The global 3D printed wall panels market is experiencing robust expansion, driven by rising demand for customized architectural interiors and sustainable building materials. According to a 2023 report by Grand View Research, the global 3D printing construction market was valued at USD 4.3 billion and is expected to grow at a compound annual growth rate (CAGR) of 22.2% from 2023 to 2030—much of which is attributable to the adoption of 3D printed interior elements such as wall panels. Similarly, Mordor Intelligence projects that the architectural 3D printing market will witness accelerated adoption over the next decade, fueled by advancements in printing materials, design flexibility, and reduced lead times. As architects, designers, and developers increasingly prioritize both aesthetics and efficiency, 3D printed wall panels are emerging as a preferred solution for creating intricate, lightweight, and eco-friendly interior surfaces. With innovation concentrated in regions like North America, Europe, and parts of Asia-Pacific, a new wave of manufacturers is leading the charge in redefining modern interior spaces through additive manufacturing. Here are the top 10 3D printed wall panels manufacturers shaping this transformative industry.

Top 10 3D Printed Wall Panels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

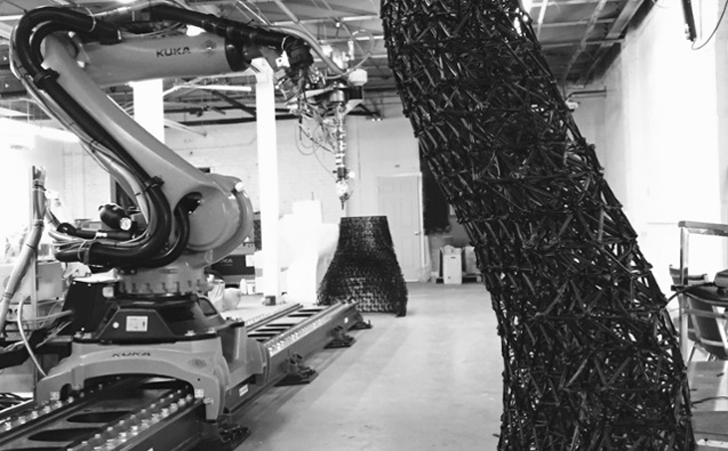

#1 BRANCH TECHNOLOGY

Domain Est. 2012

Website: branchtechnology.com

Key Highlights: Patented 3D-printed fabrication technology combining additive manufacturing, prefabrication, and digital technology at construction scale, with true design ……

#2 Mighty Buildings®

Domain Est. 2017

Website: mightybuildings.com

Key Highlights: Introducing the most complete 3D printed wall system The Mighty Wall System is a factory-made complete wall system that brings the fastest, most resilient ……

#3 3d wall panels

Domain Est. 2021

Website: smartprofile.us

Key Highlights: Transform your home with textured 3D wall panels, ceiling panels, and RV panels from SmartProfile. Starting as low as $7, our DIY renovation solutions offer ……

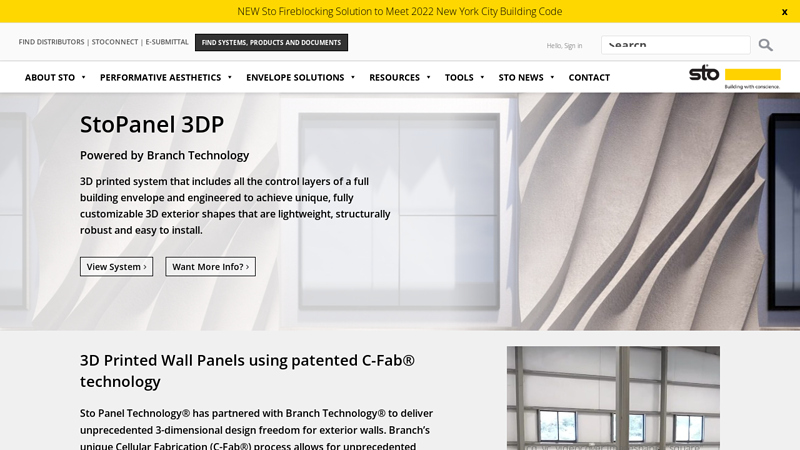

#4 StoPanel 3DP

Domain Est. 1996

Website: stocorp.com

Key Highlights: 3D printed system that includes all the control layers of a full building envelope and engineered to achieve unique, fully customizable 3D exterior shapes….

