The global 3D crystal laser engraving market is experiencing steady expansion, driven by rising demand for personalized gifts, corporate awards, and custom decorative items. According to a 2023 report by Mordor Intelligence, the global laser engraving market was valued at USD 1.42 billion and is projected to grow at a CAGR of 6.8% through 2028. A significant contributor to this growth is the increasing adoption of laser-based customization in consumer and industrial sectors, particularly in premium giftware and commemorative products—categories where 3D crystal laser engraving plays a pivotal role. Advancements in laser technology, coupled with greater accessibility to precision diode and CO₂ lasers, have enabled manufacturers to offer intricate, photorealistic engravings within transparent materials such as optical crystal. As e-commerce platforms and online customization services proliferate, the market has seen heightened competition among manufacturers to deliver high-resolution, scalable, and design-flexible solutions. This growing ecosystem has given rise to a new generation of specialized 3D crystal laser engraving manufacturers—companies balancing technical innovation, production efficiency, and artistic precision. Based on market presence, technological capability, customer reach, and output quality, the following analysis highlights the top 10 manufacturers shaping this niche yet rapidly expanding industry.

Top 10 3D Crystal Laser Engraving Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

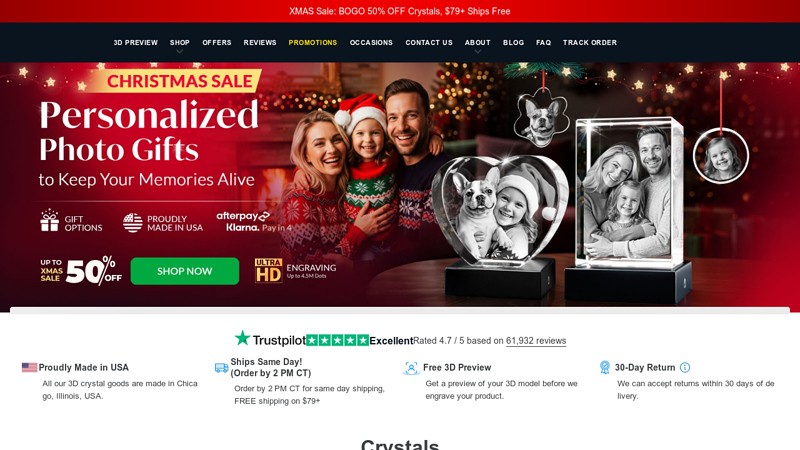

#1 3D Crystals by ArtPix 3D®

#2 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

#3 Personalized 3D Crystal Photos by Beyond Memories®

Website: beyond-memories.com

Key Highlights: Your source for personalized 3D crystal engraving. Beyond Memories® uses the newest innovation of capturing memories in crystals, the perfect gift….

