The global 3D crystal engraving machine market has experienced steady expansion, driven by rising demand in personalized gifting, corporate awards, and custom décor. According to Grand View Research, the global laser engraving machines market—under which 3D crystal engraving technology falls—was valued at USD 1.78 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by advancements in laser precision, increased adoption of automation in manufacturing, and growing consumer preference for customized products. Mordor Intelligence further projects that demand for high-precision engraving solutions will surge across industries including retail, healthcare, and electronics, creating strong opportunities for specialized equipment providers. In this evolving landscape, a select group of manufacturers has emerged as leaders in 3D crystal engraving technology, combining innovation, accuracy, and scalability to meet expanding global demand.

Top 10 3D Crystal Engraving Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 3D Glass Crystal Laser Engraving Machine Supplier in China …

Website: stnlaser.com

Key Highlights: Wuhan Syntony Laser Co., Ltd is a dedicated developer and manufacturer of 3D laser engraving products in China. · STN Laser crystal machine can engrave 2d and ……

#2 3D crystal laser engraving machine manufacturer

Website: vitro.de

Key Highlights: Our laser systems are compatible for a wide range of applications. Whether small production, individual production, small and large series production….

#3 3d photo crystal laser engraving machine

Website: arguslaser.net

Key Highlights: Argus Laser is a leading China 3d photo crystal laser engraving machine manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of ……

#4 Laser Equipment Supplier

Website: radianlaser.com

Key Highlights: Radian Laser Systems designs and manufactures high-end 2D and 3D (3-axis) fiber, CO2, and UV galvanometer-based laser and marking solutions. Our laser machinery ……

#5 3D Crystal

Website: 3d-crystal.com

Key Highlights: 3D laser engraving and marking on all materials by Grüner Laser Products GmbH. 3D Crystal: we guarantee you best reliability and unbeatable Quality….

#6 Laser engravers & laser cutters

Website: gravotech.com

Key Highlights: Our laser tables are designed to engrave, mark and cut on a wide variety of materials (plastic, wood, metal, leather, glass, paper, stone) and shapes….

#7 Perfect Laser 3D crystal engraving machine

Website: perfectlaser.net

Key Highlights: Perfect Laser offers 3D crystal engraving machine,widely used for 3D crystal engraving and 3D portraits for human image.affordable and easy-to-use….

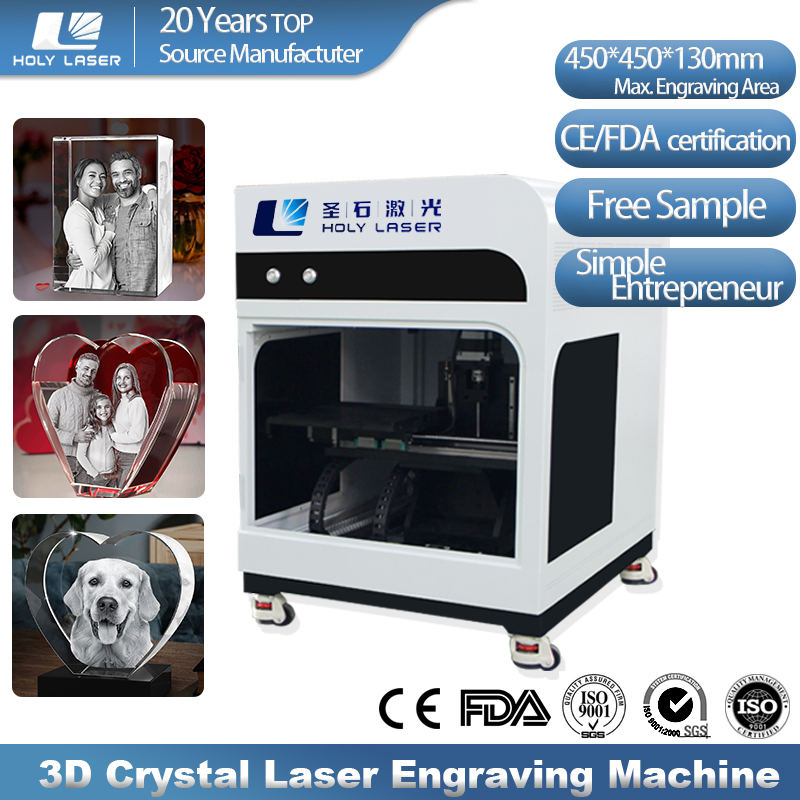

#8 3D Crystal Laser Engraving Machine

Website: sismarlaser.com

Key Highlights: Start small, impress big. With the UV 3D Laser Engraving Machine, your startup can create both emotional 3D crystal keepsakes and surface-engraved products, ……

#9 Master Sub

Website: heatsign.com

Key Highlights: The 3D Crystal Laser Engraving Machine from HeatSign is designed for creating stunning sub-surface engravings in crystal and glass….