#5 DIRTT Construction Systems

Domain Est. 2003

Website: dirtt.com

Key Highlights: Speed up construction by up to 30% with DIRTT’s modular construction systems. Get accurate, real-time pricing and adaptable solutions for any project….

#6 3D Wall Panels

Domain Est. 2010

Website: soelbergi.com

Key Highlights: Soelberg provides the widest variety of thoughtfully designed 3D wall panels to include wave walls and organic and geometric graphic pattern options….

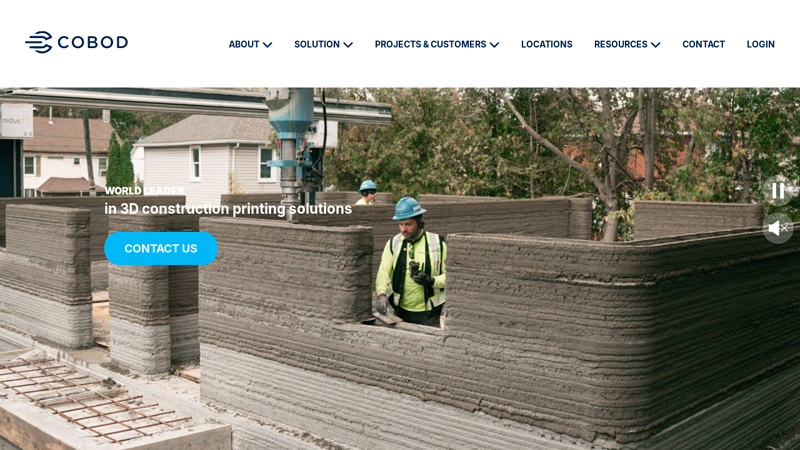

#7 COBOD

Domain Est. 2013

Website: cobod.com

Key Highlights: COBOD is the world leader in 3D construction printing solutions. We are continuously adding wider automation and robotics to construction….

