The global 3D printing market is experiencing robust expansion, driven by increasing demand for rapid prototyping, customized manufacturing, and lightweight components across aerospace, automotive, and industrial sectors. According to Grand View Research, the global 3D printing market size was valued at USD 18.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 22.5% from 2023 to 2030. As additive manufacturing technologies mature, specialized component production—such as 3D printed latches—has emerged as a high-potential niche. These latches, known for design flexibility, reduced part count, and on-demand manufacturing, are increasingly adopted in applications requiring precision, durability, and rapid iteration. With companies leveraging advanced materials like nylon, polycarbonate, and metal alloys in additive processes, the demand for reliable, innovative latch solutions has surged. This growth trajectory, supported by expanding industrial adoption and supply chain digitization, sets the stage for the leading manufacturers shaping the future of 3D printed latch technology.

Top 8 3D Printed Latch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Latch Manufacturers

Domain Est. 2015

Website: latchmanufacturers.com

Key Highlights: Easily locate latch manufacturers that are able to provide many options of latches, including: locking or non-locking, stainless steel or carbon steel, ……

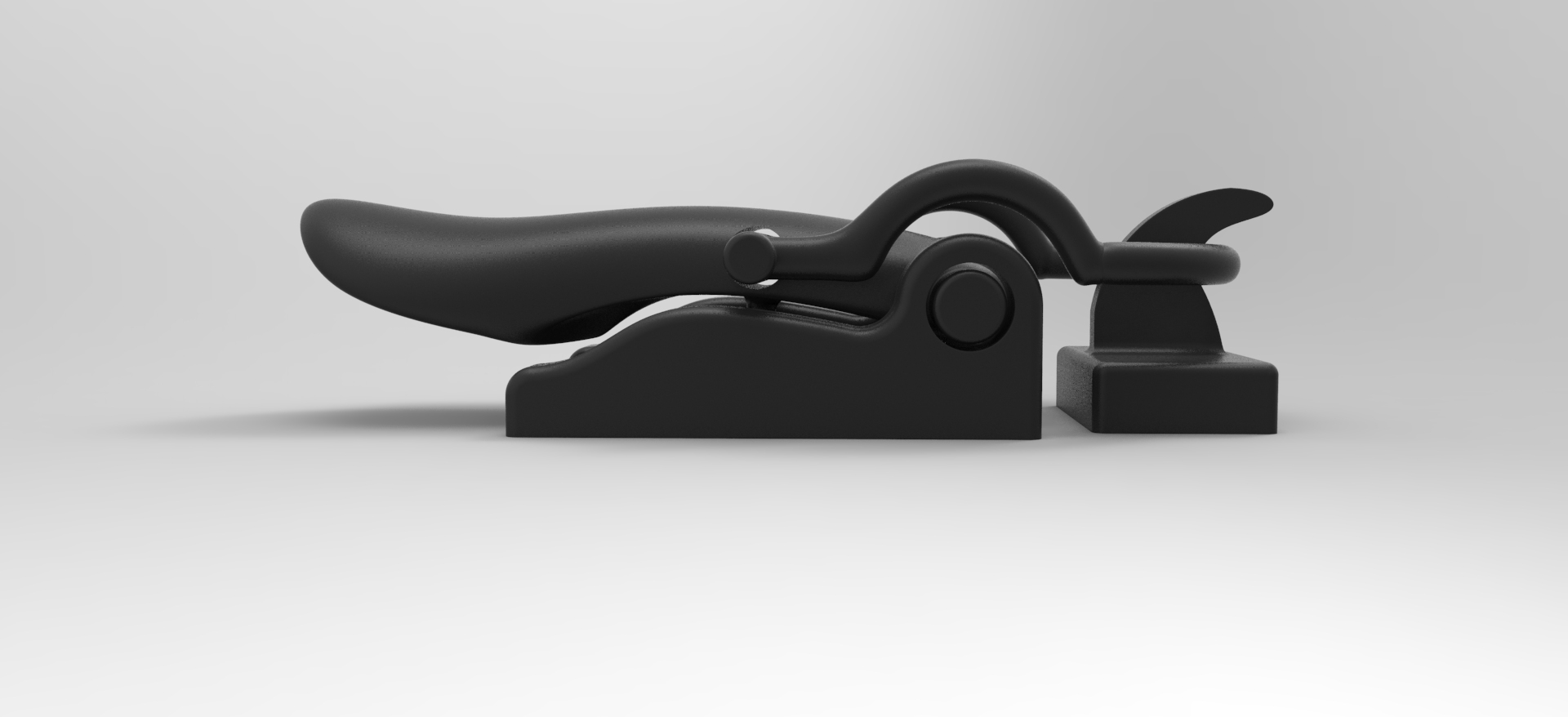

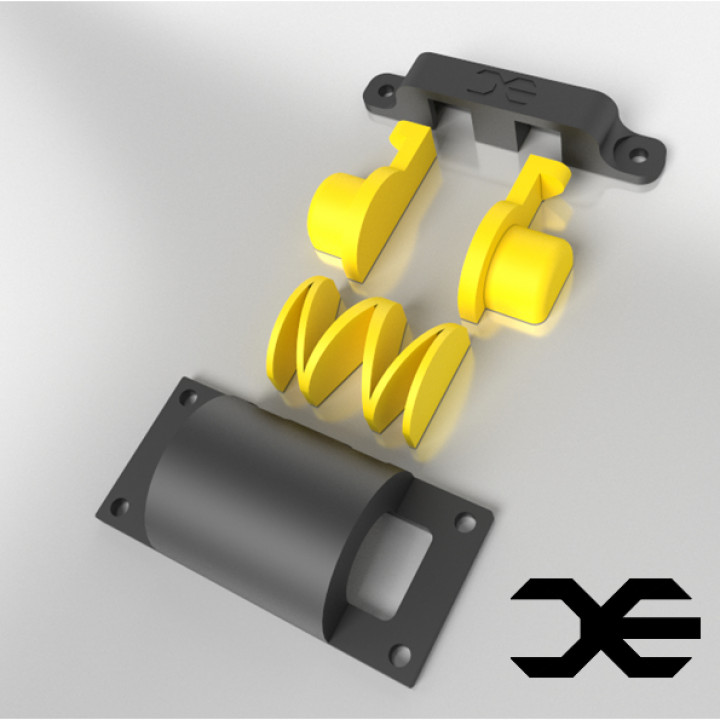

#2 3D Printable Latch V3

Domain Est. 1989

Website: autodesk.com

Key Highlights: Gallery · Architecture, Engineering & Construction · Product Design & Manufacturing · Media & Entertainment · Assets….

