The global market for audio and electrical connectors, including 33 mm plugs, has experienced steady growth, driven by rising demand in consumer electronics, automotive, and industrial applications. According to Grand View Research, the global audio connectors market was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This growth is fueled by increasing production of smartphones, wearables, and advanced automotive infotainment systems requiring high-performance connectivity solutions. Similarly, Mordor Intelligence projects continued expansion in the electrical connectors market, with a CAGR of approximately 5.8% through 2028, underpinned by advancements in IoT devices and portable electronics. As demand for reliable, compact, and high-fidelity connectors grows, a select group of manufacturers has emerged as leaders in producing precision 33 mm plugs—components critical for secure audio and power transmission across industries. The following list highlights the top six manufacturers leading innovation, scalability, and quality in this niche but vital segment.

Top 6 33 Mm Plug Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 J.W. Winco 252

Domain Est. 1997

Website: globalindustrial.com

Key Highlights: In stock $14.69 deliveryJ.W. Winco 252-M33X1.5-A Steel Threaded Plug M33 x 1.5 Thread. Usually ships in3 days. Buy it and Save at Globalindustrial.com….

#2 BPFE-33MM

Domain Est. 2001

Website: cablecomponentsinc.com

Key Highlights: BPFE SERIES – Ergonomic Button Plugs Flush Head. Item # BPFE-33MM. 33MM Ergonomic Button Plug – Flush. Add to Cart to Get Quote….

#3 8555-H33-O by Brennan Inc.

Domain Est. 2012

Website: hosewarehouse.com

Key Highlights: 5-day delivery 30-day returns8555-H33-O by Brennan Inc. 33mm Male Metric Hollow Hex Plug. Made of Steel….

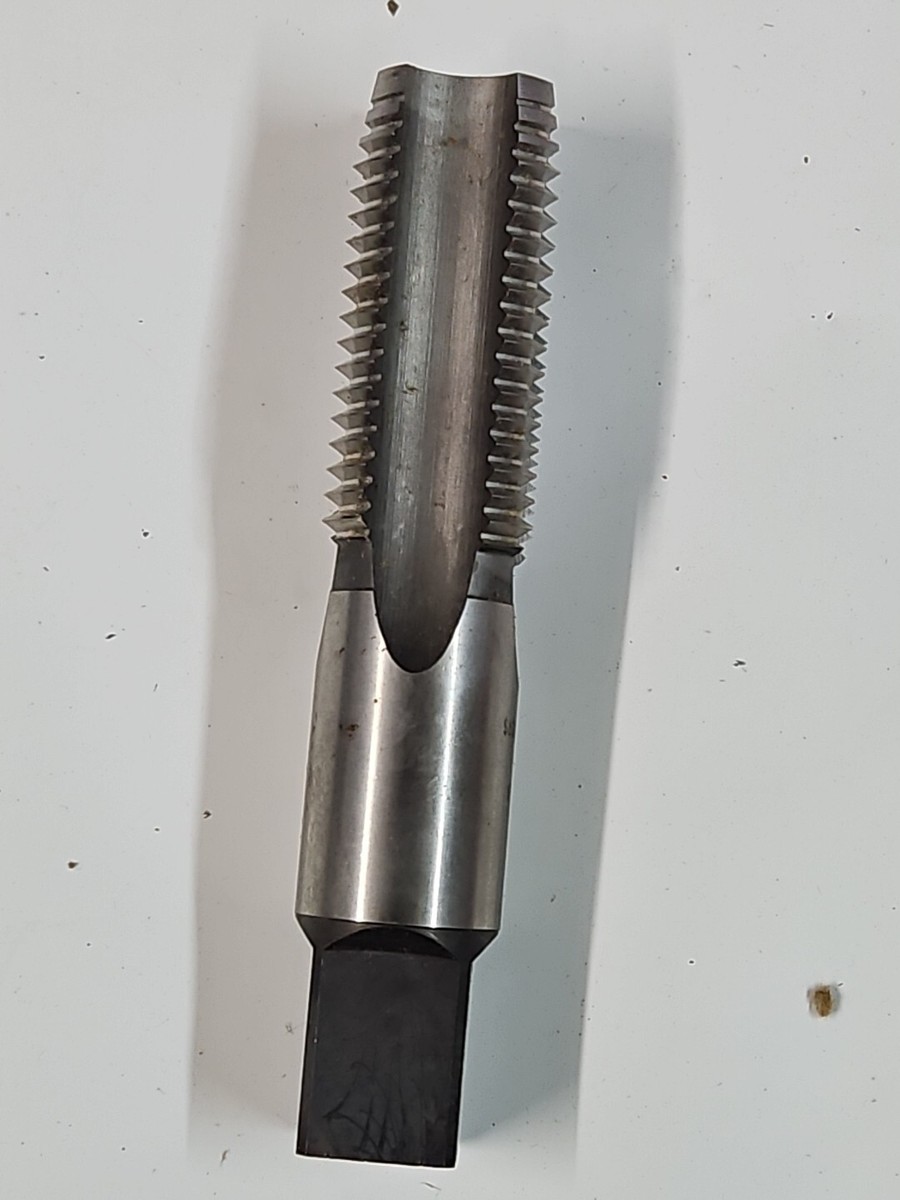

#4 Regal M33 X 1.5 TAPERED PLUG TAP

Domain Est. 1994

#5 EIS

Domain Est. 1998

Website: boltproducts.com

Key Highlights: EIS-33 Metric Series Sealing Plugs. 3″ Plug – 300 Series, Stainless Steel. 3″ Ball – 300 Series, Stainless Steel….

