control Compliance

Certain 3D printers—especially those capable of printing high-strength materials, aerospace components, or weapons—may be subject to export controls:

– ITAR (U.S.): May apply if printer is intended for defense-related applications

– EAR (U.S.): Check Commerce Control List (CCL) for applicable Export Control Classification Numbers (ECCN)

– Dual-use regulations (EU, etc.): Apply to technologies usable in both civilian and military applications

Obtain necessary export licenses before shipping restricted models internationally.

After-Sales Compliance and Support

Provide users with:

– Multilingual user manuals and safety instructions

– Warranty and repair information compliant with local consumer protection laws

– Access to spare parts and technical support

Maintain records for traceability and product recall readiness as required by regional regulations.

Summary and Best Practices

- Verify country-specific import requirements early in the supply chain

- Maintain up-to-date compliance certifications and technical documentation

- Partner with experienced freight forwarders familiar with high-tech equipment

- Regularly audit compliance processes to adapt to changing regulations

Adhering to this guide ensures smooth logistics operations and minimizes legal and financial risks associated with global 3D printer distribution.

Conclusion for Sourcing a 3D Printer:

In conclusion, sourcing a 3D printer requires a careful evaluation of technical specifications, application requirements, budget constraints, and long-term operational needs. After assessing various models, technologies (such as FDM, SLA, or SLS), and vendor offerings, the selected 3D printer aligns well with our production goals, offering the right balance of print quality, speed, reliability, and scalability. Additionally, considerations such as after-sales support, warranty, consumable availability, and user training have been factored in to ensure smooth integration into our workflow. This investment is expected to enhance prototyping capabilities, reduce lead times, and support innovation, ultimately delivering a strong return on investment. With proper utilization and maintenance, the chosen 3D printer will be a valuable asset in meeting both current and future manufacturing and design challenges.