The global 3D printing market is undergoing rapid transformation, with specialized segments like 3D crystal printing gaining traction across industries such as personalized gifting, architectural modeling, and high-end décor. According to a report by Mordor Intelligence, the global 3D printing market was valued at USD 18.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 23.5% from 2024 to 2029. A key contributor to this expansion is the rising demand for precision engraving and custom-designed crystal products, driven by advancements in laser modulation and software integration. As consumer and enterprise interest in personalized, high-clarity 3D crystal outputs increases, a select group of manufacturers have emerged as leaders in developing printers capable of delivering intricate internal engravings with micron-level accuracy. These innovations are not only enhancing product aesthetics but also enabling scalable customization in luxury and promotional markets. The following list highlights the top 10 manufacturers at the forefront of this niche yet rapidly evolving segment.

Top 10 3D Crystal Printer Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

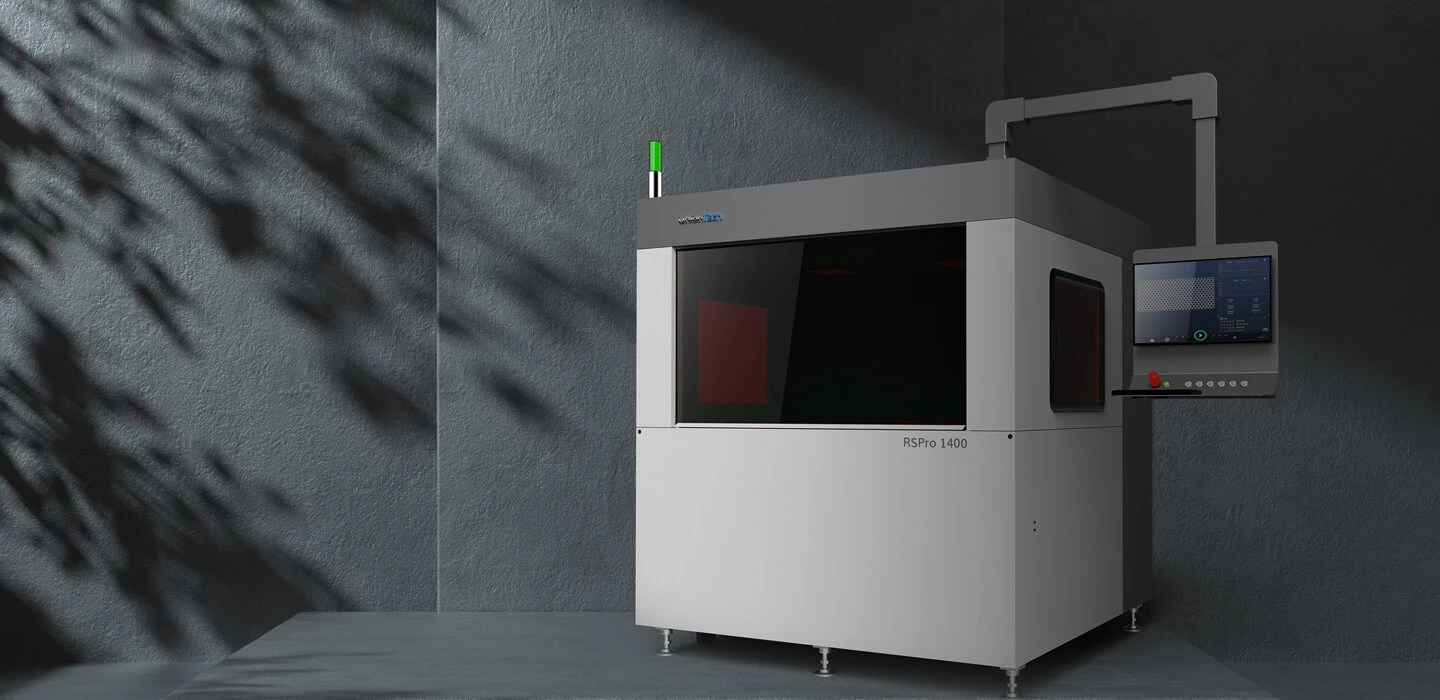

#1 UnionTech

Website: uniontech3d.com

Key Highlights: UnionTech is a global industrial 3D printer manufacturer and offers one-stop additive manufacturing solutions, including 3D printers, materials, software, and ……

