The global pavers market is experiencing steady growth, driven by increasing urbanization, rising infrastructure investments, and growing demand for aesthetic and durable outdoor surfacing solutions. According to Grand View Research, the global concrete pavers market size was valued at USD 37.4 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by the construction of residential driveways, walkways, and commercial outdoor spaces, where 36×36 pavers—known for their modular design, ease of installation, and visual appeal—are becoming a preferred choice. With expanding demand for sustainable and low-maintenance hardscaping materials, manufacturers are increasingly focusing on innovation in texture, color, and load-bearing capacity. As the market becomes more competitive, identifying leading producers of 36×36 pavers is essential for contractors, landscapers, and developers seeking high-quality, reliable products. Here’s a data-driven look at the top 10 manufacturers shaping this segment.

Top 10 36X36 Pavers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

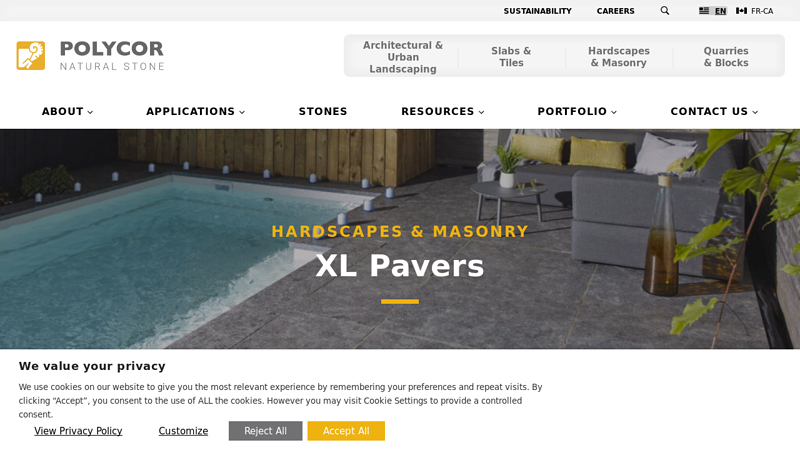

#1 XL Pavers

Domain Est. 1997

Website: polycor.com

Key Highlights: With Polycor’s new extra large, natural stone pavers, you can enhance entrances, walkways, and patios, boosting your home’s curb appeal and resale value….

#2 Paver Specifications

Domain Est. 2003

Website: sunnybrookpressedconcrete.com

Key Highlights: With our precision engineering, we can manufacture our pavers to meet any architectural or engineering specification. … 36 x 36. Detectable Warning Paver ……

#3 Large Concrete Landscape Pavers 36 in. x 36 in. (Specify Color)

Domain Est. 1995

Website: siteone.com

Key Highlights: These 36 in. x 36 in. pavers, available in a variety of colors, offer endless possibilities for enhancing your landscape design. Whether you’re creating a patio ……

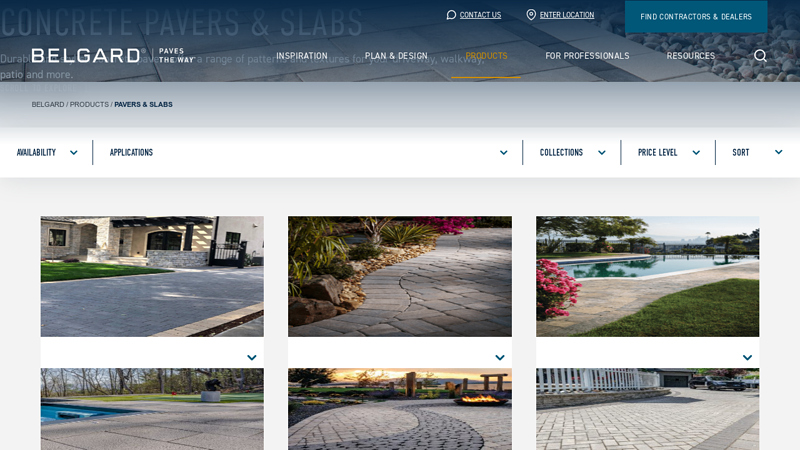

#4 Concrete Pavers & Slabs for Patios, Driveways & More

Domain Est. 1997

Website: belgard.com

Key Highlights: Concrete Pavers & Slabs. Durable and stylish concrete pavers offer a range of patterns and textures for your driveway, walkway, patio and more….

