The global stainless steel market is experiencing steady expansion, driven by rising demand across construction, automotive, and industrial manufacturing sectors. According to Grand View Research, the global stainless steel market size was valued at USD 137.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. A significant portion of this demand stems from 304 stainless steel—the most widely used austenitic grade—known for its excellent corrosion resistance, durability, and versatility in both indoor and outdoor applications. With industries increasingly prioritizing material longevity and cost-efficiency, the demand for high-quality 304 stainless steel plates continues to rise, particularly in Asia-Pacific, North America, and Europe. As supply chains globalize and standards for material performance tighten, identifying reliable manufacturers becomes critical. Below are the top 10 304 stainless steel plate manufacturers leading the market through production scale, quality certifications, innovation, and geographic reach.

Top 10 304 Stainless Steel Plate Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 North American Stainless

Domain Est. 1999 | Founded: 1990

Website: northamericanstainless.com

Key Highlights: Founded in 1990, North American Stainless (NAS) has undertaken several phases of expansion to become the largest, fully integrated stainless steel producer in ……

#2 304 Stainless Steel Sheet & Plate

Domain Est. 1999

#3 Stainless Steel Plate and Sheet Supplier

Domain Est. 1996

Website: onealsteel.com

Key Highlights: Shop 304 & 316 stainless steel sheets and plates in different gauges, including 14 GA, 16 GA, 18 GA, and more. Order 3/16″, 1/4″, and 1/2″ plates….

#4 Custom Size 304 Stainless Steel Sheet Metal Supplier and …

Domain Est. 1997

Website: stanch.com

Key Highlights: Stanch is an industry-leading supplier of cold rolled stainless steel sheets, we offer wide range of high quality stainless steel sheets in various finishes….

#5 Stainless Steel Plate – SS Sheet Supplier

Domain Est. 1997

Website: twmetals.com

Key Highlights: TW Metals supplies stainless steel plates & sheets in 304/304L, 304 straight grade, 316/316L and 321 are available at TW Metals. Contact us today!…

#6 Stainless Steel Plate and Sheet

Domain Est. 1999

Website: stainlessandalloy.com

Key Highlights: We provide high-quality stainless steel plate & stainless steel sheet for many applications including custom fabrication and construction projects….

#7 304/304L & 316/316L Stainless Steel Sheet & Plate

Domain Est. 2000

Website: americanstainlesscorp.com

Key Highlights: At American Stainless Corporation, we’re here to help you with your stainless steel sheets and plates for your next project. Call us today to learn more….

#8 Stainless steel supplier in the world

Domain Est. 2001

Website: international.myjacquet.com

Key Highlights: Discover our stainless steel grades. We offer a large stock of plates: austenitic, duplex, refractory, ferritic, superaustenitic, martensitic….

#9 304 Stainless Steel Plate

Domain Est. 2005

Website: midweststeelsupply.com

Key Highlights: In stockMidwest Steel & Aluminum stocks and processes high-quality 304 / 304L stainless steel plate, a standard 18-8 stainless alloy containing 18% chromium and 8% ……

#10 304/304L Stainless Steel Plate

Domain Est. 2011

Website: kloecknermetals.com

Key Highlights: 304/304L stainless steel plate is one of the most popular stainless grades, supplied nationwide across our network of 55+ branches….

