The global laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly and non-abrasive surface treatment solutions across industries such as automotive, aerospace, and precision manufacturing. According to Grand View Research, the global laser cleaning market size was valued at USD 490.3 million in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 22.6% from 2023 to 2030. This surge is attributed to the rising adoption of pulse laser technology, particularly in high-precision applications requiring minimal thermal impact. Among the most sought-after systems are 300W pulse laser cleaning machines, which offer an optimal balance of power, portability, and cleaning efficiency. As industrial players prioritize automation and sustainability, the demand for reliable, high-performance equipment has intensified—spurring innovation among manufacturers. Based on market presence, technological advancement, and customer footprint, the following eight companies have emerged as leading manufacturers of 300W pulse laser cleaning machines.

Top 8 300W Pulse Laser Cleaning Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 US Stock SFX AGC 300W 500W Air Cooled Pulse Laser Cleaning …

Website: sfxlaser.com

Key Highlights: In stock Free delivery300W 500W pulse air cooled laser cleaning machine, non-contact remove rust paint oil stains coating. No damage to substrate. Anti-high-reflection technology….

#2 Argento Lux

Website: argentolux.com

Key Highlights: A-LUX 300W PulseLite Laser Cleaning Machine. A-LUX 500W-PW Laser Cleaning … Our company provides state-of-the-art Industrial Laser Equipment Sales and ……

#3 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: Use pulse laser cleaning machines for delicate materials. They remove contamination with virtually no heat-affected zone (HAZ) and no substrate damage….

#4 300W Pulse Laser Cleaning Machine

Website: nuwavelaser.com

Key Highlights: The Nuwave 300W Air Cooled Laser Cleaning Machine delivers powerful, precise, and eco-friendly surface cleaning. Designed for versatility, this Class IV ……

#5 BK

Website: baikeopto.com

Key Highlights: In stockBAIKEOPTO laser cleaning machines include 100W, 200W, 300W, 500W pulse laser cleaning, single-mode laser cleaning, multi-mode laser cleaning, ……

#6 300W Pulse Laser Cleaning Machine For Wood Metal Paint Rust …

Website: xinglaser.com

Key Highlights: In stockThis is a 300W Pulse Laser Cleaning Machine, it is widely used for precision mould rust removal, paint cleaning of wood metal, oxidized Aluminum Removing ……

#7 Fortune Laser Pulses 200W/300W Handheld Laser Cleaning Machine

Website: fortunelaser.com

Key Highlights: 200W 300W Laser Cleaning Machine Features: 22-inch trolley case control system: Built-in laser source, laser head and accessories; One-touch operation easy ……

#8 300W Pulse Laser Cleaning Machine

Website: bogongcnc.com

Key Highlights: Rating 3.5 (13) 300W Laser Cleaning Machine use Pulse Laser Cleaning Source and professional stable laser cleaning head and system….

