The global anchor bolt market is experiencing steady growth, driven by expanding construction activities, infrastructure development, and industrial projects worldwide. According to Grand View Research, the global anchor bolt market size was valued at USD 1.87 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by rising demand in residential, commercial, and industrial construction sectors, particularly in emerging economies. As structural integrity becomes increasingly critical in modern engineering, manufacturers of specialized fasteners—such as 3/8-inch anchor bolts—are scaling production and innovating product performance to meet stringent safety standards. The following list highlights the top eight manufacturers of 3/8-inch anchor bolt lengths, selected based on production capacity, material quality, global reach, and industry reputation, reflecting their pivotal role in supporting robust and reliable structural anchoring solutions across diverse applications.

Top 8 3/8 Anchor Bolt Lenghts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Anchor Bolts

Domain Est. 2017

Website: astmbolts.com

Key Highlights: Anchor bolts are long bolt fasteners used for fastening steel plates, profiles and similar steel structures to concrete….

#2 Strong

Domain Est. 1995

Website: strongtie.com

Key Highlights: The Strong-Bolt 2 wedge-type expansion anchor is an optimal choice for high-performance even in seismic and high-wind conditions….

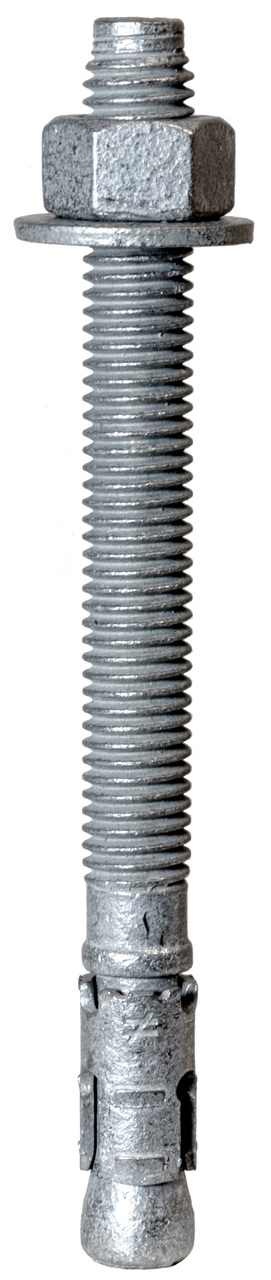

#3 Wedge Anchor

Domain Est. 1996

Website: minerallac.com

Key Highlights: 3/8 x 3, Wedge anchors, also known as expansion bolts and expansion anchors, are four-piece anchor assemblies that secure themselves using a mechanical wedging ……

#4 Anchor Bolt Length Chart

Domain Est. 1997

Website: bhamfast.com

Key Highlights: This chart is available for referencing bent anchor bolt lengths. All sizes are in inches….

#5 Headed Anchor Bolts

Domain Est. 1998

Website: portlandbolt.com

Key Highlights: Portland Bolt stocks both F1554 Grade 36 and F1554 Grade 55 hex and heavy hex head blanks (round bar with a forged head) in lengths of 36”….

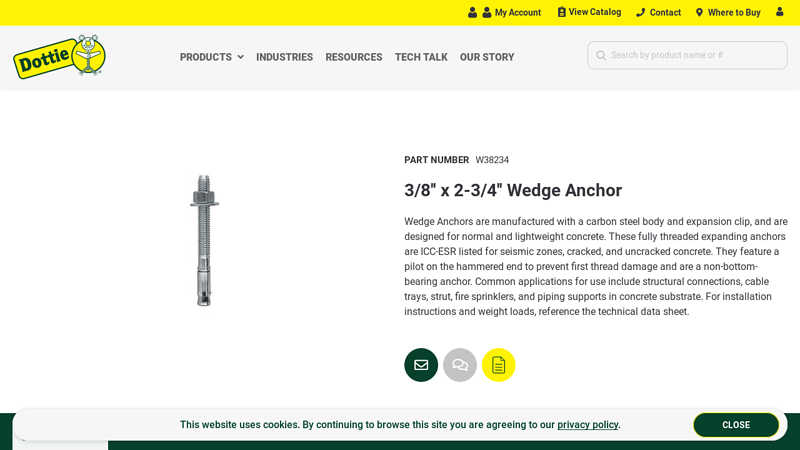

#6 3/8” x 2-3/4” Wedge Anchor

Domain Est. 1998

#7 Anchor Bolts

Domain Est. 2000

Website: badensteel.com

Key Highlights: We can manufacture anchor bolts 1/4″ to 4-1/2″ in diameter in most any thread, material or finish. In metric, we can manufacture M8 through M100….