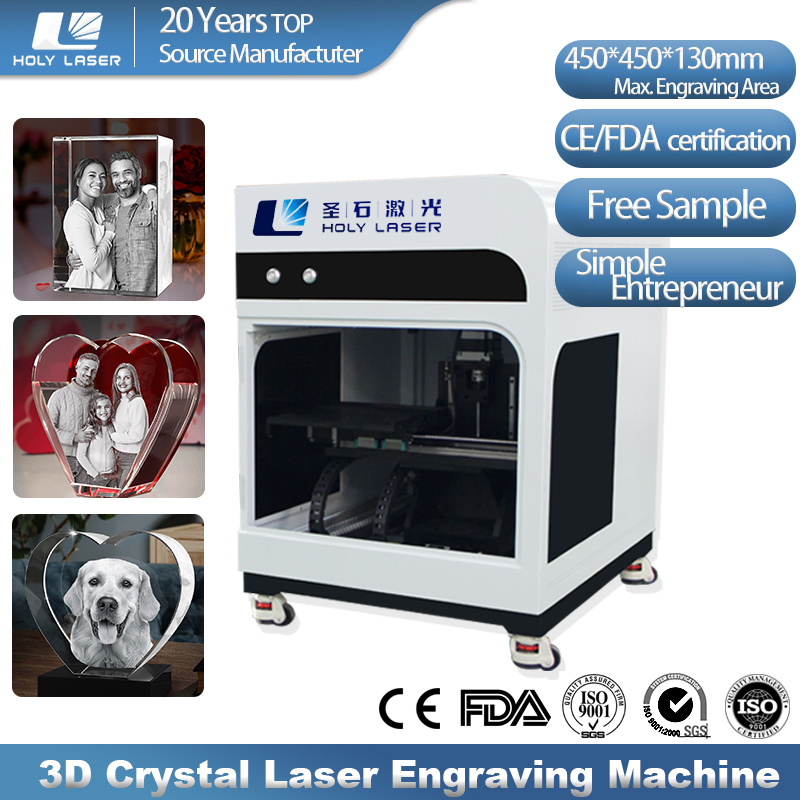

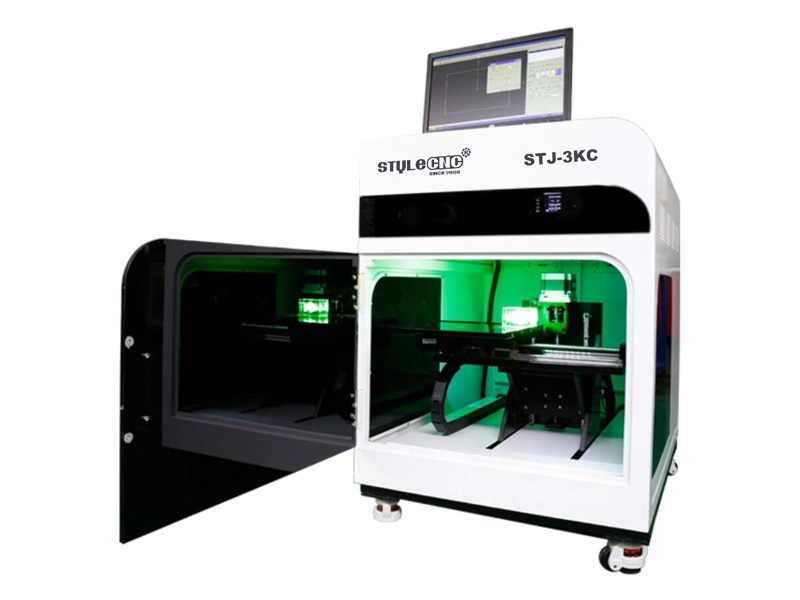

#4 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems designs and manufactures high-end 2D and 3D (3-axis) fiber, CO2, and UV galvanometer-based laser and marking solutions….

#5 3Dinnovation

Website: 3dinnovation.com

Key Highlights: Free delivery over $150 30-day returns3 easy steps to order. Choose your perfect crystal. Upload your photo write personal engraving. We will convert it into 3d and laser it into y…

#6 CrystalProteins

Website: crystalproteins.com

Key Highlights: 3D models lasered into glass. CrystalProteins creates accurate 3D etchings inside blocks of glass, giving real-world insight into complex structures….

#7 3D Subsurface Laser Engraving

Website: crystal-d.com

Key Highlights: Our 3D subsurface engraving process comes in, allowing us to recreate any image inside a crystal award or gift in two or three dimensions….

#8 Custom Laser

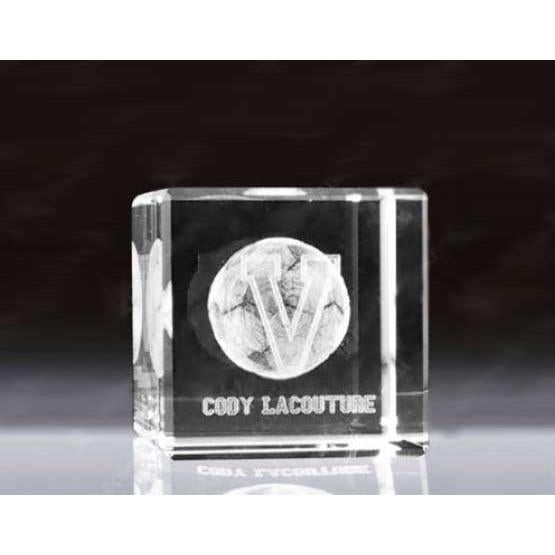

#9 3d Crystal Shop

Website: 3dcrystalshop.co.uk

Key Highlights: 30-day returnsWe have 15 Years Of 3D Engraving Experience, Specialising in People, Pets, Buildings, Cars, baby scans and Corporate 4D Conversions….

#10 3d Crystal Engraving How It Works – Blog

Website: 3dcrystal.com

Key Highlights: Our 3d photo engraved crystals go through a different process because we use better crystal art and high-tech laser engraving technology….

