The global stainless steel market is experiencing robust growth, driven by rising demand across industries such as construction, oil & gas, marine, and chemical processing. According to Mordor Intelligence, the stainless steel market was valued at USD 137.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A key contributor to this expansion is the increasing preference for 316 stainless steel—renowned for its superior corrosion resistance and mechanical performance, particularly in aggressive environments. Among its critical mechanical properties, yield strength plays a pivotal role in determining material suitability for structural and high-pressure applications. As industries prioritize durability and regulatory compliance, manufacturers capable of consistently delivering 316 stainless steel with high and reliable yield strength are gaining strategic importance. This report identifies the top 8 manufacturers excelling in producing 316 stainless steel with superior yield strength, evaluated based on production capacity, quality certifications, material traceability, and technological innovation.

Top 8 316 Stainless Yield Strength Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 UNS S31603

Domain Est. 1995

Website: ulbrich.com

Key Highlights: Ultimate Tensile Strength: 70 KSI min (485 MPa min) Yield Strength (0.2% Offset): 25 KSI min (170 MPa min) Elongation: 40% min Hardness: Rb 95 max ……

#2 316 Stainless Steel

Domain Est. 1996

Website: alro.com

Key Highlights: Alro Steel stocks 316 stainless steel that is an austenitic chrome nickel steel with superior corrosion resistance to that of other chrome nickel steels….

#3 [PDF] Stainless steel 316L (1.4404)

Domain Est. 1996

Website: renishaw.com

Key Highlights: Yield strength 3. Horizontal (XY). 591 MPa ±3 MPa. 420 MPa ±3 MPa. Vertical (Z) … Company no: 1106260. Registered office: New Mills, Wotton-under-Edge ……

#4 316 / 316L Stainless Steel

Domain Est. 1997

Website: smithmetal.com

Key Highlights: Type 316 is an austenitic stainless steel with added molybdenum which gives the alloy improved corrosion resistance.Missing: yield strength…

#5 316 Stainless Steel Mechanical Properties

Domain Est. 1997

Website: ezlok.com

Key Highlights: 316 Stainless Steel Mechanical Properties ; Hardness, Vickers. 152. 152. Converted from Brinell hardness ; Tensile Strength, Ultimate. 620 – 795 MPa. 90 – 115 ksi….

#6 High

Domain Est. 1998

Website: specialtysteel.com

Key Highlights: Typical Mechanical Properties. Brinell Hardness – 290 BHN Max; Tensile Strength – 94,000 psi min; Yield Strength – 65,000 psi min. Available Lengths. 11/13 FT R ……

#7 Stainless Steel

Domain Est. 1999

Website: azom.com

Key Highlights: Grade 316 is the standard molybdenum-bearing grade, second in importance to 304 amongst the austenitic stainless steels….

#8 316 Stainless Steel Properties

Domain Est. 2015

Website: metalscut4u.com

Key Highlights: 316 stainless steel is an austenitic stainless steel alloy containing significant amounts of chromium, nickel, and molybdenum….