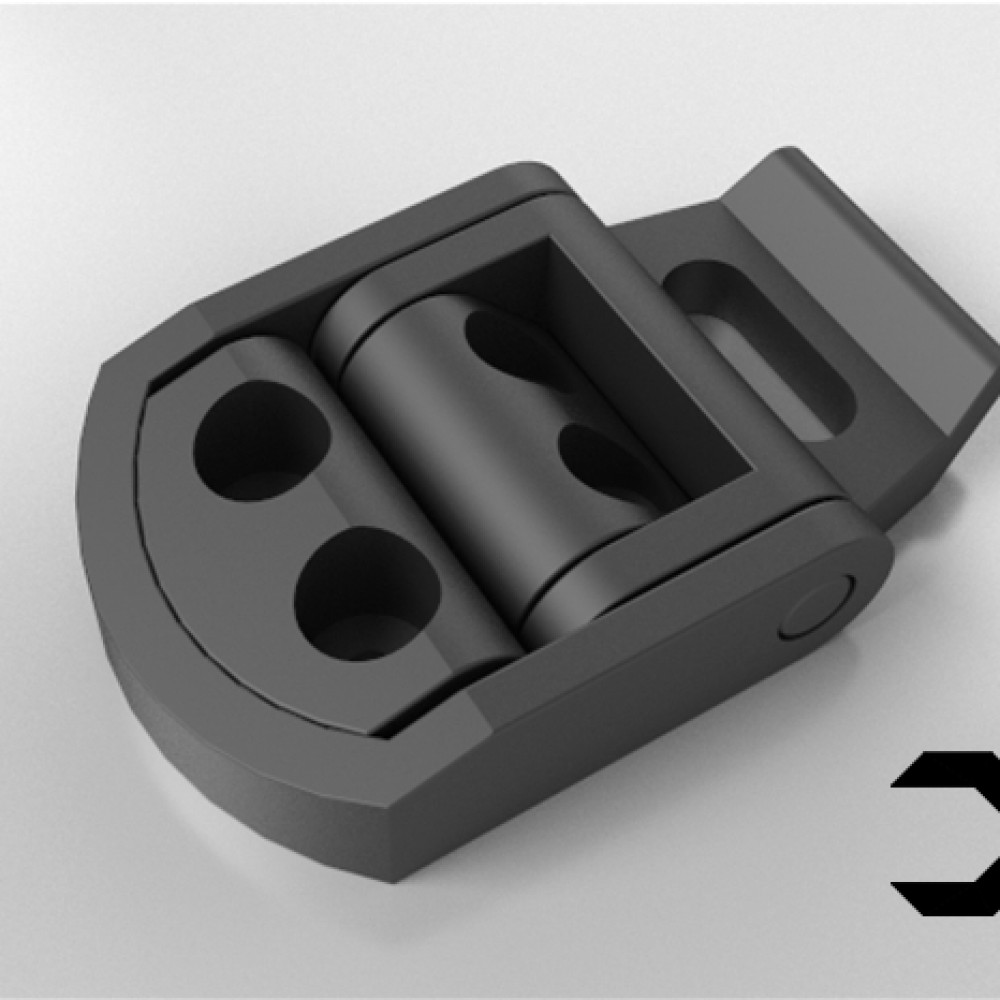

#3 Airbus Helicopters to start large

Domain Est. 1995

Website: airbus.com

Key Highlights: Airbus Helicopters has officially launched the production of latch shafts for the doors of A350 XWB passenger aircraft using 3D manufacturing….

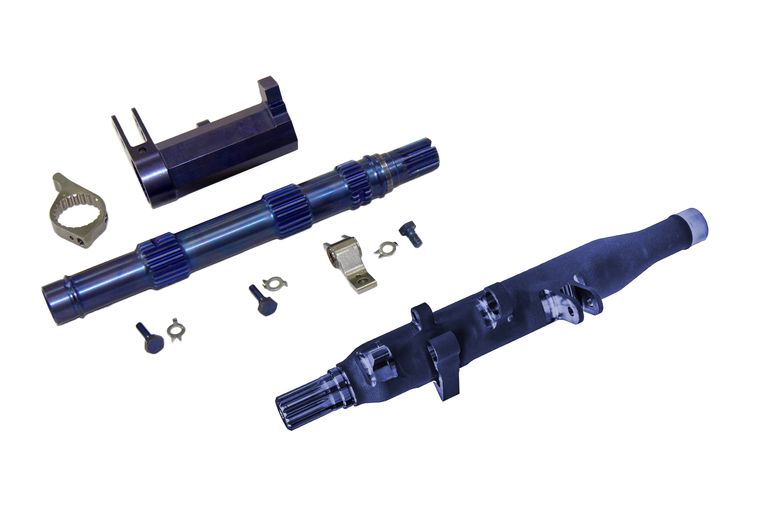

#4 Flush Slam Latch MS

Domain Est. 2008

Website: tai-sam.com

Key Highlights: Vibration Resistant. Push to Close Latch.PA; Material: Nylon glass fiber,black; Panel thickness: 1~12m/m; Can be unlocked internally….

#5 “latching mechanism” 3D Models to Print

Domain Est. 2012

Website: yeggi.com

Key Highlights: 10000+ “latching mechanism” printable 3D Models. Every Day new 3D Models from all over the World. Click to find the best Results for latching mechanism ……

