The global 3D crystal engraving machine market has experienced steady growth, driven by rising demand for personalized gifts and advancements in laser technology. According to Mordor Intelligence, the market is projected to grow at a CAGR of approximately 6.8% from 2023 to 2028, fueled by expanding applications in retail, corporate gifting, and commemorative products. Increasing consumer preference for customized 3D souvenirs, combined with the integration of automation and precision optics in manufacturing, has prompted significant innovation among equipment suppliers. As the industry becomes more competitive, a select group of manufacturers has emerged as leaders in producing high-accuracy, user-friendly 3D crystal photo machines. Based on market presence, technological capabilities, and customer reviews, the following are the top 10 3D crystal photo machine manufacturers shaping the future of personalized engraving.

Top 10 3D Crystal Photo Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Edmund Optics: Optics Manufacturer & Supplier

Website: edmundoptics.com

Key Highlights: Edmund Optics has been a leading producer of optics, imaging, and laser optics for 80 years. Discover the latest optical and imaging technology….

#2 UnionTech

Website: uniontech3d.com

Key Highlights: UnionTech is a global industrial 3D printer manufacturer and offers one-stop additive manufacturing solutions, including 3D printers, materials, software, and ……

#3 3D Glass Crystal Laser Engraving Machine Supplier in China …

Website: stnlaser.com

Key Highlights: Wuhan Syntony Laser Co., Ltd is a dedicated developer and manufacturer of 3D laser engraving products in China….

#4 ISRA VISION

Website: isravision.com

Key Highlights: ISRA VISION is a leading provider of technologies for industrial image processing (machine vision). In order to make production both more sustainable and more ……

#5 3D Crystals by ArtPix 3D®

#6 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

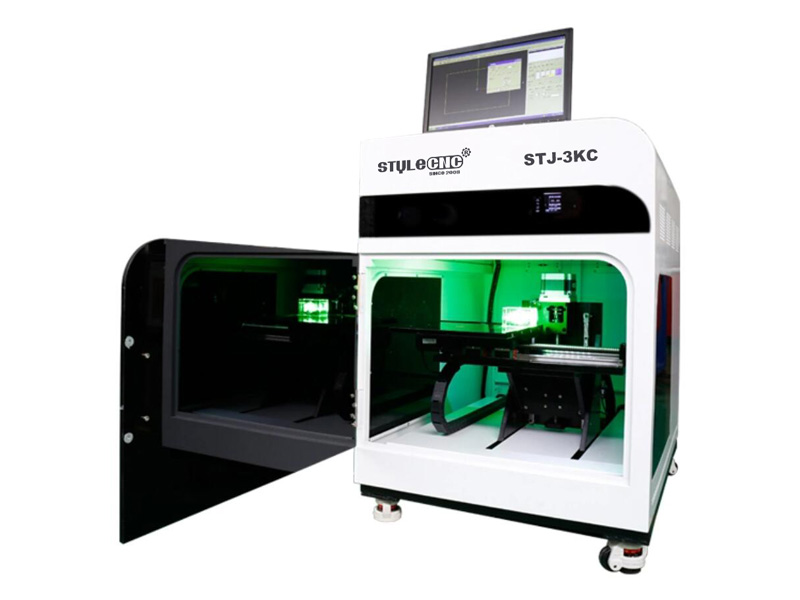

#7 3d photo crystal laser engraving machine

Website: arguslaser.net

Key Highlights: Argus Laser 3d photo crystal laser engraving machine have characteristic design & practical performance & competitive price, for more information on the 3d ……