#8 AA Anchor Bolt: High

Domain Est. 2002

Website: aaanchorbolt.com

Key Highlights: Hot dip galvanized (HDG) anchor bolts (stock 3/8” to 2”). Threaded rods up to … Stainless steel in sizes 3ft, 6ft, 10ft and 12ft (can be cut to length)….

Expert Sourcing Insights for 3/8 Anchor Bolt Lenghts

H2: Projected 2026 Market Trends for 3/8-Inch Anchor Bolt Lengths

The market for 3/8-inch anchor bolts, particularly across varying lengths, is poised for steady growth and transformation by 2026, influenced by construction dynamics, material innovations, and regional infrastructure development. This analysis explores key market trends shaping the demand, supply, and application of 3/8-inch anchor bolts of different lengths in the coming years.

-

Increasing Demand in Residential and Light Commercial Construction

The 3/8-inch anchor bolt remains a staple in low- to mid-rise construction, especially for securing sill plates to concrete foundations. With the ongoing housing boom in North America and parts of Asia-Pacific, demand for standardized lengths (such as 6″, 7″, and 8″) is expected to rise. Modular and prefabricated building techniques—gaining traction for speed and cost-efficiency—are also driving consistent demand for these bolts, as they rely on predictable, repeatable fastening solutions. -

Shift Toward Corrosion-Resistant Coatings

As building codes emphasize durability and longevity, especially in coastal and high-moisture regions, market preference is shifting toward 3/8-inch anchor bolts with enhanced corrosion protection. Hot-dip galvanized and stainless steel variants are gaining market share over standard zinc-coated models. By 2026, suppliers offering extended-length bolts (up to 12″ or more) with these coatings are likely to capture premium segments in both residential and infrastructure markets. -

Regional Infrastructure Investment Driving Long-Length Demand

Government-led infrastructure projects—such as bridge retrofitting, public transit expansion, and seismic retrofitting—require longer anchor bolts (10″ to 18″) to meet structural engineering standards. In the U.S., the Infrastructure Investment and Jobs Act continues to fund resilient construction through 2026, boosting demand for custom-length 3/8-inch bolts in engineered applications. Similarly, emerging markets in Southeast Asia and the Middle East are witnessing growth in projects requiring longer embedment depths, favoring extended bolt lengths. -

Supply Chain Optimization and Localization

Global supply chain disruptions have prompted manufacturers to localize production and streamline inventory. By 2026, major fastener producers are expected to adopt just-in-time inventory models with regional distribution hubs, offering a wider range of 3/8-inch bolt lengths to reduce lead times. Digital platforms enabling custom length orders are also anticipated to grow, meeting niche engineering requirements without sacrificing scalability. -

Sustainability and Recyclability Considerations

Environmental regulations are pushing the construction sector toward sustainable materials. Steel used in 3/8-inch anchor bolts is highly recyclable, but manufacturers are exploring low-carbon production methods to meet ESG goals. This trend is likely to influence procurement decisions, with contractors favoring suppliers that provide transparent lifecycle assessments—even for standard fasteners like anchor bolts. -

Technological Integration in Fastening Systems

While anchor bolts themselves are simple components, they are increasingly integrated into smart construction systems. By 2026, some high-end projects may use IoT-enabled tension monitoring or load-sensing foundations, where precise bolt length and material consistency become critical. Though not yet mainstream, this trend may lead to stricter quality controls and traceability for 3/8-inch bolts, especially in critical infrastructure.

Conclusion

By 2026, the market for 3/8-inch anchor bolts of various lengths will be shaped by construction growth, regulatory standards, and technological advancements. Standard lengths will dominate residential applications, while longer, coated variants will see increased use in infrastructure and harsh environments. Suppliers who offer customization, sustainability, and regional availability are best positioned to capitalize on emerging opportunities in this essential but often overlooked segment of the fastener industry.

