The global 3D crystal laser engraving market is experiencing robust growth, driven by increasing demand in personalized gifting, corporate awards, and decorative arts. According to Grand View Research, the global personalized gifts market size was valued at USD 5.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030—fueled significantly by advancements in laser engraving technologies. Parallel trends in digital customization and e-commerce have elevated the prominence of 3D crystal laser manufacturers who deliver precision, scalability, and innovative design capabilities. As consumer and corporate clients seek high-quality, bespoke crystal products, a select group of manufacturers have emerged as industry leaders, combining cutting-edge laser technology with artistic craftsmanship. The following list highlights the top 10 3D crystal laser manufacturers shaping this dynamic landscape.

Top 10 3D Crystal Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Crystal Laser Gift

Website: crystallasergifts.com

Key Highlights: Free delivery3D Laser Gifts is a leading manufacturer of 3D laser etched crystals. We at 3D Laser Gifts use the latest German technology of laser engraving in crystals….

#2 3D crystal laser engraving machine manufacturer

Website: vitro.de

Key Highlights: Our laser systems are compatible for a wide range of applications. Whether small production, individual production, small and large series production….

#3 Laser Crystal

Website: lasercrystal.co.uk

Key Highlights: Here at Laser Crystal, we are the UK’s leading manufacturer of high-quality bespoke 3D laser engraved glass awards, trophies and paperweights….

#4 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

#5 CrystalProteins

Website: crystalproteins.com

Key Highlights: 3D models lasered into glass. CrystalProteins creates accurate 3D etchings inside blocks of glass, giving real-world insight into complex structures….

#6 Personalized 3D Crystal Photos by Beyond Memories®

Website: beyond-memories.com

Key Highlights: Your source for personalized 3D crystal engraving. Beyond Memories® uses the newest innovation of capturing memories in crystals, the perfect gift….

#7 3D Crystals by ArtPix 3D®

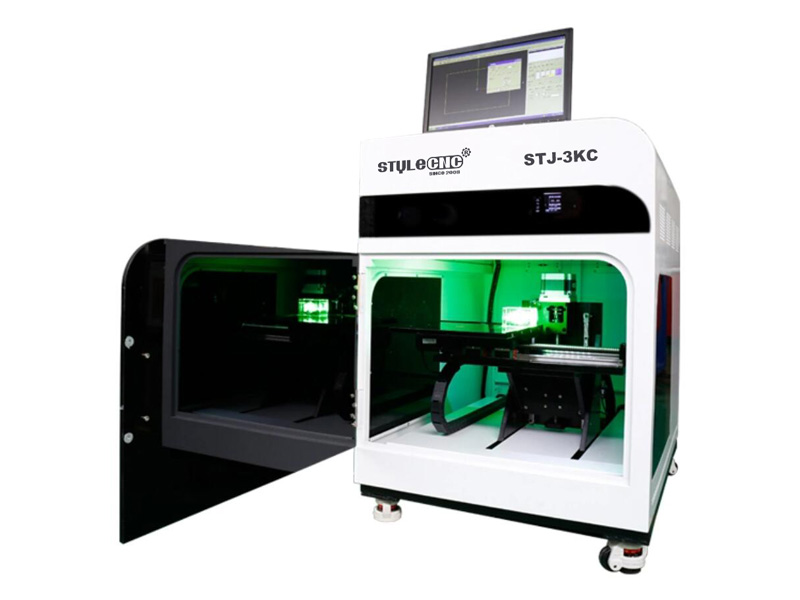

#8 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems designs and manufactures high-end 2D and 3D (3-axis) fiber, CO2, and UV galvanometer-based laser and marking solutions….

#9 3Dinnovation

Website: 3dinnovation.com

Key Highlights: Free delivery over $150 30-day returns…

#10 3d Crystal Engraving How It Works – Blog

Website: 3dcrystal.com

Key Highlights: Our 3d photo engraved crystals go through a different process because we use better crystal art and high-tech laser engraving technology….

