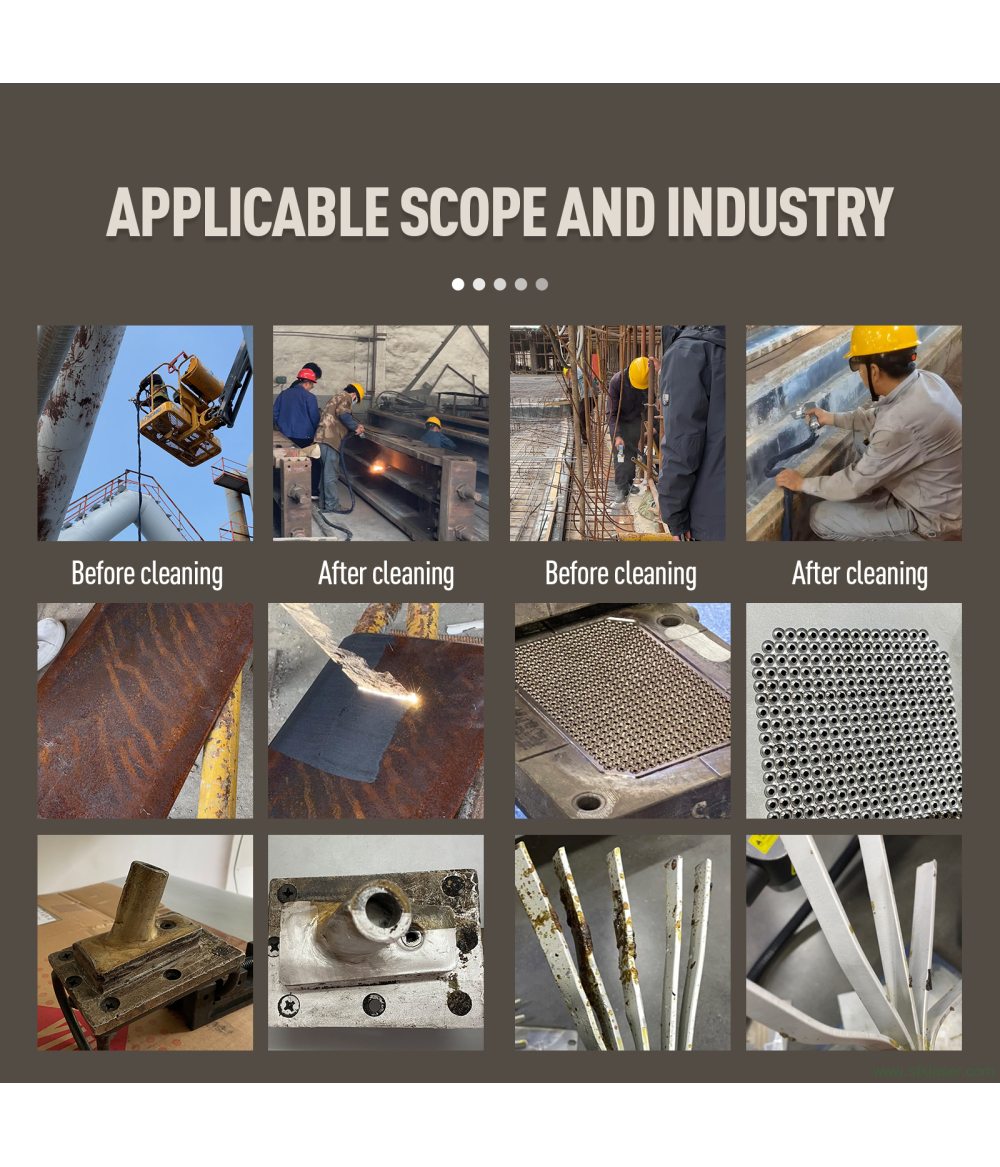

The global pulse laser market is experiencing robust expansion, driven by increasing demand across industrial, medical, and defense applications. According to Grand View Research, the global laser diode market—encompassing pulse laser technologies—was valued at USD 13.86 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 15.6% from 2024 to 2030. This surge is fueled by advancements in precision manufacturing, growing adoption in laser ranging and sensing, and rising integration in medical treatments such as dermatology and ophthalmology. As 300W pulse lasers become critical for high-throughput materials processing, including cutting, welding, and surface cleaning, manufacturers are innovating rapidly to meet performance, reliability, and efficiency demands. In this competitive landscape, a select group of companies has emerged as leaders in engineering and commercializing high-power pulse lasers. Based on market presence, technological innovation, and application reach, here are the top 7 manufacturers shaping the 300W pulse laser sector.

