The global 3D laser crystal engraving machine market is experiencing steady growth, driven by rising demand in personalized gifting, industrial marking, and artistic applications. According to a report by Mordor Intelligence, the global laser marking and engraving market was valued at USD 8.94 billion in 2023 and is projected to reach USD 13.54 billion by 2029, growing at a CAGR of 6.98% during the forecast period. This expansion is fueled by advancements in laser technology, increased adoption in the electronics and automotive sectors, and growing consumer interest in customized decorative items. With 3D crystal engraving emerging as a niche yet fast-evolving segment, manufacturers are innovating rapidly to enhance precision, speed, and user accessibility. As demand surges, identifying leading players becomes critical for businesses and creatives seeking reliable, high-performance solutions. Based on market presence, technological innovation, and product range, here are the top 9 manufacturers shaping the 3D laser crystal engraving landscape.

Top 9 3D Laser Crystal Engraving Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 3D crystal laser engraving machine manufacturer

Website: vitro.de

Key Highlights: Our laser systems are compatible for a wide range of applications. Whether small production, individual production, small and large series production….

#2 Laser crystal engraving machine

Website: laserwuhan.com

Key Highlights: HJZ Laser 3D laser crystal engraving machine is to engrave 2D or 3D design inside of crystal, glass, acrylic and other transparent material without any hurt to ……

#3 3d photo crystal laser engraving machine

Website: arguslaser.net

Key Highlights: Argus Laser is a leading China 3d photo crystal laser engraving machine manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of ……

#4 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems designs and manufactures high-end 2D and 3D (3-axis) fiber, CO2, and UV galvanometer-based laser and marking solutions….

#5 3D Crystal Laser Engraving Machine

Website: sismarlaser.com

Key Highlights: Start small, impress big. With the UV 3D Laser Engraving Machine, your startup can create both emotional 3D crystal keepsakes and surface-engraved products, ……

#6 Perfect Laser 3D crystal engraving machine

Website: perfectlaser.net

Key Highlights: Perfect Laser offers 3D crystal engraving machine,widely used for 3D crystal engraving and 3D portraits for human image.affordable and easy-to-use….