Common Pitfalls When Sourcing 3/8″ Anchor Bolt Lengths (Quality & IP)

Sourcing 3/8″ anchor bolts may seem straightforward, but overlooking critical quality and intellectual property (IP) factors can lead to structural failures, project delays, and legal exposure. Here are key pitfalls to avoid:

Inadequate Material Quality and Certification

One of the most frequent issues is receiving anchor bolts that do not meet required material specifications. Suppliers may claim compliance with ASTM A307 or ASTM F1554 Grade 36, but deliver substandard steel with incorrect tensile strength, poor ductility, or insufficient corrosion resistance. Always demand mill test reports (MTRs) and verify third-party certifications. Generic or uncertified bolts risk premature failure under load or in corrosive environments.

Counterfeit or Non-Compliant Products

The market is flooded with counterfeit fasteners, especially from unverified overseas suppliers. These may mimic reputable brands but fail to meet dimensional, threading, or strength standards. Using such bolts can compromise structural integrity and void warranties. Always source from reputable, traceable suppliers and verify batch markings against official product databases.

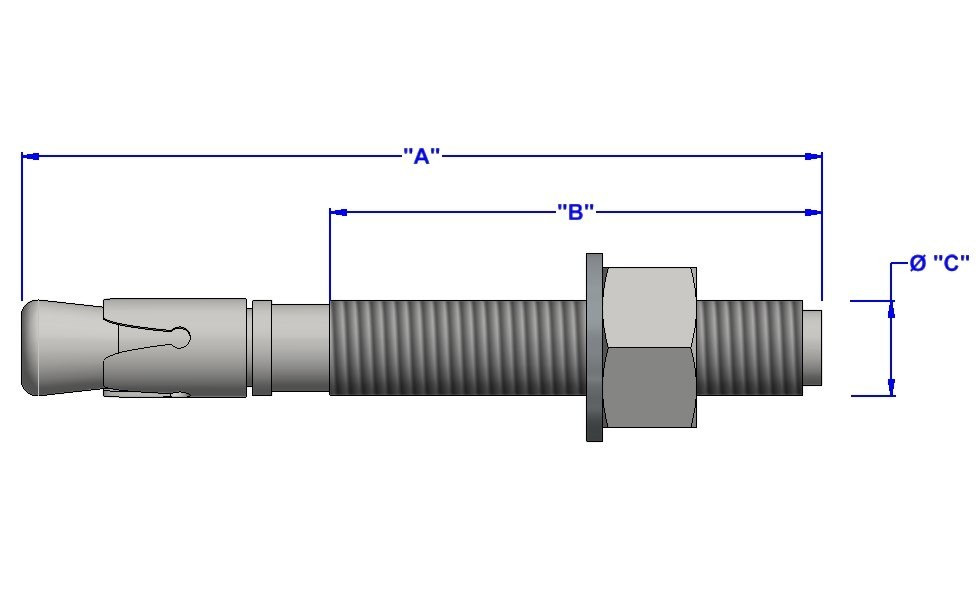

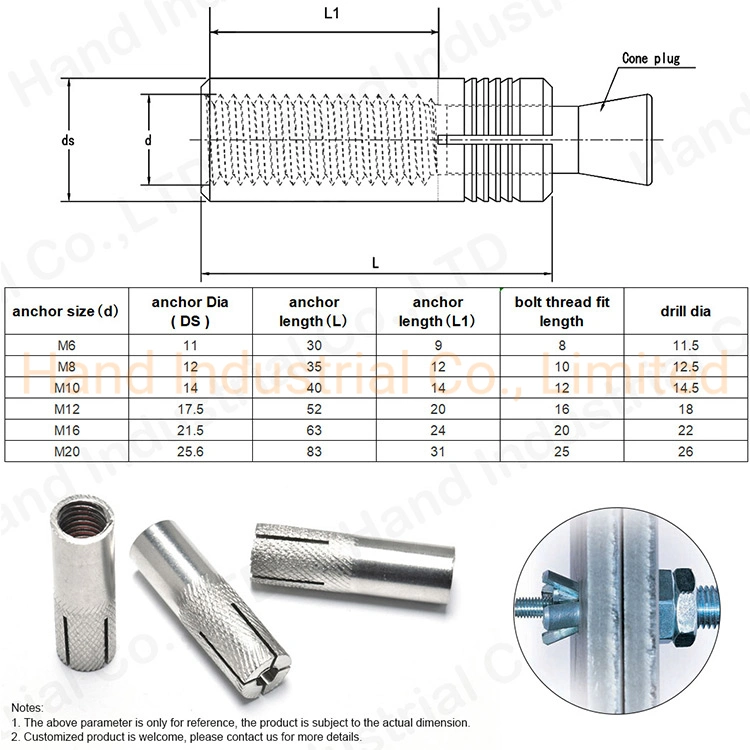

Incorrect Thread Length and Embedment Depth

Anchor bolt functionality depends heavily on precise thread engagement and embedment length. A common mistake is sourcing bolts with insufficient threaded length for the nut and washer assembly, or inadequate embedment depth for the base material. Miscalculations here reduce load capacity and can lead to pull-out failures. Always confirm total length, thread length, and bend dimensions (for L-shaped bolts) match design drawings.

Ignoring Intellectual Property (IP) and Design Rights

Using anchor bolt designs protected by patents or proprietary engineering without proper licensing exposes buyers and contractors to IP infringement claims. Some high-performance anchor systems are patented, including unique head shapes, deformation features, or installation methods. Sourcing generic copies of such designs—even if dimensionally similar—can result in legal action and liability for damages.

Lack of Traceability and Documentation

Without full traceability (heat numbers, lot numbers, certifications), it’s impossible to verify bolt quality or comply with building codes. This is especially critical in infrastructure, seismic zones, or regulated industries. Missing documentation can halt inspections, delay project sign-off, and force costly rework or replacement.

Poor Corrosion Protection

