The global stainless steel fasteners market, driven by rising demand in construction, automotive, and industrial manufacturing, is projected to grow at a CAGR of 5.2% from 2023 to 2028, according to Mordor Intelligence. With increasing emphasis on corrosion resistance and durability in critical applications, 316 stainless steel bolts—known for their superior performance in harsh environments—have become a preferred choice across marine, chemical processing, and offshore industries. As demand surges, particularly in Asia-Pacific and North America, the competitive landscape is reshaping, with manufacturers investing in advanced production technologies and stringent quality certifications. Based on market presence, production capacity, material quality, and global distribution, we analyze the top 10 manufacturers leading innovation and supply in the 316 stainless steel bolts segment.

Top 10 316 Stainless Bolts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 U

Domain Est. 1999

Website: uboltit.com

Key Highlights: At U-Bolt-It, we custom manufacture bolts and fasteners made to meet all your requirements and in all materials from stainless steel and exotic materials….

#2 316 Stainless Steel Hex Bolts – 316 SS Hex Bolts

Domain Est. 2003

Website: kdfasteners.com

Key Highlights: We carry 316 series stainless steel hex bolts in both a hex cap screw and a hex tap bolt (full thread). We start at ¼-20 thread and can do special large ……

#3 316 Stainless Steel Fasteners

Domain Est. 2017

Website: jfeindia.com

Key Highlights: JF Engineering Products LLP is One of the best Manufacturer and Exporter of 316 Stainless Steel Fasteners, We have various range, dimensions and Size of ……

#4 Stainless Steel T316

Domain Est. 1999

Website: tacomascrew.com

Key Highlights: 5–6 day deliveryFasteners · Bolts · Cap Screws & Hex Bolts · Stainless Steel T316. 120 items. Sort by: Best Match, Product Number A – Z, Product Number Z – A. Per page: 24. of ……

#5 304 & 316 Stainless Steel Bolts

Domain Est. 2001

Website: dalecompany.com

Key Highlights: The Dale Company is a stainless steel nut distributor that supplies 304 & 316 stainless steel bolts such as anchor bolts, U-bolts, round U-bolts, square U- ……

#6 T Head Bolts & Nuts

Domain Est. 2001

Website: trumbull-mfg.com

Key Highlights: STAINLESS STEEL T-HEAD BOLTS. Type 304 or Type 316. The 3/4″ x 4″ bolt is threaded 1/2″ longer than the standard to permit use as a 3/4″ x 3-1/2″ bolt….

#7 Type 316 Stainless Steel Fasteners

Domain Est. 2002

Website: fastenersolutions.com

Key Highlights: Shop high-performance 316 stainless steel fasteners built for strength and corrosion resistance. Find 316 stainless steel bolts and nuts, screws, and more….

#8 Marsh Fasteners

Domain Est. 2003

Website: marshfasteners.com

Key Highlights: As top fastener suppliers, our extensive inventory of quality fasteners includes stainless steel fasteners in 18-8, 304 & 316 Stainless Steel….

#9 Stainless Bolts Screws and Studs

Domain Est. 2014

Website: wdscomponents.com

Key Highlights: 30-day returns316 grade stainless steel bolts, screws, and studs are high-quality fasteners made from an alloy of steel with a significant addition of chromium, nickel, and ……

#10 Nuts and Bolts

Domain Est. 2019

Website: usstainless.com

Key Highlights: 30-day returnsShop By Price ; Stainless Steel 316 M6 Eye Bolt Welded 6mm x 100mm (1/4″ x · $2.77 ; Stainless Steel 316 UBolt M8 (5/16″) by 80mm Marine Grade · $3.22. $4.22….

Expert Sourcing Insights for 316 Stainless Bolts

H2: Projected 2026 Market Trends for 316 Stainless Steel Bolts

The global market for 316 stainless steel bolts is expected to experience steady growth by 2026, driven by increasing demand across key industrial sectors and sustained material advantages in corrosive environments. As industries prioritize durability, sustainability, and compliance with international standards, 316 stainless steel bolts—known for their superior corrosion resistance, high tensile strength, and performance in chloride-rich environments—are becoming the fastener of choice in critical applications.

One major trend shaping the 2026 outlook is the expansion of infrastructure and construction projects in emerging economies, particularly in Asia-Pacific and the Middle East. Governments are investing heavily in water treatment plants, desalination facilities, coastal infrastructure, and chemical processing plants—all environments where 316 stainless steel bolts are essential due to their resistance to saltwater and chemical exposure.

Additionally, the renewable energy sector, especially offshore wind farms and solar installations in coastal regions, is expected to significantly drive demand. These applications require fasteners that can withstand harsh marine conditions, positioning 316 stainless steel bolts as a preferred solution. By 2026, increased project pipelines in offshore wind development, especially in Europe and East Asia, will further bolster market growth.

Another emerging trend is the growing emphasis on sustainable and long-life materials in engineering and construction. With lifecycle cost analysis becoming standard practice, specifiers are increasingly selecting 316 stainless steel over carbon steel or lower-grade stainless alternatives to reduce maintenance and replacement costs. This shift is supported by stricter environmental regulations and green building certifications, which favor corrosion-resistant, low-maintenance materials.