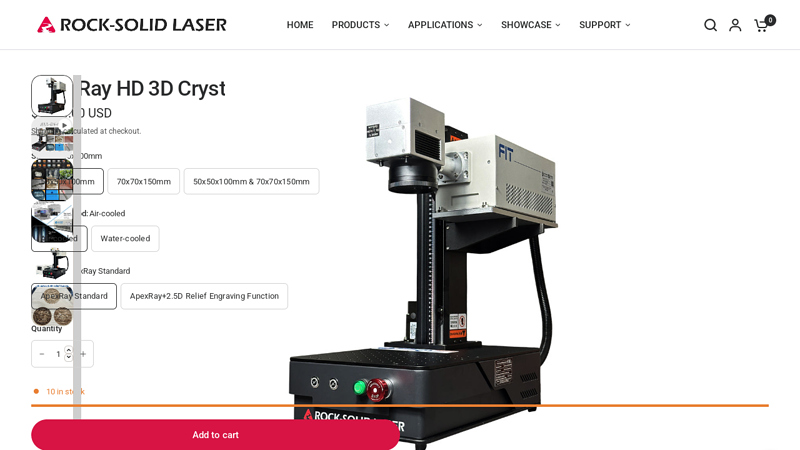

#10 ApexRay HD 3D Crystal Subsurface Laser Engraving Machine

Expert Sourcing Insights for 3D Crystal Engraving Machine

H2: Projected 2026 Market Trends for 3D Crystal Engraving Machines

By 2026, the global market for 3D crystal engraving machines is expected to undergo significant transformation, driven by technological innovation, expanding applications, and shifting consumer preferences. Key trends shaping the industry include advancements in laser precision, increased demand in personalized gifting and industrial sectors, integration with digital platforms, and growing accessibility through cost-effective models.

-

Technological Advancements in Laser and Software Integration

By 2026, 3D crystal engraving machines are anticipated to feature enhanced diode and CO₂ laser systems with improved accuracy, enabling finer detailing and faster processing times. Machine learning algorithms and AI-powered design software will allow for automated 3D model optimization, reducing user input and minimizing errors. Real-time preview and augmented reality (AR) integration will streamline the design process, making it more intuitive for both professionals and hobbyists. -

Rise in Personalization and Custom Gifting

The demand for personalized gifts—such as custom-engraved awards, wedding mementos, and corporate tokens—is expected to surge, particularly in e-commerce and retail sectors. Consumers increasingly value unique, emotionally resonant products, fueling growth in small-to-medium enterprises (SMEs) offering on-demand crystal engraving services. This trend is amplified by social media influence and the popularity of experiential gifting. -

Expansion into Industrial and Architectural Applications

Beyond consumer markets, 3D crystal engraving is gaining traction in industrial design, architectural modeling, and medical visualization. High-precision machines are being adopted for prototyping, data visualization (e.g., 3D anatomical models), and luxury décor. As industries seek innovative ways to present complex data or designs, crystal-based 3D engravings offer a durable and visually striking medium. -

Growth of Desktop and DIY Engraving Systems

The market will see a proliferation of compact, user-friendly 3D crystal engravers targeting hobbyists, educators, and small businesses. These desktop models are expected to become more affordable and compatible with open-source design platforms, encouraging community-driven innovation. Subscription-based software models and cloud-based design libraries may further lower entry barriers. -

Sustainability and Material Innovation

Environmental considerations will influence machine and material development. Manufacturers are likely to introduce recyclable or eco-certified crystal materials and energy-efficient engraving systems. Water-based polishing techniques and reduced laser power consumption will align with global sustainability standards, appealing to eco-conscious consumers and businesses. -

Regional Market Growth and Competitive Landscape

Asia-Pacific, particularly China and India, is projected to be a key growth region due to rising disposable income, digital adoption, and manufacturing capabilities. North America and Europe will maintain strong demand in premium and industrial segments. The competitive landscape will intensify, with established players innovating alongside emerging startups, leading to broader product differentiation and pricing strategies.