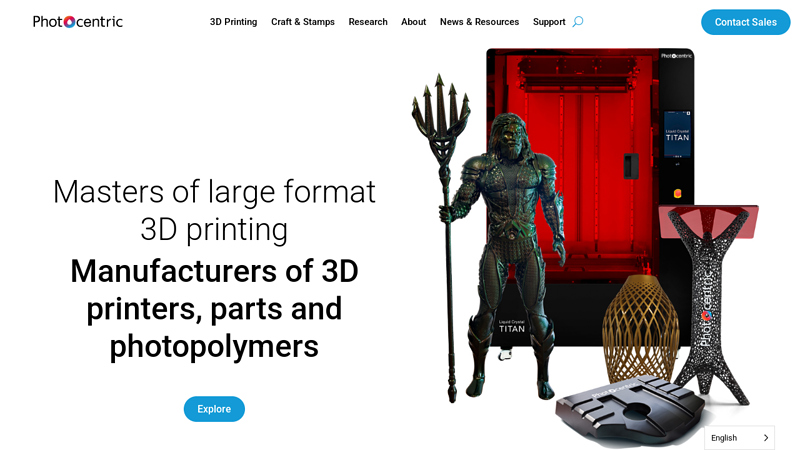

#2 Photocentric

Website: photocentricgroup.com

Key Highlights: Manufacturers of 3D printers, parts and photopolymers · 3D Printers from the inventors of LCD 3D printing · 3D Materials from the manufacturer….

#3 InssTek

Website: insstek.com

Key Highlights: InssTek offers metal 3D printing services using DED technology. It specializes in multi material manufacturing technology by precisely controlling various ……

#4 High Precision Industrial 3D Printers

Website: nematx.com

Key Highlights: We are developing high resolution industrial 3D printing machines & novel liquid crystal polymer (LCP) 3D printing materials to additively manufacture high ……

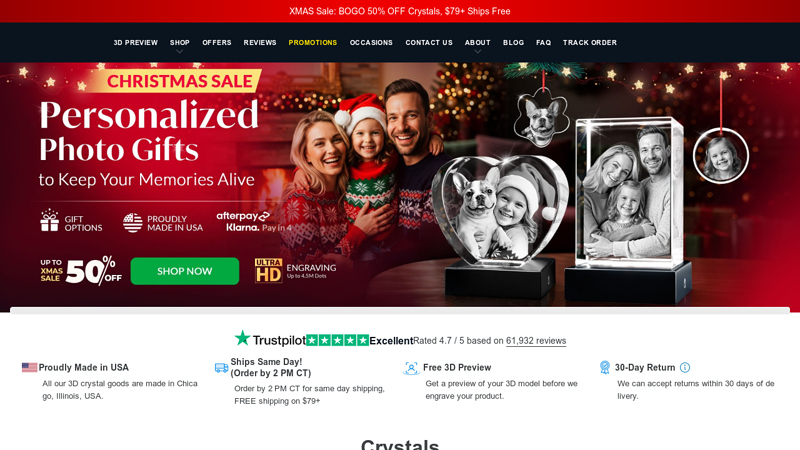

#5 3D Crystals by ArtPix 3D®

#6 3Dinnovation

Website: 3dinnovation.com

Key Highlights: Free delivery over $150 30-day returns…

#7 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

#8 Creality

Website: creality.com

Key Highlights: The Creality Ender 3 V3 SE sets a new baseline for cheap 3D printing, blending a familiar form with the beginner-friendly fully automatic bed leveling and self- ……

#9 Merit 3D

Website: merit3d.com

Key Highlights: Merit3D delivers high-quality, production-scale parts using advanced additive manufacturing. Eliminate tooling costs, accelerate your time-to-market, and….

#10 CrystalProteins

Website: crystalproteins.com

Key Highlights: 3D models lasered into glass. CrystalProteins creates accurate 3D etchings inside blocks of glass, giving real-world insight into complex structures….