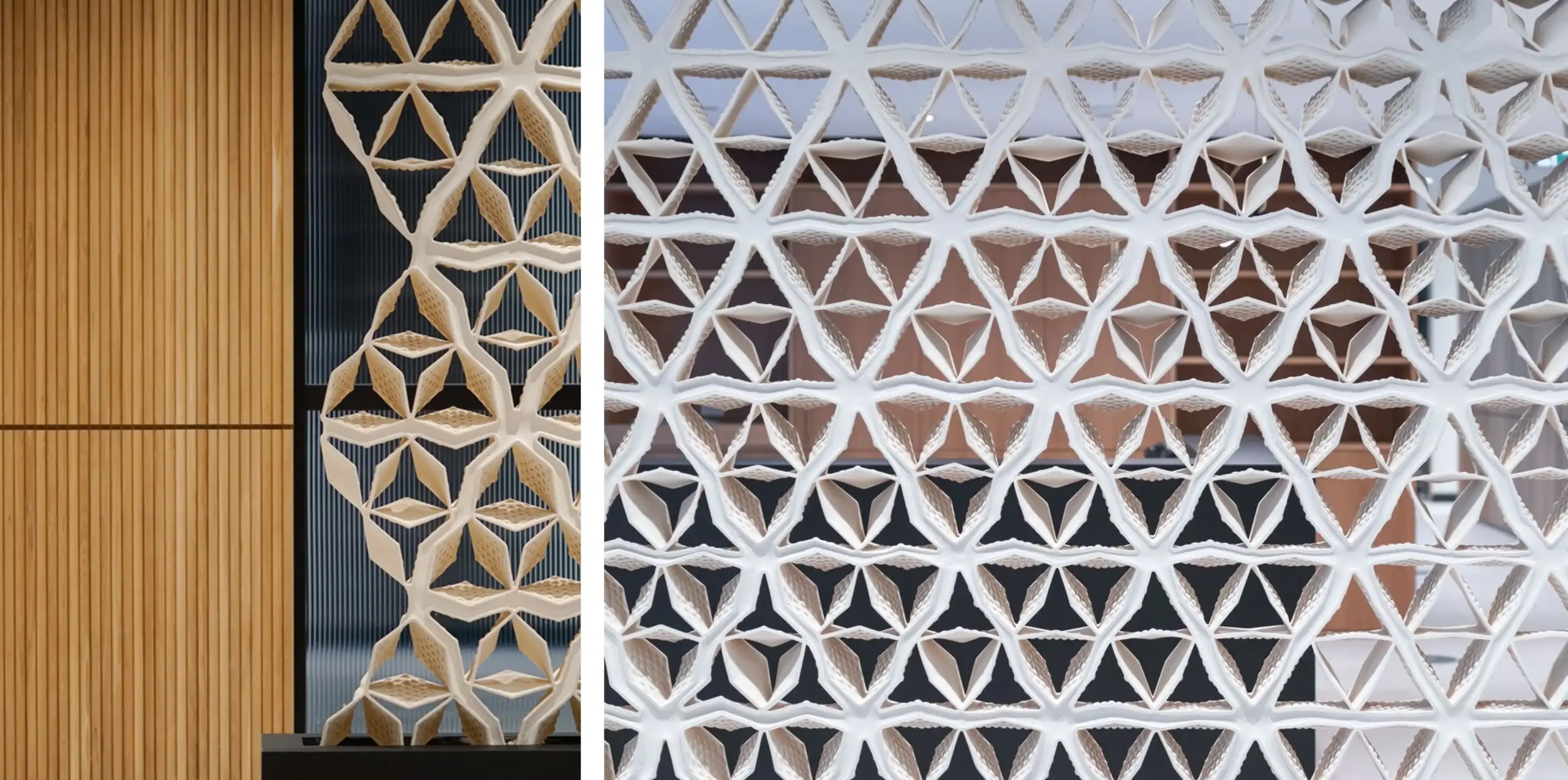

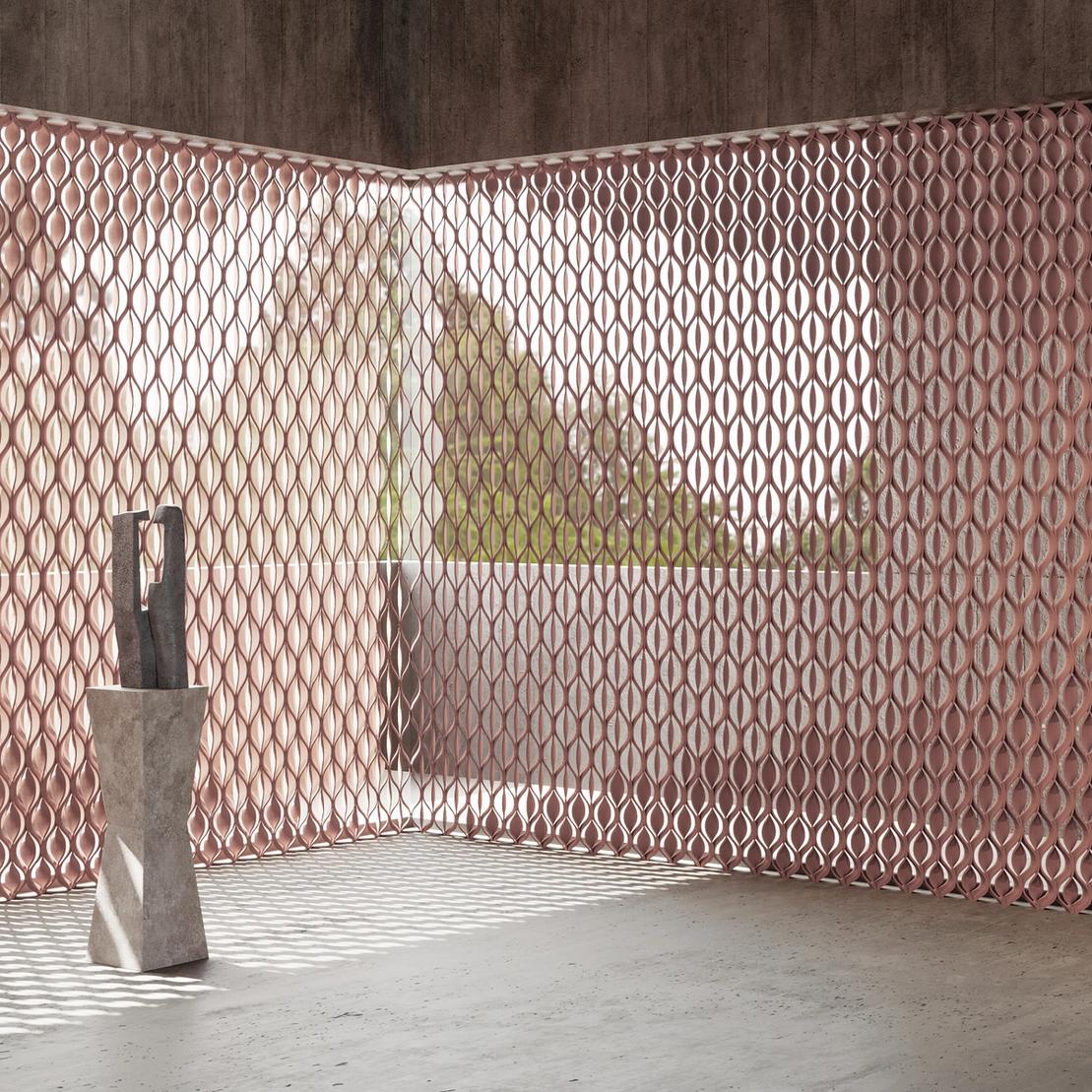

#8 Aectual

Domain Est. 2017

Website: aectual.com

Key Highlights: Design your circular interior with recycled materials and 3D-printed precision. Beautifully made, perfectly fitted, and built to last. Explore our systems….