On the supply side, market dynamics are being influenced by fluctuations in raw material prices, particularly nickel and molybdenum—key alloying elements in 316 stainless steel. While price volatility may pressure margins, manufacturers are responding through process optimization, recycling initiatives, and strategic sourcing to maintain competitive pricing.

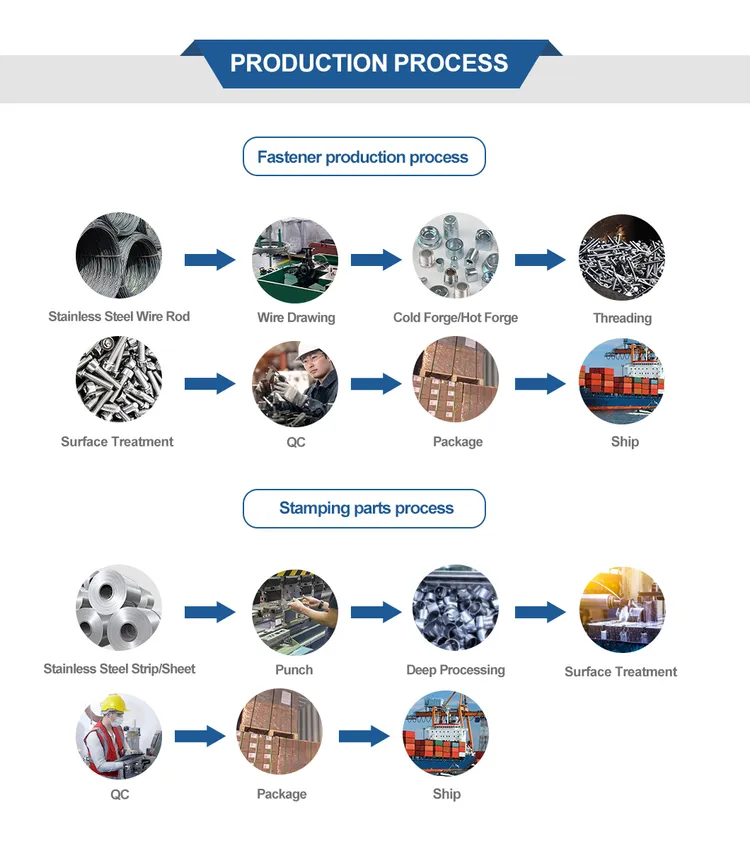

Technological advances in manufacturing, such as precision cold forging and automated quality control, are also improving product consistency and reducing lead times. These efficiencies are enabling suppliers to meet rising global demand while adhering to stringent industry standards like ASTM A193, A320, and ISO 3506.

In conclusion, the 2026 market for 316 stainless steel bolts is poised for robust growth, underpinned by rising demand in infrastructure, energy, and marine applications, along with a broader industry shift toward durable, sustainable materials. Companies that invest in innovation, quality assurance, and supply chain resilience are likely to capture significant market share in this evolving landscape.

H2: Common Pitfalls When Sourcing 316 Stainless Steel Bolts (Quality & Intellectual Property)

Sourcing 316 stainless steel bolts can present several challenges, particularly concerning material quality and potential intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

1. Substandard Material Composition

A major issue is receiving bolts that do not meet genuine 316 stainless steel specifications. Some suppliers may substitute lower-grade materials like 304 or even non-stainless steel, mislabeling them as 316. This compromises corrosion resistance—especially in marine or chemical environments—and reduces structural integrity. Without proper certification (e.g., mill test reports to EN 10204 3.1), buyers risk project failure or safety hazards.

2. Lack of Traceability and Certification

Many low-cost suppliers fail to provide full material traceability or valid certifications. This absence makes it difficult to verify compliance with international standards (e.g., ASTM A193, ISO 3506). Without documented proof, organizations expose themselves to compliance risks, particularly in regulated industries like oil & gas, marine, or pharmaceuticals.

3. Poor Manufacturing Quality

Even with correct material, poor thread rolling, inconsistent heat treatment, or inadequate surface finish can impair bolt performance. Inconsistent tensile strength or thread accuracy leads to galling, seizing, or fastener failure under load. Off-spec manufacturing is common with unqualified suppliers, especially in regions with weak quality oversight.

4. Counterfeit or Non-Compliant Markings

Some counterfeit bolts are stamped with fake grade markings (e.g., “A4-80” for 316) to mimic authentic products. These markings do not reflect actual performance. Buyers may unknowingly install non-compliant hardware, leading to liability in case of failure.

5. Intellectual Property (IP) Infringement Risks

When sourcing specialized bolt designs (e.g., patented drive systems, security heads, or proprietary coatings), there’s a risk of IP infringement. Some manufacturers illegally replicate patented fastener designs without licensing. Purchasing such items—even unknowingly—can expose the buyer to legal action, especially in jurisdictions with strong IP enforcement.