Expert Sourcing Insights for 3D Crystal Laser

H2: 2026 Market Trends for 3D Crystal Laser Engraving

The 3D crystal laser engraving market is poised for notable transformation by 2026, driven by advancements in laser technology, growing consumer demand for personalized gifts, and expanding applications across industries. Key trends shaping the market include:

-

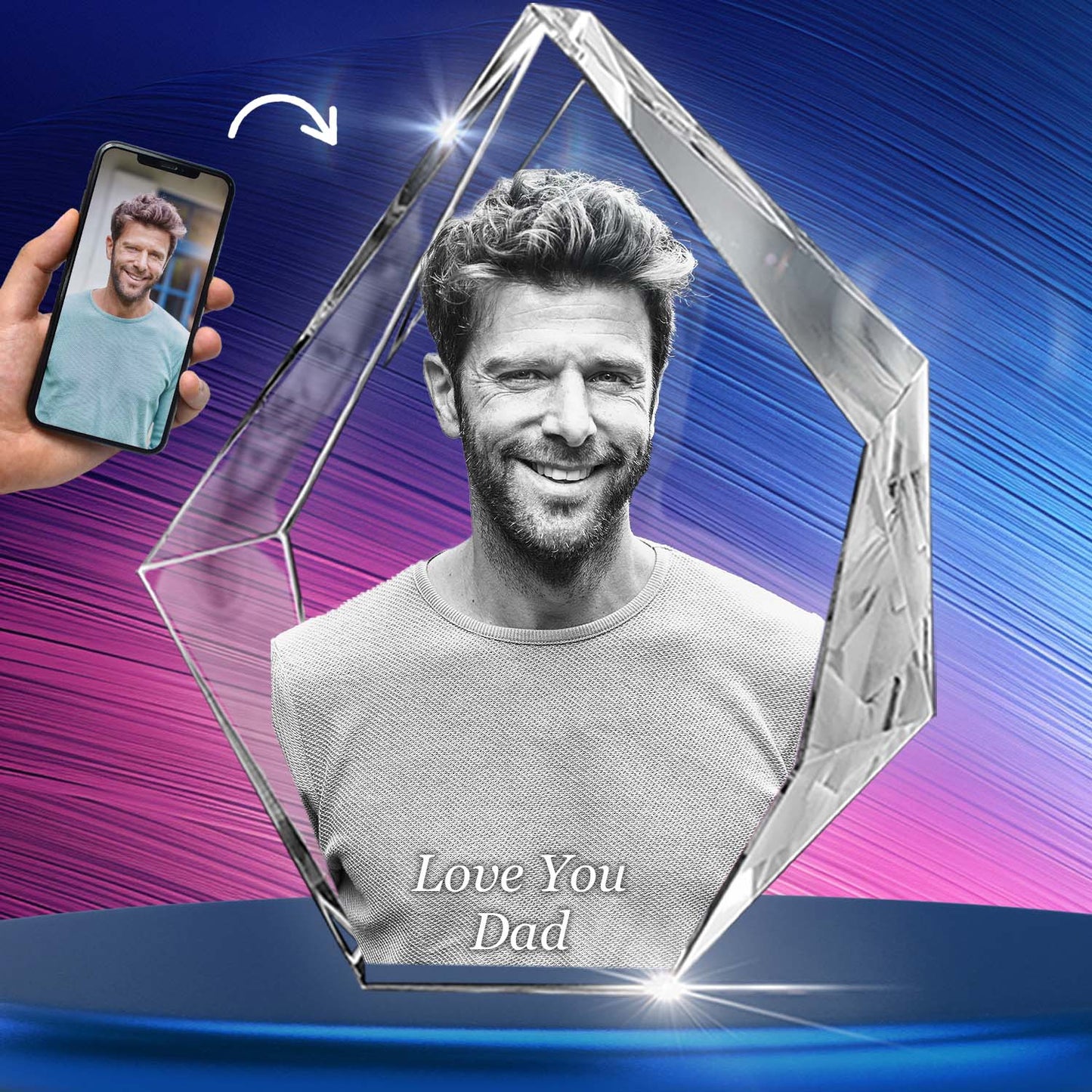

Increased Demand for Personalization

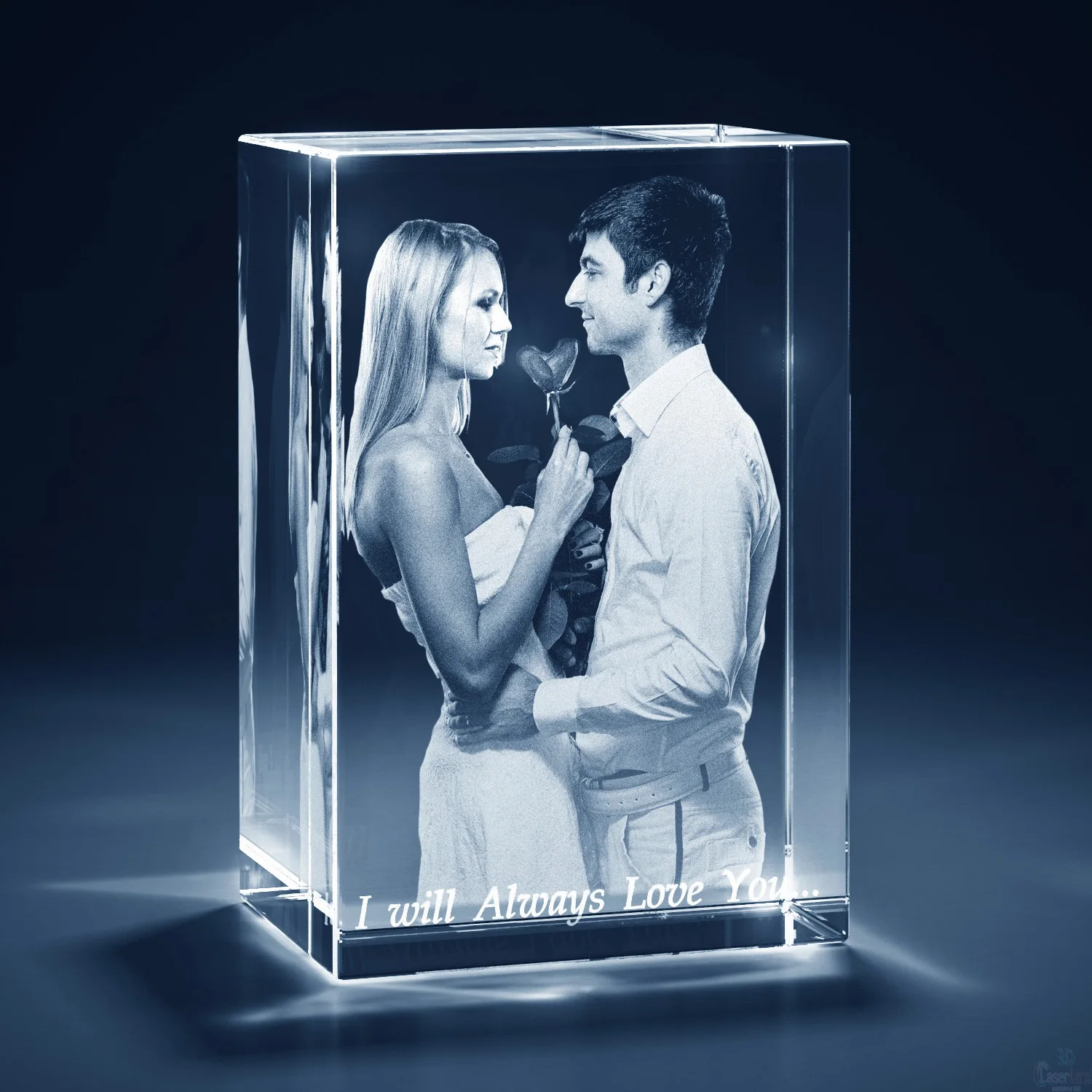

By 2026, the consumer preference for customized and emotionally resonant products will continue to fuel growth in the 3D crystal laser market. From personalized awards and wedding keepsakes to corporate gifts, the ability to embed intricate 3D images, names, and messages inside crystal blocks will remain a compelling value proposition. E-commerce platforms are expected to further amplify accessibility, enabling on-demand production and global reach. -

