The global 3D glass laser engraving market is experiencing robust growth, driven by rising demand for personalized and high-precision decorative and industrial markings across sectors such as luxury goods, electronics, automotive, and architecture. According to a 2023 report by Mordor Intelligence, the global laser engraving market is projected to grow at a CAGR of over 7.2% from 2023 to 2028, with glass engraving emerging as a key segment due to advancements in fiber and CO2 laser technologies that enable intricate three-dimensional designs. Grand View Research further supports this momentum, noting that the increasing adoption of automated laser systems in manufacturing and the surge in customized consumer products are accelerating industry expansion. As demand for durable, high-resolution engraving solutions rises, a select group of manufacturers has distinguished themselves through innovation, precision, and scalability—setting the standard in the competitive landscape of 3D glass laser engraving.

Top 10 3D Glass Laser Engraving Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 3d Glass Laser Engraving

Website: feeltek.net

Key Highlights: 3d Glass Laser Engraving Manufacturers, Factory, Suppliers From China, Aggressive price with top quality and satisfying support make us earned extra ……

#2 3D Glass Engraving Machine Manufactures and Suppliers

Website: cklasermachine.com

Key Highlights: CKLASER is one of the leading manufacturers and suppliers of 3d glass engraving machine. Top quality, great selection and expert advice are our main ……

#3 Fiber Laser Engraving Machine

Website: haotianlasers.com

Key Highlights: As a leading manufacturer, not a reseller, we specialize in crafting high-quality CO2 laser engraving machines, UV laser marking machines, and fiber laser ……

#4 3D Crystals by ArtPix 3D®

#5 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

#6 Personalized 3D Crystal Photos by Beyond Memories®

Website: beyond-memories.com

Key Highlights: Your source for personalized 3D crystal engraving. Beyond Memories® uses the newest innovation of capturing memories in crystals, the perfect gift….

#7 3Dinnovation

Website: 3dinnovation.com

Key Highlights: Free delivery over $150 30-day returns3 easy steps to order. Choose your perfect crystal. Upload your photo write personal engraving. We will convert it into 3d and laser it into y…

#8 Custom Laser

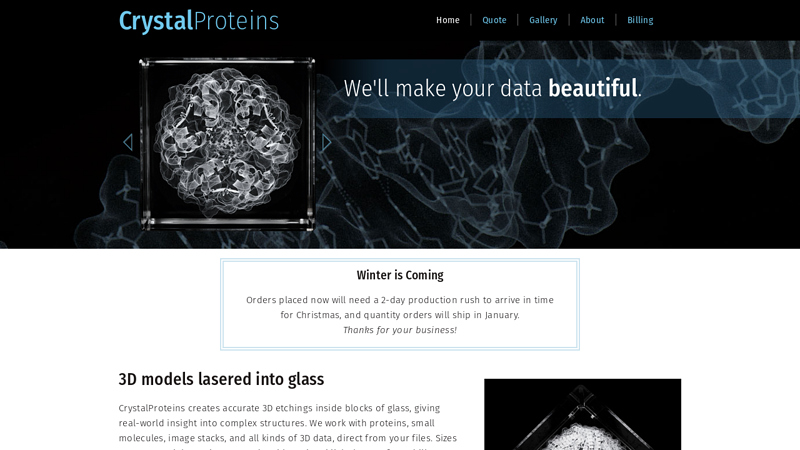

#9 CrystalProteins

Website: crystalproteins.com

Key Highlights: 3D models lasered into glass. CrystalProteins creates accurate 3D etchings inside blocks of glass, giving real-world insight into complex structures….

#10 3D Subsurface Laser Engraving

Website: crystal-d.com

Key Highlights: Our 3D subsurface engraving process comes in, allowing us to recreate any image inside a crystal award or gift in two or three dimensions….

