The global stainless steel market is experiencing robust growth, driven by increasing demand across industries such as construction, automotive, energy, and consumer goods. According to Grand View Research, the global stainless steel market size was valued at USD 134.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. A significant portion of this demand is attributed to 304 stainless steel, the most widely used grade due to its excellent corrosion resistance, formability, and durability. Mordor Intelligence projects similar momentum, noting sustained industrial expansion in Asia-Pacific—particularly in China and India—as a key growth driver for stainless steel plate consumption. With rising infrastructure investments and stringent material performance standards, sourcing high-quality 304 stainless plates has become critical for manufacturers and fabricators. As competition intensifies, identifying reliable and scalable suppliers is essential. Based on production capacity, geographic reach, certifications, and market reputation, here are the top 10 manufacturers leading the 304 stainless steel plate segment.

Top 10 304 Stainless Plate Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 304 Stainless Steel Sheet & Plate

Domain Est. 1999

#2 Stainless Steel Plate and Sheet Supplier

Domain Est. 1996

Website: onealsteel.com

Key Highlights: Shop our T304/304L and T316/316L stainless plate products now. We offer a range of stainless plate thicknesses including: 3/16″, 1/4″, and 1/2″….

#3 Custom Size 304 Stainless Steel Sheet Metal Supplier and …

Domain Est. 1997

Website: stanch.com

Key Highlights: Stanch is an industry-leading supplier of cold rolled stainless steel sheets, we offer wide range of high quality stainless steel sheets in various finishes….

#4 Stainless Steel Plate – SS Sheet Supplier

Domain Est. 1997

Website: twmetals.com

Key Highlights: TW Metals supplies stainless steel plates & sheets in 304/304L, 304 straight grade, 316/316L and 321 are available at TW Metals. Contact us today!…

#5 North American Stainless

Domain Est. 1999 | Founded: 1990

Website: northamericanstainless.com

Key Highlights: North American Stainless is part of the Acerinox Group. Founded in 1990, North American Stainless (NAS) has undertaken several phases of expansion to become ……

#6 Stainless Steel Plate

Domain Est. 1999

Website: pennstainless.com

Key Highlights: Find quality stainless steel plates for your project at Penn Stainless, including diamond plate steel, 304/L, 316/L, and more with custom processing….

#7 304/304L & 316/316L Stainless Steel Sheet & Plate

Domain Est. 2000

Website: americanstainlesscorp.com

Key Highlights: At American Stainless Corporation, we’re here to help you with your stainless steel sheets and plates for your next project. Call us today to learn more….

#8 Stainless steel supplier in the world

Domain Est. 2001

Website: international.myjacquet.com

Key Highlights: Discover our stainless steel grades. We offer a large stock of plates: austenitic, duplex, refractory, ferritic, superaustenitic, martensitic….

#9 304 Stainless Steel Plate

Domain Est. 2005

Website: midweststeelsupply.com

Key Highlights: In stockMidwest Steel & Aluminum stocks and processes high-quality 304 / 304L stainless steel plate, a standard 18-8 stainless alloy containing 18% chromium and 8% ……

#10 304/304L Stainless Steel Plate

Domain Est. 2011

Website: kloecknermetals.com

Key Highlights: 304/304L stainless steel plate is one of the most popular stainless grades, supplied nationwide across our network of 55+ branches….

Expert Sourcing Insights for 304 Stainless Plate

H2: Market Trends for 304 Stainless Steel Plate in 2026

The global market for 304 stainless steel plate is projected to undergo significant transformation by 2026, driven by evolving industrial demands, sustainability imperatives, and regional economic dynamics. As one of the most widely used austenitic stainless steel grades, 304 stainless plate—known for its excellent corrosion resistance, formability, and durability—continues to be a material of choice across construction, automotive, food processing, and energy sectors. The following trends are expected to shape the 304 stainless steel plate market in 2026:

-

Increased Demand from Renewable Energy Sectors

The global push toward clean energy infrastructure will boost demand for 304 stainless steel plate, particularly in solar panel frames, wind turbine components, and hydrogen storage systems. Its resistance to environmental degradation makes it ideal for outdoor and high-moisture applications, positioning it as a key material in the energy transition. -