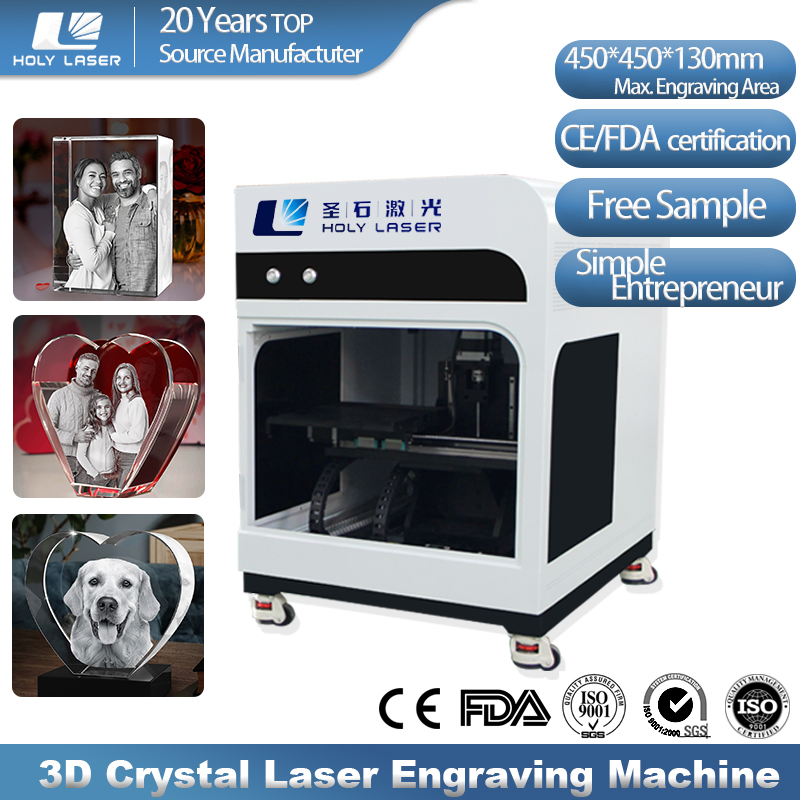

Technological Advancements in Laser Precision and Speed

Ongoing improvements in laser diode technology and software algorithms will enhance the resolution, depth, and clarity of 3D engravings. By 2026, faster processing times and reduced energy consumption will make high-quality crystal engraving more cost-effective for both small businesses and large-scale manufacturers. Integration with AI-driven design tools will allow real-time preview and customization, reducing error rates and improving customer satisfaction. -

Expansion into New Applications

Beyond traditional giftware, the 3D crystal laser market is expected to expand into sectors such as architecture (for 3D scale models), healthcare (for anatomical models and medical training), and entertainment (for collectible figurines and memorabilia). Museums and educational institutions may increasingly adopt laser-engraved crystal models for interactive exhibits. -

Sustainability and Material Innovation

Environmental awareness will drive demand for eco-friendly crystal alternatives and recyclable packaging. By 2026, manufacturers may shift toward lead-free optical glass and biodegradable materials to meet green consumer standards. Energy-efficient laser systems will also align with broader sustainability goals in manufacturing. -

Market Consolidation and Competitive Landscape

The market is likely to see consolidation, with larger firms acquiring niche players to enhance technological capabilities and distribution networks. Simultaneously, the democratization of laser engraving machines—through affordable desktop units—will empower small entrepreneurs and makerspaces, fostering innovation but increasing competition.

In summary, the 2026 3D crystal laser market will be characterized by higher customization, technological sophistication, broader industrial adoption, and a stronger focus on sustainability—positioning it for sustained global growth.

Common Pitfalls When Sourcing 3D Crystal Laser Engraved Products

Sourcing 3D crystal laser engraved items—popular for awards, gifts, and corporate branding—can be deceptively complex. While visually stunning, several pitfalls related to quality and intellectual property (IP) can undermine your project if not carefully managed.

Quality Concerns

Inconsistent Laser Engraving Precision

Low-cost suppliers may use outdated or poorly calibrated laser equipment, resulting in blurry, misaligned, or fragmented internal images. This is especially problematic for intricate designs or text, where fine details may be lost or distorted. Always request physical samples before bulk ordering.

Substandard Crystal Material

Not all “crystal” is equal. Many suppliers use optical-grade glass instead of genuine lead crystal or high-quality K9 glass. Inferior materials can appear cloudy, have internal bubbles or streaks, and lack the brilliance and clarity expected in premium products. Insist on material specifications and verify with sample testing.

Poor Finishing and Polishing

Even with a well-engraved interior, poor exterior finishing can ruin the product’s aesthetic. Rough edges, uneven polishing, or fingerprints etched into the surface are common with mass-produced imports. Evaluate tactile quality and visual clarity in person when possible.

Lack of Quality Control Processes

Many overseas manufacturers lack rigorous QC protocols. This can lead to high defect rates, including cracked crystals, misaligned engravings, or inconsistent sizes. Ask about their inspection procedures and defect tolerance levels.

Intellectual Property Risks

Unauthorized Use of Licensed or Copyrighted Designs

Suppliers, particularly in regions with lax IP enforcement, may offer to engrave popular characters, logos, or artwork without proper licensing. Sourcing such items exposes your business to legal liability for copyright or trademark infringement, even if you were unaware.