Expert Sourcing Insights for 300W Pulse Laser Cleaning Machine

H2: Market Trends for 300W Pulse Laser Cleaning Machines in 2026

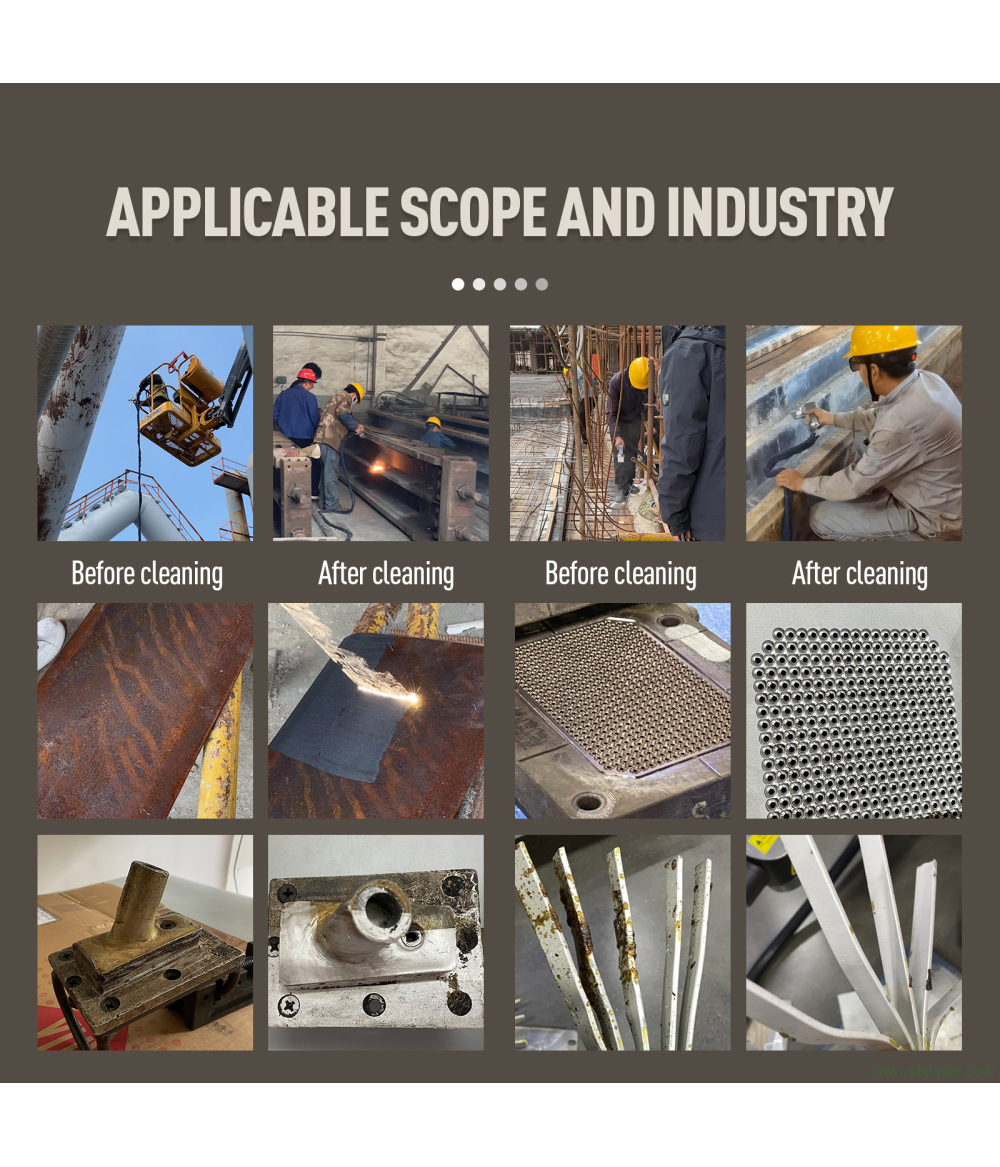

By 2026, the market for 300W pulse laser cleaning machines is expected to experience robust growth, driven by increasing demand for eco-friendly, efficient, and precise industrial cleaning solutions across multiple sectors. Key trends shaping this market include technological advancements, rising environmental regulations, and expanding applications in manufacturing, automotive, aerospace, and heritage conservation.

-

Growing Adoption of Green Manufacturing Practices

Environmental regulations are tightening globally, prompting industries to abandon chemical-based and abrasive cleaning methods. The 300W pulse laser cleaning machine offers a non-toxic, solvent-free, and waste-minimizing alternative, aligning with sustainability goals. By 2026, regulatory pressures in North America, Europe, and parts of Asia-Pacific will accelerate the shift toward laser cleaning technologies, especially for surface preparation and maintenance tasks. -

Technological Improvements and Cost Reductions

Advancements in fiber laser efficiency, pulse control, and beam delivery systems are enhancing the performance of 300W machines. Improved portability, user interfaces, and integration with robotics and IoT platforms are making these systems more accessible and easier to deploy. Economies of scale and increased competition are expected to lower equipment costs, making 300W systems viable for small and medium-sized enterprises (SMEs) by 2026. -

Expansion in Automotive and Aerospace Applications

The automotive sector is increasingly using 300W pulse lasers for rust removal, paint stripping, and weld preparation. Aerospace manufacturers are adopting the technology for precision cleaning of turbine blades and composite materials without substrate damage. As electric vehicle (EV) production ramps up, demand for high-precision, non-contact cleaning in battery and motor assembly will further boost market adoption. -

Rise of Automation and Industry 4.0 Integration

Integration with automated production lines and robotic arms is a key trend. By 2026, smart 300W laser systems with real-time monitoring, adaptive cleaning algorithms, and predictive maintenance features will become standard, enhancing productivity and reducing downtime in industrial settings. -

Geographic Market Growth

Asia-Pacific, particularly China, Japan, and South Korea, is projected to lead market growth due to rapid industrialization and government support for advanced manufacturing. North America and Europe will maintain strong demand, driven by aerospace, defense, and infrastructure maintenance needs. Emerging markets in Southeast Asia and India are also expected to adopt laser cleaning as part of industrial modernization efforts. -

Increased Competition and Innovation

The competitive landscape will intensify, with both established laser equipment manufacturers and new entrants offering differentiated 300W models. Innovation will focus on improving cleaning speed, energy efficiency, and ease of use. Strategic partnerships between laser providers and industrial automation companies are likely to emerge, broadening market reach.