Top 7 300W Pulse Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#2 300W Pulse Laser Cleaning Machine

Website: nuwavelaser.com

Key Highlights: The Nuwave 300W Air Cooled Laser Cleaning Machine delivers powerful, precise, and eco-friendly surface cleaning. Designed for versatility, this Class IV ……

#3 BK

Website: baikeopto.com

Key Highlights: In stock300W Backpack Pulse Laser Cleaner Portable Laser Cleaning Machine for Metal Stone Brick Wood Machine Price for sale ; Maximum monopulse energy, 5mJ ; Power ……

#4 300W Pulse Laser Cleaning Machine For Wood Metal Paint Rust …

Website: xinglaser.com

Key Highlights: In stockThis is a 300W Pulse Laser Cleaning Machine, it is widely used for precision mould rust removal, paint cleaning of wood metal, oxidized Aluminum Removing ……

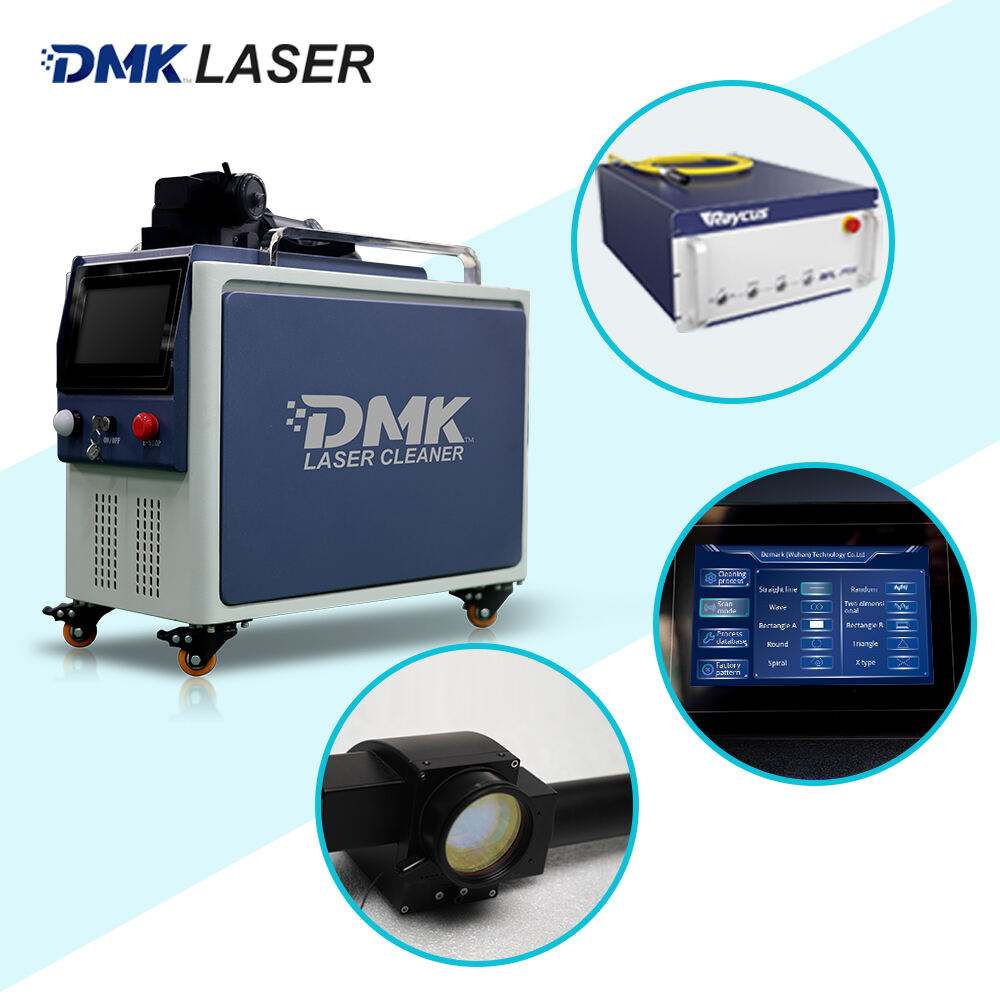

#5 DMK 300W Pulse Laser Rust Removal

Website: laserdmk.com

Key Highlights: The 300W pulse fiber laser cleaning machine, equipped with Raycus, MAX, or JPT laser sources, is highly versatile and can effectively remove rust, oil, oxide ……

#6 Fortune Laser Pulses 200W/300W Handheld Laser Cleaning Machine

Website: fortunelaser.com

Key Highlights: 200W 300W Laser Cleaning Machine Features: 22-inch trolley case control system: Built-in laser source, laser head and accessories; One-touch operation easy ……

#7 300W Pulse Laser Cleaning Machine

Website: bogongcnc.com

Key Highlights: Rating 3.5 (13) 300W Laser Cleaning Machine use Pulse Laser Cleaning Source and professional stable laser cleaning head and system….