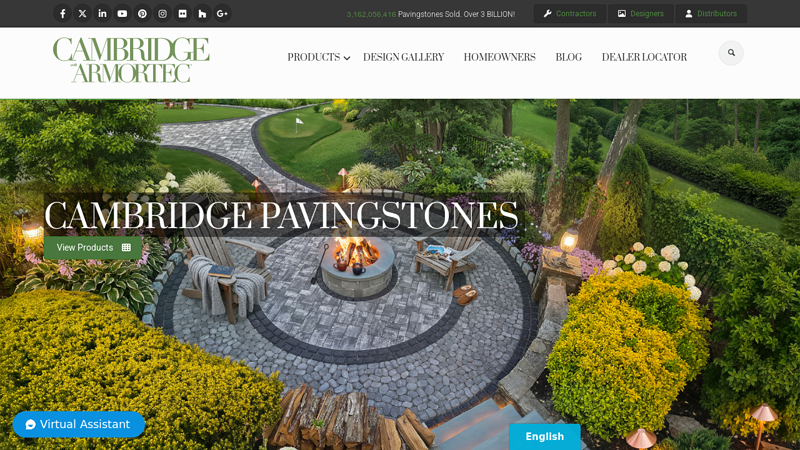

#5 Cambridge Pavers

Domain Est. 1998

Website: cambridgepavers.com

Key Highlights: Cambridge Pavingstones with ArmorTec offers pavings options for patios, pools, walkways, driveways, landscape walls and outdoor living solutions….

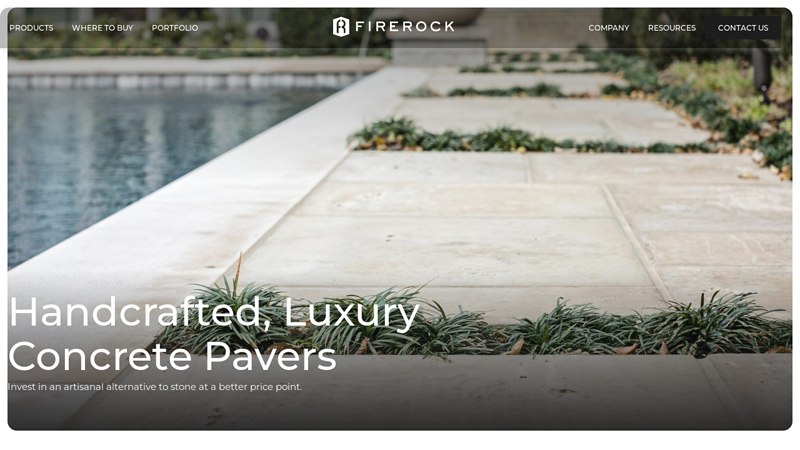

#6 Pavers

Domain Est. 2002

Website: firerock.us

Key Highlights: Handcrafted, Luxury Concrete Pavers. Invest in an artisanal alternative to stone at a better price point. Built with Care in America….

#7 Concrete Pavers

Domain Est. 2003

Website: stonesdirect.com

Key Highlights: Concrete Pavers & Natural Stone Pavers: Transform your outdoor spaces with durable concrete and timeless natural stone paving solutions….