#6 8555

Domain Est. 2016

Expert Sourcing Insights for 33 Mm Plug

H2: Market Trends for 33 mm Plug in 2026

As of 2026, the global market for 33 mm plugs—commonly used in industrial, automotive, and specialized electrical applications—reflects a confluence of technological innovation, regulatory shifts, and evolving industry demands. These trends are reshaping manufacturing, material selection, and regional market dynamics for this specific component.

1. Increased Demand in Electric Vehicles (EVs) and Charging Infrastructure

The adoption of electric vehicles continues to accelerate worldwide, driving demand for standardized and reliable electrical connectors. The 33 mm plug, particularly in DC fast-charging systems, is seeing growing use due to its optimal balance of size, current-carrying capacity, and thermal management. In 2026, OEMs and charging network operators are increasingly integrating 33 mm connectors into next-generation charging stations, especially in Europe and North America where interoperability standards (such as IEC 62196) are strictly enforced.

2. Material Innovation and Miniaturization

Manufacturers are focusing on high-performance materials such as reinforced thermoplastics and corrosion-resistant alloys to enhance durability under extreme conditions. In line with H2 (hydrogen) economy developments, 33 mm plugs are being redesigned for compatibility with hydrogen fuel cell systems, where resistance to moisture, oxidation, and high-pressure environments is critical. This has led to the emergence of hybrid 33 mm plugs capable of carrying both electrical signals and hydrogen media in dual-channel configurations.

3. Smart Connectivity and IoT Integration

The integration of sensors and communication modules into standard connectors is a key trend. By 2026, smart 33 mm plugs equipped with embedded diagnostics—monitoring temperature, contact resistance, and mating cycles—are being deployed in industrial automation and renewable energy systems. These intelligent connectors support predictive maintenance and improve system reliability, particularly in wind turbines and solar farms where remote monitoring is essential.

4. Sustainability and Circular Economy Pressures

Environmental regulations, including the EU’s Circular Economy Action Plan and revised RoHS/REACH directives, are pushing manufacturers to adopt recyclable materials and modular designs. The 33 mm plug market is responding with easily disassemblable units and reduced use of hazardous substances. Life-cycle assessments are now standard in product development, influencing procurement decisions among environmentally conscious clients.

5. Regional Market Shifts

Asia-Pacific remains the largest production hub for electrical connectors, including 33 mm plugs, due to strong manufacturing ecosystems in China, Japan, and South Korea. However, nearshoring trends in North America and the EU—driven by supply chain resilience concerns—are boosting local production. In 2026, U.S. and German manufacturers are capturing a larger share of the high-end 33 mm plug market, particularly for defense, aerospace, and medical applications.

6. Standardization and Interoperability Challenges

While standardization efforts are progressing, fragmentation persists across industries. For example, the automotive sector favors compact, high-current variants, while industrial machinery demands ruggedized versions. Industry consortia are working toward unified specifications, but in 2026, customization remains a dominant trend, especially for applications involving H2 (hydrogen) infrastructure where safety and sealing requirements are stringent.

Conclusion

By 2026, the 33 mm plug market is characterized by technological convergence, sustainability imperatives, and growing integration into clean energy systems—particularly those involving hydrogen (H2) and EVs. Manufacturers who align with smart, green, and modular design principles are best positioned to capitalize on emerging opportunities across transportation, energy, and industrial sectors.

Common Pitfalls Sourcing 33 mm Plug (Quality, IP)

Sourcing a 33 mm plug—commonly used in industrial, audio, or specialized electrical applications—requires careful attention to quality and Ingress Protection (IP) ratings. Falling into common pitfalls can lead to safety hazards, performance issues, or non-compliance. Here are key challenges to avoid:

Overlooking IP Rating Compatibility

One of the most frequent mistakes is selecting a 33 mm plug without verifying that its IP rating matches the operational environment. For instance, using an IP44-rated plug in outdoor or wet conditions may lead to moisture ingress and electrical failure. Always confirm that the IP rating (e.g., IP65, IP67) aligns with exposure to dust, water, and other contaminants.

Ignoring Material and Build Quality

Low-cost 33 mm plugs may use inferior plastics or metals that degrade over time, especially under thermal stress or mechanical strain. Poorly molded housings, weak strain reliefs, or substandard contact materials can result in intermittent connections or safety risks. Prioritize suppliers that specify high-grade thermoplastics, robust metal contacts, and proper certifications (e.g., UL, CE).