Expert Sourcing Insights for 300W Pulse Laser

H2: 2026 Market Trends for 300W Pulse Lasers

The global market for 300W pulse lasers is poised for substantial evolution by 2026, driven by advancements in industrial manufacturing, rising demand for precision processing, and innovations in laser technology. These mid-power pulsed lasers—typically fiber or solid-state systems operating in the nanosecond to picosecond pulse duration range—are increasingly critical across a variety of high-tech sectors. Below are the key market trends expected to shape the 300W pulse laser landscape in 2026.

1. Expansion in Industrial Micromachining and Precision Manufacturing

The adoption of 300W pulse lasers is accelerating in micromachining applications such as drilling, cutting, and surface texturing. Industries such as electronics, aerospace, and medical device manufacturing are leveraging these lasers for their ability to process delicate materials (e.g., ceramics, thin metals, and polymers) with minimal heat-affected zones. By 2026, growing demand for miniaturized components in consumer electronics and electric vehicles (EVs) is expected to drive market growth.

2. Surge in Adoption within the EV and Battery Manufacturing Sector

One of the most significant growth drivers for 300W pulse lasers is their use in lithium-ion battery production. These lasers are employed in electrode structuring, tab cutting, and cleaning processes, where high precision and reliability are paramount. As global EV production scales to meet sustainability targets, the demand for efficient and defect-free battery manufacturing will boost investments in pulsed laser systems, particularly in Asia-Pacific and North America.

3. Advancements in Ultrafast Laser Technology

While 300W systems are traditionally associated with nanosecond pulses, there is a growing convergence with picosecond and femtosecond technologies at this power level. Improved thermal management, higher wall-plug efficiency, and better beam quality are enabling ultrafast 300W lasers to become more commercially viable. By 2026, these systems are expected to gain traction in high-value applications such as semiconductor scribing and solar cell processing.

4. Regional Market Growth and Supply Chain Localization

Asia-Pacific, led by China, Japan, and South Korea, is anticipated to dominate the 300W pulse laser market in 2026. Local manufacturing ecosystems, government support for advanced manufacturing, and strong electronics supply chains are accelerating deployment. Meanwhile, North America and Europe are focusing on high-precision applications in defense, aerospace, and medical fields, supported by R&D investments and automation initiatives.

5. Increased Integration with Smart Manufacturing and Industry 4.0

300W pulse lasers are increasingly being integrated into automated production lines with real-time monitoring, AI-driven process optimization, and IoT connectivity. By 2026, smart laser systems capable of adaptive pulsing and predictive maintenance will offer improved throughput and reduced downtime, making them essential components of Industry 4.0 strategies.

6. Competitive Landscape and Price Pressure

The market is becoming more competitive with the entry of new manufacturers from China and South Korea, offering cost-effective alternatives to established Western and Japanese brands. This competition is driving down prices and encouraging innovation in modular, scalable laser platforms. However, differentiation through reliability, service support, and application-specific solutions will remain key for market leaders.

7. Focus on Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing laser manufacturers to improve energy efficiency and reduce waste. 300W pulse lasers with higher electro-optical conversion rates and recyclable components are gaining favor. By 2026, green manufacturing standards are expected to influence procurement decisions across industrial sectors.

Conclusion

By 2026, the 300W pulse laser market will be characterized by technological convergence, expanded industrial applications, and strong regional growth—particularly in EVs, electronics, and smart manufacturing. Companies that innovate in system integration, energy efficiency, and application-specific performance will be best positioned to capture market share in this dynamic and rapidly advancing field.