Design Theft and Replication

Custom designs shared with unvetted suppliers can be copied and resold to competitors. This is a significant risk when providing unique artwork or proprietary branding. Always use non-disclosure agreements (NDAs) and work only with trusted partners.

Lack of IP Compliance Documentation

Reputable suppliers should provide proof of rights or licensing for any third-party IP used. Absence of such documentation is a red flag. Ensure your contract explicitly states that the supplier is responsible for IP compliance.

Grey-Market or Counterfeit Production

Some factories produce “inspired by” versions of well-known crystal products, mimicking high-end brands. Sourcing these items—even unknowingly—can harm your brand reputation and lead to legal disputes.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence: vet suppliers with on-site audits or third-party inspections, demand samples, review contracts for IP clauses, and prioritize partners with proven quality control and ethical practices. Clear communication and formal agreements are essential to protect both product integrity and legal standing.

Logistics & Compliance Guide for 3D Crystal Laser Engraved Products

Product Overview

3D crystal laser engraved items are precision-crafted glass or optical crystal products featuring internal laser-etched designs, images, or text. Common applications include corporate awards, personalized gifts, and commemorative items. These products are fragile and require careful handling throughout the supply chain.

Packaging Requirements

Use double-walled corrugated cardboard boxes with crush-resistant inner lining. Each crystal must be individually wrapped in anti-static bubble wrap or foam inserts and secured within a rigid inner tray to prevent movement. Include void fill (e.g., air pillows or paper) to eliminate shifting during transit. Clearly label packages as “Fragile,” “This Side Up,” and “Handle with Care” using standardized icons and text.

Shipping & Transportation

Ship via carriers experienced in handling fragile goods (e.g., FedEx, DHL, UPS). For international shipments, select services with tracking and insurance. Avoid ground-only routes with excessive transfers. Maintain stable temperatures (10°C to 30°C) and avoid high humidity during transit. Do not stack heavy items on crystal shipments.

Import/Export Compliance

Verify destination country regulations for glass or crystal imports. Most countries do not impose restrictions on non-decorative glass, but some may require product certification or labeling. Use Harmonized System (HS) code 7018.10 for “Glass in the form of cubes or other articles obtained by hot working.” Include accurate commercial invoices, packing lists, and certificates of origin where required.

Safety & Labeling Standards

Ensure products meet applicable safety standards such as EN 71-1 (EU toy safety – though typically not classified as toys) or general consumer product safety guidelines. Avoid sharp edges; all crystal items should be polished and free of splinters. No hazardous materials are used in the laser engraving process.

Environmental & Regulatory Considerations

Laser engraving uses Class 4 lasers; ensure equipment complies with IEC 60825-1 for laser safety. Manufacturing facilities must adhere to local occupational health and safety regulations. Crystal materials are typically lead-free; confirm material composition for REACH (EU) and Proposition 65 (California) compliance if applicable.

Returns & Reverse Logistics

Establish a clear returns policy for damaged goods. Require photo documentation upon delivery. Use prepaid return labels with reinforced packaging for replacements. Assess damaged items for recycling or safe disposal per local waste regulations.

Carrier & Insurance Recommendations

Insure shipments for full replacement value. Require signature upon delivery for high-value orders. Use carriers offering real-time tracking and delivery confirmation. For international consignments, include customs brokerage services to avoid delays.

Final Notes

Always verify country-specific import duties, taxes, and labeling requirements prior to shipment. Maintain detailed records of compliance documentation for audit purposes. Regularly review logistics partners for performance and adherence to handling protocols.

Conclusion for Sourcing 3D Crystal Laser Engraving:

Sourcing 3D laser crystal engraving products involves careful consideration of quality, technology, customization capabilities, and supplier reliability. These elegant, three-dimensional engraved crystals serve as premium gifts, corporate awards, or commemorative items, making precision and clarity essential. After evaluating various suppliers, it is evident that choosing a provider with advanced laser technology, high-quality optical crystal, and a proven track record in design accuracy ensures a superior end product. Additionally, factors such as lead times, pricing, customization options, and customer service play a crucial role in successful procurement. By partnering with a reputable and experienced 3D crystal laser engraving supplier, businesses and individuals can consistently deliver impactful, high-end keepsakes that meet both aesthetic and functional expectations. Ultimately, investing time in selecting the right source enhances both product quality and customer satisfaction.