Expert Sourcing Insights for 3D Crystal Laser Engraving

H2: Projected Market Trends for 3D Crystal Laser Engraving in 2026

By 2026, the 3D crystal laser engraving market is expected to experience notable growth and transformation, driven by advancements in laser technology, rising consumer demand for personalized products, and expanding applications across multiple industries. Several key trends are anticipated to shape the landscape of this niche yet rapidly evolving sector.

-

Increased Demand for Personalized Gifts and Keepsakes

The global preference for customized and emotionally resonant gifts will continue to fuel the 3D crystal laser engraving market. Consumers are increasingly seeking unique mementos for events such as weddings, anniversaries, graduations, and corporate milestones. Online platforms offering on-demand customization will gain traction, enabling customers to upload photos and design 3D-engraved crystal souvenirs with ease. -

Advancements in Laser Precision and Software Integration

By 2026, improvements in laser diode technology and optics will allow for higher resolution and more intricate 3D engravings within crystal blocks. Enhanced software tools—featuring AI-driven image conversion and real-time 3D modeling—will streamline the design process, reduce production time, and improve accuracy. This will make the technology more accessible to small businesses and independent artisans. -

Expansion into New Industries

Beyond the gift and decoration sector, 3D crystal engraving is expected to penetrate new verticals: - Corporate Branding: Custom awards, executive gifts, and promotional items with embedded logos or 3D brand imagery.

- Healthcare and Biometrics: Experimental use in creating 3D models of medical scans (e.g., MRI or CT) for educational or diagnostic visualization.

-

Art and Collectibles: Artists and galleries adopting laser-engraved crystal as a novel medium for digital art preservation and NFT-linked physical collectibles.

-

Sustainability and Eco-Conscious Production

As environmental concerns grow, manufacturers are likely to adopt sustainable practices, such as using recycled crystal materials and energy-efficient laser systems. Transparent supply chains and eco-labeling will become selling points for environmentally aware consumers. -

Geographic Market Growth

While North America and Europe remain strong markets, Asia-Pacific—particularly China, India, and Southeast Asia—is projected to see accelerated growth due to rising disposable income, digital adoption, and demand for personalized luxury items. Localized production hubs may emerge to reduce shipping times and costs. -

Integration with Digital Platforms and E-Commerce

The synergy between 3D crystal engraving services and e-commerce platforms will deepen. Augmented Reality (AR) tools will allow customers to preview engravings in real-time before purchase. Subscription models and AI-curated gift suggestions may also become common.

In conclusion, the 3D crystal laser engraving market in 2026 will be characterized by technological refinement, broader industry adoption, and a strong consumer pull toward personalization. Businesses that innovate in design flexibility, sustainability, and digital integration are poised to lead this dynamic market.

Common Pitfalls in Sourcing 3D Crystal Laser Engraving (Quality, IP)

Poor Image-to-Crystal Translation

Low-resolution or improperly formatted source images often result in blurry, distorted, or incomplete engravings. Suppliers may lack the software expertise to optimize images for 3D depth mapping, leading to unsatisfactory final products that fail to capture fine details or intended proportions.

Inconsistent Crystal Quality

Sourced crystals can vary significantly in clarity, cut precision, and internal defects. Lower-tier suppliers may use glass or low-grade crystal with bubbles, striations, or inconsistent refractive properties, diminishing the brilliance and perceived value of the laser engraving.

Inadequate Laser Precision and Calibration

Machines that are poorly maintained or operated by untrained technicians can produce uneven focal points, jagged edges, or misplaced internal points. This results in a lack of sharpness, depth distortion, or misaligned 3D models, especially noticeable in intricate designs.

Intellectual Property (IP) Infringement Risks

Sourcing from regions with weak IP enforcement increases the risk of unauthorized replication of copyrighted designs, trademarks, or licensed characters. Buyers may unknowingly receive products that violate IP laws, exposing them to legal liability and reputational damage.

Lack of Design Confidentiality

Unsecured communication channels or unprofessional suppliers may lead to the unauthorized sharing or duplication of custom design files. Without proper NDAs or data protection protocols, proprietary concepts risk being copied or sold to competitors.

Overpromising on Capabilities

Some suppliers exaggerate their ability to render complex 3D models, multi-layer engravings, or color effects. This can result in failed production runs, delays, or products that fall far short of expectations, especially when scaling from prototypes to bulk orders.

Inconsistent Sizing and Positioning

Without strict quality control, dimensions and engraving placement can vary between units. Misalignment of the image within the crystal block or inconsistent base sizes affects presentation and customer satisfaction, particularly for corporate gifts or awards.