#7 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

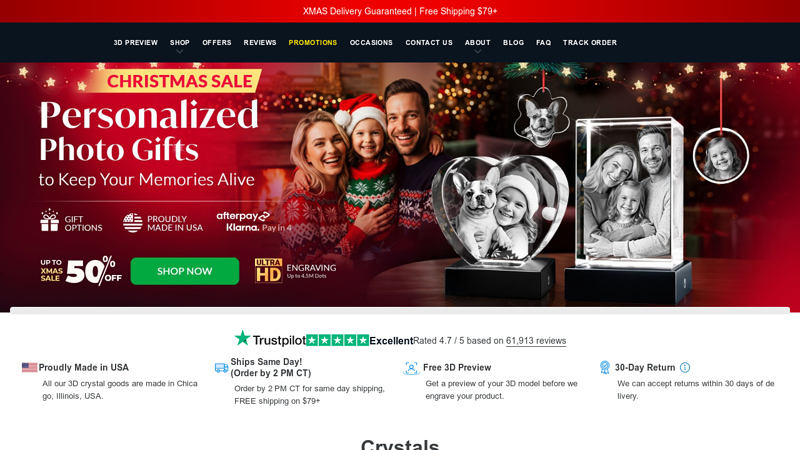

#8 3D Crystals by ArtPix 3D®

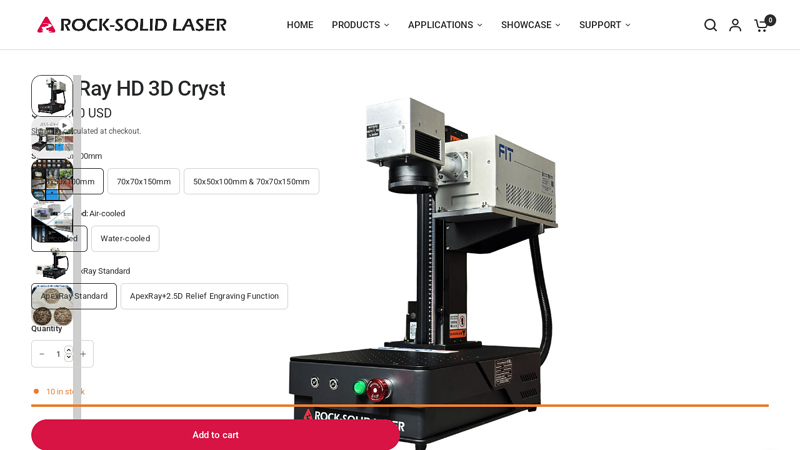

#9 ApexRay HD 3D Crystal Subsurface Laser Engraving Machine

Expert Sourcing Insights for 3D Laser Crystal Engraving Machine

H2: 2026 Market Trends for 3D Laser Crystal Engraving Machines

The global market for 3D laser crystal engraving machines is poised for significant transformation by 2026, driven by technological advancements, rising demand for personalized products, and expanding applications across industries. Key trends shaping the market include increased automation, integration with AI and IoT, growing adoption in the promotional and gift sectors, and a shift toward compact, user-friendly systems. Regions such as North America, Europe, and Asia-Pacific are expected to lead in both innovation and market share. Additionally, sustainability concerns and the need for energy-efficient systems are influencing product development. As businesses and consumers alike seek unique, high-precision customization, the 3D laser crystal engraving machine market is projected to experience steady growth, with a CAGR of approximately 8–10% through 2026.

Common Pitfalls When Sourcing 3D Laser Crystal Engraving Machines (Quality & IP)

Sourcing a 3D laser crystal engraving machine involves navigating several critical challenges, particularly concerning quality assurance and intellectual property (IP) protection. Overlooking these pitfalls can lead to significant financial losses, operational delays, or legal complications.

Poor Build Quality and Component Reliability

Many suppliers, especially lower-cost manufacturers, use substandard materials and components to cut costs. This includes under-spec’d lasers, low-grade motion systems (stepper motors, rails), and fragile enclosures. Machines with poor build quality suffer from inconsistent engraving depth, misalignment over time, mechanical failures, and short lifespans, resulting in higher total cost of ownership due to repairs and downtime.

Inaccurate or Overstated Performance Specifications

Suppliers may exaggerate key performance metrics such as engraving speed, resolution, maximum crystal size, or laser power. For instance, a machine advertised with “high precision” may deliver inconsistent dot placement in 3D space, leading to blurry or distorted images. Verifying specifications through independent testing or third-party reviews is essential to avoid performance shortfalls.

Lack of After-Sales Support and Spare Parts Availability

A major risk when sourcing from overseas or less-established vendors is the absence of reliable technical support, training, and readily available spare parts. When a machine breaks down, long wait times for repairs or replacement components can halt production. Ensure the supplier offers clear service level agreements (SLAs), accessible support channels, and a documented parts supply chain.

Use of Counterfeit or Unlicensed Software/Firmware

Some machines come preloaded with pirated or reverse-engineered control software. This not only violates intellectual property rights but also introduces security vulnerabilities, limits functionality, and prevents access to updates or technical support. Always confirm software licensing and request proof of legitimate software procurement from the supplier.

Infringement of Patented Technologies

The 3D laser crystal engraving space involves patented optical systems, motion control algorithms, and software features. Sourcing a machine that incorporates patented technology without authorization exposes the buyer to legal risks, including cease-and-desist orders or liability for infringement. Conduct due diligence on the machine’s technology and request documentation from the supplier confirming freedom to operate.

Insufficient IP Protection for Custom Designs

When integrating the machine into a production workflow, ensure that any proprietary design files or engraving patterns are protected. Some machine software may lack robust access controls or encryption, increasing the risk of design theft or unauthorized replication. Choose systems with strong data security features and clear IP ownership clauses in vendor contracts.