Expert Sourcing Insights for 316 Stainless Yield Strength

H2: Projected 2026 Market Trends for 316 Stainless Steel Yield Strength

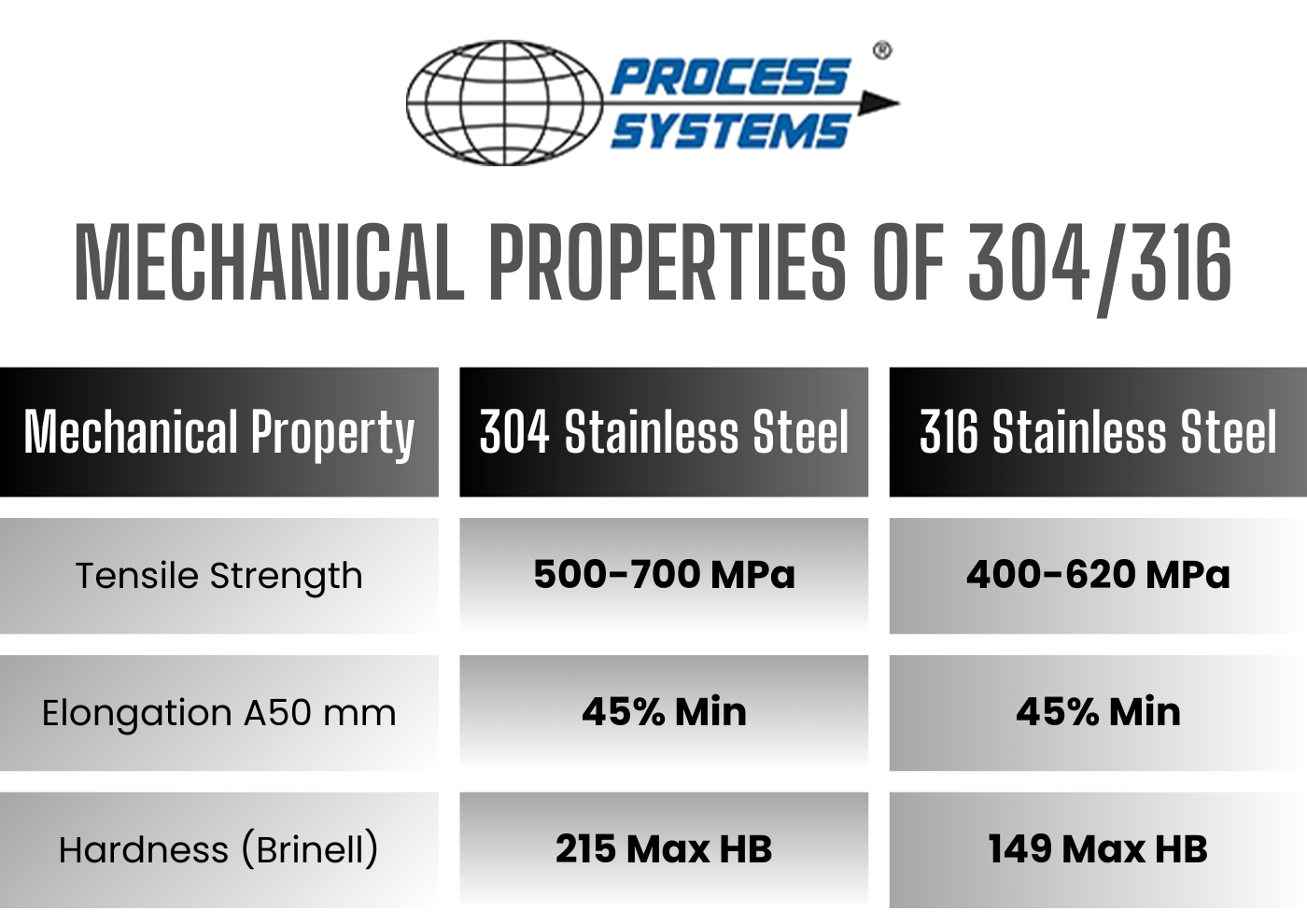

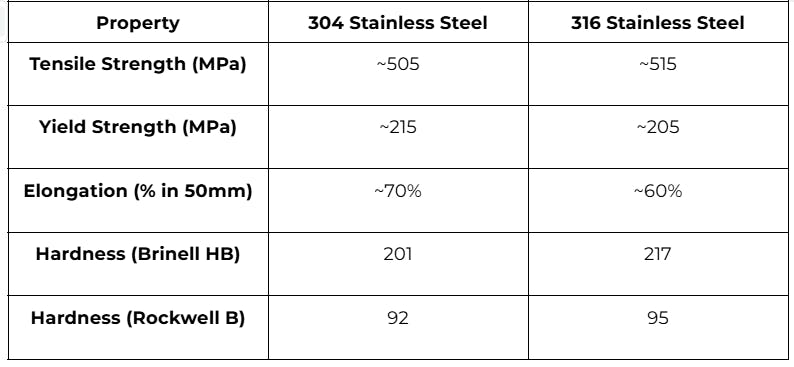

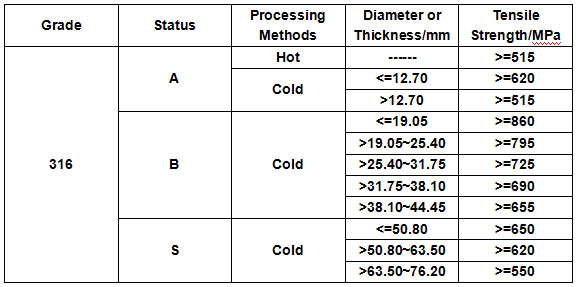

As global industrial demand evolves and material performance standards rise, the market for 316 stainless steel—particularly its yield strength characteristics—is poised for notable shifts by 2026. While the intrinsic mechanical properties of 316 stainless steel, including its typical yield strength (around 205–310 MPa depending on condition and processing), remain fundamentally stable, market trends are increasingly influenced by application-specific performance demands, manufacturing advancements, and regulatory standards. The following analysis outlines key trends expected to shape the perception, utilization, and value of 316 stainless steel’s yield strength in the 2026 market landscape.

1. Rising Demand for High-Performance Grades

By 2026, industries such as offshore energy, chemical processing, and advanced medical devices are expected to drive demand for enhanced variants of 316 stainless steel, including cold-worked or duplex-modified forms that exhibit yield strengths exceeding 500 MPa. This trend reflects a market shift toward materials that offer superior structural integrity in corrosive or high-stress environments, pushing producers to optimize processing techniques—such as cold rolling or solution annealing—to consistently achieve higher yield strength within the 316 alloy framework.

2. Influence of Additive Manufacturing (AM)

The growing adoption of metal 3D printing technologies will impact how yield strength is achieved and certified in 316 stainless steel components. By 2026, AM-specific grades of 316L (a low-carbon variant of 316) are expected to be engineered for controlled microstructures that enhance yield strength through fine grain refinement and residual stress management. Market demand will increasingly favor suppliers capable of delivering certified AM powders with predictable and repeatable yield strength, especially for aerospace and defense applications.