Growth in Infrastructure and Construction in Emerging Economies

Expanding urbanization in Asia-Pacific (especially India, Southeast Asia), Africa, and Latin America will drive construction activity, increasing the need for durable and low-maintenance materials. 304 stainless steel plate is increasingly specified in architectural cladding, water treatment facilities, and public infrastructure due to its longevity and aesthetic appeal. -

Supply Chain Diversification and Regionalization

Following geopolitical disruptions and trade tensions, manufacturers are shifting toward localized production and supply chains. This trend is prompting investment in regional stainless steel production hubs, reducing reliance on traditional exporters like China. Countries such as Indonesia, Turkey, and India are expected to increase their domestic output of 304 plates to meet growing regional demand. -

Sustainability and Circular Economy Pressures

Environmental regulations and corporate ESG (Environmental, Social, Governance) goals are pushing producers to adopt greener practices. In 2026, the recycling rate of stainless steel is expected to exceed 90%, with greater use of electric arc furnaces (EAFs) powered by renewable energy. This enhances the sustainability profile of 304 plates and supports compliance with green building standards like LEED and BREEAM. -

Price Volatility Due to Raw Material Fluctuations

The cost of key alloying elements—particularly nickel and chromium—will remain a critical factor. With nickel prices influenced by Indonesian export policies and growing demand from the EV battery sector, 304 stainless plate prices may experience volatility. Producers are exploring alternative sourcing and hedging strategies to stabilize input costs. -

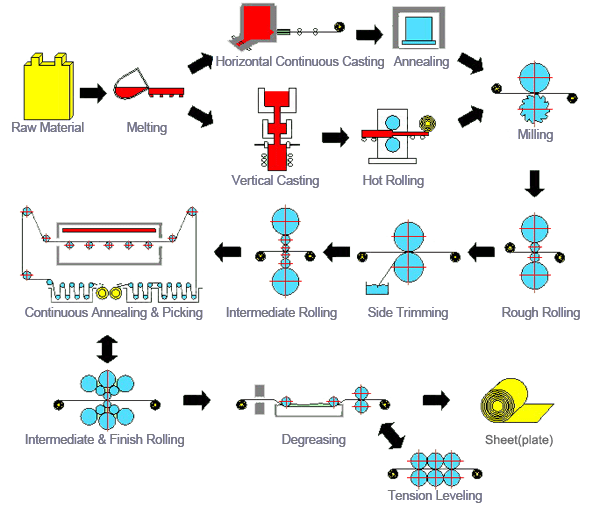

Technological Advancements in Processing and Finishing

Innovations in cold rolling, surface treatment, and precision cutting are improving the quality and consistency of 304 stainless steel plates. Laser cutting, automated polishing, and anti-fingerprint coatings are enhancing product value, especially for high-end architectural and consumer applications. -

Competition from Alternative Grades and Materials

While 304 remains dominant, cost-sensitive applications are increasingly adopting 304L (low carbon) or switching to 201 or 430 grades where corrosion resistance requirements are lower. Additionally, advances in coated carbon steel and composite materials may challenge stainless steel in some segments, though 304 retains strong advantages in hygiene and longevity. -

Strong Demand from Food and Pharmaceutical Industries

Regulatory standards requiring non-reactive, easily cleanable surfaces will sustain demand for 304 stainless steel in processing equipment, storage tanks, and conveyors. Its compliance with FDA and EHEDG standards ensures continued preference in hygienic environments.

Conclusion:

By 2026, the 304 stainless steel plate market will be characterized by resilient demand, regional production shifts, and increasing emphasis on sustainability. While price volatility and competition pose challenges, the material’s versatility and performance ensure its central role in key growth industries. Stakeholders who invest in innovation, supply chain resilience, and environmental stewardship are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing 304 Stainless Steel Plate (Quality & IP)

Sourcing 304 stainless steel plate requires careful attention to both material quality and intellectual property (IP) compliance. Overlooking these aspects can lead to project delays, safety risks, financial losses, and legal exposure. Here are the most common pitfalls:

Quality-Related Pitfalls

- Substandard Chemical Composition: Suppliers may provide material that falls outside ASTM A240/A480 specifications for 304 (e.g., insufficient chromium/nickel, excessive carbon, or low molybdenum). This compromises corrosion resistance and mechanical properties. Always demand and verify Mill Test Certificates (MTCs/CMTRs) with full chemical analysis.