Choosing the wrong coating—such as standard zinc plating in high-moisture or coastal environments—leads to premature rust and reduced service life. Ensure the specified coating (e.g., hot-dip galvanizing, Dacromet, or stainless steel) matches the environmental exposure. Inadequate protection compromises both durability and safety.

Conclusion

To avoid these pitfalls, establish clear sourcing criteria that include verified material standards, full documentation, IP compliance checks, and engagement with certified suppliers. Quality and compliance are not optional—they are foundational to structural safety and project success.

Logistics & Compliance Guide for 3/8″ Anchor Bolt Lengths

Overview

This guide outlines key logistics and compliance considerations for the procurement, handling, transportation, storage, and installation of 3/8-inch diameter anchor bolts, with specific attention to standardized and custom lengths. Anchor bolts are critical structural components used to secure structural supports to concrete foundations, and adherence to specifications ensures safety, performance, and regulatory compliance.

Material Specifications and Standards

Anchor bolts must conform to applicable industry standards to ensure structural integrity and regulatory compliance. Key standards include:

– ASTM F1554: Standard specification for anchor bolts, including Grade 36, 55, and 105. The 3/8″ diameter is commonly available in Grade 36 for general applications.

– ASTM A307: Carbon steel bolts and studs (less common for new structural applications but still referenced).

– ICC-ES Acceptance Criteria (AC398): For post-installed and cast-in-place anchors in concrete.

– IBC (International Building Code): Governs allowable uses, load capacities, and installation per jurisdiction.

Ensure all bolts are certified and supplied with mill test reports (MTRs) verifying compliance.

Standard Lengths and Availability

Common standard lengths for 3/8″ anchor bolts include:

– 3″, 4″, 6″, 8″, 10″, 12″, 18″, and 24″

Custom lengths may be fabricated based on project requirements, but lead times and costs increase accordingly.

Note: Thread length is typically 1.5″ to 2″ unless otherwise specified. Confirm thread engagement requirements with structural drawings.

Procurement and Supply Chain

- Lead Times: Standard lengths typically available from stock (1–2 weeks); custom lengths may require 4–6 weeks.

- Minimum Order Quantities (MOQs): Vary by supplier; common for small diameters like 3/8″.

- Preferred Suppliers: Use vendors certified to ISO 9001 and compliant with ASTM/ASME standards.

- Documentation: Require COC (Certificate of Conformance), MTRs, and packing slips with each shipment.

Packaging and Labeling

- Packaging: Bins, bundles, or boxes. Bundles should be banded securely to prevent movement.