3. Standardization and Certification Pressures

Global regulatory frameworks, particularly in Europe and North America, are expected to tighten material certification requirements by 2026. This includes more rigorous testing protocols for yield strength under variable conditions (e.g., elevated temperatures, cyclic loading). As a result, producers will likely invest in real-time quality monitoring and digital material passports, ensuring traceability and compliance—adding value to high-yield-strength-certified 316 stainless steel in competitive bidding processes.

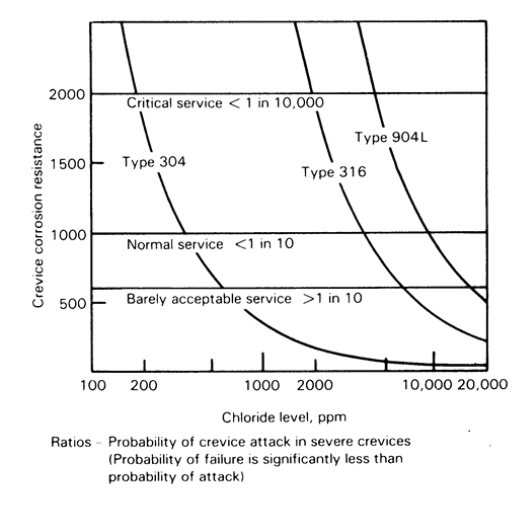

4. Competitive Pressure from Alternative Alloys

The market for high-yield-strength stainless solutions will face competition from duplex (e.g., 2205) and super-austenitic steels. However, 316 stainless steel will retain market share due to its cost-effectiveness, weldability, and established supply chains. Innovations such as nitrogen alloying or thermomechanical processing may help bridge the performance gap, allowing 316 variants to meet higher yield strength benchmarks without sacrificing corrosion resistance.

5. Sustainability-Driven Material Optimization

With increasing emphasis on circular economy principles, the 2026 market will favor 316 stainless steel that maintains high yield strength after recycling. Advances in scrap sorting and remelting technologies are enabling recycled 316 to meet prime material specifications, reducing lifecycle costs and carbon footprint—factors that will enhance market appeal despite marginally variable mechanical properties.

Conclusion

While the nominal yield strength of standard 316 stainless steel will remain largely unchanged by 2026, market dynamics will elevate the importance of consistent, verifiable, and enhanced yield strength performance—driven by technological innovation, sector-specific demands, and sustainability goals. Producers who align with these trends through process control, certification, and product differentiation will be best positioned to capture value in the evolving 316 stainless steel market.