Expert Sourcing Insights for 304 Stainless Steel Plate

H2: Projected 2026 Market Trends for 304 Stainless Steel Plate

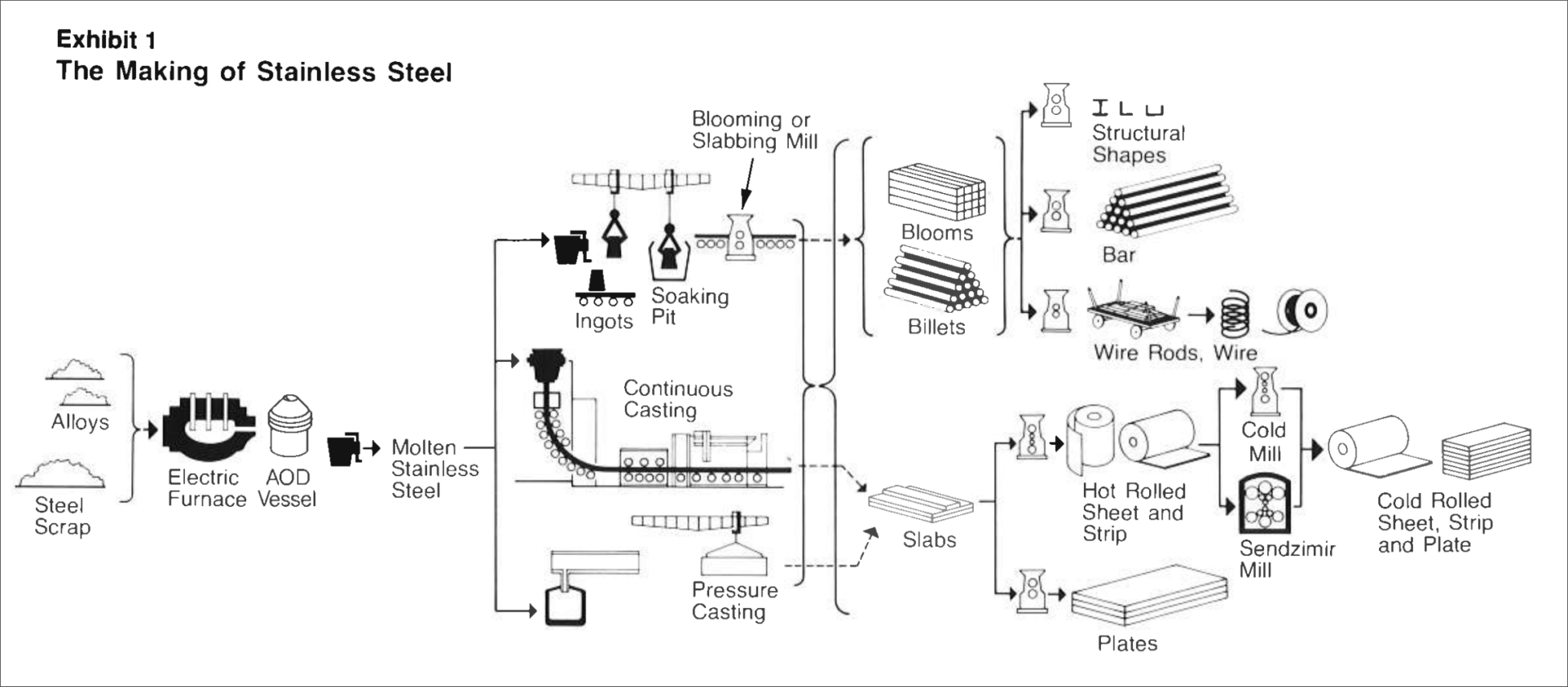

The global market for 304 stainless steel plate is expected to undergo significant transformation by 2026, driven by evolving industrial demand, supply chain dynamics, sustainability initiatives, and technological advancements. As one of the most widely used austenitic stainless steel grades, 304 stainless steel plate—known for its excellent corrosion resistance, formability, and durability—will continue to play a pivotal role across sectors such as construction, automotive, energy, and consumer goods.

1. Rising Demand from Infrastructure and Construction

Urbanization and government-led infrastructure development, particularly in Asia-Pacific (China, India, and Southeast Asia), will remain primary drivers of 304 stainless steel plate demand. The material’s resistance to environmental degradation and low lifecycle maintenance costs make it a preferred choice for architectural applications, water treatment systems, and public infrastructure. By 2026, increased investment in green buildings and smart cities is expected to further boost consumption.

2. Growth in Renewable Energy and Industrial Applications

The global push toward clean energy will elevate demand for 304 stainless steel plates in solar panel frames, wind turbine components, and energy storage systems. Its compatibility with harsh operating environments and resistance to oxidation support its use in energy infrastructure. Additionally, chemical processing, food and beverage, and pharmaceutical industries will sustain steady demand due to stringent hygiene and corrosion resistance requirements.

3. Supply Chain Resilience and Regional Production Shifts

Geopolitical tensions and trade policies will continue to influence raw material sourcing and production strategies. By 2026, manufacturers are expected to diversify supply chains, with increased regional production in India, Southeast Asia, and Eastern Europe to mitigate risks. Nickel and chromium price volatility—key constituents of 304 stainless steel—will remain a concern, prompting investment in recycling and alternative alloy development.

4. Sustainability and Recycling Trends

Environmental regulations and ESG (Environmental, Social, and Governance) criteria will drive higher adoption of recycled stainless steel. The high recyclability rate of 304 stainless steel (over 90%) supports circular economy models. By 2026, leading producers are expected to integrate more recycled content into production, reducing carbon footprint and aligning with global climate goals.