- Inadequate Mechanical Properties: Plates may fail to meet required tensile strength, yield strength, or elongation standards. Relying solely on visual inspection or supplier claims is insufficient; ensure MTCs confirm compliance with specified mechanical tests.

- Poor Surface Finish and Defects: Issues like pitting, scale, scratches, dents, or inconsistent finishes can affect aesthetics, weldability, and performance. Clearly specify the required finish (e.g., 2B, No. 1, BA) and inspect upon delivery.

- Incorrect Dimensions and Tolerances: Deviations in thickness, width, length, or flatness can cause fit-up problems and rework. Verify measurements against order specifications and relevant standards (ASTM A480).

- Compromised Microstructure: Improper heat treatment or hot/cold rolling can lead to sensitization (chromium carbide precipitation at grain boundaries), reducing corrosion resistance. This is especially critical for welded applications. Request evidence of proper processing.

- Lack of Traceability and Documentation: Incomplete or falsified MTCs, missing heat numbers, or unclear material traceability prevent verification of quality and compliance. Insist on full, legible documentation tied to the specific material shipment.

Intellectual Property (IP)-Related Pitfalls

- Unauthorized Use of Brand Names or Grades: Suppliers may falsely label material as “304” when it is an inferior or non-standard alloy, infringing on trademarked specifications. Verify authenticity through independent testing if in doubt.

- Counterfeit Certifications: Fabricated or altered Mill Test Certificates misrepresent the material’s origin, composition, and compliance, posing significant IP and safety risks. Cross-check certification details with the stated mill and consider third-party verification for critical applications.

- Misappropriation of Technical Specifications: Using detailed supplier specifications, proprietary processing methods, or unique alloy formulas without authorization constitutes IP theft. Ensure your sourcing process respects confidential information and contracts.

- Infringement on Patented Processes: Some stainless steel production methods (e.g., specialized annealing or finishing techniques) may be patented. Sourcing material produced using such methods without a license could expose the buyer to liability, especially if the supplier is infringing.

- Ambiguous or Inadequate Contracts: Failure to include clear IP clauses in purchase agreements regarding ownership of custom designs, specifications, and liability for IP infringement by the supplier leaves the buyer vulnerable. Contracts should explicitly address IP rights and indemnification.

Avoiding these pitfalls requires due diligence, clear specifications, verification of documentation, and robust contractual agreements.

Logistics & Compliance Guide for 304 Stainless Steel Plate

Overview of 304 Stainless Steel Plate

304 stainless steel plate is one of the most widely used austenitic stainless steels, known for its excellent corrosion resistance, formability, and durability. It contains 18% chromium and 8% nickel (18/8 stainless), making it suitable for a variety of industrial, architectural, and food-processing applications. This guide outlines key logistics and compliance considerations when importing, exporting, or distributing 304 stainless steel plate.

Material Specifications & Standards

To ensure compliance, 304 stainless steel plate must conform to recognized international and national standards. Key specifications include:

– ASTM A240/A240M: Standard specification for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and general applications.

– EN 10088-2: European standard for stainless steels – Technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes.

– JIS G4304: Japanese Industrial Standard for hot-rolled stainless steel plate, sheet, and strip.

– GB/T 4237: Chinese standard for stainless steel hot-rolled steel plate/sheet/strip.

Ensure mill test certificates (MTCs), such as EN 10204 3.1 or 3.2, are provided to verify chemical composition and mechanical properties.

Regulatory & Import Compliance

Compliance requirements vary by destination country. Key considerations include:

– Customs Classification: Classify under the appropriate HS (Harmonized System) code. For 304 stainless steel plate, typical codes include:

– 7219.32 (flat-rolled products, of stainless steel, not further worked than cold-rolled, width ≥600 mm)

– 7219.33 (cold-rolled, width <600 mm)

– Confirm exact codes with local customs authorities, as subcategories vary.