Expert Sourcing Insights for 3D Crystal Printer

2026 Market Trends for 3D Crystal Printers

The 3D crystal printer market is poised for significant transformation by 2026, driven by technological advancements, expanding applications, and shifting consumer and industrial demands. Here are the key trends expected to shape the industry:

H2: Advancements in Printing Precision and Speed

By 2026, 3D crystal printers are expected to achieve unprecedented levels of precision and speed. Innovations in laser focusing systems and real-time beam control will enable sub-micron resolution, allowing for the creation of highly intricate internal engravings with exceptional clarity. Simultaneously, improvements in galvanometric mirror systems and adaptive optics will reduce print times by up to 40% compared to current models. This enhanced efficiency will make high-volume production—such as personalized corporate gifts or serialized collectibles—more economically viable, expanding the commercial appeal of the technology.

H2: Expansion into Medical and Biotech Applications

A major trend by 2026 will be the exploration of 3D crystal printing in advanced scientific fields. Researchers are beginning to utilize ultra-precise internal structuring of optical crystals for applications in biosensors, lab-on-a-chip devices, and photonics-based medical diagnostics. The ability to embed microfluidic channels or optical waveguides within transparent materials opens new frontiers in miniaturized medical equipment. While still in early stages, partnerships between crystal printer manufacturers and biotech firms are expected to grow, potentially leading to specialized medical-grade printing systems.

H2: Integration with AI and Customization Platforms

Artificial intelligence will play a transformative role in 3D crystal printing by 2026. AI-powered design software will enable users to convert photos, voice recordings, or even emotional themes into complex 3D engravings automatically. Cloud-based platforms will allow seamless integration with e-commerce sites, supporting on-demand customization at scale. For instance, consumers could upload a wedding video, and an AI system would generate a dynamic 3D holographic representation embedded in crystal. This trend will drive mass personalization and open new revenue streams for online retailers and creative studios.

H2: Sustainability and Material Innovation

Environmental concerns will influence material development in the crystal printing sector. By 2026, expect increased demand for eco-friendly alternatives to traditional leaded glass, such as bio-based or recycled optical-grade crystals. Manufacturers will emphasize energy-efficient laser systems and closed-loop production processes to reduce carbon footprints. Additionally, innovations in composite materials—combining crystal with sustainable polymers or recycled glass—could lead to new hybrid products that maintain optical quality while improving sustainability credentials.

H2: Growth in Industrial and Architectural Design

Beyond consumer gifts, 3D crystal printers will gain traction in industrial design and architecture by 2026. Design firms will use the technology to create high-fidelity 3D models of buildings, urban plans, or product prototypes embedded with dynamic lighting effects. These crystal models serve both functional presentation purposes and artistic displays. Furthermore, integration with BIM (Building Information Modeling) software will allow architects to directly convert digital models into tangible crystal representations, enhancing client communication and project visualization.

In summary, the 2026 landscape for 3D crystal printers will be defined by higher performance, broader applications, intelligent automation, and sustainability. As the technology matures, it will move beyond novelty items to become a valuable tool across diverse industries, from healthcare to architecture, while remaining accessible for personalized consumer markets.

Common Pitfalls When Sourcing a 3D Crystal Printer: Quality and Intellectual Property Risks