Expert Sourcing Insights for 3D Glass Laser Engraving

H2: 2026 Market Trends for 3D Glass Laser Engraving

The 3D glass laser engraving market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications. Key trends shaping the landscape include:

1. Surge in Personalization and Premiumization: Consumers increasingly demand unique, high-value items. 3D laser engraving enables intricate, deep, and photorealistic designs (like portraits, logos, or 3D models) within glass, fueling demand in luxury goods (premium crystal awards, bespoke tableware), personalized gifts (engraved whiskey glasses, anniversary keepsakes), and high-end home décor. This trend elevates glass products from commodities to personalized art, commanding premium prices.

2. Advancements in Laser Technology and Software: Core drivers of market growth include:

* Faster Processing & Higher Precision: Development of more powerful, stable ultrafast lasers (femtosecond, picosecond) enables faster engraving speeds and finer detail resolution, improving throughput and enabling new design complexities.

* Improved 3D Modeling & Rendering Software: User-friendly, integrated software platforms with advanced 3D modeling capabilities (converting 2D images to 3D depth maps, real-time previews) lower the barrier to entry and enhance design possibilities.

* Automation & Integration: Increased adoption of robotic arms and conveyor systems for loading/unloading and multi-axis positioning will boost production efficiency and enable continuous, high-volume manufacturing, particularly for industrial applications.

3. Expansion into New Application Sectors: Beyond traditional awards and gifts, 3D glass engraving is finding new footholds:

* Architectural & Interior Design: Use in creating unique decorative panels, signage, lighting fixtures, and feature walls with embedded 3D art or structural patterns.

* Medical & Scientific Devices: Engraving identification marks, calibration scales, or decorative elements on specialized glass components (e.g., labware, sensor housings) where durability and precision are critical.

* Electronics & Consumer Tech: Potential for decorative or functional engraving on smartphone covers, smartwatch faces, or display components, although material compatibility and process challenges remain.

* Art & Sculpture: Adoption by artists as a medium for creating intricate sculptures and gallery pieces, pushing the boundaries of the technology.

4. Focus on Sustainability and Material Innovation: Growing environmental awareness will influence:

* Energy Efficiency: Development of more energy-efficient laser systems to reduce operational costs and environmental impact.

* Material Sourcing: Increased demand for engraving on recycled glass or sustainably sourced specialty glass types.

* Process Optimization: Minimizing waste through precise material usage and optimized nesting software.

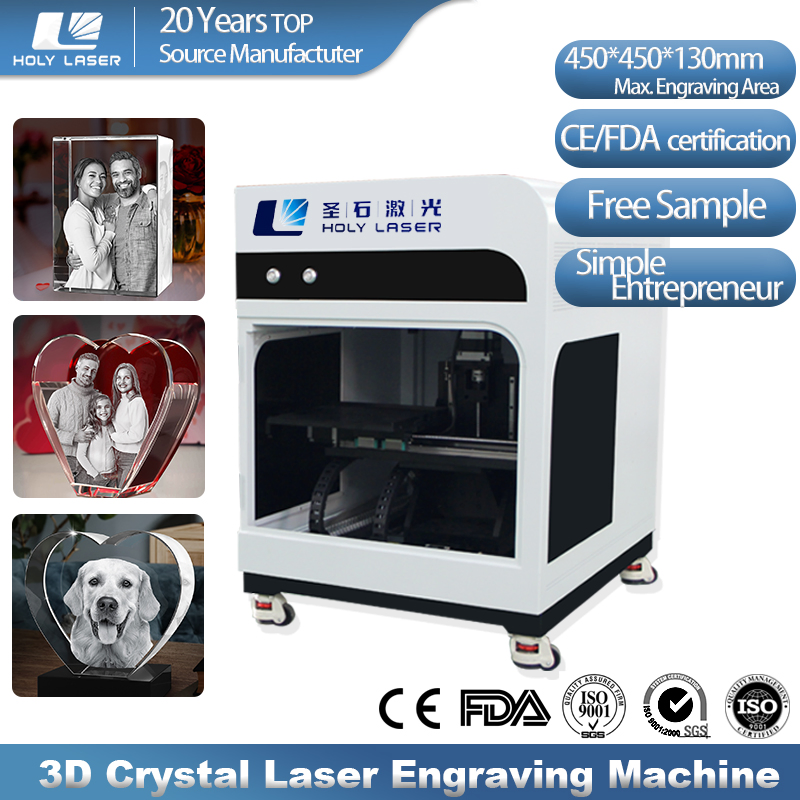

5. Democratization and Market Fragmentation: The market will see a bifurcation:

* High-End Industrial Systems: Continued development of sophisticated, automated systems for large manufacturers and specialized industrial players.