– Import Duties & Tariffs: Be aware of anti-dumping duties or countervailing duties (e.g., in the U.S. or EU) that may apply to stainless steel products from certain countries. Check current trade remedies via official government databases.

– Country of Origin Marking: Products must be clearly marked with the country of origin per destination market requirements (e.g., “Made in China” for U.S. imports).

Packaging, Handling & Transportation

Proper logistics handling prevents damage and ensures product integrity:

– Packaging: Plates are typically bundled with protective interleave paper or film to prevent scratching. Wooden crates or steel strapping may be used for secure transit. Avoid exposure to moisture to prevent staining.

– Handling: Use non-magnetic lifting equipment (slings, vacuum lifters) to avoid surface damage. Keep plates dry and separated from carbon steel to prevent cross-contamination and rust transfer.

– Transportation:

– Use covered trucks or containers to protect from weather.

– For international shipments, ensure compliance with IMDG Code (for sea freight) and IATA (if air freight is used, though rare due to weight).

– Secure loads properly to prevent shifting during transit.

Environmental & Safety Compliance

- REACH & RoHS (EU): 304 stainless steel is generally compliant, but verify that no restricted substances are present in coatings or packaging.

- OSHA & WHMIS (U.S./Canada): Provide Safety Data Sheets (SDS) for stainless steel products. While bulk metal is not hazardous, grinding or machining can produce hazardous dust; proper workplace safety measures must be communicated.

- Waste & Recycling: Stainless steel is 100% recyclable. Ensure end-of-life handling follows local environmental regulations.

Quality Assurance & Documentation

Mandatory documentation includes:

– Mill Test Certificate (MTC) confirming compliance with applicable standards

– Commercial invoice, packing list, and bill of lading/airway bill

– Certificate of Origin (required for preferential tariffs under trade agreements)

– Phytosanitary certificate (if wooden packaging is used—ISPM 15 compliant)

Special Considerations for End-Use Applications

Certain industries have additional compliance needs:

– Food & Beverage: Must comply with FDA 21 CFR or EU 1935/2004 for food contact materials. 304 is generally approved but verify surface finish (e.g., #4 finish) and passivation.

– Pharmaceutical & Medical: May require additional certifications (e.g., ASME BPE for bioprocessing equipment).

– Construction: May need CE marking (EU) or ASTM certifications depending on local building codes.

Conclusion

Successfully managing the logistics and compliance of 304 stainless steel plate requires attention to material standards, customs regulations, proper handling, and documentation. Partnering with certified suppliers and experienced freight forwarders ensures compliance across the supply chain and minimizes delays or penalties. Regularly monitor regulatory updates, especially in trade-sensitive markets.

Conclusion for Sourcing 304 Stainless Steel Plate

In conclusion, sourcing 304 stainless steel plates requires a strategic approach that balances cost, quality, and reliability. As one of the most widely used austenitic stainless steels, 304 offers excellent corrosion resistance, durability, and formability, making it ideal for diverse applications in industries such as food processing, construction, chemical, and manufacturing.

To ensure optimal sourcing outcomes, it is essential to:

- Select Certified Suppliers: Partner with reputable suppliers who provide mill test certificates (MTCs) and comply with international standards such as ASTM A240 or JIS SUS304, ensuring material traceability and quality assurance.

- Evaluate Total Cost: Look beyond unit price to include shipping, tariffs, lead times, and potential risks related to supply chain disruptions.

- Prioritize Quality Control: Conduct material testing (e.g., PMI, tensile, and bend tests) upon delivery to confirm compliance with required specifications.

- Consider Lead Times and Minimum Order Quantities (MOQs): Align supplier capabilities with project timelines and inventory needs.

- Explore Local vs. International Options: Weigh the advantages of local suppliers (faster delivery, lower logistics risk) against potentially lower prices from international markets.

Ultimately, successful sourcing of 304 stainless steel plates hinges on thorough due diligence, strong supplier relationships, and a clear understanding of application-specific requirements. By focusing on quality, reliability, and long-term value, businesses can secure the necessary materials to support operational efficiency and product integrity.