The global laser cleaning market is experiencing robust expansion, driven by increasing demand for eco-friendly, precise, and efficient surface treatment solutions across industries such as automotive, aerospace, and manufacturing. According to a 2023 report by Mordor Intelligence, the market was valued at USD 714.2 million in 2022 and is projected to grow at a CAGR of 20.4% from 2023 to 2028, reaching an estimated USD 2.1 billion by the end of the forecast period. This growth is largely fueled by the rising adoption of pulse laser technologies, particularly 300-watt systems, which offer optimal balance between cleaning efficiency and operational cost. As industries shift away from abrasive and chemical cleaning methods, the demand for high-performance pulse laser cleaners has surged, prompting a competitive landscape of manufacturers innovating in power stability, portability, and automation. In this data-driven context, identifying the top seven manufacturers of 300-watt pulse laser cleaners becomes critical for businesses aiming to invest in scalable, reliable, and future-ready cleaning technology.

Top 7 300 Watt Pulse Laser Cleaner Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Argento Lux

Website: argentolux.com

Key Highlights: A-LUX 2000W-CW Laser Cleaning Machine. A-LUX 300W PulseLite Laser Cleaning Machine. A-LUX 500W-PW Laser Cleaning Machine. Unleash Precision, Unveil Perfection ……

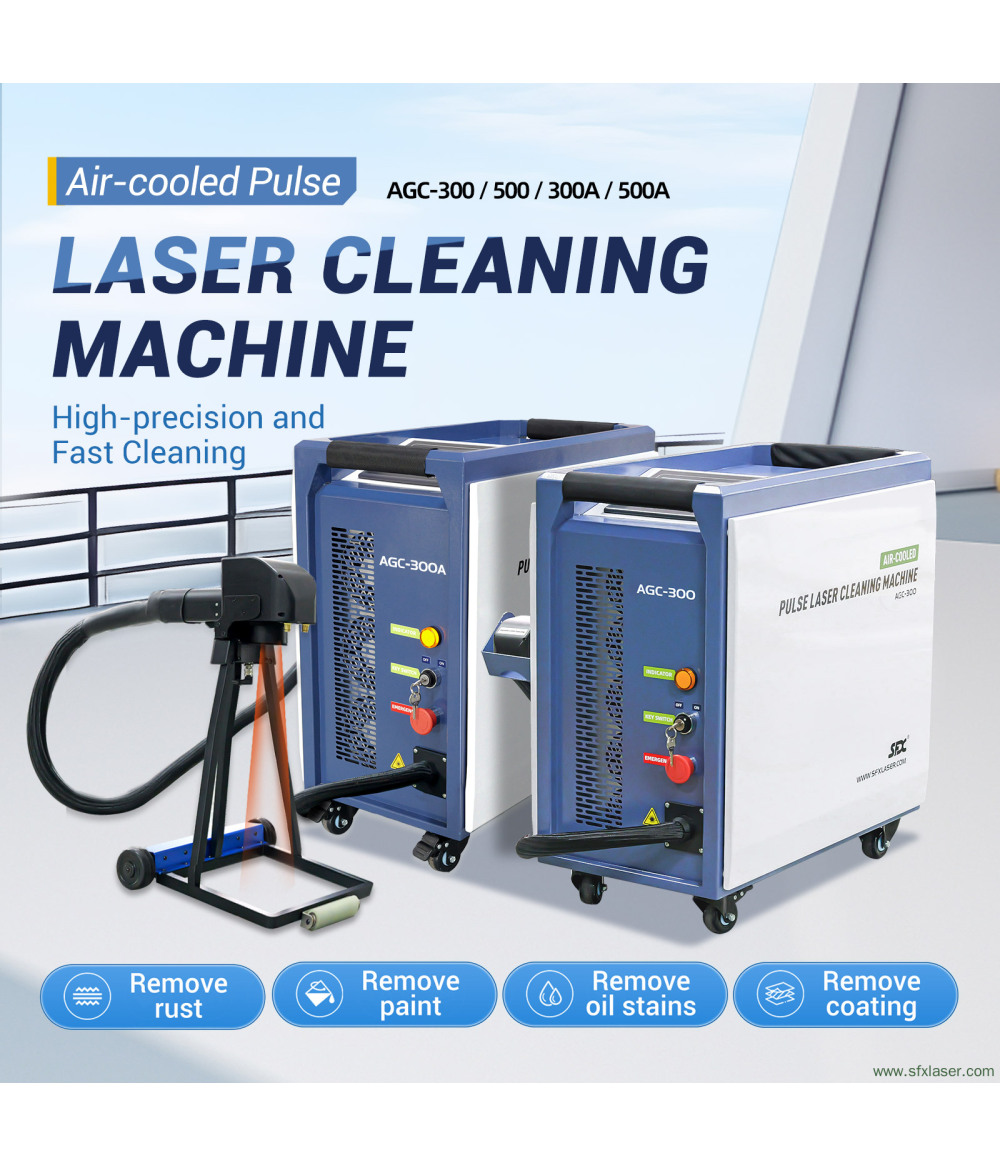

#2 US Stock SFX AGC 300W 500W Air Cooled Pulse Laser Cleaning …

Website: sfxlaser.com

Key Highlights: In stock Free delivery300W 500W pulse air cooled laser cleaning machine, non-contact remove rust paint oil stains coating. No damage to substrate. Anti-high-reflection technology….

#3 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: A 300W laser cleaner with a pulse energy of 12.5mJ is effective for cleaning rust and paint. It will cause no damage to the material’s surface. Conclusion….