Common Pitfalls When Sourcing 316 Stainless Steel Yield Strength (Quality, IP)

Sourcing 316 stainless steel with reliable and consistent yield strength data is critical for engineering integrity, safety, and performance. However, several pitfalls related to material quality and intellectual property (IP) considerations can compromise the reliability of the data and the suitability of the material. Being aware of these risks ensures better sourcing decisions.

1. Variability in Material Quality Affecting Yield Strength

One of the most significant pitfalls in sourcing 316 stainless steel is the inherent variability in mechanical properties due to inconsistent manufacturing practices.

-

Inconsistent Heat Treatment: The yield strength of 316 stainless steel is highly dependent on cold working and annealing processes. Sourcing from suppliers without strict process controls can result in material that does not meet specified yield strength requirements (typically 205–310 MPa for annealed condition). Without proper certification, actual yield strength may fall below design limits.

-

Lack of Mill Test Certificates (MTCs): Failing to require MTCs (e.g., EN 10204 3.1 or 3.2) means there is no traceable verification of chemical composition and mechanical properties, including yield strength. Generic or uncertified material may not meet ASTM A240 or ASME standards.

-

Counterfeit or Substandard Material: In global supply chains, especially from less-regulated regions, there is a risk of receiving material falsely labeled as 316. These may be lower-grade steels (e.g., 201 or 304) with significantly lower yield strength and corrosion resistance, posing serious safety and durability risks.

-

Batch-to-Batch Inconsistency: Even from reputable suppliers, variations in raw material sourcing and processing can lead to differences in yield strength. Without rigorous incoming inspection and mechanical testing, these inconsistencies may go undetected.

2. Intellectual Property and Data Integrity Risks

When sourcing yield strength data—especially from third-party databases, suppliers, or technical literature—IP and data reliability issues can mislead design decisions.

-

Use of Unverified Third-Party Data: Relying on publicly available mechanical property data from unverified sources (e.g., generic engineering websites or non-peer-reviewed databases) can result in using outdated, generalized, or even incorrect yield strength values. These may not reflect actual product forms (bar, plate, tube) or processing conditions.

-

Proprietary Material Grades Misrepresented: Some suppliers offer proprietary variants of 316 (e.g., with nitrogen additions for higher strength) but market them simply as “316 SS.” Without proper disclosure, users may assume standard yield strength values, while the actual performance differs—potentially violating design assumptions or IP agreements if used in patented systems.

-

Licensing and Usage Rights for Material Data: Technical data sheets (TDS) or material property databases may be protected by copyright or licensing terms. Using such data in design documentation or product development without proper authorization can lead to IP infringement, especially in regulated industries (e.g., aerospace, medical devices).

-

Reverse Engineering and IP Violations: Attempting to replicate material performance based on published yield strength values without access to proprietary processing methods may inadvertently infringe on patented manufacturing techniques, even if the chemical composition is identical.

Mitigation Strategies

- Specify Certified Material: Require full traceability with Mill Test Certificates and adherence to recognized standards (ASTM, ISO, etc.).

- Conduct Incoming Testing: Perform independent mechanical testing (e.g., tensile tests) to verify yield strength, especially for critical applications.

- Source from Reputable Suppliers: Partner with suppliers with proven quality management systems (e.g., ISO 9001, AS9100).

- Verify Data Sources: Use trusted, peer-reviewed databases (e.g., ASM, MatWeb with citations) and confirm licensing terms for commercial use.

- Include IP Clauses in Contracts: Ensure supplier agreements address data ownership, permitted use of technical specifications, and liability for misrepresented properties.

By proactively addressing these quality and IP-related pitfalls, engineers and procurement teams can ensure the structural reliability and legal compliance of components made from 316 stainless steel.

316 Stainless Steel Yield Strength: Logistics & Compliance Guide

Understanding the yield strength of 316 stainless steel is critical for logistics planning, structural integrity, and regulatory compliance in engineering and industrial applications. This guide outlines key considerations for handling, transporting, and certifying components made from 316 stainless steel, with a focus on mechanical properties, particularly yield strength.