Hidden Costs and Minimum Order Constraints

Initial quotes may exclude setup fees, design conversion charges, or mold costs for custom shapes. Additionally, undisclosed MOQs (minimum order quantities) can make small-batch sourcing impractical or cost-prohibitive.

Logistics & Compliance Guide for 3D Crystal Laser Engraving

Product Overview and Handling

3D crystal laser engraving involves using focused laser beams to create internal fracturing patterns within solid optical glass or crystal blocks, resulting in detailed three-dimensional images. These fragile items require careful handling, packaging, and shipping to prevent damage. The final product is typically made from leaded crystal or high-clarity optical glass, both of which are sensitive to impact and thermal shock.

Packaging Requirements

Use double-walled corrugated boxes with interior cushioning such as molded foam inserts, bubble wrap, or air-filled pouches to immobilize the crystal. Each piece should be individually wrapped in anti-static, non-abrasive material (e.g., microfiber or polyethylene film). Clearly label packages as “Fragile,” “This Side Up,” and “Protect from Moisture.” Avoid using recycled or low-density cardboard that may compress during transit.

Shipping and Transportation

Ship via carriers offering tracking, insurance, and handling for fragile goods (e.g., FedEx, UPS, DHL). Avoid economy ground services for international or long-distance domestic shipments due to increased handling risks. For international shipments, ensure compliance with IATA and IMDG regulations if transporting by air or sea, even though crystals are non-hazardous. Temperature-controlled transport is recommended in extreme climates to prevent thermal stress cracking.

Import/Export Compliance

Verify tariff classifications (HS Code) for crystal display items—commonly under 7013.99 or 9613.00 depending on composition and use. Most countries classify non-functional engraved crystals as decorative items or novelties. Check destination-specific import restrictions, especially in regions with strict material regulations (e.g., EU REACH, California Proposition 65). Leaded crystal may require disclosure due to lead content, even if encapsulated.

Regulatory and Safety Standards

Ensure products comply with applicable consumer safety standards. In the U.S., adhere to CPSIA guidelines for decorative items, particularly regarding lead content. While the lead in crystal is typically inert and contained, labeling may be required if lead exceeds 100 ppm in accessible parts. In the EU, follow REACH regulations and provide a Declaration of Conformity if required. Laser operation must comply with FDA/CDRH (U.S.) or IEC 60825 (international) standards for Class 1 or Class 4 laser systems, depending on the engraving equipment used.

Environmental and Disposal Considerations

Crystals are inert and non-toxic under normal conditions but should not be incinerated due to potential lead oxide release (if leaded). Recommend recycling through glass or specialty material recyclers. Provide customers with disposal guidance, especially for enterprise or institutional clients subject to environmental compliance (e.g., WEEE in the EU may not apply, but local waste rules should be followed).

Labeling and Documentation

Include product origin, material composition (e.g., “Optical Crystal” or “Leaded Crystal – Handle with Care”), country of manufacture, and supplier contact information on packaging or inserts. For commercial shipments, provide commercial invoices, packing lists, and certificates of origin when required. Retain records of compliance testing (e.g., lead content verification) for audit purposes.

Risk Mitigation and Insurance

Maintain product liability and cargo insurance covering breakage, loss, and regulatory non-compliance. Conduct periodic audits of packaging durability and carrier performance. Implement a returns and damage reporting protocol to analyze failure points and improve logistics processes.

Conclusion for Sourcing 3D Crystal Laser Engraving

Sourcing 3D crystal laser engraving services offers a unique opportunity to create high-impact, personalized, and premium-quality decorative or promotional items. Whether for corporate gifts, awards, wedding memorabilia, or custom retail products, the precision and elegance of laser-engraved crystal leave a lasting impression. When sourcing this service, it is crucial to evaluate suppliers based on engraving quality, material clarity, customization capabilities, production lead times, and cost-effectiveness.

Many reliable manufacturers, particularly in regions like China, offer competitive pricing and advanced laser technology, enabling intricate 3D designs within optical glass. However, due diligence is essential to ensure consistent quality, ethical manufacturing practices, and strong communication. Ordering samples, verifying certifications, and assessing customer reviews are recommended steps before committing to large orders.

In summary, with careful supplier selection and attention to design and logistics, sourcing 3D crystal laser engraving can be a highly rewarding endeavor—delivering stunning, high-value products that stand out in any market or occasion.