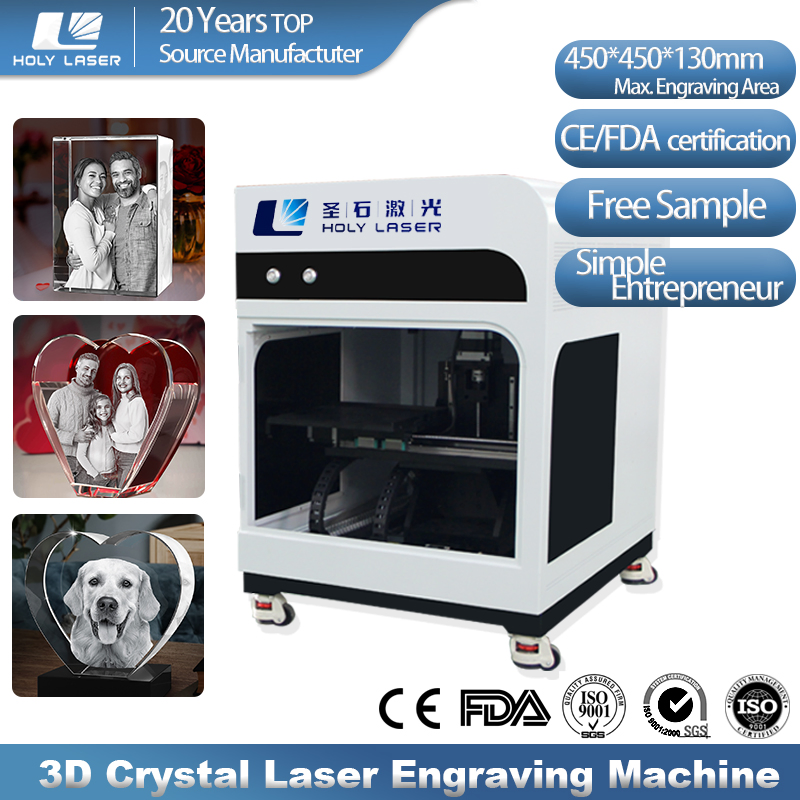

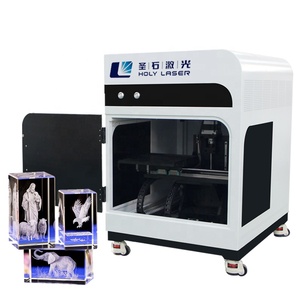

#8 3D Crystal Laser Engraving Machine

Website: sismarlaser.com

Key Highlights: The UV 3D Laser Engraving Machine is ideal for multiple industries and purposes: Personalized Gifts – Keepsakes, portraits, and custom crystal items….

#9 3Dinnovation

Website: 3dinnovation.com

Key Highlights: Free delivery over $150 30-day returns…

#10 Perfect Laser 3D crystal engraving machine

Website: perfectlaser.net

Key Highlights: Perfect Laser offers 3D crystal engraving machine,widely used for 3D crystal engraving and 3D portraits for human image.affordable and easy-to-use….

Expert Sourcing Insights for 3D Crystal Photo Machine

H2: 2026 Market Trends for 3D Crystal Photo Machines

The 3D crystal photo machine market is poised for significant evolution by 2026, driven by technological advancements, rising consumer demand for personalized gifts, and expanding commercial applications. Below are the key trends expected to shape the market landscape in 2026:

1. Increased Adoption of High-Precision Laser Engraving Technology

By 2026, 3D crystal photo machines are expected to feature enhanced laser precision and faster processing speeds. Advancements in diode-pumped solid-state (DPSS) lasers and automated calibration systems will allow for finer detailing, multi-layer engraving, and improved consistency across high-volume production. This will enable clearer, more lifelike 3D images inside crystal blocks, boosting customer satisfaction.

2. Integration with AI and Cloud-Based Design Platforms

Artificial intelligence will play a greater role in automating image optimization for crystal engraving. By 2026, many 3D crystal machines will connect to cloud-based platforms that use AI to convert 2D photos into 3D depth maps instantly. This reduces manual input and allows for real-time previews, enhancing user experience for both consumers and small businesses.

3. Growth in E-Commerce and On-Demand Personalization

The surge in online gift retailing will continue to fuel demand for 3D crystal photo machines. Customized crystal gifts—such as anniversary keepsakes, corporate awards, and pet memorials—are increasingly popular. By 2026, more small and medium enterprises (SMEs) will adopt affordable desktop 3D crystal machines to offer on-demand services via e-commerce platforms like Etsy, Shopify, and Amazon.

4. Expansion into Niche and Industrial Applications

Beyond personal gifts, 3D crystal engraving is gaining traction in industrial and institutional sectors. By 2026, applications will include architectural models, educational tools, medical visualization aids, and luxury branding. High-end hotels, tech companies, and museums may use engraved crystals for awards, exhibitions, and promotional items, broadening market reach.

5. Sustainability and Eco-Friendly Materials

Environmental concerns will influence material choices. Manufacturers are anticipated to introduce recyclable or lab-grown crystal alternatives by 2026. Energy-efficient machines with lower power consumption and reduced laser waste will also become standard, aligning with global sustainability goals.