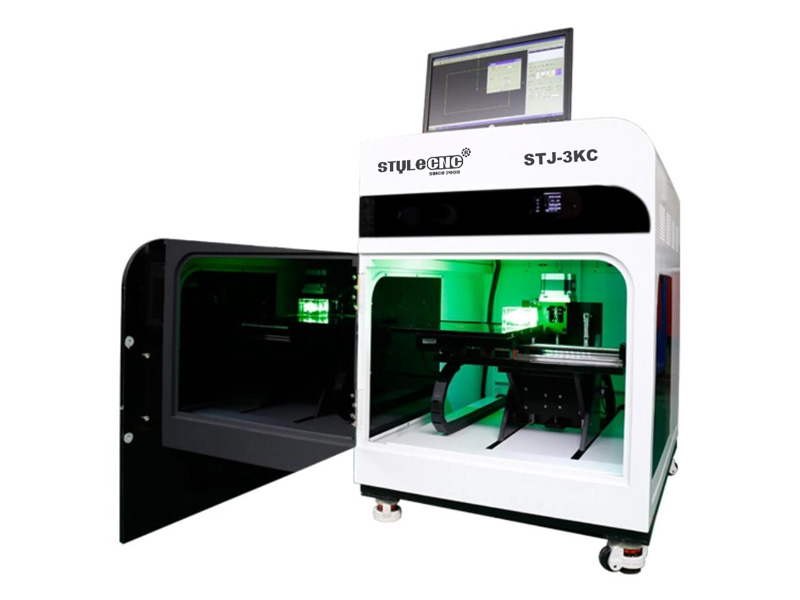

Sourcing a 3D crystal printer—typically referring to laser engraving systems that create internal 3D images within glass or crystal blocks—can be fraught with challenges, especially concerning product quality and intellectual property (IP) protection. Buyers, particularly businesses or entrepreneurs entering this niche market, must be vigilant to avoid costly mistakes.

Quality Inconsistencies and Technical Shortcomings

One of the most prevalent pitfalls when sourcing 3D crystal printers, especially from overseas suppliers or lesser-known manufacturers, is inconsistent or subpar product quality. Many low-cost systems on the market suffer from poor laser precision, unstable mechanics, and inadequate software integration. This results in blurry or misaligned engravings, reduced throughput, and frequent maintenance issues. Additionally, components such as laser diodes may degrade quickly if not properly cooled or rated for continuous use. Buyers often discover too late that advertised specifications—like engraving speed, maximum block size, or resolution—do not match real-world performance, leading to customer dissatisfaction and increased operational costs.

Lack of After-Sales Support and Spare Parts Availability

Even if a 3D crystal printer initially performs well, sourcing from unreliable vendors often means limited access to technical support, software updates, or replacement parts. When a critical component fails, delays in obtaining replacements can halt production entirely. Some manufacturers disappear or stop supporting older models, leaving buyers stranded. It’s crucial to vet suppliers for their service history, warranty terms, and global support infrastructure before committing to a purchase.

Intellectual Property Infringement Risks

Another significant risk involves intellectual property. Many affordable 3D crystal printers, particularly those from certain regions, may incorporate cloned or reverse-engineered software and firmware that infringe on patented technologies or copyrighted code. Using such equipment exposes buyers to legal liability, especially in jurisdictions with strict IP enforcement. Furthermore, proprietary design files or customer data processed by compromised software could be at risk of unauthorized access or misuse. Buyers should ensure that the equipment they source uses licensed, legitimate software and complies with regional IP laws.

Inadequate Software and Compatibility Limitations

The software bundled with many budget 3D crystal printers is often outdated, poorly documented, or incompatible with modern design tools. This limits customization, slows workflow, and may require costly third-party solutions to bridge functionality gaps. Some systems lock users into proprietary formats or restrict file inputs, reducing flexibility. Confirming software compatibility, update policies, and API access before purchase is essential for long-term operational efficiency.

Hidden Costs and Misleading Marketing

Suppliers may advertise low upfront prices while omitting essential costs such as import duties, required calibration tools, or subscription-based software licenses. Additionally, marketing materials may exaggerate capabilities using stock photos or demo videos not created with the actual product. Conducting independent verification through live demos, user reviews, or third-party testing can help uncover these discrepancies.

To mitigate these pitfalls, buyers should prioritize suppliers with transparent operations, verifiable customer references, robust warranties, and a clear commitment to IP compliance. Investing time in due diligence ultimately ensures reliable performance and protects against legal and financial risks.

Logistics & Compliance Guide for 3D Crystal Printer

Product Classification and Regulatory Framework

The 3D Crystal Printer is classified as a specialized laser-based manufacturing device designed to engrave internal designs within transparent materials such as glass or crystal. Due to its use of laser technology, it falls under multiple regulatory categories, including electrical equipment, laser safety, and machinery safety. Compliance with regional and international standards is mandatory for legal distribution and operation.