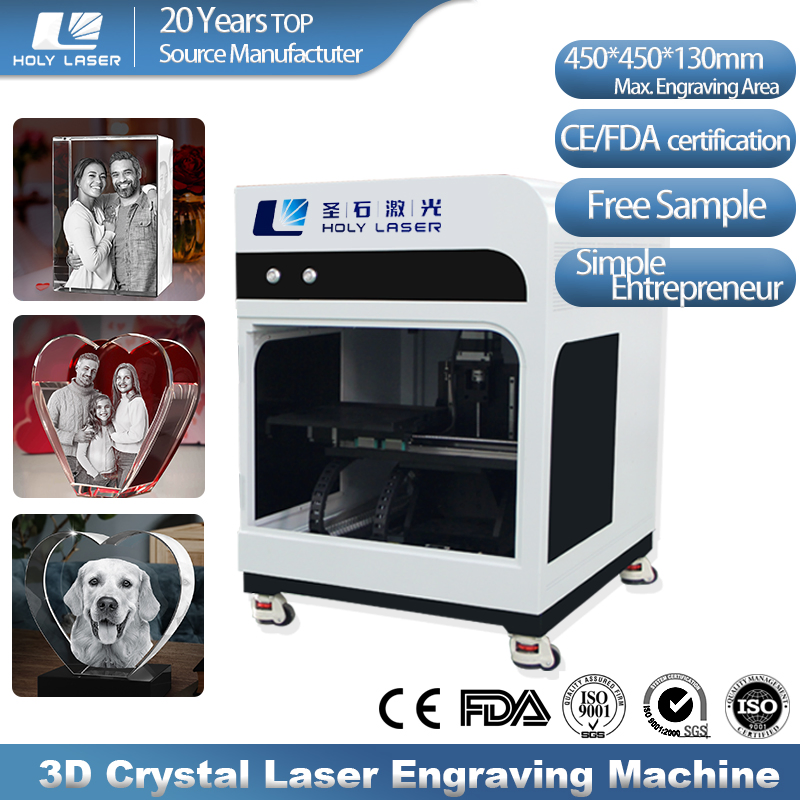

Absence of Compliance and Safety Certifications

Machines lacking proper safety certifications (e.g., CE, FDA, or laser safety Class 1 compliance) may pose hazards to operators and fail regulatory inspections. Non-compliant lasers can also be seized at customs. Always verify that the machine meets international safety and electromagnetic compatibility (EMC) standards for your target market.

Logistics & Compliance Guide for 3D Laser Crystal Engraving Machine

Shipping & Handling Requirements

When transporting a 3D laser crystal engraving machine, proper packaging and handling are essential to prevent damage. The machine must be securely packed in a rigid, shock-absorbent crate with internal foam or custom-cut inserts to immobilize all components. Ensure the laser head and motion system are locked or padded to avoid internal movement. Use weather-resistant packaging to protect against moisture and label the package as “Fragile,” “This Side Up,” and “Do Not Stack.” For international shipments, include a detailed packing list and commercial invoice. Coordinate with freight carriers experienced in handling precision equipment, and opt for tracking and insurance coverage.

Import/Export Regulations

Compliance with international trade regulations is critical when shipping 3D laser crystal engraving machines. These devices may be classified under Harmonized System (HS) Code 8479.89 (other machines having individual functions) or 8515.80 (electrodeless industrial machines), depending on the model and region. Verify the correct HS code with local customs authorities. Machines containing laser components may be subject to export controls under the Export Administration Regulations (EAR) in the U.S. or equivalent frameworks in other countries. Confirm whether a license is required based on the destination country and laser specifications (e.g., power output). Always provide accurate technical documentation, including laser class certification, to facilitate smooth customs clearance.