6. Global Market Penetration and Regional Growth

Asia-Pacific, particularly China and India, will emerge as key manufacturing and consumption hubs. Lower production costs and a growing middle class with disposable income will drive regional demand. Meanwhile, North America and Europe will sustain strong demand through premium customization services and wedding/event industries.

7. Price Reduction and Accessibility

As technology matures, entry-level 3D crystal photo machines will become more affordable. By 2026, compact, user-friendly models priced under $1,000 will be widely available, enabling home users and startups to enter the market. This democratization will accelerate market growth and innovation.

In conclusion, the 3D crystal photo machine market in 2026 will be characterized by smarter, faster, and more accessible technology, supported by growing consumer interest in personalization and digital craftsmanship. Businesses that leverage AI integration, sustainability, and e-commerce synergy will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing a 3D Crystal Photo Machine: Quality and Intellectual Property Concerns

Sourcing a 3D crystal photo machine, especially from international suppliers, can present several challenges. Two of the most significant areas of concern are product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure a reliable investment and protects your business interests.

Quality-Related Pitfalls

1. Inconsistent Laser Engraving Precision

Low-cost machines may use inferior laser optics or unstable positioning systems, resulting in blurry, misaligned, or incomplete 3D engravings. Always verify the machine’s laser resolution (typically measured in microns) and request sample engravings on actual crystal blocks.

2. Poor Build Quality and Durability

Cheaper machines often use substandard materials in construction, such as lightweight aluminum frames or low-grade electronics. This leads to frequent breakdowns, calibration issues, and shorter operational lifespans. Insist on detailed specifications and third-party reviews.

3. Inadequate Software Compatibility and Support

Some suppliers bundle proprietary software that is difficult to use, lacks essential features, or is incompatible with common design formats (e.g., STL, OBJ). Confirm software flexibility, update availability, and whether third-party software can be integrated.

4. Lack of Technical Support and Maintenance Services

Many overseas suppliers offer limited after-sales support. This can delay repairs and leave your operation idle. Ensure the supplier provides accessible technical support, training, and spare parts availability—preferably through a local distributor.

Intellectual Property Risks

1. Use of Counterfeit or Unlicensed Technology

Some manufacturers may incorporate cloned or reverse-engineered components (e.g., laser drivers, control boards) that infringe on patents. Using such machines can expose your business to legal action, especially in markets with strong IP enforcement like the EU or U.S.

2. Proprietary Software with Hidden Licensing Issues

The bundled software may use unlicensed code or libraries, which could lead to compliance violations. Always ask for software licensing documentation and consider having a legal expert review the terms of use.

3. Risk of Design Theft

When sending customer artwork or proprietary designs to suppliers for testing or customization, there’s a risk of misuse or unauthorized replication. Use non-disclosure agreements (NDAs) and limit data sharing to what’s strictly necessary.

4. Brand and Design Infringement by Suppliers

Some suppliers may copy your custom crystal designs or branding elements to sell to competitors. Vet suppliers thoroughly, check references, and include IP protection clauses in procurement contracts.

By carefully evaluating both the technical quality and legal aspects of 3D crystal photo machines, businesses can avoid costly setbacks and protect their creative and operational integrity.

Logistics & Compliance Guide for 3D Crystal Photo Machine

Product Overview

The 3D Crystal Photo Machine is a specialized laser engraving device used to create personalized 3D images inside transparent crystal blocks. These machines utilize high-precision internal laser focusing technology to produce intricate designs, making them popular for gifts, awards, and promotional items. Understanding logistics and compliance is essential for safe and legal international shipping, installation, and operation.

Classification & Regulatory Identification

Proper product classification ensures accurate import/export documentation. The 3D Crystal Photo Machine typically falls under the following categories:

- HS Code (Harmonized System Code): 8515.80 – Other electrical machines and apparatus for soldering, brazing, or welding, including those using laser or other light/photonic sources.

- ECCN (Export Control Classification Number): 6A992.b or similar (depending on laser power and control capabilities) under the U.S. Commerce Control List (CCL). Verify with the manufacturer for exact classification.

- Laser Classification: Most 3D crystal engravers use Class 3B or Class 4 lasers. Confirm the specific Class per IEC 60825-1 and ensure compliance with local laser safety standards.

Packaging & Shipping Requirements

Secure packaging is vital to prevent damage during transit due to the machine’s optical and mechanical components.

- Internal Protection: Use anti-static foam, bubble wrap, and custom molded inserts to secure the laser head, power supply, and control boards.