In conclusion, the 3D crystal engraving machine market in 2026 will be characterized by smarter, more accessible technology, diversified applications, and a strong consumer focus on customization and quality. Businesses that leverage automation, sustainability, and digital integration will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing a 3D Crystal Engraving Machine: Quality and Intellectual Property Risks

Sourcing a 3D crystal engraving machine, especially from overseas suppliers, involves significant risks related to product quality and intellectual property (IP) protection. Failing to address these pitfalls can lead to financial loss, operational delays, legal disputes, and damage to brand reputation. Below are the key challenges to watch for.

Poor Build Quality and Component Reliability

Many low-cost 3D crystal engraving machines, particularly from less reputable manufacturers, use substandard materials and components. This includes low-grade optical lenses, imprecise stepper motors, or unstable frame construction. Such flaws result in inconsistent engraving depth, misalignment, and frequent mechanical failures, increasing downtime and maintenance costs.

Inaccurate or Inconsistent Engraving Performance

A major quality concern is the machine’s ability to consistently reproduce high-precision 3D images within crystal blocks. Poorly calibrated lasers or inadequate software algorithms lead to blurry, distorted, or misplaced engravings. Buyers may discover that demo units perform well, but production units fail to meet the same standards—highlighting inconsistencies in manufacturing and quality control.

Lack of After-Sales Support and Spare Parts Availability

Many suppliers, especially those operating through online marketplaces, offer limited technical support and long response times. When machines break down, sourcing replacement parts can take weeks or months, halting production. Some vendors may not stock spare parts at all, rendering the machine useless after a single critical component fails.

Misrepresentation of Technical Specifications

Suppliers may exaggerate laser power, engraving speed, maximum crystal size, or software compatibility. For example, a machine advertised as “5W laser” might deliver significantly less actual output, impacting engraving depth and clarity. Always verify specs with independent testing or third-party reports before purchase.

Software Limitations and Proprietary Lock-In

The bundled software is critical for 3D crystal design and machine control. Some vendors use proprietary software that only works with their hardware, preventing integration with existing design tools. Others may provide outdated or unstable software with limited features, requiring costly third-party upgrades or custom development.

Intellectual Property Infringement Risks

Using a machine that incorporates copied or reverse-engineered technology can expose buyers to legal liability. Some manufacturers replicate patented laser control systems, motion algorithms, or software interfaces. If your business uses such a machine, you could face cease-and-desist orders or lawsuits, particularly in markets with strong IP enforcement like the EU or North America.

No Clear Warranty or Legal Recourse

Contracts from certain suppliers lack enforceable warranties or dispute resolution mechanisms. If the machine fails to perform, buyers may find themselves without legal recourse, especially when dealing with offshore vendors not subject to local consumer protection laws. Payment terms like full upfront transfers further increase financial risk.

Counterfeit or Refurbished Machines Sold as New

Unscrupulous sellers may pass off used, refurbished, or cloned machines as brand-new units. These machines often lack original firmware, have shortened lifespans, and may include non-certified components that compromise safety and performance.

Inadequate Compliance with Safety and Regulatory Standards

Laser-based equipment must comply with safety standards (e.g., FDA/CDRH in the U.S., CE in Europe). Machines sourced without proper certification may be illegal to operate, fail customs inspections, or pose health risks due to unshielded laser emissions or poor electrical design.

Failure to Protect Your Own Designs

When working with third-party vendors or shared platforms, there’s a risk that your custom 3D crystal designs could be copied or resold without permission. Ensure data security measures are in place and that contractual agreements explicitly prohibit the unauthorized use or distribution of your creative content.

To mitigate these risks, conduct thorough due diligence: request live demonstrations, verify certifications, audit the supplier’s manufacturing process, use secure payment methods, and consult legal counsel before signing contracts—especially for cross-border transactions.

Logistics & Compliance Guide for 3D Crystal Engraving Machine

This guide provides essential information for the safe, legal, and efficient transportation, import/export, and operation of a 3D Crystal Engraving Machine. Adherence to these guidelines ensures regulatory compliance and smooth logistics operations.

Shipping and Transportation

Proper packaging and handling are critical to prevent damage during transit. The 3D crystal engraving machine must be securely packed in its original manufacturer’s crate or a custom wooden export crate with internal foam or foam-in-place cushioning to immobilize all components. Use shock indicators on the exterior to monitor impacts. For international shipments, ensure the packaging meets ISPM 15 standards for wooden materials. Choose a reliable freight forwarder experienced in handling precision equipment, and always insure the shipment for its full replacement value. Clearly label all packages as “Fragile,” “This Side Up,” and “Precision Equipment.”