* Accessible Prosumer/Small Business Solutions: Emergence of more affordable, compact, and user-friendly desktop or benchtop 3D laser engravers, enabling small businesses, artisans, and even hobbyists to enter the market, fostering innovation and niche product creation.

6. Integration with Digital Platforms & E-commerce: Seamless integration between online design tools, e-commerce platforms, and engraving machines will become standard, enabling direct-to-consumer (D2C) personalized product sales with rapid turnaround times (“click-to-engrave”).

In conclusion, by 2026, the 3D glass laser engraving market will be characterized by technological maturity enabling faster, more intricate, and accessible production, driven by strong demand for personalization across diverse and expanding applications, while navigating challenges related to cost, scalability for mass production, and material limitations. The convergence of advanced hardware, intelligent software, and digital connectivity will define the competitive landscape.

H2. Common Pitfalls in Sourcing 3D Glass Laser Engraving: Quality and Intellectual Property Concerns

When sourcing 3D glass laser engraving services, businesses often encounter critical challenges related to both product quality and intellectual property (IP) protection. Understanding these pitfalls is essential to ensure consistent output, brand integrity, and legal compliance.

1. Inconsistent Engraving Quality

One of the most prevalent issues is variability in engraving precision and finish. Low-quality laser systems or poorly calibrated equipment can result in blurry, uneven, or misaligned engravings. Factors such as glass type, thickness, and internal stress may affect how the laser interacts with the material. Suppliers lacking expertise in 3D crystal engraving may not account for these variables, leading to high defect rates and customer dissatisfaction.

2. Limited Design Complexity Handling

Not all providers can accurately reproduce intricate 3D models or fine details. Sourcing from vendors without advanced software capabilities (e.g., 3D modeling and depth mapping tools) can result in simplified or distorted outputs. This is especially problematic for custom artworks, corporate awards, or personalized gifts where fidelity to the original design is crucial.

3. Lack of Material Quality Control

The clarity, composition, and internal flaws of the glass significantly impact the final engraving. Sourcing from suppliers who use substandard or inconsistent glass materials may lead to undesirable visual effects, such as clouding, fractures during engraving, or poor light refraction. Transparent supply chain documentation on glass sourcing is often missing.

4. Inadequate Intellectual Property Protections

When sharing proprietary designs, logos, or 3D models with third-party engravers, there is a risk of unauthorized duplication or distribution. Many overseas or low-cost suppliers operate in jurisdictions with weak IP enforcement, increasing the likelihood of design theft or counterfeiting. Contracts may lack clear clauses on data confidentiality, usage rights, or destruction of design files post-production.

5. Poor File Handling and Data Security

Digital design files are vulnerable during transmission and storage. Suppliers without secure file-sharing protocols or data encryption practices may expose sensitive IP to breaches. Additionally, some vendors retain copies of designs for future use without consent, creating long-term IP risks.

6. Misaligned Expectations Due to Inadequate Prototyping

Skipping the prototyping phase or relying solely on digital previews can lead to mismatches between expectations and final products. Without physical samples, clients may overlook depth perception issues, lighting effects, or scale inaccuracies until mass production begins.

7. Language and Communication Barriers

Especially when sourcing internationally, misunderstandings about design intent, quality standards, or project timelines can compromise outcomes. Miscommunication may result in incorrect engravings, delayed shipments, or repeated revisions—increasing costs and time-to-market.