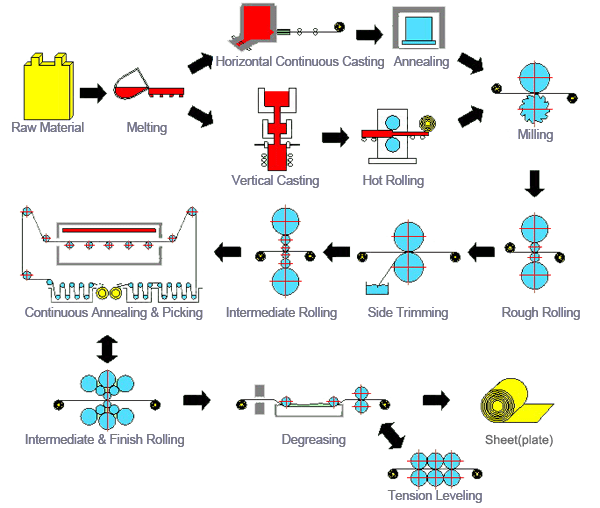

5. Technological Advancements and Product Differentiation

Innovations in steel processing—such as precision cutting, surface finishing, and smart manufacturing (Industry 4.0 integration)—will enhance product quality and reduce waste. Customized 304 plates with improved surface treatments or hybrid composites may emerge to meet niche market demands in high-tech applications.

6. Competitive Landscape and Price Outlook

The market will see continued consolidation among major producers, with Chinese manufacturers maintaining dominant output, while EU and North American producers focus on high-value, specialty-grade offerings. Prices of 304 stainless steel plate in 2026 will likely remain sensitive to nickel market fluctuations, energy costs, and global trade flows, with moderate upward pressure expected due to inflationary trends and decarbonization investments.

In conclusion, the 2026 market for 304 stainless steel plate will be characterized by steady demand growth, sustainability-driven innovation, and strategic adaptation to global economic shifts. Stakeholders who invest in efficient production, supply chain resilience, and eco-friendly practices will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing 304 Stainless Steel Plate (Quality & IP)

Sourcing 304 stainless steel plate involves navigating several potential pitfalls related to both material quality and intellectual property (IP) considerations. Failing to address these can lead to project delays, increased costs, safety risks, and legal exposure. Below are the key pitfalls to avoid:

Quality-Related Pitfalls

1. Substandard Chemical Composition

A primary risk is receiving material that does not meet ASTM A240 or equivalent standards for 304 stainless steel. Unscrupulous suppliers may under-specify critical alloying elements like chromium (Cr), nickel (Ni), and molybdenum (Mo), or exceed limits for impurities (e.g., sulfur, phosphorus). This compromises corrosion resistance, mechanical strength, and overall performance. Always demand certified mill test reports (MTRs) with actual chemical analysis and verify them through third-party testing when necessary.

2. Inadequate Mechanical Properties

Even with correct chemistry, poor processing (e.g., improper heat treatment or cold working) can result in plates that fail to meet required tensile strength, yield strength, or elongation specifications. Ensure MTRs include mechanical test results and confirm they align with your application’s demands, especially for structural or pressure-containing uses.

3. Poor Surface Finish and Dimensional Accuracy

Off-spec thickness, flatness, or surface defects (e.g., pitting, scale, scratches) can impact weldability, fit-up, and final product performance. Verify surface finish requirements (e.g., 2B, No. 4, BA) and dimensional tolerances per standards like ASTM A480. Inspect received material or use a reputable supplier with consistent quality control.

4. Misrepresentation of Origin and Mill Certification

Some suppliers falsely claim material originates from reputable mills or provide forged documentation. This increases the risk of counterfeit or subpar material. Source from trusted suppliers with verifiable mill traceability and insist on original, legible MTRs with heat/lot numbers matching the material.

5. Lack of Traceability and Documentation

Incomplete or missing documentation makes it difficult to verify compliance, especially in regulated industries (e.g., food, pharmaceuticals, nuclear). Ensure full traceability from heat number to final product and retain all quality records for audit and compliance purposes.

Intellectual Property (IP)-Related Pitfalls

1. Unauthorized Use of Proprietary Specifications

Some suppliers may claim compliance with proprietary or patented processing methods (e.g., specific annealing or polishing techniques) without proper licensing. Using such material in end products could expose your company to IP infringement claims. Verify that any referenced proprietary processes are either licensed or not protected.

2. Counterfeit or Falsified Branding

High-demand mills (e.g., Outokumpu, Acerinox) are frequently counterfeited. Fake branding misleads buyers about material quality and origin, potentially violating trademarks and exposing downstream users to liability. Inspect mill markings and packaging carefully and cross-check with known authentic patterns.

3. Inadequate Supplier Due Diligence on IP Compliance

Suppliers may unknowingly or negligently source material produced using patented technologies (e.g., energy-efficient melting processes). If your supply chain uses infringing materials, your organization could face legal action despite not directly violating IP laws. Conduct due diligence on suppliers’ IP compliance practices and include IP warranties in procurement contracts.