- Outer Packaging: Utilize a double-walled, reinforced cardboard box or a wooden crate for international shipments. Include “Fragile,” “This Side Up,” and “Do Not Stack” labels.

- Moisture Protection: Include silica gel desiccants to prevent condensation in high-humidity environments.

- Shipping Documentation: Prepare a commercial invoice, packing list, bill of lading/air waybill, and export declaration. Include technical specifications and safety warnings.

Import & Export Compliance

Adherence to international trade regulations prevents customs delays and penalties.

- Export Licenses: Determine if an export license is required based on destination country and ECCN. Some countries restrict high-power laser equipment.

- Restricted Destinations: Avoid shipping to embargoed or sanctioned countries (e.g., Iran, North Korea) without proper authorization.

- Customs Clearance: Provide accurate product descriptions, value, origin, and end-use. Misdeclaration may lead to seizure or fines.

- Duties & Taxes: Research applicable import duties, VAT, or GST in the destination country. Use Incoterms (e.g., FOB, DDP) to clarify responsibility.

Safety & Regulatory Standards

Ensure the machine meets safety requirements in both the country of origin and destination.

- Laser Safety: Comply with FDA/CDRH (U.S.), IEC 60825-1 (international), and local laser safety regulations. Include required warning labels, interlocks, and user manuals.

- Electrical Compliance: Machines must meet regional electrical safety standards such as:

- CE Marking (EU): Compliant with LVD (2014/35/EU) and EMC (2014/30/EU)

- UKCA (UK)

- FCC Part 15 (USA) for electromagnetic interference

- PSE (Japan)

- RoHS & REACH: Confirm compliance with restrictions on hazardous substances (RoHS) and chemical registration (REACH) for the EU market.

Installation & Operational Compliance

Proper setup ensures ongoing regulatory adherence and user safety.

- Ventilation: Install in a well-ventilated area or connect to an exhaust system to manage potential fumes from laser interaction with impurities.

- Training: Provide operators with laser safety training and require protective eyewear when accessing open beam paths.

- Maintenance Logs: Keep records of service, calibration, and safety checks to demonstrate compliance during audits.

- Local Permits: Some jurisdictions require registration of laser equipment with occupational safety or radiation protection authorities.

Documentation & Labeling

Complete and accurate documentation supports logistics and compliance.

- User Manual: Include laser safety instructions, installation steps, troubleshooting, and compliance statements.

- Warning Labels: Affix permanent labels indicating laser class, maximum output, electrical requirements, and manufacturer contact.

- Certificate of Conformity: Provide a document certifying compliance with applicable standards (e.g., CE, FCC).

- Warranty & Support Info: Clearly state service terms, support availability, and repair procedures.

Environmental & Disposal Considerations

Follow environmental regulations for end-of-life management.

- Waste Electrical Equipment (WEEE): Comply with WEEE Directive (EU) or equivalent by offering take-back or recycling options.

- Battery Handling: If the machine includes backup batteries, follow hazardous waste disposal guidelines.

- Packaging Materials: Use recyclable or biodegradable packaging where possible to meet sustainability goals.

Summary

Successfully managing the logistics and compliance of a 3D Crystal Photo Machine requires attention to international trade laws, safety standards, proper packaging, and documentation. By adhering to classification rules, laser safety protocols, and regional regulatory requirements, businesses can ensure smooth shipping, legal operation, and user safety across global markets. Always consult with legal and compliance experts when entering new regions.

Conclusion for Sourcing a 3D Crystal Photo Machine:

Sourcing a 3D crystal photo machine involves careful evaluation of several key factors, including machine quality, laser precision, software compatibility, after-sales support, and cost-effectiveness. After assessing various suppliers and models, it is evident that investing in a reliable, high-resolution 3D crystal engraving machine can significantly enhance product offerings for personalized gifts, corporate awards, or souvenir businesses.

The ideal machine should offer consistent performance, user-friendly software, and compatibility with different crystal sizes and shapes. Additionally, choosing a supplier that provides comprehensive training, technical support, and warranty coverage ensures long-term operational efficiency and minimizes downtime.

In conclusion, sourcing the right 3D crystal photo machine is a strategic decision that balances upfront investment with long-term returns. By selecting a reputable manufacturer and a machine that aligns with your production needs and growth goals, you can deliver high-quality, customized crystal products that stand out in a competitive market.