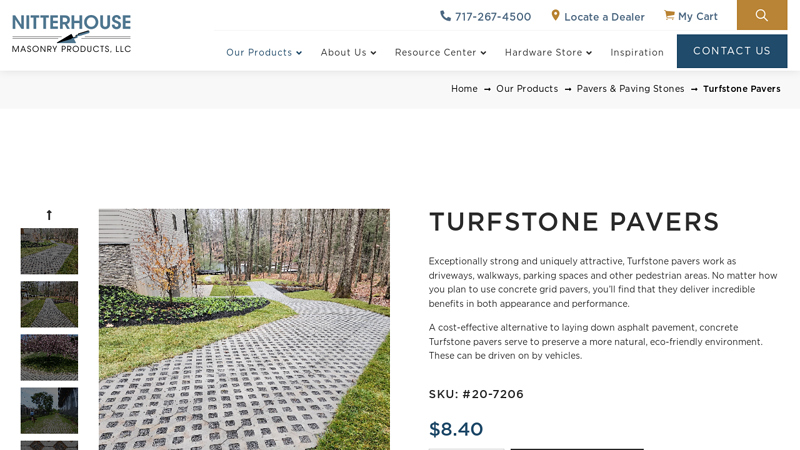

#8 Turfstone Pavers – Concrete Grid Pavers

Domain Est. 2011

Website: nitterhousemasonry.com

Key Highlights: In stock $150 deliveryExceptionally strong and uniquely attractive, Turfstone pavers work as driveways, walkways, parking spaces and other pedestrian areas….

#9 Arterra Porcelain Pavers

Domain Est. 2012

Website: msisurfaces.com

Key Highlights: Arterra Porcelain Pavers offer the ultimate worry-free surface that never fades, stains, or needs any sealing. Set them on grass, sand, or on concrete….

#10 Olympic Pavers

Domain Est. 2014

Website: castohn.com

Key Highlights: Big, Bold and Beautiful. Large rectangular pavers with an exposed sand finish for an immensely dramatic look that compliment any contemporary design….

Expert Sourcing Insights for 36X36 Pavers

H2: Market Trends for 36×36 Pavers in 2026

As we approach 2026, the market for 36×36 pavers—large-format paving stones typically measuring 36 inches by 36 inches—is expected to experience significant evolution driven by shifts in consumer preferences, construction technology, sustainability demands, and material innovation. These pavers, popular in both residential and commercial hardscaping applications, are poised to benefit from broader trends in outdoor living, urban development, and eco-conscious design.

1. Rising Demand for Large-Format Pavers

The preference for seamless, modern aesthetics in outdoor spaces continues to fuel demand for larger paver sizes like 36×36. These oversized pavers reduce grout lines and installation joints, creating a sleek, continuous surface that mimics natural stone or concrete slabs. In 2026, this trend is expected to intensify, particularly in high-end residential landscaping, rooftop terraces, and urban plazas where minimalist design is favored.

2. Growth in Residential Outdoor Living Spaces

The post-pandemic emphasis on home improvement and outdoor living remains strong. Homeowners are investing in luxury backyard environments, including outdoor kitchens, fire pits, and entertainment areas. The 36×36 paver size offers efficiency in coverage and a premium look, making it a preferred choice for patios and pool decks. Market analysts project continued growth in DIY and contractor-driven installations of large-format pavers through 2026.

3. Advancements in Manufacturing and Material Technology

Concrete and porcelain 36×36 pavers are seeing improvements in durability, slip resistance, and color retention. Innovations in manufacturing, such as ultra-high-performance concrete (UHPC) and digitally printed porcelain surfaces, allow for greater design flexibility and enhanced performance. By 2026, expect wider availability of lightweight composite 36×36 pavers that maintain structural integrity while easing transport and installation.

4. Sustainability and Permeable Paver Solutions

With increasing focus on stormwater management and green building certification (e.g., LEED), permeable 36×36 paver systems are gaining traction. These systems allow water infiltration, reducing runoff and supporting sustainable urban drainage (SUDS). Municipalities and developers are adopting such solutions in public walkways and mixed-use developments. The integration of recycled materials in paver production is also expected to rise, aligning with ESG (Environmental, Social, and Governance) goals.

5. Commercial and Urban Infrastructure Adoption

Cities are investing in pedestrian-friendly infrastructure, including widened sidewalks, park plazas, and transit hubs. The 36×36 size offers faster installation and a more uniform appearance, appealing to municipal and commercial projects. In 2026, urban renewal projects in North America and Europe are likely to specify large-format pavers for both functionality and visual impact.

6. Regional Market Variations

In North America, the 36×36 paver market is expanding due to strong housing markets in Sun Belt regions (e.g., Texas, Florida, Arizona), where outdoor living is year-round. In Europe, demand is driven by urban regeneration and climate resilience initiatives. Meanwhile, emerging markets in the Middle East and Asia are adopting large-format pavers in luxury developments and smart city projects.