4. Failure to Protect Custom Alloy or Processing IP

If you’re sourcing custom-processed 304 (e.g., specialized tempering or coating), ensure contractual protections (NDAs, IP clauses) are in place to prevent the supplier from replicating or disclosing your proprietary methods to competitors.

By proactively addressing these quality and IP pitfalls through rigorous supplier vetting, comprehensive documentation, and independent verification, organizations can mitigate risk and ensure reliable, compliant sourcing of 304 stainless steel plate.

Logistics & Compliance Guide for 304 Stainless Steel Plate

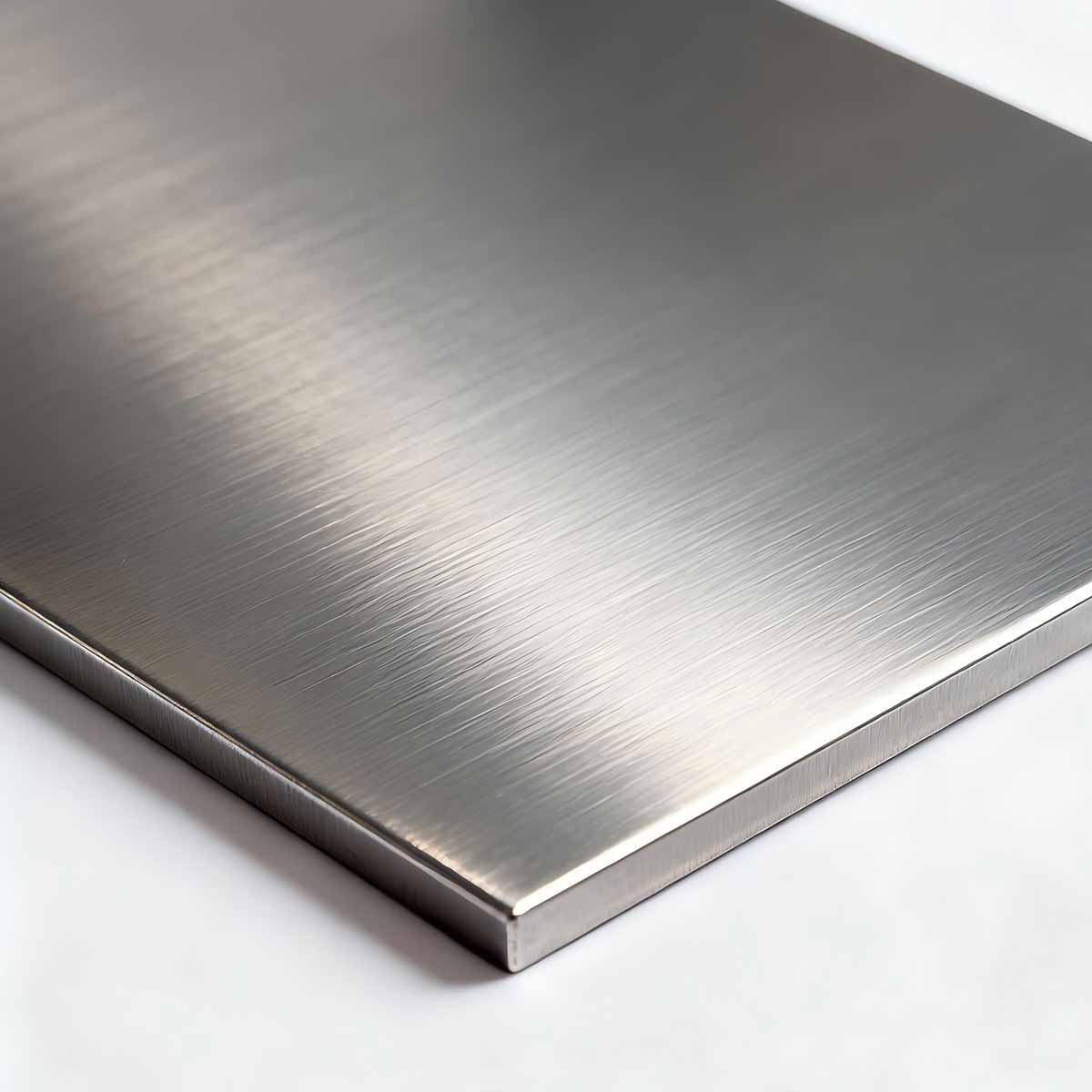

Overview of 304 Stainless Steel Plate

304 stainless steel plate is one of the most widely used austenitic stainless steels, known for its excellent corrosion resistance, formability, and weldability. It contains approximately 18% chromium and 8% nickel (18/8 stainless), making it suitable for a broad range of applications in industries such as food processing, architecture, chemical, and medical equipment. Proper logistics and compliance management are essential to ensure material integrity, regulatory adherence, and timely delivery.