To mitigate these risks, businesses should vet suppliers thoroughly, request physical samples, establish clear contractual IP terms, and use secure collaboration tools. Prioritizing partners with proven technical expertise, quality certifications, and transparent operational practices is key to successful 3D glass laser engraving sourcing.

Logistics & Compliance Guide for 3D Glass Laser Engraving

This guide outlines key logistical considerations and compliance requirements for businesses involved in 3D glass laser engraving operations, ensuring smooth production, safe handling, and adherence to regulatory standards.

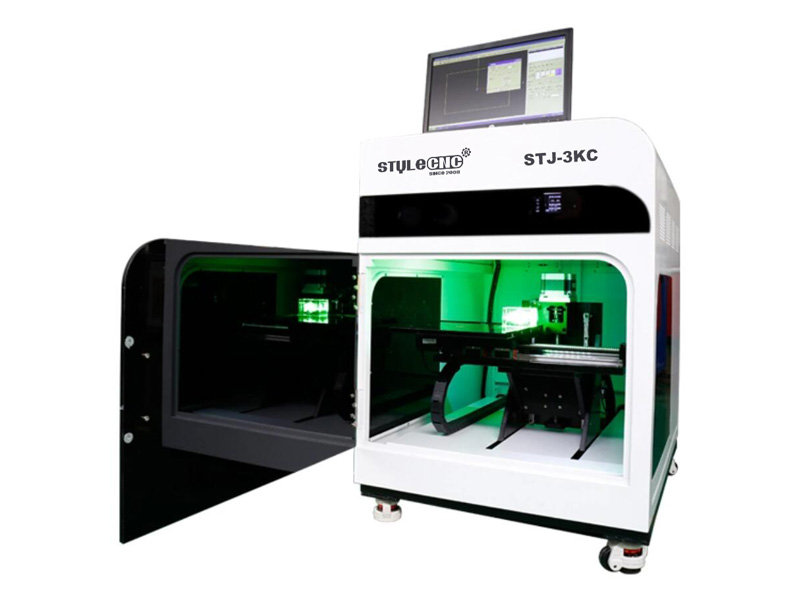

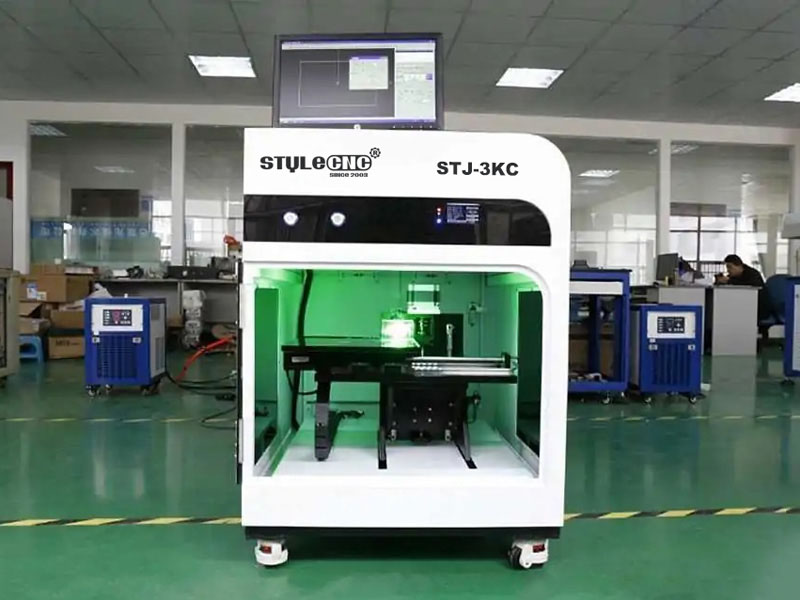

Equipment and Facility Requirements

Ensure your laser engraving setup and workspace meet technical and safety standards. Use industrial-grade CO₂ or fiber lasers with precise 3D motion control compatible with glass materials. The facility must provide stable power supply, climate control (to minimize thermal expansion effects on glass), and adequate ventilation or fume extraction systems to capture fine glass particulates generated during engraving. Install laser safety enclosures with interlocks and appropriate warning signage (e.g., Class 1 or 4 laser warnings per IEC 60825), and conduct regular equipment maintenance as per manufacturer guidelines.