7. Price and Supply Chain Considerations

While raw material costs (cement, resins, energy) may fluctuate, economies of scale and improved logistics are expected to stabilize pricing for 36×36 pavers by 2026. Domestic manufacturing investments in the U.S. and EU aim to reduce reliance on imports and mitigate supply chain disruptions, enhancing product availability.

Conclusion

By 2026, the 36×36 paver segment will be shaped by design innovation, sustainability imperatives, and growing demand for high-performance hardscaping solutions. As consumers and developers prioritize aesthetics, functionality, and environmental responsibility, large-format pavers are set to become a standard in modern outdoor design. Companies that invest in R&D, eco-friendly production, and targeted marketing will be best positioned to capitalize on this expanding market.

Common Pitfalls When Sourcing 36×36 Pavers (Quality, IP)

Sourcing large-format 36×36 pavers can significantly enhance the aesthetic and functional value of outdoor spaces. However, several common pitfalls related to quality and intellectual property (IP) can compromise project outcomes if not carefully addressed. Being aware of these issues early in the procurement process helps ensure you receive durable, high-performing materials that are both legally and ethically sound.

Poor Material Quality and Inconsistent Manufacturing

One of the most frequent challenges is receiving pavers that do not meet expected quality standards. Low-grade concrete or improperly cured materials can lead to cracking, spalling, or uneven coloration. When pavers are mass-produced, especially overseas, inconsistent batching and lack of quality control may result in visible defects, dimensional inaccuracies, or variable surface finishes. Always request physical samples and verify compliance with ASTM or relevant regional standards (e.g., ASTM C936 for solid concrete interlocking pavement units).

Inadequate Slip Resistance and Surface Texture

Large pavers are often used in high-traffic or wet areas such as pool decks and patios. A common oversight is selecting pavers with overly smooth finishes that become hazardous when wet. Ensure the surface has appropriate texture or anti-slip ratings, particularly for exterior applications. Verify the coefficient of friction (COF) meets safety standards for the intended use.

Lack of Structural Integrity and Load Rating

36×36 pavers are heavy and require sufficient compressive strength to endure foot and vehicular traffic. Pavers with inadequate PSI ratings (typically below 8,000 psi for heavy-use areas) may crack under pressure or over time. Confirm load-bearing specifications and ensure the pavers are designed for the intended application—pedestrian vs. driveway use requires different structural performance.

Misrepresentation of Intellectual Property (IP) and Design Authenticity

Another critical risk is inadvertently sourcing pavers that infringe on patented designs or trademarks. Many premium paver patterns (e.g., specific textures, edge profiles, or modular layouts) are protected under design patents or registered IP. Suppliers, particularly third-party or offshore manufacturers, may replicate these designs without authorization. Purchasing such products exposes buyers to legal liability and reputational risk. Always verify that the supplier holds proper licensing or offers original, non-infringing designs.

Insufficient Documentation and Traceability

Reputable suppliers should provide technical data sheets, test reports, and IP documentation upon request. A red flag is the absence of verifiable certifications or reluctance to disclose manufacturing origins. Ensure there is full traceability from manufacturer to end user, especially for projects requiring compliance with building codes or sustainability standards.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: vet suppliers, request third-party test results, verify IP rights, and inspect samples in person. Partnering with trusted, transparent manufacturers minimizes risk and ensures your 36×36 pavers deliver long-term performance and compliance.

Logistics & Compliance Guide for 36×36 Pavers

Product Overview

36×36 pavers are large-format concrete or stone units commonly used in commercial and high-end residential hardscaping projects. Due to their size and weight (typically 150–250 lbs per unit), special attention must be paid to handling, transportation, storage, and compliance with safety and regulatory standards.

Weight and Dimensions

- Nominal Size: 36 inches x 36 inches (91.4 cm x 91.4 cm)

- Thickness: Varies (commonly 2″, 2.25″, or 3″)

- Weight per Unit: 150–250 lbs (68–113 kg), depending on material and thickness

- Pallet Configuration: Typically 4–6 pavers per pallet (600–1,200 lbs per loaded pallet)

Transportation Requirements

- Truck Type: Use flatbed, step-deck, or curtain-side trailers with secure tie-down points. Avoid standard box trucks unless equipped with forklift access.