In summary, by 2026, the 300W pulse laser cleaning machine market will be shaped by sustainability mandates, technological innovation, and expanding industrial applications. As operational benefits become more widely recognized and costs continue to decline, the 300W segment is poised for significant penetration across global manufacturing and maintenance sectors.

Common Pitfalls When Sourcing a 300W Pulse Laser Cleaning Machine (Quality & IP)

Sourcing a 300W pulse laser cleaning machine involves significant investment and technical complexity. Buyers often encounter critical pitfalls related to quality assurance and intellectual property (IP) risks. Being aware of these challenges is essential to avoid costly mistakes, operational failures, and legal exposure.

1. Overlooking Laser Source Quality and Authenticity

A major quality pitfall is assuming all “300W” lasers are equal. Many suppliers use underpowered or low-quality laser sources that degrade quickly or fail to meet performance claims.

- Counterfeit or Rebranded Components: Some manufacturers source cheap, uncertified laser diodes or fiber modules and rebrand them as high-grade components (e.g., falsely claiming Raycus or IPG equivalency).

- Power Inflation: Suppliers may advertise peak pulse power (e.g., 300W) while the average power is significantly lower, leading to poor cleaning efficiency.

- Lack of Certification: Absence of proper certifications (CE, FDA, RoHS) or test reports from independent labs raises red flags about reliability and safety.

Mitigation: Demand detailed specifications, request third-party power test reports, verify laser source manufacturer authenticity, and insist on a trial period with measurable performance benchmarks.

2. Poor System Integration and Build Quality

Even with a quality laser source, poor engineering integration can undermine performance and longevity.

- Inadequate Cooling Systems: Pulse lasers generate significant heat. Substandard cooling (e.g., undersized chillers or inefficient heat dissipation) leads to thermal throttling, unstable output, and premature component failure.

- Low-Grade Optics and Scanning Heads: Using uncoated or low-damage-threshold optics results in beam degradation, reduced cleaning efficiency, and frequent replacements.

- Flimsy Mechanical Design: Lightweight or poorly assembled frames and moving parts reduce precision, increase vibration, and shorten machine lifespan.

Mitigation: Inspect build materials, request details on cooling capacity and optical specifications, and evaluate the manufacturer’s track record for durability through customer references or site visits.

3. Hidden IP Infringement Risks

Purchasing a laser cleaning machine from a supplier with questionable IP practices can expose the buyer to legal liability.

- Cloned or Reverse-Engineered Designs: Some manufacturers copy control software, mechanical designs, or optical layouts protected by patents or copyrights without licensing.

- Unlicensed Software: Use of pirated or unlicensed control systems (e.g., unauthorized versions of EZCAD or proprietary motion control software) poses compliance and security risks.

- Component-Level IP Violations: The machine may incorporate patented technologies (e.g., specific beam delivery methods or safety interlocks) without permission.

Mitigation: Require the supplier to provide IP indemnification clauses in the contract, verify software licensing, and conduct due diligence on the manufacturer’s reputation and R&D capabilities.

4. Inadequate After-Sales Support and Documentation

Quality extends beyond the initial product to ongoing support, which is often underestimated.

- Lack of Technical Expertise: Suppliers may lack trained engineers to troubleshoot complex laser issues, leading to prolonged downtime.

- Missing or Poor Documentation: Absence of detailed operation manuals, maintenance guides, or circuit diagrams hampers safe and effective use.

- No Firmware/Software Updates: Failure to provide updates can result in unresolved bugs or security vulnerabilities.

Mitigation: Evaluate service response times, request sample documentation, and confirm software update policies before purchase.

5. Misrepresentation of Cleaning Performance

Suppliers may exaggerate real-world cleaning capabilities based on ideal lab conditions.

- Unrealistic Speed/Throughput Claims: Performance tested on thin rust or paint may not translate to thick coatings or oxidized surfaces.

- Limited Material Testing Data: Lack of verified data across various substrates (e.g., steel, aluminum, concrete) makes it hard to assess suitability.

- No Safety or Environmental Data: Omission of fume extraction requirements or safety classifications (e.g., Class 4 laser) can lead to compliance issues.