H2: Common Pitfalls When Sourcing a 300W Pulse Laser – Quality and Intellectual Property (IP) Concerns

Sourcing a 300W pulse laser involves significant technical, financial, and legal considerations, particularly regarding product quality and intellectual property (IP) protection. Buyers often encounter several pitfalls that can compromise performance, reliability, and legal standing. Key issues include:

-

Inflated or Misrepresented Specifications

Many suppliers, especially from less-regulated markets, exaggerate laser output (e.g., labeling average power as peak power) or omit critical performance metrics such as pulse duration, beam quality (M² factor), and stability. A 300W pulse laser may deliver significantly lower effective power under real-world conditions due to poor thermal management or duty cycle limitations. -

Lack of Quality Control and Certification

Low-cost manufacturers may lack ISO certifications (e.g., ISO 9001) or fail to implement rigorous testing protocols. Components such as diodes, optics, and cooling systems may be substandard, leading to shortened lifespan, frequent maintenance, or operational failure in industrial environments. -

Incomplete or Absent Documentation

Reputable lasers come with detailed technical documentation, safety certifications (e.g., FDA, CE), and calibration reports. Omissions suggest potential non-compliance with international standards and raise red flags about product legitimacy and traceability. -

IP Infringement Risks

Some suppliers reverse-engineer or clone designs from established brands, potentially violating patents or proprietary technologies. Purchasing such equipment exposes buyers to legal liability, especially in regions with strict IP enforcement (e.g., the U.S. or EU). This also undermines innovation and may result in limited technical support or firmware updates. -

Opaque Supply Chain and Component Sourcing

The origin of key components (e.g., laser diodes, Q-switches) is often undisclosed. Components may be counterfeit, recycled, or sourced from unauthorized distributors, affecting performance and voiding warranties. -

Limited After-Sales Support and Warranty Coverage

Poor post-purchase service—such as delayed technical support, unavailable spare parts, or restrictive warranty terms—can disrupt operations and increase total cost of ownership. IP-laden software or control systems may also be locked, preventing integration or modification. -

Failure to Verify IP Ownership

Buyers may neglect to confirm whether the supplier holds legitimate IP rights or licenses. Engaging in due diligence—such as reviewing patent databases or requesting IP indemnification clauses in contracts—is critical to avoiding infringement claims.

Recommendations:

– Source from established manufacturers with verifiable track records and third-party certifications.

– Request independent test reports or conduct on-site evaluations.

– Include IP warranty clauses in procurement contracts.

– Consult legal experts to assess IP risks, especially for integration into proprietary systems.

Avoiding these pitfalls ensures reliable performance, legal compliance, and long-term operational efficiency when deploying high-power pulsed laser systems.

H2: Logistics & Compliance Guide for 300W Pulse Laser

1. Product Classification & Regulatory Overview

1.1 Laser Classification (IEC 60825-1 / FDA 21 CFR 1040.10)

– The 300W pulsed laser is classified as a Class 4 Laser due to its high power output (>500 mW for continuous wave; pulsed lasers are assessed using accessible emission limits (AEL)).

– Class 4 lasers pose severe hazards: eye and skin injury, fire risk, and potential for generating hazardous airborne contaminants (e.g., laser-generated airborne contaminants – LGACs).

– Mandatory compliance with:

– IEC 60825-1: International standard for laser product safety.

– FDA/CDRH (Center for Devices and Radiological Health): U.S. regulatory body requiring product reporting, variance (if applicable), and compliance certification.

– CDRH Product Report: Required before U.S. market entry.

1.2 Harmonized System (HS) Code

– Typical HS Code: 9013.20.00 – “Laser diodes and other laser generators.”

– Note: Final classification may vary by country; verify with local customs authority.

– Accurate classification ensures correct tariffs and import procedures.

1.3 Export Controls

– Subject to dual-use regulations due to potential military applications.

– Export Control Classification Number (ECCN): Likely 6A003.b.4 under the Export Administration Regulations (EAR).

– Applies to lasers with average output power ≥ 1 W and specific pulse characteristics.

– Requires license for export to many destinations (check Commerce Control List).

– ITAR (International Traffic in Arms Regulations): Not typically applicable unless integrated into defense systems.

2. Packaging & Shipping Requirements

2.1 Packaging Standards

– Use rigid, shock-resistant packaging with internal cushioning to protect optical components.

– Include:

– Desiccant packs to prevent moisture damage.

– Anti-static materials if sensitive electronics are included.

– Secure fixation to prevent movement during transit.

– Clearly label with:

– “Fragile – Handle with Care”

– “This Way Up”

– “Protect from Moisture”

2.2 Labeling & Documentation

– Laser Warning Label: Required per IEC 60825-1:

– Class 4 Laser Product symbol (black-on-yellow triangle).

– Wavelength and maximum output (e.g., “300W Peak Power, 1064 nm”).

– Caution statement: “Avoid exposure to beam and scattered radiation.”

– Shipping Labels:

– Proper shipping name: “Laser Product – Not Restricted” (if non-hazardous for transport).