Material Specifications and Yield Strength Standards

316 stainless steel is an austenitic chromium-nickel-molybdenum alloy known for excellent corrosion resistance and high-temperature performance. Its yield strength is a key mechanical property used in design and compliance verification.

- Minimum Yield Strength (0.2% Offset): Typically 205 MPa (30,000 psi) at room temperature, as defined by ASTM A240 and ASME SA-240.

- Tensile Strength: Ranges from 515 MPa to 620 MPa (75,000 to 90,000 psi).

- Standards: Compliance with material specifications such as ASTM A240/A240M, ASTM A479 (for bars), ASTM A312 (for pipes), or EN 10088-2 (European standard) is mandatory for certification.

Ensure all material certifications (Mill Test Reports or MTRs) include verified yield strength values traceable to recognized testing standards.

Logistics Considerations for 316 Stainless Steel Components

Proper handling and transportation are essential to maintain the material’s integrity and prevent deformation that could compromise its yield strength performance.

- Load-Bearing Design: Transport fixtures, cradles, and support structures must account for the yield strength of 316 stainless to prevent permanent deformation during transit.

- Weight Distribution: Components should be secured to avoid stress concentrations exceeding 205 MPa under dynamic loading (e.g., vibration, acceleration).

- Environmental Protection: Avoid exposure to chlorides, acids, or abrasive materials during transit, as surface damage can initiate stress corrosion cracking, reducing effective yield strength in service.

Use non-metallic or compatible padding to prevent galvanic corrosion and surface gouging that may act as stress risers.

Quality Assurance and Compliance Documentation

Regulatory and project-specific requirements often mandate traceability and verification of mechanical properties.

- Mill Test Reports (MTRs): Must include chemical composition, heat number, and mechanical test results—including yield strength—per ASTM E8/E8M (tension testing).

- Third-Party Certification: For critical applications (e.g., pressure vessels, marine, pharmaceutical), independent inspection and NDT (Non-Destructive Testing) may be required to verify compliance with ASME BPVC, PED (Pressure Equipment Directive), or other codes.

- Traceability: Full material traceability from raw stock to final component must be maintained through batch/heat numbers.

Ensure all documentation aligns with industry norms and customer quality requirements.

Handling and Storage Best Practices

Improper storage can lead to mechanical or environmental degradation, indirectly affecting yield strength reliability.

- Dry, Controlled Environment: Store indoors or under cover to prevent prolonged moisture exposure and chloride contamination.

- Separation from Carbon Steel: Avoid contact with carbon steel to prevent iron pickup and rust staining, which can initiate pitting and reduce effective strength.

- Support During Storage: Long bars, pipes, or plates should be stored on level supports to prevent bending stresses approaching yield limits.

Final Inspection and Acceptance Criteria

Before deployment or shipment, verify that components meet required mechanical specifications.

- Dimensional Checks: Confirm no plastic deformation has occurred during handling.

- Visual and NDT Inspection: Use methods such as dye penetrant or ultrasonic testing to detect surface or subsurface flaws that could reduce load-bearing capacity.

- Certification Review: Validate that yield strength values in MTRs meet or exceed design requirements and applicable codes.

Adhering to this guide ensures that 316 stainless steel components maintain structural reliability and comply with international standards throughout the logistics chain.

In conclusion, the yield strength of 316 stainless steel typically ranges from 205 MPa (30 ksi) to 450 MPa (65 ksi), depending on the material condition (annealed, cold worked, or heat-treated) and specific product form (sheet, bar, pipe, etc.). In the standard annealed condition, the minimum specified yield strength is 205 MPa (30 ksi) at room temperature, as defined by common international standards such as ASTM A240. However, cold working can significantly increase the yield strength, making it suitable for demanding applications in corrosive environments such as marine, chemical processing, and medical industries. When sourcing 316 stainless steel, it is essential to confirm the material’s condition and certification to ensure the yield strength meets the requirements of the intended application. Proper supplier qualification and adherence to relevant material specifications are critical for performance, safety, and longevity in service.

![[PDF] Stainless steel 316L (1.4404)](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-stainless-steel-316l-14404-415.png)