International Shipping and Import Regulations

When shipping 3D Crystal Printers internationally, exporters must adhere to the Harmonized System (HS) Code 8479.89, which covers “machines having individual functions not elsewhere specified or included.” Accurate customs declaration is required, including technical specifications, value, and end-use. Import duties, value-added tax (VAT), and local clearance procedures vary by country; pre-shipment verification with local customs authorities is strongly recommended.

Laser Safety Compliance

The 3D Crystal Printer utilizes a Class 4 laser, the highest risk classification, requiring strict adherence to laser safety standards. The device must comply with IEC 60825-1 (international) and FDA 21 CFR Part 1040.10 (United States). Key requirements include:

– Permanent laser safety labels in accordance with ANSI Z535.4

– Interlock systems to prevent operation when enclosures are open

– Emission indicators and key-controlled power switches

– Protective housing designed to prevent direct or scattered beam exposure

Electrical and Electromagnetic Compatibility (EMC)

The printer must meet the essential requirements of the EU’s Low Voltage Directive (2014/35/EU) and Electromagnetic Compatibility Directive (2014/30/EU). Certification marks such as CE (Europe), UKCA (United Kingdom), and FCC Part 15 (United States) are required for market access. Devices must undergo testing for electrical safety, radio frequency interference, and immunity to electromagnetic disturbances.

Packaging and Handling Instructions

To ensure safe transit, the 3D Crystal Printer must be packaged in a double-walled cardboard box with custom foam inserts securing all internal components, especially the laser module and optical elements. The package must display:

– “Fragile” and “This Side Up” orientation labels

– Laser warning symbols per IEC 60825

– Handling instructions in multiple languages for international shipments

– A moisture barrier if shipping to high-humidity destinations

End-User Compliance and Training Requirements

End users must operate the 3D Crystal Printer in compliance with occupational health and safety regulations. Employers are responsible for providing:

– Laser safety training certified by an accredited provider

– Personal protective equipment (PPE), including laser safety goggles with appropriate optical density

– Controlled access to the operational area with posted warning signs

– Maintenance logs and service records as required by local regulations

Environmental and Disposal Regulations

At end-of-life, the 3D Crystal Printer must be disposed of in accordance with WEEE (Waste Electrical and Electronic Equipment) Directive 2012/19/EU in Europe and equivalent e-waste regulations elsewhere. The laser module and power supply may contain hazardous materials requiring specialized recycling. Users must not disassemble the laser components and should return the device to an authorized collection point or manufacturer take-back program.

Software and Data Compliance

The control software for the 3D Crystal Printer may be subject to export controls under the Wassenaar Arrangement, particularly if it includes advanced pattern generation or automation features. Exporters must evaluate software classification under ECCN 3D003. Additionally, data privacy laws such as GDPR apply if the software collects or processes user information. Clear end-user license agreements (EULA) and data handling policies are required.

Ongoing Regulatory Monitoring

Regulatory requirements for laser devices and manufacturing equipment may change. Manufacturers and distributors must implement a compliance monitoring program to track updates from regulatory bodies such as the FDA, EU Commission, and national standards organizations. Regular audits, product re-certification, and field compliance checks are essential to maintain legal market access.

Conclusion on Sourcing a 3D Crystal Printer

Sourcing a 3D crystal printer requires careful evaluation of several key factors including technology type, print quality, production capacity, vendor reliability, and post-sales support. These specialized printers—often utilizing laser engraving or internal glass modification techniques—deliver high-precision, three-dimensional images inside crystal blocks, making them ideal for personalized gifts, awards, and premium decorative items.

After assessing the market, it is evident that selecting the right supplier involves balancing upfront investment with long-term operational efficiency. Key considerations include the printer’s resolution, compatibility with various crystal sizes and shapes, software integration, and ease of use. Additionally, sourcing from reputable manufacturers—preferably with proven track records in durability and technical support—ensures minimal downtime and consistent output quality.

Ultimately, partnering with a supplier that offers comprehensive training, maintenance services, and warranty coverage will maximize return on investment. Whether for small-scale customization or large-volume production, sourcing the right 3D crystal printer can significantly enhance product offerings and customer satisfaction in niche and luxury markets.