- Loading/Unloading: Requires forklift (minimum 5,000 lb capacity) or telehandler with appropriate attachments (e.g., boom lift with lifting frame). Never manually lift.

- Securing Loads: Use ratchet straps, load bars, or edge protectors to prevent shifting. Follow FMCSA guidelines for securing heavy cargo.

- Stacking Limit: Do not stack loaded pallets higher than two tiers during transit to avoid collapse or damage.

Storage Guidelines

- Location: Store on a flat, level, well-drained surface. Avoid grass or loose soil.

- Pallet Support: Keep pavers on original pallets; never remove until ready for installation.

- Weather Protection: Cover with breathable tarps to prevent moisture absorption and staining. Avoid plastic sheeting, which can trap moisture and cause efflorescence.

- Stack Height: Limit stacked pallets to two high to prevent crushing lower units and ensure stability.

Handling & Safety

- Personal Protective Equipment (PPE): Operators must wear steel-toed boots, gloves, and back support. Use mechanical lifting aids at all times.

- Forklift Operation: Only certified personnel may operate lifting equipment. Maintain clear paths and designated loading zones.

- Material Handling Equipment (MHE): Use vacuum lifters or specialized paver forks to prevent cracking or chipping.

- OSHA Compliance: Follow OSHA 29 CFR 1926 standards for construction materials handling, including safe lifting practices and workplace safety.

Regulatory & Environmental Compliance

- DOT Regulations: Comply with Department of Transportation rules for weight distribution and cargo securement (49 CFR Parts 390–399).

- Material Safety Data Sheets (MSDS): Maintain MSDS for any sealants, adhesives, or coatings used with pavers.

- Environmental Protection: Prevent dust and runoff during cutting or installation. Follow EPA and local stormwater regulations (e.g., NPDES permits if applicable).

- ADA Considerations: Ensure final installation meets ADA accessibility standards for slope, surface firmness, and detectable warnings where required.

Import/Export Considerations (if applicable)

- HTS Code: Verify Harmonized Tariff Schedule code (e.g., 6802.91 or 6802.92 for stone; 3824.90 for concrete) for international shipments.

- Customs Documentation: Provide commercial invoice, bill of lading, packing list, and certificate of origin.

- Quarantine/Inspection: Stone pavers may require inspection under USDA APHIS guidelines to prevent invasive species in raw materials.

Quality Assurance & Inspection

- Pre-Delivery Inspection: Check for cracks, chips, color variation, and dimensional accuracy before accepting shipment.

- Batch Traceability: Maintain lot numbers and manufacturer certifications (e.g., ASTM C936 for concrete pavers).

- Installation Compliance: Follow ICPI (Interlocking Concrete Pavement Institute) guidelines for base preparation, jointing, and edge restraint.

Emergency & Incident Response

- Spill/Contamination: Immediately contain and clean up sealant or chemical spills per local environmental regulations.

- Injury Protocol: Report any handling-related injuries per OSHA requirements and conduct incident review.

- Damage Reporting: Document and report damaged units upon delivery to supplier within 24–48 hours.

Adhering to this logistics and compliance guide ensures safe, efficient handling of 36×36 pavers while minimizing risk and maintaining regulatory standards throughout the supply chain.

Conclusion for Sourcing 36×36 Pavers:

After evaluating various suppliers, material options (such as concrete, natural stone, and porcelain), pricing, availability, lead times, and quality standards, sourcing 36×36 pavers is both feasible and advantageous for large-scale residential or commercial projects seeking a high-end, seamless aesthetic. These oversized pavers offer reduced grout lines and faster installation compared to traditional pavers, contributing to cost and labor efficiencies over time.

Key considerations include selecting a reputable supplier that ensures consistent color, texture, and dimensional accuracy, as well as confirming compliance with load-bearing and slip-resistance requirements for the intended application (e.g., driveways, patios, or pool decks). While initial costs may be higher than standard pavers, the long-term durability, low maintenance, and superior visual appeal make 36×36 pavers a worthwhile investment.

In conclusion, with proper planning, supplier vetting, and logistical coordination (especially regarding delivery and handling of large-format units), sourcing 36×36 pavers can successfully enhance the functionality and modern elegance of any hardscape project.