Mitigation: Require on-site or third-party performance validation using your specific materials and conditions. Confirm compliance with local safety standards.

By proactively addressing these quality and IP-related pitfalls, buyers can make informed decisions, ensure operational reliability, and protect themselves from legal and financial risks when sourcing a 300W pulse laser cleaning machine.

H2: Logistics & Compliance Guide – 300W Pulse Laser Cleaning Machine

This guide outlines the essential logistics and compliance considerations for the international shipment, import, and safe operation of the 300W Pulse Laser Cleaning Machine. Adherence is critical for regulatory approval, operational safety, and avoiding customs delays or penalties.

H2.1: International Shipping & Logistics

- Packaging:

- Robustness: Machine must be secured in a custom-engineered, shock-absorbing wooden crate (ISPM 15 compliant) with internal bracing to prevent movement. Include desiccant packs.

- Labeling: Clearly affixed labels: “Fragile,” “This Side Up,” “Do Not Stack,” “Keep Dry,” machine weight, dimensions, and center of gravity. Include the Laser Warning Label (Class 4) on the crate exterior.

- Contents: Packing list detailing machine, accessories (nozzle set, safety glasses, power cable, manual), and any tools must be sealed in a waterproof pouch on the crate interior.

- Incoterms: Clearly define responsibility (e.g., FOB [Port of Export], DAP [Named Place of Import]). DDP is recommended for maximum control but increases exporter liability.

- Carrier Selection:

- Use freight forwarders experienced with Class 4 laser equipment and hazardous goods (if batteries are included).

- Air Freight: Strictly prohibited for Class 4 lasers without special permits (IATA Dangerous Goods Regulations, likely Class 9 – Miscellaneous). Ground/sea is standard.

- Ocean Freight: Primary method. Ensure container is waterproof and secured. Consider container desiccants.

- Documentation:

- Commercial Invoice: Detailed description (“300W Pulsed Fiber Laser Cleaning System”), full technical specs, HS Code, value, country of origin.

- Packing List: Itemized list, weights, dimensions, total package count.

- Bill of Lading (B/L) or Air Waybill (AWB): Accurate consignee/notify details.

- Certificate of Origin: Required by many countries for tariffs.

- Laser Safety Certificate: Document confirming compliance with IEC 60825-1 (see H2.2).

- RoHS/REACH Declaration: Proof of compliance with EU substance restrictions (critical for EU shipments).

- Export License (if required): Check Wassenaar Arrangement controls for lasers (3A001). A license may be required for export to certain destinations/countries.

H2.2: Regulatory Compliance

- Laser Safety (Critical – Class 4):

- IEC 60825-1: Mandatory compliance. Requires:

- Built-in safety interlocks (e.g., cover switches).

- Key-controlled master switch.

- Emission indicator (laser on warning light).

- Beam shutter or attenuator.

- Clearly visible Class 4 Laser Warning Labels on the machine and packaging.

- Protective housing preventing access to hazardous radiation during normal operation.

- FDA/CDRH (USA): Mandatory registration and reporting. Submit:

- Product Report (Form FDA 2877) before shipment.

- Annual Report.

- Laser Notice: Include required label and statement in manual (“Complies with 21 CFR 1040.10 and 1040.11, except for deviations pursuant to Laser Notice No. 50…”).

- Local Regulations: Verify requirements in the destination country (e.g., Health Canada, TÜV in Germany, ANVISA in Brazil). CE Marking requires compliance with the EU Laser Product Standard (EN 60825-1).

- IEC 60825-1: Mandatory compliance. Requires:

- Electrical Safety:

- CE Marking (EU): Compliance with Low Voltage Directive (2014/35/EU) and EMC Directive (2014/30/EU) via standards like EN 61010-1 (Safety) and EN 61326-1 (EMC).

- UL/ETL (USA/Canada): Required for market access. Compliance with standards like UL 61010-1.

- PSE (Japan): Required for electrical equipment.

- CCC (China): Required for specified electrical products.

- Environmental & Substance Regulations:

- RoHS (EU/China/UK/etc.): Restriction of Hazardous Substances. Provide Declaration of Conformity.

- REACH (EU): Registration, Evaluation, Authorisation of Chemicals. Provide SVHC (Substances of Very High Concern) declaration if applicable.

- WEEE (EU): Waste Electrical and Electronic Equipment. Registration may be required for the importer/distributor.