– UN number: Typically UN 3499 – “Environmental hazard, liquid, n.o.s.” (if coolant present).

– Hazard Class: Only if batteries or hazardous materials are included (e.g., Class 9 for lithium batteries).

2.3 Transport Considerations

– Air Freight (IATA):

– No special restriction for lasers alone, but verify if power supply or coolant is hazardous.

– Lithium batteries (if used) must comply with IATA Dangerous Goods Regulations (DGR), Section II or I depending on watt-hours.

– Sea & Ground (IMDG/ADR): Apply if hazardous components present.

– Temperature Control: Avoid extreme temperatures; store and ship between 5°C–40°C unless specified.

3. Import & Customs Compliance

3.1 Required Documentation

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Conformity (CE, FCC, RoHS if applicable)

– FDA Registration & Product Report (for U.S. imports)

– Export License (if required by ECCN)

– Statement of Non-Inclusion of Conflict Minerals (if applicable)

3.2 Regional Compliance

– European Union:

– CE Marking per Directive 2014/35/EU (Low Voltage) and 2011/65/EU (RoHS).

– Compliance with EMC Directive 2014/30/EU.

– Registration in EUDAMED (if classified as medical laser).

– United States:

– FDA CDRH compliance: File Laser Product Report via FDA’s Electronic Submission Gateway (ESG).

– Ensure manufacturer has a U.S. Agent if foreign-based.

– China:

– Requires CCC Mark if applicable; lasers may fall under voluntary certification.

– Import license for dual-use items possible.

– Canada:

– Comply with Radiation Emitting Devices Act (REDA).

– Report to Health Canada.

4. Installation & Operational Compliance

4.1 Safety Requirements

– Engineering Controls:

– Interlocks, beam enclosures, key-controlled power switch.

– Emergency stop buttons.

– Administrative Controls:

– Laser safety officer (LSO) designation (per ANSI Z136.1).

– Training for operators.

– Controlled access to laser area.

– Personal Protective Equipment (PPE):

– Laser safety goggles with correct optical density (OD) for wavelength and power.

– Flame-resistant lab coats.

4.2 Facility Requirements

– Designated Laser Controlled Area with warning signs (e.g., “Laser Radiation – Avoid Eye or Skin Exposure”).

– Beam path enclosed or terminated in a beam dump.

– Ventilation/filtration if processing materials generate fumes.

5. Documentation & Recordkeeping

- Maintain:

- FDA Product Reports (U.S.)

- EU Declaration of Conformity

- Risk assessment per ISO 14971 (if medical use)

- Service and calibration logs

- Training records for users

- Retain for minimum of 5–10 years depending on jurisdiction.

6. Summary Checklist

| Task | Required? | Responsible Party |

|——|———–|——————-|

| Class 4 Laser Labeling | Yes | Manufacturer |

| FDA Product Report (U.S.) | Yes | U.S. Importer/Agent |

| CE Marking & EU Docs | Yes (EU) | Manufacturer/Importer |

| ECCN Classification & License | Case-by-case | Exporter |

| Proper Packaging & Labeling | Yes | Shipper |

| Operator Training & LSO | Yes | End User |

| Safety Interlocks & Enclosure | Yes | Integrator/User |

Note: Regulations vary by country and application (industrial, medical, research). Always consult local authorities and legal counsel prior to shipment or deployment.

This guide is for informational purposes and does not constitute legal advice.

Conclusion for Sourcing a 300W Pulse Laser

After a comprehensive evaluation of technical specifications, supplier capabilities, cost considerations, and market availability, sourcing a 300W pulsed laser requires a strategic balance between performance, reliability, and budget. Pulsed lasers at this power level are well-suited for industrial applications such as precision machining, laser marking, micromachining, and surface treatment, where high peak power and controlled thermal input are critical.

Key findings indicate that fiber-based pulsed lasers offer superior beam quality, energy efficiency, and maintenance advantages over older technologies like Nd:YAG. Leading manufacturers from regions such as the United States, Germany, Japan, and China provide reliable options, with increasing competition driving improvements in cost-effectiveness and service support.

For procurement, it is recommended to prioritize suppliers offering proven track records, comprehensive technical support, and scalability options. Additionally, considerations such as pulse duration, repetition rate, cooling requirements, and system integration must align with the intended application to ensure optimal performance.

In conclusion, while multiple viable suppliers exist, a thorough supplier assessment—factoring in warranty, lead time, after-sales service, and customization potential—is essential. Selecting the right 300W pulsed laser will significantly enhance process efficiency and product quality, making it a strategic investment in advanced manufacturing capabilities.