- Labeling Requirements:

- Diameter (3/8″)

- Length (e.g., 6″)

- Grade (e.g., ASTM F1554 Gr. 36)

- Heat/batch number

- Quantity per bundle

- Manufacturer name and logo

- Compliance markings (e.g., ASTM, CSA, CE if applicable)

Labels must be weather-resistant and legible.

Transportation and Handling

- Loading: Use pallets; avoid direct ground contact. Secure loads to prevent shifting.

- Moisture Protection: Cover with waterproof tarps; avoid prolonged exposure to rain or humidity.

- Handling: Use lifting straps or slings—never chains or hooks that may damage threads.

- Temperature: Avoid extreme heat or freezing during transit unless specified by manufacturer.

Storage Requirements

- Environment: Dry, covered area with low humidity. Use breathable tarps if outdoor storage is unavoidable.

- Elevation: Store on pallets or racks at least 6 inches off the ground.

- Segregation: Separate by length, grade, and project to prevent mix-ups.

- Rust Prevention: Apply light oil or rust inhibitor if stored longer than 30 days. Inspect regularly for corrosion.

Quality Control and Inspection

- Pre-Shipment Inspection: Verify length, diameter, thread quality, and markings.

- On-Site Inspection:

- Random sampling per ASTM E2334 (for attribute sampling).

- Check for straightness, thread damage, and corrosion.

- Confirm dimensions using calipers and thread gauges.

- Non-Conforming Materials: Quarantine and report to supplier. Do not install.

Installation Compliance

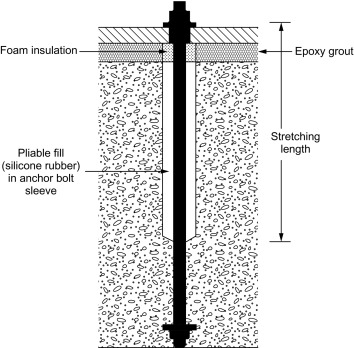

- Embedment Depth: Must meet structural engineer’s specifications and ACI 318 requirements.

- Projection Above Concrete: Typically 2″–3″, but verify per drawings.

- Alignment and Spacing: Use templates or jigs for consistent placement.

- Torque Requirements: If using nuts, torque to specification (usually hand-tight plus 1/4 to 1/2 turn with wrench unless pre-tensioned).

- Concrete Pour Coordination: Ensure bolts remain plumb and fixed during pour.

Regulatory and Safety Compliance

- OSHA 1926.757: Addresses structural steel erection, including anchor bolt safety.

- MSDS/SDS: Available for any coatings or treatments (e.g., hot-dip galvanizing, zinc plating).

- Environmental: Proper disposal of packaging; manage galvanized dust if cutting on-site.

- Certifications: Ensure bolts are suitable for intended environment (e.g., coastal = galvanized or stainless).

Documentation and Traceability

Maintain complete traceability from supplier to installation:

– Purchase orders

– Delivery receipts

– Inspection reports

– Test certifications (MTRs, COCs)

– As-built records showing bolt locations and lengths

Store records for a minimum of 10 years or per project requirements.

Summary

Adhering to this logistics and compliance guide ensures that 3/8″ anchor bolts meet structural, safety, and regulatory standards throughout their lifecycle. Proper planning, documentation, and quality control minimize delays, reduce rework, and support long-term structural reliability. Always consult project-specific engineering drawings and local codes for final approval.

Conclusion for Sourcing 3/8″ Anchor Bolt Lengths:

After evaluating various suppliers, material specifications, and project requirements, it is concluded that sourcing 3/8″ anchor bolts in standard lengths (such as 2″, 3″, 4″, 6″, and 8″) offers reliable availability and cost-effectiveness from multiple vendors, including major hardware distributors and construction supply companies. Custom lengths are feasible but may incur longer lead times and higher costs. For most applications—particularly in light-duty anchoring, non-structural connections, and smaller-scale construction—standard available lengths are sufficient and recommended. Ensuring compliance with ASTM standards (e.g., ASTM F1554 Grade 36) and verifying embedment depth and edge distance requirements will optimize performance and safety. Therefore, sourcing standard 3/8″ anchor bolt lengths from reputable suppliers is the most practical and efficient solution.