The global 3D laser marking market is experiencing robust growth, driven by increasing demand for precision marking solutions across industries such as automotive, electronics, medical devices, and aerospace. According to a report by Mordor Intelligence, the global laser marking and engraving market was valued at USD 976.4 million in 2023 and is projected to reach USD 1.43 billion by 2029, growing at a CAGR of approximately 6.5% during the forecast period. This expansion is fueled by advancements in laser technology, rising adoption of automation in manufacturing, and the need for permanent, high-resolution marking for traceability and branding. As 3D laser marking systems gain traction for their ability to handle complex geometries and curved surfaces with high accuracy, a growing number of manufacturers are innovating to meet evolving industrial demands. In this competitive landscape, nine key players have distinguished themselves through technological leadership, global reach, and strong R&D investments—shaping the future of industrial marking solutions.

Top 9 3D Laser Marking Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Industrial Laser Markers

Website: telesis.com

Key Highlights: Laser marking systems are ideal for manufacturers looking to mark serial numbers, codes, logos and more on their products. Learn more today!…

#2 Focus on laser

Founded: 1996

Website: hanslaser.net

Key Highlights: Han’s Laser Technology Industry Group Co., Ltd, a public company which was established in 1996, has now become the flagship of Chinese national laser ……

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 HGLASER

Website: hglaserglobal.com

Key Highlights: HGLASER is a leading provider of laser cutting machine, laser marking mahcine and laser cleaning machine.Email:[email protected]….

#5 3D Scanhead For Laser Marking Machine Manufactures and Suppliers

Website: cklasermachine.com

Key Highlights: CKLASER is one of the leading manufacturers and suppliers of 3d scanhead for laser marking machine. Top quality, great selection and expert advice are our ……

#6 Full Spectrum Laser

#7 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems designs and manufactures high-end 2D and 3D (3-axis) fiber, CO2, and UV galvanometer-based laser and marking solutions….

#8 Gravotech

Website: gravotech.us

Key Highlights: Gravotech designs, manufactures, and distributes innovative engraving, marking, and cutting solutions….

#9 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

Expert Sourcing Insights for 3D Laser Marking

H2: 2026 Market Trends in 3D Laser Marking

As we approach 2026, the 3D laser marking market is undergoing transformative growth driven by advancements in industrial automation, precision manufacturing, and the rising demand for product traceability and customization. This analysis explores key trends shaping the 3D laser marking industry, highlighting technological innovations, sector-specific applications, regional developments, and evolving customer expectations.