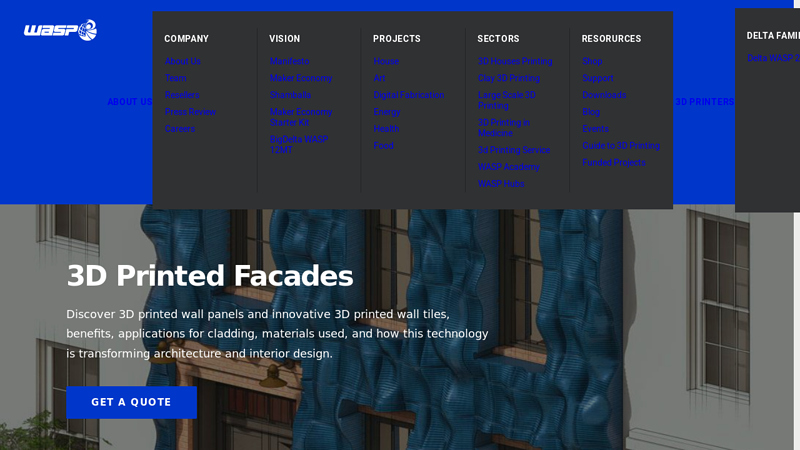

#9 3D Printed Wall Panels

Domain Est. 2017

Website: 3dwasp.com

Key Highlights: Discover 3D printed wall panels and innovative 3D printed wall tiles … New architectural exterior surfaces manufactured using ceramic 3D printing….