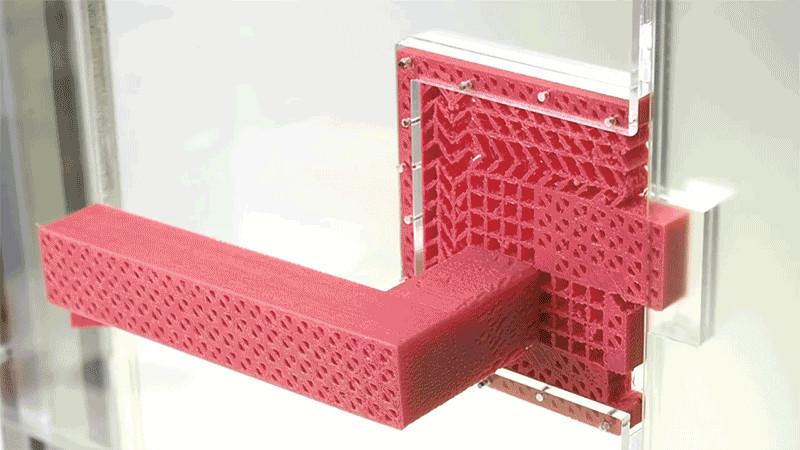

#6 Magnetic Door Latch

Domain Est. 2013

Website: 3dprintingcanada.com

Key Highlights: 14-day returnsMagnetic Door Latch with pre-drilled installation holds. 2 part set, magnet plus metal plate. Brand: 3D Printing Canada / Reviews. Magnetic Door Latch. In Stock….

#7 Latch Lock

Domain Est. 2014

Website: makerworld.com

Key Highlights: The 2-piece latch lock installs in seconds without the need for tools, screws, or drilling, making it the perfect temporary solution for travel or home use….

#8 3D Printed Latch

Domain Est. 2016

Website: 3deo.co

Key Highlights: ErgoKiwi wanted to utilize metal 3D printing for a latch used in their ergonomic cutting tool. They were underwhelmed by the visual quality of another metal 3D ……

Expert Sourcing Insights for 3D Printed Latch

H2: 2026 Market Trends for 3D-Printed Latches

The global market for 3D-printed latches is poised for significant transformation by 2026, driven by advancements in additive manufacturing, rising demand for customization, and expanding applications across aerospace, automotive, healthcare, and consumer electronics industries. As companies increasingly adopt Industry 4.0 principles, 3D printing offers a strategic advantage in producing lightweight, complex, and functionally integrated latch components that traditional manufacturing methods struggle to achieve efficiently.

One major trend shaping the 2026 outlook is the shift toward on-demand and decentralized production. 3D-printed latches enable manufacturers to produce parts locally and in smaller batches, reducing lead times and inventory costs. This is particularly relevant in industries like automotive and aerospace, where customized latch solutions are needed for prototypes or limited-run models. By 2026, an estimated 30% of industrial latch components in niche applications are expected to be 3D printed, according to market analysts at SmarTech Analysis.

Material innovation is another key driver. The development of high-performance thermoplastics (e.g., PEEK, ULTEM) and composite filaments enhances the durability, heat resistance, and mechanical strength of 3D-printed latches, making them viable for mission-critical applications. Metal 3D printing technologies, such as selective laser melting (SLM), are also gaining traction for producing robust latches in aerospace and defense, where reliability under stress is paramount.

Additionally, design flexibility enabled by generative design software allows engineers to optimize latch geometry for weight reduction and performance. By 2026, AI-driven design tools are expected to be integrated into over 50% of 3D printing workflows for functional components like latches, accelerating innovation and reducing material waste.

Sustainability concerns are further accelerating adoption. 3D printing generates less scrap material compared to subtractive methods, aligning with corporate environmental goals. As regulations tighten around carbon emissions and circular economy principles, 3D-printed latches—especially those using recyclable or bio-based materials—will gain favor among eco-conscious manufacturers.

In conclusion, the 2026 market for 3D-printed latches will be characterized by increased industrial adoption, material and design innovation, and a growing emphasis on sustainability and supply chain resilience. Companies that leverage these trends early will gain a competitive edge in delivering smarter, lighter, and more adaptable fastening solutions.

Common Pitfalls When Sourcing 3D Printed Latches: Quality and Intellectual Property Concerns

Sourcing 3D printed latches—whether for prototyping, low-volume production, or end-use parts—can offer significant advantages in design flexibility and speed. However, without careful oversight, companies risk encountering critical pitfalls related to part quality and intellectual property (IP) protection. Understanding these challenges is essential to ensure reliable performance and legal compliance.

Quality Consistency and Material Limitations

One of the most significant pitfalls when sourcing 3D printed latches is inconsistent part quality. Unlike traditional manufacturing methods such as injection molding, 3D printing processes (e.g., FDM, SLS, SLA) can produce variable results due to factors like printer calibration, layer adhesion, material batch differences, and post-processing methods. Latches, which often require precise tolerances and mechanical strength, are particularly sensitive to these variations. Warping, layer delamination, or surface roughness can compromise latch functionality, leading to premature failure under stress or repeated use.