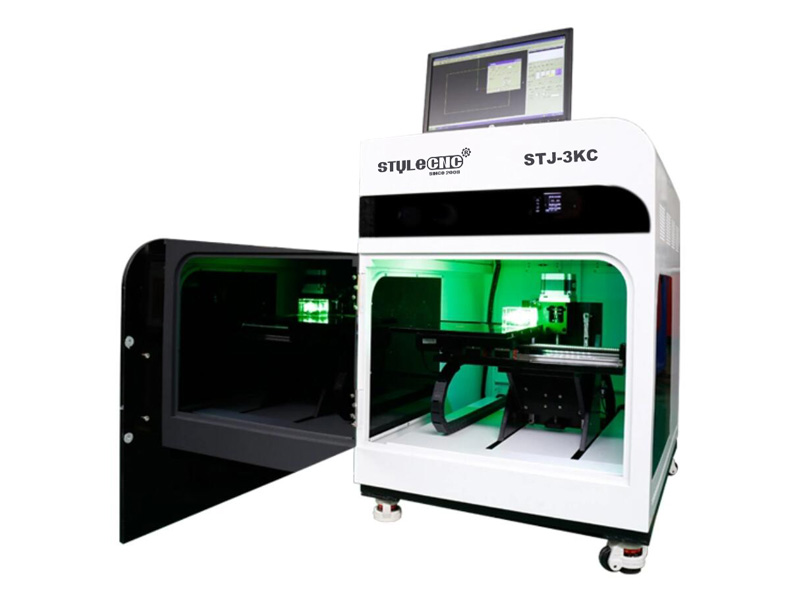

Safety & Laser Classification Compliance

3D laser crystal engraving machines typically use Class 3B or Class 4 lasers, which require strict adherence to safety standards. Ensure the machine complies with the IEC 60825-1 standard for laser product safety and carries appropriate warning labels. In the United States, compliance with the FDA/CDRH (Center for Devices and Radiological Health) regulations under 21 CFR 1040.10 and 1040.11 is mandatory. This includes submitting a Laser Product Report and obtaining a variance if the device does not meet standard performance requirements. Users must also implement engineering controls such as interlocks, emergency stop buttons, and protective enclosures. Provide operators with laser safety training and appropriate personal protective equipment (PPE), including laser safety goggles.

Electrical & CE Marking Requirements (EU)

For distribution within the European Union, the 3D laser crystal engraving machine must comply with the EU’s CE marking directives. Key applicable directives include the Machinery Directive (2006/42/EC), the Low Voltage Directive (2014/35/EU), and the Electromagnetic Compatibility (EMC) Directive (2014/30/EU). Conduct a risk assessment, implement necessary safety measures, and compile a Technical File. The machine must be equipped with CE-compliant power supplies and proper grounding. Include multilingual user manuals and safety instructions. Affix the CE mark only after full conformity assessment and maintain documentation for at least 10 years. Non-compliant devices may be detained at EU borders or subject to market withdrawal.

Environmental & RoHS Compliance

Electronic components in 3D laser engraving machines must comply with environmental regulations such as the EU’s Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU. This restricts the use of lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE) in electrical and electronic equipment. Ensure all circuit boards, power supplies, and connectors meet RoHS standards by obtaining compliance certificates from component suppliers. Additionally, consider Waste Electrical and Electronic Equipment (WEEE) Directive obligations, which may require registration and participation in recycling programs in certain countries. Document compliance and include RoHS statements in product specifications and user manuals.

Operational & Workplace Safety Standards

Deploying a 3D laser crystal engraving machine in commercial or industrial settings requires adherence to workplace safety regulations. In the U.S., compliance with OSHA standards (e.g., 29 CFR 1910.97 for non-ionizing radiation and 1910.145 for safety signage) is required. Install the machine in a dedicated, well-ventilated area with fume extraction systems to manage any airborne particulates generated during engraving. Establish standard operating procedures (SOPs) and conduct regular maintenance checks on laser alignment and safety features. Train all operators on emergency procedures and proper machine use. Maintain logs for inspections, repairs, and safety drills to demonstrate due diligence in regulatory audits.

Conclusion for Sourcing a 3D Laser Crystal Engraving Machine

After thorough research and evaluation of available options, sourcing a 3D laser crystal engraving machine proves to be a strategic investment for enhancing product customization, expanding service offerings, and meeting growing demand for personalized gifts and promotional items. The key factors considered—such as precision, reliability, ease of use, software compatibility, after-sales support, and cost-effectiveness—highlight the importance of selecting a machine that balances performance with long-term value.

Machines from reputable manufacturers offering fiber or diode laser technology, intuitive software interfaces, and strong customer service support stand out as optimal choices. Additionally, assessing warranty terms, training availability, and scalability ensures the selected machine aligns with both current operational needs and future business growth.

In conclusion, investing in a high-quality 3D laser crystal engraving machine will not only improve production efficiency and product quality but also provide a competitive edge in the personalized goods market. With the right equipment and support, businesses can unlock new revenue streams and deliver exceptional, high-value products to their customers.