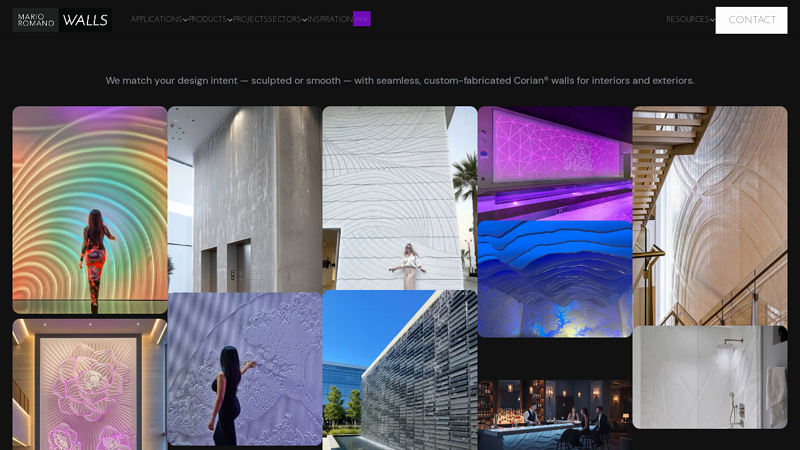

#10 Mario Romano Walls

Domain Est. 2022

Website: mrwalls.io

Key Highlights: Explore the world’s most beautiful 3D textured wall solutions. Infinite customization and designs made with Corian©. Enhance your space with MR Walls!…

Expert Sourcing Insights for 3D Printed Wall Panels

H2: 2026 Market Trends for 3D Printed Wall Panels

The market for 3D printed wall panels is poised for significant transformation by 2026, driven by technological advancements, growing demand for sustainable building materials, and increasing customization in architectural design. As additive manufacturing matures, its integration into interior design and construction sectors is accelerating, positioning 3D printed wall panels as a key innovation in modern building practices.

1. Expansion of Design Customization and Architectural Aesthetics

By 2026, 3D printed wall panels are expected to dominate high-end residential, commercial, and hospitality sectors due to their unparalleled design flexibility. Architects and interior designers are increasingly leveraging 3D printing to create intricate, bespoke patterns and textures that are difficult or impossible to achieve with traditional manufacturing. Generative design software and AI integration will allow for rapid prototyping and personalized panel solutions tailored to client preferences, fueling demand in luxury and boutique markets.

2. Sustainable Materials and Eco-Friendly Production

Sustainability remains a core driver of market growth. Leading manufacturers are shifting toward bio-based polymers, recycled plastics, and composite materials made from industrial waste (e.g., construction debris or agricultural byproducts). By 2026, regulatory pressures and green building certifications (such as LEED and BREEAM) are projected to favor low-carbon, recyclable wall solutions, giving environmentally conscious 3D printed panels a competitive edge. The additive nature of 3D printing also minimizes material waste, aligning with circular economy principles.

3. Integration with Smart Building Technologies

The convergence of 3D printing and smart infrastructure is paving the way for multifunctional wall panels. By 2026, expect to see panels embedded with sensors, LED lighting, temperature regulation systems, or acoustic dampening materials. These “smart” panels will support IoT-enabled buildings, enhancing energy efficiency and occupant comfort—particularly in smart offices, healthcare facilities, and urban housing developments.

4. Cost Reduction and Scalability Improvements

While 3D printing has historically faced cost and speed barriers, ongoing advancements in large-format printers and faster printing technologies (e.g., continuous liquid interface production, or CLIP) are expected to make production more scalable by 2026. As economies of scale take effect and printer costs decline, mid-market applications—including retail spaces and affordable housing—will begin to adopt 3D printed panels, broadening the market beyond niche luxury segments.

5. Regional Market Growth and Industry Adoption

Europe and North America will remain early adopters due to strong R&D ecosystems and supportive regulatory frameworks. However, rapid urbanization in Asia-Pacific—particularly in China, India, and Southeast Asia—will drive substantial growth, as governments invest in smart cities and modular construction. Collaborations between 3D printing firms and construction companies are likely to increase, accelerating commercial deployment.

6. Challenges and Barriers

Despite positive momentum, challenges remain. Regulatory standards for fire resistance, structural integrity, and indoor air quality are still evolving for 3D printed building components. Additionally, workforce training and integration into existing construction workflows present adoption hurdles. Overcoming these will be critical for mainstream acceptance by 2026.

In conclusion, the 3D printed wall panel market in 2026 will be defined by innovation in materials, design, and functionality. With sustainability, customization, and digital integration at its core, the sector is set to reshape interior architecture and contribute significantly to the future of smart, eco-conscious construction.