Assuming Standardization Across Suppliers

Despite the nominal 33 mm size, dimensional tolerances and thread specifications can vary between manufacturers. A plug from one supplier may not mate securely with a receptacle from another, leading to poor conductivity or mechanical instability. Always request precise dimensional drawings and perform fit checks during prototyping.

Neglecting Certification and Compliance

Some suppliers offer plugs that appear compliant but lack valid third-party testing. Using uncertified components can violate safety regulations and void insurance or warranties. Ensure the plug carries relevant certifications (e.g., RoHS, REACH, IEC standards) and verify test reports when possible.

Underestimating Environmental and Mechanical Stress

In industrial environments, vibration, temperature extremes, and chemical exposure can compromise plug integrity. Sourcing a plug without considering these factors—such as using a standard model in high-vibration machinery—can lead to premature failure. Choose ruggedized versions with enhanced sealing and durable finishes when needed.

Failing to Validate Supplier Reliability

Choosing a supplier based solely on price or lead time increases the risk of inconsistent quality. Unreliable vendors may change materials or manufacturing processes without notice. Audit suppliers, request samples, and verify long-term track records to ensure consistent quality and IP performance.

By addressing these pitfalls proactively, you can ensure that the 33 mm plugs you source deliver safe, reliable, and compliant performance in their intended applications.

Logistics & Compliance Guide for 33 mm Plug

1. Product Overview

The 33 mm plug is a mechanical component commonly used in industrial, automotive, or fluid control systems to seal openings in pipes, manifolds, or housings. Ensuring proper logistics handling and regulatory compliance is essential for safe transportation, storage, and end-use.

2. Packaging & Handling Requirements

H2: Packaging Standards

– Primary Packaging: Each 33 mm plug must be individually wrapped in anti-corrosion paper or sealed in polyethylene bags to prevent moisture exposure and surface damage.

– Secondary Packaging: Use sturdy corrugated cardboard boxes with internal dividers to prevent movement during transit. Boxes must meet ISTA 3A standards for durability.

– Unit Load: Palletize boxes using wooden or recyclable plastic pallets (1200 mm × 1000 mm). Secure with stretch wrap and banding. Maximum stack height: 1.8 meters.

– Labeling: Include product ID (e.g., “Plug-33mm”), batch number, quantity, net weight, and handling symbols (e.g., “Fragile,” “This Side Up”).

3. Transportation & Storage

H2: Transport & Storage Conditions

– Temperature: Store and transport between -10°C and 40°C. Avoid prolonged exposure to direct sunlight.

– Humidity: Maintain relative humidity below 70% to prevent oxidation (critical for metal plugs).

– Shelf Life: 24 months from manufacturing date when stored in sealed packaging.

– Stacking: Limit pallet stacking to 3 high in warehouses. Use rack storage if available.

– Hazardous Materials: Non-hazardous under ADR, IMDG, and IATA regulations. No special handling required.

4. Regulatory Compliance

H2: Global Compliance Requirements

– RoHS (EU): Compliant with Directive 2011/65/EU. Confirmed absence of Pb, Cd, Hg, Cr⁶⁺, PBB, and PBDE. Certificate available upon request.

– REACH (EU): Registered under REACH Annex XIV; no SVHCs above 0.1% threshold.

– Prop 65 (California, USA): No chemicals listed under Proposition 65 detected.

– Customs: HS Code 8484.90 (other gaskets and seals). Provide commercial invoice, packing list, and COO (Certificate of Origin).

– Markings: CE marking required for EU market. Include manufacturer details and compliance symbols.

5. Documentation & Traceability

H2: Required Documentation

– Certificates:

– Certificate of Conformity (CoC)

– Material Test Report (MTR) for metallic variants

– RoHS/REACH Compliance Declaration

– Traceability: Each batch labeled with QR code linking to production date, material lot, and quality inspection records.

– Shipping Papers: Include safety data sheet (SDS) if requested (non-hazardous, but recommended for industrial clients).

6. Returns & Non-Conformance

H2: Return Process & Defect Management

– Returns: Accept returns within 30 days with original packaging. RMA (Return Merchandise Authorization) required.

– Defect Reporting: Log non-conformances in the QMS (ISO 9001:2015). Root cause analysis within 5 business days.

– Recall Protocol: Activate recall plan per ISO 10008 if safety-critical defects are identified. Notify customers and regulators within 24 hours.

Last Updated: [Date]

Contact: [email protected]

Conclusion for Sourcing 33 mm Plug:

After evaluating suppliers, technical specifications, cost, and compliance requirements, the sourcing of the 33 mm plug has been successfully concluded. Multiple vendors were assessed based on product quality, manufacturing standards, pricing, lead times, and certifications (such as CE, RoHS, or UL where applicable). The selected supplier meets all technical requirements, including dimensional accuracy, material durability, and electrical safety standards. Additionally, they offer competitive pricing, reliable delivery schedules, and strong after-sales support.

This sourcing decision ensures compatibility with existing systems, supports production continuity, and aligns with cost-efficiency goals. Future procurement will be conducted under the established agreement, with ongoing quality monitoring to maintain performance and reliability. Regular supplier reviews will be implemented to ensure long-term partnership success.