-

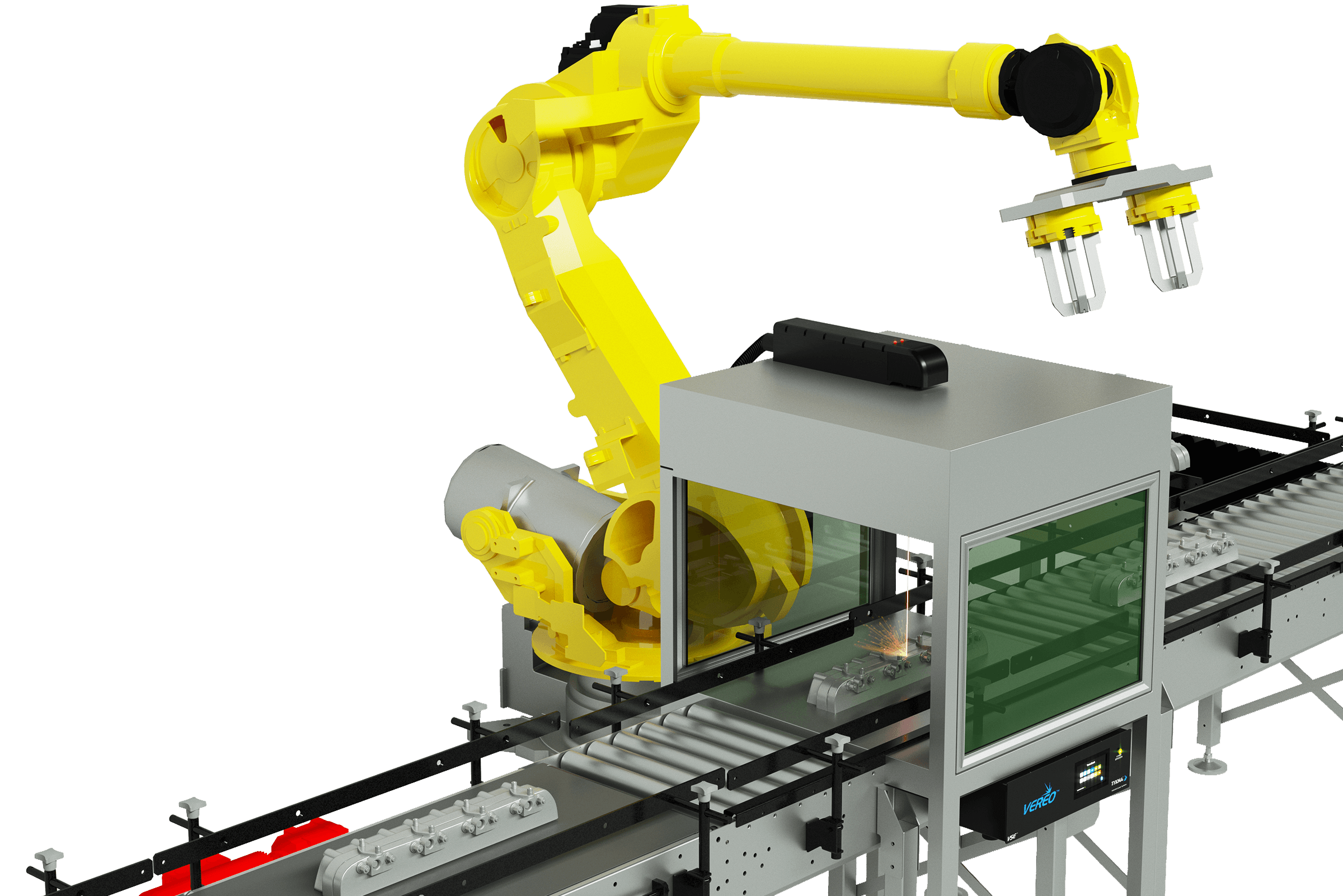

Increased Adoption in High-Precision Industries

By 2026, industries such as aerospace, medical devices, and automotive are increasingly leveraging 3D laser marking for permanent, high-resolution identification on complex geometries. The ability of 3D laser systems to mark curved, uneven, or multi-planar surfaces with micron-level accuracy is becoming a critical advantage. This trend is fueled by stringent regulatory requirements for part traceability (e.g., UDI in healthcare and AS9100 in aerospace), pushing manufacturers to adopt more reliable and durable marking solutions. -

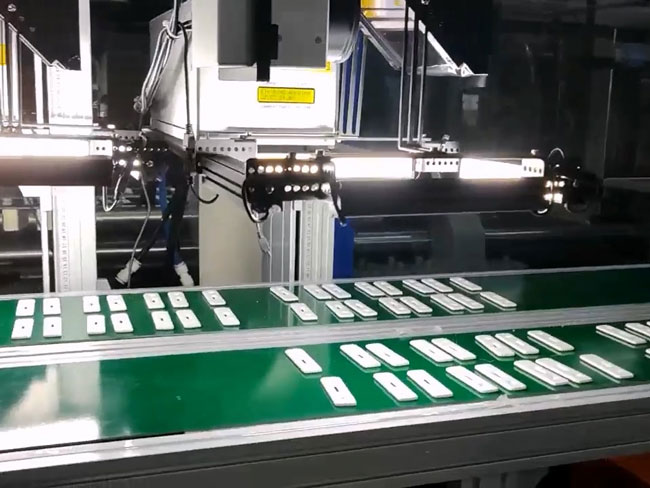

Integration with Smart Manufacturing and Industry 4.0

3D laser marking systems are being seamlessly integrated into smart factories through IoT-enabled platforms and digital twins. By 2026, most new laser marking systems are expected to feature real-time monitoring, predictive maintenance, and connectivity with MES (Manufacturing Execution Systems). This allows for automated job setup, quality control, and data logging, enhancing production efficiency and reducing human error. -

Advancements in Laser Source Technology

There is a marked shift toward ultrafast lasers—particularly picosecond and femtosecond lasers—in 3D marking applications. These lasers offer cold ablation, minimizing heat-affected zones and enabling high-contrast, damage-free marking on sensitive or reflective materials like ceramics, polymers, and coated metals. Fiber and hybrid laser systems are also being optimized for 3D dynamic focusing, improving processing speed and flexibility. -