Import/Export Regulations

Compliance with international trade regulations is mandatory. Before shipping across borders, verify the Harmonized System (HS) code for the machine—typically under 8477.40 (Machines for working stone, ceramics, etc.). Obtain any required export licenses from your home country, especially if the machine contains controlled laser or optical components. Ensure the destination country allows importation of such equipment and check for import restrictions or bans related to laser devices. Prepare accurate commercial invoices, packing lists, and certificates of origin. Consult with a customs broker if necessary to navigate tariffs, duties, and local import policies.

Laser Safety Compliance

3D crystal engraving machines often use Class 3B or Class 4 lasers, which are subject to strict safety regulations. Confirm that the machine complies with the IEC 60825-1 standard for laser product safety. In the United States, adherence to FDA/CDRH (Center for Devices and Radiological Health) regulations under 21 CFR 1040.10 and 1040.11 is required. In the European Union, conformity with the CE marking directive (such as the Machinery Directive 2006/42/EC and the Laser Product Standard EN 60825-1) is mandatory. Provide required laser warning labels, interlocks, and a key-controlled power switch. Maintain a laser safety officer (LSO) if operating a Class 4 laser in a professional setting.

Electrical and EMC Standards

Ensure the machine meets electrical safety and electromagnetic compatibility (EMC) standards for the target market. In the U.S., this includes UL/CSA certification to standards like UL 61010-1. In the EU, CE marking under the Low Voltage Directive (2014/35/EU) and EMC Directive (2014/30/EU) is required. Verify voltage compatibility (e.g., 110V vs. 220V) and provide appropriate power adapters or transformers if needed. The machine should include overload protection, proper grounding, and shielding to prevent electromagnetic interference with other devices.

Workplace Safety and Installation

Install the machine in a clean, stable, and well-ventilated area free from dust and vibrations. Follow the manufacturer’s installation instructions precisely, including anchoring the unit if recommended. Operators must be trained on emergency shutdown procedures and proper handling of materials. Provide appropriate personal protective equipment (PPE), such as laser safety goggles rated for the machine’s wavelength. Implement local exhaust ventilation if engraving processes generate particulates. Conduct regular safety inspections and maintain a log of machine maintenance and safety checks.

Documentation and Recordkeeping

Maintain comprehensive records for compliance and traceability. This includes the original purchase invoice, technical specifications, user and service manuals, conformity declarations (DoC), laser classification reports, calibration certificates, and maintenance logs. Retain shipping documents, customs filings, and import/export licenses for at least five years. In regulated environments, documentation may be subject to inspection by authorities such as OSHA, FDA, or EU notified bodies.

Environmental and Disposal Compliance

Dispose of machine components, packaging, and consumables in accordance with local environmental regulations. Laser systems may contain batteries, electronic circuit boards, or optical components that are classified as hazardous waste under directives like WEEE (EU) or state-specific regulations (e.g., California). Do not dismantle laser modules—return them to the manufacturer or an authorized facility for proper recycling. Packaging materials should be recycled or disposed of following local waste management policies.

Conclusion: Sourcing a 3D Crystal Engraving Machine

After thorough evaluation of available options, sourcing a 3D crystal engraving machine proves to be a strategic investment for enhancing product customization, expanding service offerings, and meeting growing customer demand for personalized, high-quality gifts and awards. Key factors such as precision, reliability, ease of use, compatibility with design software, and after-sales support must be prioritized when selecting a supplier.

Laser systems utilizing internal engraving (also known as 3D laser subsurface engraving) provide crisp, durable results and are ideal for detailed portraits, logos, and multi-layered designs within crystal blocks. While entry-level machines offer a cost-effective entry point, mid-to-high-end models from reputable manufacturers deliver superior accuracy, faster processing times, and longer lifespans—justifying the higher initial cost over time.

Sourcing from established suppliers—whether domestic or international—requires due diligence in assessing warranty terms, technical support, training availability, and user reviews. Machines with modular designs and software compatibility (e.g., with AutoCAD, Adobe Illustrator, or dedicated 3D crystal software) ensure scalability and integration into existing workflows.

In conclusion, investing in a high-quality 3D crystal engraving machine not only elevates the aesthetic and commercial value of your offerings but also positions your business competitively in niche markets such as corporate awards, wedding memorabilia, and personalized luxury items. Careful sourcing, based on technical specifications, vendor reputation, and long-term operational needs, will ensure a strong return on investment and sustained customer satisfaction.