Moreover, the mechanical properties of 3D printed materials—especially common thermoplastics like PLA or ABS—may not match those of injection-molded equivalents. Impact resistance, creep behavior, and long-term durability are often inferior, which can be problematic in applications requiring repeated actuation or exposure to environmental stressors. Sourcing from vendors without rigorous quality control protocols increases the risk of receiving non-conforming parts.

Intellectual Property Risks and Design Protection

Another major concern is the potential for intellectual property (IP) infringement or exposure. When outsourcing 3D printing, especially to third-party service bureaus or overseas manufacturers, design files (typically in STL or STEP format) must be shared, creating opportunities for unauthorized duplication or distribution. Without proper contractual safeguards—such as non-disclosure agreements (NDAs) or clearly defined IP ownership clauses—companies risk losing control over proprietary designs.

Additionally, sourcing latches from open marketplaces or unverified suppliers increases the chance of inadvertently using a design that infringes on existing patents or copyrights. Unlike standardized components, 3D printed latches are often custom or semi-custom, making it harder to verify originality. This exposes the buyer to legal liability, recall costs, and reputational damage.

To mitigate these risks, organizations should vet suppliers thoroughly, require certifications (e.g., ISO 9001), use digital rights management (DRM) tools for design files, and ensure contracts explicitly protect IP rights. Investing in trusted partners and robust legal frameworks is essential for secure and high-quality sourcing of 3D printed components.

Logistics & Compliance Guide for 3D Printed Latch

Design & Material Specifications

Ensure the 3D printed latch design adheres to standardized dimensions and tolerances for interchangeability and functionality. Utilize materials that meet relevant industry certifications (e.g., UL, RoHS, REACH) based on the intended application environment (indoor, outdoor, load-bearing, etc.). Document material data sheets (MDS) and certificate of compliance (CoC) for traceability.

Manufacturing & Quality Control

Implement consistent 3D printing parameters (layer height, infill density, print speed) to maintain structural integrity. Conduct routine quality checks including dimensional inspection, stress testing, and visual defect analysis. Maintain a production log with batch numbers, machine IDs, and operator details for full traceability.

Packaging & Labeling

Package the latch to prevent damage during transit, using anti-static or protective materials where necessary. Label each unit or batch with part number, material type, manufacturing date, and compliance marks (e.g., CE, FCC if applicable). Include user instructions and safety warnings if required.

Shipping & Distribution

Classify the 3D printed latch under the appropriate Harmonized System (HS) code for customs purposes—typically under 3926.30 (other articles of plastics) or a more specific code based on function. Prepare commercial invoice, packing list, and bill of lading. Confirm compliance with destination country import regulations, especially for plastic components and low-voltage mechanical devices.

Regulatory Compliance

Verify adherence to regional regulations such as:

– EU: REACH (chemical safety), RoHS (hazardous substances), CE marking if part of a larger assembly.

– USA: FCC rules (if embedded electronics), CPSC guidelines for consumer products.

– International: ISO 9001 (quality management) and ISO 14001 (environmental) if applicable.

Documentation & Recordkeeping

Maintain accessible records of design files, material certifications, test reports, shipping documents, and compliance declarations for a minimum of five years. Implement a document control system to manage revisions and ensure up-to-date compliance.

End-of-Life & Sustainability

Provide disposal guidance based on material composition. Encourage recycling through take-back programs or partnerships with certified e-waste handlers. Align with circular economy principles by designing for disassembly and reuse where possible.

Conclusion for Sourcing a 3D Printed Latch:

Sourcing a 3D printed latch offers a compelling combination of design flexibility, rapid prototyping, cost-efficiency for low to medium volumes, and the ability to customize solutions tailored to specific application requirements. By leveraging additive manufacturing, organizations can reduce lead times, minimize tooling costs, and iterate quickly during product development. While traditional manufacturing methods may still be preferable for high-volume production due to economies of scale and material durability, 3D printing provides an ideal solution for prototypes, specialized components, or low-volume applications where customization and speed are critical.

When sourcing 3D printed latches, it is essential to carefully evaluate material properties, print resolution, structural integrity, and environmental resistance to ensure the final part meets functional demands. Partnering with a reliable 3D printing service provider or investing in in-house capabilities can further enhance control over quality and turnaround time.

In conclusion, 3D printing is a viable and often advantageous method for sourcing latches—especially in niche, custom, or time-sensitive applications—offering innovation and agility in design and production.