Growth in Customization and Anti-Counterfeiting

With rising consumer demand for personalized products and brand protection, companies are using 3D laser marking for intricate designs, QR codes, and micro-engravings that are difficult to replicate. In sectors like luxury goods, electronics, and pharmaceuticals, this technology supports anti-counterfeiting measures and enhances customer engagement through unique, traceable identifiers. -

Expansion in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, is emerging as a dominant force in the 3D laser marking market. Rapid industrialization, government initiatives promoting advanced manufacturing (e.g., “Make in India,” “China 2025”), and growing electronics production are accelerating adoption. Local manufacturers are also investing in R&D to develop cost-effective, high-performance systems tailored to regional needs. -

Sustainability and Eco-Friendly Processing

Environmental concerns are influencing equipment design and usage. 3D laser marking is gaining favor over chemical or ink-based methods due to its non-contact, waste-free nature. By 2026, energy-efficient laser systems with low power consumption and longer operational lifespans are becoming standard, aligning with global sustainability goals. -

Software and AI-Driven Enhancements

Sophisticated software solutions with AI-powered image recognition and adaptive path planning are enhancing the usability of 3D laser marking systems. These tools allow for automatic surface detection, distortion correction, and optimal parameter selection, reducing setup time and enabling non-expert operators to achieve high-quality results.

Conclusion

By 2026, the 3D laser marking market is poised for robust expansion, driven by technological convergence, regulatory demands, and the need for smart, sustainable manufacturing. Companies that invest in integrated, flexible, and intelligent marking solutions will be best positioned to capitalize on these evolving trends across diverse industrial sectors.

Common Pitfalls in Sourcing 3D Laser Marking Systems (Quality and Intellectual Property)

Quality-Related Pitfalls

Inadequate System Calibration and Repeatability

A frequent quality issue arises when 3D laser marking systems are not properly calibrated for complex geometries. Poor calibration leads to inconsistent mark depth, contrast, or accuracy across curved or uneven surfaces. Buyers may overlook the need for dynamic focus control and real-time tracking validation, resulting in non-uniform markings that fail quality inspections.

Substandard Optics and Laser Components

Low-cost suppliers may use inferior lenses, galvanometers, or laser sources that degrade quickly under continuous operation. This compromises beam quality and long-term reliability. Without proper verification, buyers risk receiving systems with short lifespans and frequent maintenance needs, increasing total cost of ownership.

Insufficient Integration with Production Environment

Many 3D laser markers are designed for lab conditions but fail in harsh industrial settings. Vibration, temperature fluctuations, and dust can affect marking precision. Sourcing without testing under real-world conditions often leads to unexpected downtime and rework.

Lack of Comprehensive Testing and Validation Protocols

Suppliers may provide minimal test reports or use non-representative samples. Without access to detailed performance data—such as marking speed vs. legibility, edge sharpness, and material compatibility—buyers cannot verify claims. This increases the risk of receiving a system that performs poorly on actual production parts.

Intellectual Property (IP)-Related Pitfalls

Unclear Ownership of Custom Software and Parameters

When custom marking algorithms or motion paths are developed for a specific 3D application, ownership may not be explicitly defined in contracts. Suppliers could retain rights to software enhancements, limiting the buyer’s ability to modify, replicate, or transfer the solution.

Use of Proprietary or Licensed Third-Party Technology

Some 3D laser systems incorporate patented scanning mechanisms, control software, or optical designs. If the supplier lacks proper licensing or transparency, the end user may face liability for IP infringement, especially in regulated industries or international markets.

Reverse Engineering and Design Copying Risks

Sharing detailed 3D CAD models or marking requirements with untrusted suppliers increases the risk of design imitation. Without robust non-disclosure agreements (NDAs) and IP protection clauses, competitors may gain access to proprietary product features or manufacturing processes.

Limited Access to Firmware and Source Code

Suppliers may lock down firmware or restrict access to configuration files, preventing in-house troubleshooting or integration with existing MES/SCADA systems. This creates dependency on the vendor and potential long-term IP control issues, especially if support is discontinued.