Common Pitfalls Sourcing 3D Printed Wall Panels: Quality and Intellectual Property

Sourcing 3D printed wall panels offers exciting design possibilities, but it comes with significant risks, particularly concerning quality consistency and intellectual property (IP) protection. Ignoring these areas can lead to project delays, legal disputes, and compromised end products.

Quality Inconsistencies and Material Limitations

One of the most frequent challenges is ensuring consistent quality across batches and suppliers. 3D printing processes—especially FDM (Fused Deposition Modeling) or SLA (Stereolithography)—can produce variable surface finishes, dimensional accuracy, and structural integrity due to differences in printer calibration, filament/resin quality, and post-processing techniques. Without strict quality control protocols, panels may exhibit warping, layer misalignment, or inconsistent textures. Additionally, material limitations such as UV degradation, flammability, or poor durability in humid environments can undermine long-term performance if not properly specified and tested.

Lack of Standardization and Scalability Issues

Unlike mass-manufactured building materials, 3D printed panels often lack industry-wide standards, making it difficult to compare offerings or ensure compatibility with construction methods. Each supplier may use proprietary software, materials, or printers, leading to inconsistencies. Scaling production can also be problematic; what works for a prototype may not be feasible for large commercial projects due to machine throughput, lead times, and cost escalation. Buyers may face unexpected delays or quality drops when transitioning from sample to full production.

Intellectual Property Infringement and Design Theft

3D printing inherently involves digital design files (e.g., STL or OBJ formats), which are easily copied, shared, or modified without authorization. When sourcing panels, there’s a risk that the supplier may be using designs protected by copyright, trademarks, or design patents without proper licensing. Conversely, if you provide your own design, inadequate contractual safeguards can expose your IP to theft or unauthorized replication. Without clear agreements on ownership, usage rights, and non-disclosure, your unique architectural vision could be reproduced for competitors or other projects.

Inadequate Legal and Contractual Protections

Many sourcing agreements fail to address IP ownership, confidentiality, or liability for design infringement. Suppliers may claim rights over design modifications or reuse your concepts in their portfolios. Without explicit clauses defining IP ownership, usage permissions, and indemnification, buyers risk legal exposure. Additionally, unclear warranties on material performance or print quality leave purchasers with limited recourse if panels fail to meet specifications or building codes.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence on suppliers, request physical samples, verify material certifications, and insist on third-party quality testing. Legally, use contracts that clearly assign IP ownership to the buyer, include non-disclosure agreements (NDAs), and require proof of original or licensed designs. Consider watermarking or digital rights management (DRM) for design files, and work with reputable partners who adhere to industry best practices in both manufacturing and IP compliance.

Logistics & Compliance Guide for 3D Printed Wall Panels

Product Classification and Regulatory Compliance

3D printed wall panels are typically classified as building materials or architectural components, depending on their application. Compliance with regional and international regulations is essential for legal distribution and installation. Key standards include:

- International Building Code (IBC): Ensures structural safety, fire resistance, and durability in construction applications.

- ASTM E84 (Surface Burning Characteristics of Building Materials): Evaluates flame spread and smoke development for interior wall finishes.

- LEED Certification Considerations: Sustainable materials and manufacturing processes may contribute to green building credits.

- CE Marking (EU): Required for construction products placed on the European market under the Construction Products Regulation (CPR) (EU) No 305/2011.

- UL/ETL Certification: May be required for fire safety and electrical compliance if panels include integrated lighting or sensors.

Manufacturers must provide a Declaration of Performance (DoP) for CE-marked products and ensure material safety data sheets (MSDS/SDS) are available for all components.

Material Safety and Environmental Regulations

3D printed wall panels are commonly made from thermoplastics (e.g., ABS, PETG, PLA), composites, or recycled polymers. Compliance with the following regulations is critical:

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals — ensures hazardous substances are identified and controlled.

- RoHS (EU): Restriction of Hazardous Substances — particularly relevant if panels include electronic components.