- Customs & Trade:

- Accurate HS Code: 8515.21.00 (Laser machines for cutting, boring, welding, etc.) is typical. Confirm with local customs or a broker. Incorrect codes cause delays and fines.

- Import Duties & Taxes: Calculate based on HS code, value (CIF), and destination country regulations (VAT, GST, import tariffs). DAP/DDP terms include these costs.

- Prohibited/Restricted Destinations: Verify no export/import bans exist for the destination country.

H2.3: Import & Customs Clearance (Destination Country)

- Appoint a Customs Broker: Essential for navigating local procedures, duties, taxes, and documentation.

- Provide Complete Documentation: Ensure all H2.2 documents (Commercial Invoice, B/L, COO, Certificates) are accurate and match the shipment.

- Duties & Taxes: Pay or arrange payment for assessed import duties, VAT/GST, and any handling fees. Factor these into the final cost.

- Physical Inspection: Be prepared for customs to inspect the shipment. Ensure the machine is accessible and documentation is readily available.

- Laser-Specific Clearance: Some countries may require pre-approval or notification for Class 4 lasers. The importer may need to register the device locally.

H2.4: In-Country Logistics & Setup

- Final Transport: Arrange ground transport from port/airport to final destination. Ensure suitable vehicle (size, crane/lift availability).

- Site Preparation:

- Verify adequate power supply (voltage, phase, grounding) as per machine specs.

- Ensure sufficient ventilation (fumes from cleaning process).

- Designate a controlled access area meeting safety requirements (laser safety zone).

- Installation & Commissioning: Performed by qualified personnel only. Verify all safety features function.

- Handover & Training: Provide comprehensive safety and operational training to end-users, emphasizing Class 4 laser hazards (eye/skin injury, fire risk, fumes).

Key Compliance & Logistics Summary Table:

| Requirement | Key Standards/Regulations | Critical Actions | Responsible Party (Typical) |

| :——————- | :——————————— | :——————————————————————————- | :————————– |

| Laser Safety | IEC 60825-1, FDA 21 CFR 1040, Local | Class 4 Labels, Interlocks, Key Switch, Emission Indicator, Safety Certificates | Manufacturer/Exporter |

| Electrical Safety| CE (EN 61010-1, EN 61326-1), UL, PSE, CCC | Obtain required certifications, affix marks (CE, UL, etc.) | Manufacturer |

| Substances | RoHS, REACH | Provide DoC, SVHC Declaration | Manufacturer/Exporter |

| Export Control | Wassenaar Arrangement (3A001) | Determine if Export License is required | Exporter |

| US Import | FDA CDRH | File Product & Annual Reports, Include Laser Notice | US Agent/Importer |

| Customs (General)| Accurate HS Code (8515.21.00) | Correct Commercial Invoice, Packing List, COO, Pay Duties/Taxes | Exporter/Broker/Importer |

| Packaging | ISPM 15, IATA (if air) | Use certified wood crate, Fragile/Keep Dry labels, Laser Warning Label | Exporter/Freight Forwarder |

Disclaimer: This guide provides general information. Regulations vary significantly by country and are subject to change. Always consult with qualified legal counsel, regulatory specialists, and experienced freight forwarders for the specific destination country before shipment.

Conclusion: Sourcing a 300W Pulse Laser Cleaning Machine

After a comprehensive evaluation of technical specifications, supplier reliability, cost-efficiency, and application suitability, sourcing a 300W pulse laser cleaning machine proves to be a strategic investment for industries requiring precision surface cleaning with minimal substrate damage. The 300W power output offers an optimal balance between cleaning efficiency and operational control, making it suitable for removing rust, paint, oxides, and contaminants from metals, molds, and delicate components without causing thermal distortion.

Key advantages include reduced consumable usage, environmental friendliness (no chemicals or media blasting), and low maintenance requirements compared to traditional cleaning methods. Additionally, the pulse laser technology ensures selective ablation, preserving underlying materials and extending the lifespan of treated parts.

When sourcing, it is essential to prioritize suppliers offering CE, ISO, and other relevant safety certifications, comprehensive training, technical support, and warranty coverage. Machines with user-friendly interfaces, adjustable pulse parameters, and portable designs further enhance operational flexibility across diverse environments.

In conclusion, integrating a 300W pulse laser cleaning machine improves cleaning precision, reduces long-term operational costs, and supports sustainable manufacturing practices. With the right supplier and proper implementation, this technology can significantly enhance productivity and quality in maintenance, automotive, aerospace, and tooling applications.