Logistics & Compliance Guide for 3D Laser Marking

Overview of 3D Laser Marking Technology

3D laser marking utilizes focused laser beams to permanently engrave or etch identifiers, patterns, or data directly onto three-dimensional surfaces. Unlike traditional 2D marking, this technology accommodates complex geometries, curved surfaces, and variable depths, making it ideal for aerospace, medical devices, automotive, and industrial manufacturing. Proper logistics planning and adherence to compliance standards are essential to ensure traceability, safety, and regulatory conformity.

Equipment and Facility Requirements

Ensure your production environment supports high-precision 3D laser systems. This includes stable power supply, climate control (temperature and humidity), and vibration-free mounting surfaces. Laser marking stations must be enclosed with interlocked safety shields and equipped with fume extraction systems to capture particulates and volatile organic compounds (VOCs) generated during marking. Regular calibration and maintenance schedules are required to maintain accuracy and system longevity.

Material Compatibility and Handling

Verify material compatibility before initiating marking processes. Common materials include metals (stainless steel, aluminum, titanium), plastics, ceramics, and composites. Each material reacts differently to laser wavelengths and power settings; improper configuration can lead to discoloration, cracking, or hazardous emissions. Implement a material verification log and pre-process inspection protocol to prevent errors. Store and handle materials according to manufacturer specifications to avoid contamination or surface damage.

Safety and Regulatory Compliance

Adherence to international safety standards is mandatory. Key regulations include:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements

– ANSI Z136.1: Safe use of lasers in the United States

– EU Machinery Directive 2006/42/EC and Laser Product Safety (EN 60825)

Operators must undergo laser safety training and wear appropriate personal protective equipment (PPE), including laser safety goggles rated for the specific wavelength used. Conduct regular risk assessments and maintain documentation for audits.

Environmental and Waste Management

Laser marking produces particulate matter and potentially hazardous fumes, especially when processing coated or composite materials. Install certified fume extraction and filtration systems (e.g., HEPA and activated carbon filters) to meet OSHA and EPA air quality standards. Dispose of collected waste in accordance with local environmental regulations—classify waste as hazardous or non-hazardous based on composition. Maintain logs of filter changes and waste disposal for compliance tracking.

Marking Quality and Traceability Standards

Ensure markings meet industry-specific readability and permanence requirements:

– ISO 9001: Quality management systems

– ISO 13485: For medical device labeling

– AS9100: Aerospace traceability standards

– UDI (Unique Device Identification) compliance for medical devices under FDA and EU MDR

Use automated vision systems to verify mark quality (contrast, depth, legibility) and integrate with manufacturing execution systems (MES) for full traceability. Archive mark data with batch numbers, timestamps, and equipment IDs.

Supply Chain and Logistics Integration

Coordinate with suppliers and customers to standardize marking specifications (font, size, data format, location). Use GS1 standards or customer-defined templates for barcodes, Data Matrix codes, or alphanumeric identifiers. Ensure marking occurs at the appropriate production stage to avoid rework. For serialized parts, synchronize marking with ERP or PLM systems to maintain data integrity across the supply chain.

Documentation and Audit Readiness

Maintain comprehensive records including:

– Laser system calibration and maintenance logs

– Operator training certifications

– Material compatibility matrices

– Mark verification reports

– Environmental compliance documentation

Regular internal audits and readiness for third-party inspections (e.g., FDA, notified bodies) are crucial. Digitize records for easy retrieval and regulatory reporting.

Continuous Improvement and Technology Updates

Stay current with advancements in laser technology, software controls, and regulatory changes. Participate in industry forums and update standard operating procedures (SOPs) accordingly. Conduct periodic process reviews to optimize marking speed, quality, and energy efficiency while ensuring ongoing compliance.

Conclusion for Sourcing 3D Laser Marking:

Sourcing a 3D laser marking system is a strategic investment that can significantly enhance product quality, traceability, and operational efficiency. As industries such as aerospace, medical devices, automotive, and electronics demand higher precision and durable marking on complex geometries, 3D laser technology offers a reliable and scalable solution. When sourcing, it is essential to evaluate key factors including laser type (fiber, CO2, UV), marking speed, software compatibility, integration capabilities with existing production lines, and vendor support.

Prioritizing suppliers with proven expertise, strong after-sales service, and customizable solutions ensures long-term reliability and return on investment. Furthermore, considering future scalability and advancements in automation and Industry 4.0 integration will position organizations to adapt to evolving manufacturing demands. Ultimately, a well-sourced 3D laser marking system not only meets current production needs but also supports innovation, compliance, and brand integrity across the product lifecycle.