- Proposition 65 (California, USA): Requires warning labels if products contain chemicals known to cause cancer or reproductive harm.

- REACH SVHC (Substances of Very High Concern): Manufacturers must disclose if any panel materials contain substances above threshold levels.

Use of recycled or bio-based materials should be documented to support sustainability claims and comply with green procurement policies.

Packaging and Transportation Logistics

Proper packaging ensures product integrity during shipping and handling. Consider the following:

- Custom Crating: Due to the size and fragility of large panels, custom wooden or corrugated packaging is recommended to prevent warping or impact damage.

- Moisture Protection: Use moisture barriers or desiccants, especially for hygroscopic materials like nylon or certain bioplastics.

- Labeling Requirements: Clearly label packages with handling instructions (e.g., “Fragile”, “This Side Up”), product identification, country of origin, and compliance marks.

- International Shipping: For cross-border transport, ensure compliance with:

- ISPM 15: For wooden packaging materials in international shipments.

- Customs Documentation: Include commercial invoices, packing lists, and certificates of origin.

- HS Codes: Classify products correctly (e.g., 3925.30 for plastic panels or 4421.90 for wood-composite panels).

Optimize panel design for flat-pack or modular assembly to reduce shipping volume and costs.

Import/Export and Tariff Considerations

- Harmonized System (HS) Codes: Accurate classification is required for duty assessment. Common codes include:

- 3925.30: Panels, plates, and sheets of plastics for building use.

- 4421.90: Other articles of wood (if wood-based composite).

- Free Trade Agreements (FTAs): Leverage preferential tariffs under agreements like USMCA, CETA, or RCEP, if applicable.

- Import Duties and VAT/GST: Be aware of local tax structures and potential exemptions for construction materials.

Consult a customs broker for country-specific import requirements.

Installation and End-User Compliance

- Fire Safety Compliance: Panels used in commercial or public buildings must meet local fire codes. Provide flammability test reports (e.g., ASTM E84, EN 13501-1).

- Indoor Air Quality (IAQ): Materials should comply with low-VOC emissions standards such as:

- GREENGUARD Gold (UL 2818)

- EMICODE EC1 Plus

- AgBB (Germany)

- Structural Certification: If panels are load-bearing or part of a façade system, engineering certification may be required.

- Installation Guidelines: Provide detailed instructions, including fastening methods, spacing, expansion joints, and compatibility with substrates.

Sustainability and End-of-Life Management

- Recyclability: Design for disassembly and label materials to support recycling.

- Take-Back Programs: Consider implementing product stewardship programs in regions with extended producer responsibility (EPR) laws.

- Environmental Product Declarations (EPDs): Offer EPDs to support sustainable building certifications like LEED, BREEAM, or WELL.

Conclusion

Successfully navigating logistics and compliance for 3D printed wall panels requires a proactive approach to regulatory standards, material transparency, and supply chain management. By aligning with international building codes, environmental regulations, and efficient logistics practices, manufacturers can ensure safe, legal, and sustainable market entry across global regions.

Conclusion for Sourcing 3D Printed Wall Panels

Sourcing 3D printed wall panels presents a forward-thinking solution that combines aesthetic innovation, design flexibility, and sustainable production. As the construction and interior design industries continue to embrace digital fabrication, 3D printing offers unparalleled customization—enabling intricate patterns, textures, and geometries that are difficult or impossible to achieve with traditional manufacturing methods.

When sourcing these panels, it is essential to evaluate suppliers based on material quality, print resolution, structural integrity, and compliance with fire and safety standards. Additionally, considering lead times, scalability, and cost-effectiveness is crucial, especially for large-scale commercial or architectural projects.

Partnering with experienced manufacturers who utilize advanced 3D printing technologies—such as large-format printers and eco-friendly materials—can ensure durable, visually striking, and sustainable wall solutions. Overall, 3D printed wall panels represent a convergence of design freedom and efficient production, making them an ideal choice for modern, bespoke interior and exterior applications. As the technology matures and becomes more accessible, sourcing 3D printed panels will increasingly offer a competitive edge in innovative design and sustainable building practices.