Material Specifications and Certification

To maintain compliance, 304 stainless steel plates must meet recognized international standards such as ASTM A240/A240M (Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and General Applications). Suppliers must provide Mill Test Certificates (MTCs), typically following EN 10204 Type 3.1 or 3.2, verifying chemical composition, mechanical properties, and heat treatment. Certifications should include traceability to the heat number and confirmation of compliance with specified tolerance standards (e.g., thickness, flatness).

Packaging and Handling Requirements

Proper packaging is critical to prevent surface damage, contamination, and corrosion during transit. 304 stainless steel plates should be:

– Separated from carbon steel materials to avoid cross-contamination and rust transfer.

– Wrapped in protective plastic or kraft paper and secured on wooden pallets or cradles.

– Stored and handled using clean, non-ferrous lifting equipment (e.g., stainless steel or synthetic slings).

– Stacked flat with adequate support to prevent warping or edge damage.

Markings should include grade, dimensions, heat number, and manufacturer details for traceability.

Transportation and Shipping

Transport of 304 stainless steel plates must ensure physical protection and environmental control:

– Use enclosed or covered transport (e.g., dry vans, containers) to prevent exposure to moisture, salt spray, or abrasive elements.

– Secure loads to prevent shifting during transit; interleafing may be used for stacked plates.

– For international shipments, comply with Incoterms® (e.g., FOB, CIF) clearly defined in contracts.

– Maintain documentation including packing lists, commercial invoices, and certificates of origin, especially for customs clearance.

Regulatory and Customs Compliance

Import/export of 304 stainless steel plates may be subject to trade regulations and tariffs:

– Verify Harmonized System (HS) Code classification—typically 7219.32 or 7219.33 depending on dimensions and surface finish.

– Comply with anti-dumping and countervailing duties, particularly when shipping from or to regions such as the U.S., EU, or India where stainless steel trade measures may apply.

– Provide accurate country of origin declarations and, if applicable, proof of preferential treatment under free trade agreements (e.g., USMCA, EU-South Korea FTA).

– Adhere to local environmental and safety regulations (e.g., REACH in the EU, TSCA in the U.S.).

Storage and Inventory Management

Upon receipt, 304 plates should be stored in a dry, well-ventilated indoor area, off the ground and away from sources of chloride or moisture. Avoid prolonged outdoor storage. Implement a first-in, first-out (FIFO) inventory system to minimize aging effects and ensure traceability. Regular inspection for surface damage, pitting, or contamination is recommended.

Environmental, Health, and Safety (EHS) Considerations

During handling and processing, personnel should wear appropriate PPE (gloves, eye protection) to avoid injury from sharp edges. Grinding or cutting operations must include dust and fume control per OSHA or local standards. Waste material (offcuts, swarf) should be recycled through certified metal recyclers to support sustainability goals and comply with waste disposal regulations.

Quality Assurance and Auditing

Regular audits of suppliers and logistics providers are essential to ensure ongoing compliance. Audit criteria should include adherence to specified standards, packaging integrity, documentation accuracy, and delivery performance. Implement a corrective action process for non-conformances such as incorrect material, damaged goods, or missing certifications.

Conclusion

Effective logistics and compliance management for 304 stainless steel plates require attention to material specifications, proper handling, regulatory requirements, and documentation. By following this guide, companies can ensure product quality, reduce supply chain risks, and maintain adherence to international standards and trade regulations.

In conclusion, sourcing 304 stainless steel plates requires a strategic approach that balances quality, cost, supplier reliability, and supply chain efficiency. 304 stainless steel remains a preferred choice due to its excellent corrosion resistance, durability, formability, and versatility across industries such as construction, food processing, chemical, and pharmaceutical. When sourcing, it is critical to verify material certifications (e.g., mill test reports), ensure compliance with international standards (such as ASTM A240 or JIS SUS304), and assess the supplier’s production capabilities and track record.

Additionally, considerations such as lead times, minimum order quantities, logistics, and total landed cost—including tariffs and transportation—can significantly impact procurement decisions. Building long-term relationships with reputable suppliers, conducting regular quality audits, and staying informed about market fluctuations in raw material prices (e.g., nickel and chromium) will support a reliable and cost-effective supply of 304 stainless steel plates. Ultimately, a well-structured sourcing strategy ensures consistent material quality and operational efficiency for downstream manufacturing and project success.