6. Grey Market and Unauthorized Distributors

Dealing with unauthorized resellers increases the risk of receiving rebranded, recycled, or counterfeit products. These suppliers may not adhere to IP agreements or quality standards set by original manufacturers, undermining product reliability and warranty coverage.

Mitigation Strategies

– Source from reputable, certified suppliers with verifiable quality management systems (e.g., ISO 9001).

– Require full material test reports and product traceability.

– Conduct third-party inspections or lab testing (e.g., PMI – Positive Material Identification).

– Verify supplier authorization when purchasing branded or patented fastener designs.

– Include IP indemnity clauses in procurement contracts.

Avoiding these pitfalls ensures that 316 stainless steel bolts perform as expected and that sourcing practices remain legally and technically sound.

H2: Logistics & Compliance Guide for 316 Stainless Steel Bolts

1. Material Specifications and Identification

Ensure that all 316 stainless steel bolts comply with recognized international standards such as ASTM A193, ASTM A320, or ISO 3506. These standards define mechanical properties, chemical composition, and performance requirements. Verify material certification (Mill Test Certificate – MTC) is provided by the supplier, confirming the bolts are made from genuine 316 (also known as A4) stainless steel, which contains molybdenum for enhanced corrosion resistance.

2. Packaging and Labeling Requirements

– Use moisture-resistant and anti-corrosive packaging (e.g., VCI paper or sealed plastic wrapping) to prevent oxidation during transit.

– Clearly label packages with:

– Product description (e.g., “A4-70 Stainless Steel Hex Bolt, M10 x 50mm”)

– Material grade (316 / A4)

– Quantity and net weight

– Batch/lot number for traceability

– Supplier name and contact information

– Include hazard labels if applicable (though 316 stainless is non-hazardous, sharp edges may require handling warnings).

3. Storage Conditions

– Store bolts in a dry, climate-controlled environment to prevent salt-induced corrosion, especially in coastal or high-humidity areas.

– Avoid direct contact with carbon steel or other metals to prevent galvanic corrosion—use plastic or wooden pallets.

– Segregate by size, grade, and finish to avoid mix-ups and support inventory accuracy.

4. Transportation and Handling

– Use clean, dry transport vehicles; protect from rain, seawater, and extreme temperatures.

– Secure loads to prevent shifting during transit, minimizing mechanical damage.

– Handle with non-contaminating tools (e.g., stainless or plastic-coated equipment) to avoid iron contamination, which can compromise corrosion resistance.

5. Import/Export Compliance

– Verify customs classification (HS Code). For 316 stainless steel bolts, typical HS codes fall under 7318.15 or 7318.16 depending on size and type.

– Obtain necessary export documentation: commercial invoice, packing list, bill of lading/airway bill, and certificate of origin.

– Check for trade restrictions or anti-dumping duties in the destination country (e.g., EU, USA, or India may impose tariffs on fasteners from certain regions).

– Comply with REACH (EU), RoHS, and other environmental regulations if applicable.

6. Quality Assurance and Traceability

– Implement a traceability system linking each batch to its MTC and production records.

– Conduct periodic inspections for surface finish, dimensions, and mechanical strength (e.g., tensile and hardness testing) per ISO or ASTM protocols.

– Maintain documentation for audits and customer requests.

7. Industry-Specific Compliance

– Marine & Offshore: Confirm compliance with marine standards such as DNV-GL or ABS, where 316 stainless is often required for saltwater exposure.

– Food & Pharmaceutical: If used in sanitary applications, ensure bolts have a passivated surface and meet 3-A, FDA, or EHEDG requirements.

– Oil & Gas: Verify suitability for sour service environments (NACE MR0175/ISO 15156 if applicable), though 316 has limitations in high H₂S conditions.

8. Sustainability and Recycling

– 316 stainless steel is 100% recyclable; ensure end-of-life disposal follows local recycling protocols.

– Choose suppliers with environmental management systems (ISO 14001 certified) to support sustainable procurement goals.

Adhering to this guide ensures reliable performance, regulatory compliance, and smooth logistics for 316 stainless steel bolts across global supply chains.

Conclusion for Sourcing 316 Stainless Steel Bolts:

After evaluating material specifications, performance requirements, supplier reliability, and cost considerations, sourcing 316 stainless steel bolts is the optimal solution for applications requiring high corrosion resistance, particularly in harsh environments such as marine, chemical processing, or outdoor settings. The superior durability, tensile strength, and resistance to chlorides and high temperatures make 316 stainless steel a reliable choice compared to lower-grade alternatives like 304.

Key suppliers have been assessed for quality certifications (e.g., ISO, ASTM standards), lead times, and pricing competitiveness. Bulk sourcing from pre-qualified suppliers ensures consistent quality and cost-efficiency. Additionally, verifying thread type, diameter, length, and finish (e.g., passivated or polished) is critical to meet project specifications.

In conclusion, procuring 316 stainless steel bolts from reputable suppliers not only ensures long-term performance and reduced maintenance costs but also supports compliance with industry standards and safety requirements. A final approval of samples and material test certificates is recommended before full-scale procurement to confirm conformance.