Material Sourcing and Handling

Source high-quality, annealed glass free from internal stresses, coatings, or contaminants that could compromise engraving results or safety. Verify material certifications (e.g., ISO 9001) from suppliers and maintain traceability records. Handle glass sheets or items with clean gloves and use vacuum lifting tools to prevent scratches or breakage. Store materials vertically in dry, temperature-stable environments to avoid warping or moisture-related issues. Implement quality checks upon receipt to screen for defects such as bubbles, inclusions, or surface imperfections.

Operational Safety Protocols

Enforce strict safety procedures for all personnel involved in laser engraving. Operators must wear appropriate personal protective equipment (PPE), including laser safety goggles with the correct optical density (OD) rating for the laser wavelength used. Training must cover laser operation, emergency shutdown procedures, and handling of broken glass. Prohibit unauthorized access to the engraving area during operation. Maintain a clean workspace and dispose of glass waste in puncture-resistant containers clearly labeled for sharps and recyclable materials.

Environmental and Waste Management Compliance

Adhere to local and national environmental regulations regarding emissions and waste disposal. Capture and filter all airborne glass dust using HEPA filtration systems to meet indoor air quality standards (e.g., OSHA PELs for respirable crystalline silica). Recycle glass waste through certified recycling partners where possible. Maintain documentation of waste disposal, including manifests and recycling certificates. Ensure compliance with EPA or equivalent environmental authority rules for hazardous material handling, if applicable.

Regulatory and Industry Standards

Comply with relevant international and regional standards. Key standards include:

– IEC 60825-1: Safety of laser products – Equipment classification and requirements.

– ANSI Z136.1: Safe Use of Lasers (U.S.).

– ISO 11553: Safety of machinery – Laser processing machines.

– REACH & RoHS (EU): If engraving consumer goods, verify that glass materials and any coatings are free of restricted substances.

For export, ensure products meet destination market requirements, such as CE marking (Europe) or FCC regulations (U.S.), particularly if engraving electronic device components.

Shipping and Packaging of Finished Goods

Package 3D-engraved glass items to prevent chipping, cracking, or surface damage during transit. Use custom-fit foam inserts, edge protectors, and double-walled corrugated boxes. Clearly label packages as “Fragile” and “This Side Up.” For international shipments, comply with IATA/ICAO regulations for air transport of fragile goods and provide accurate customs documentation, including product descriptions, material composition, and value declarations. Consider insuring high-value engraved items.

Quality Control and Documentation

Implement a robust quality control process including pre-engraving inspection, in-process monitoring, and post-production evaluation using visual and optical measurement tools. Maintain detailed records of engraving parameters (power, speed, focus), material batches, and inspection results. For regulated industries (e.g., medical or aerospace), adhere to ISO 9001 or ISO 13485 standards and retain documentation for audit purposes.

Conclusion for Sourcing 3D Glass Laser Engraving:

Sourcing 3D glass laser engraving services offers a compelling blend of precision, customization, and aesthetic appeal, making it an excellent choice for promotional products, corporate gifts, awards, and personalized décor. When selecting a supplier, it is essential to prioritize factors such as technical capability, quality of equipment (e.g., CO2 or fiber lasers), design expertise, material compatibility, and production scalability.

Top-tier providers typically offer advanced software integration for 3D modeling, consistent engraving depth and clarity, and the ability to work with various glass types and thicknesses. Additionally, evaluating sample work, turnaround times, pricing structures, and customer support ensures alignment with project requirements and budget constraints.

Ultimately, partnering with a reliable and experienced 3D glass laser engraving supplier enables businesses and individuals to deliver high-impact, premium-quality products that stand out in both craftsmanship and visual effect. With the right vendor, the investment translates into lasting impressions and enhanced brand or personal value.