#4 300W Pulse Laser Cleaning Machine

Website: nuwavelaser.com

Key Highlights: The Nuwave 300W Air Cooled Laser Cleaning Machine delivers powerful, precise, and eco-friendly surface cleaning. Designed for versatility, this Class IV ……

#5 BK

Website: baikeopto.com

Key Highlights: In stock300W Backpack Pulse Laser Cleaner Portable Laser Cleaning Machine for Metal Stone Brick Wood Machine Price for sale ; Maximum monopulse energy, 5mJ ; Power ……

#6 Fortune Laser Pulses 200W/300W Handheld Laser Cleaning Machine

Website: fortunelaser.com

Key Highlights: 200W 300W Laser Cleaning Machine Features: 22-inch trolley case control system: Built-in laser source, laser head and accessories; One-touch operation easy ……

#7 ZAC 300W 500W G

Expert Sourcing Insights for 300 Watt Pulse Laser Cleaner

H2: 2026 Market Trends for 300 Watt Pulse Laser Cleaners

As industrial automation, sustainability initiatives, and precision manufacturing continue to gain momentum globally, the market for 300-watt pulse laser cleaners is poised for significant evolution by 2026. These mid-power laser systems, known for their balance between cleaning efficiency and operational cost, are expected to see growing adoption across multiple high-value sectors. Below is an analysis of the key market trends shaping the demand, technology, and competitive landscape for 300-watt pulse laser cleaning systems in 2026.

1. Increased Adoption in Automotive and Aerospace Manufacturing

By 2026, the automotive and aerospace industries are projected to be leading adopters of 300-watt pulse laser cleaners. These sectors demand non-abrasive, eco-friendly surface preparation methods for coating removal, corrosion cleaning, and weld seam preparation. The precision and repeatability of 300-watt systems make them ideal for cleaning intricate parts without damaging substrates. Electric vehicle (EV) manufacturers, in particular, are investing in laser cleaning for battery component preparation and motor assembly, driving demand for standardized mid-power solutions.

2. Integration with Robotics and Smart Manufacturing

The rise of Industry 4.0 is accelerating the integration of 300-watt pulse laser cleaners into robotic automation platforms. By 2026, most new systems are expected to feature IoT connectivity, real-time monitoring, and AI-driven process optimization. These smart laser cleaning cells will be capable of adaptive cleaning based on surface condition feedback, improving efficiency and reducing energy consumption. Collaborative robots (cobots) equipped with 300W laser modules will become commonplace in small-to-mid-sized production facilities, lowering entry barriers for SMEs.

3. Environmental Regulations Driving Market Growth

Stricter global environmental regulations on chemical solvents and abrasive blasting are pushing industries toward cleaner alternatives. Pulse laser cleaning produces no secondary waste and eliminates the need for chemical degreasers, aligning with ESG (Environmental, Social, and Governance) goals. The European Union’s Green Deal and similar initiatives in North America and Asia-Pacific are expected to mandate eco-friendly cleaning processes, significantly boosting the market for 300-watt laser systems, which offer scalable and compliant solutions.

4. Cost Reduction and Improved Accessibility

Technological advancements in fiber laser sources and beam delivery systems are expected to reduce the total cost of ownership for 300-watt pulse laser cleaners by 2026. Increased competition among manufacturers in China, Germany, and the U.S. is driving price reductions and faster ROI timelines—now often under two years. Modular designs and plug-and-play systems will make these units more accessible to small manufacturers, expanding the customer base beyond large industrial players.

5. Expansion into New Applications and Industries

Beyond traditional metal cleaning, 300-watt pulse lasers are finding new applications in cultural heritage restoration, nuclear decommissioning, and semiconductor tool maintenance. Museums and conservation labs are adopting laser cleaning for delicate artifact restoration, while nuclear facilities use it for decontaminating radioactive surfaces. These niche applications are expected to contribute to market diversification and sustained growth.

6. Regional Market Dynamics

Asia-Pacific, led by China and Japan, will remain the largest market for 300-watt pulse laser cleaners due to rapid industrial modernization and government support for advanced manufacturing. North America will see strong growth driven by defense, aerospace, and EV sectors. Europe will maintain steady demand, supported by green manufacturing policies. Emerging markets in Southeast Asia and India are expected to increase procurement as laser-as-a-service (LaaS) models become more available.

7. Technological Advancements

By 2026, expect significant improvements in pulse control, beam quality, and cooling efficiency. Innovations such as adjustable pulse frequency, dual-wavelength systems, and handheld ergonomics will enhance versatility. Manufacturers are also focusing on improving user safety with better fume extraction integration and real-time emission monitoring.

Conclusion

The 300-watt pulse laser cleaner market in 2026 will be characterized by broader industrial adoption, deeper technological integration, and strong growth fueled by environmental and economic drivers. As these systems become more intelligent, affordable, and versatile, they will transition from niche tools to standard equipment in modern manufacturing and maintenance workflows. Companies investing in R&D, application-specific solutions, and sustainability compliance will be best positioned to capture market share in this evolving landscape.

H2: Common Pitfalls When Sourcing a 300W Pulse Laser Cleaner (Quality & IP)

Sourcing a 300W pulsed fiber laser cleaner requires careful evaluation to avoid significant quality, performance, and intellectual property (IP) risks. Key pitfalls include:

1. Overstated or Misleading Power Specifications (Quality)

* Pitfall: Suppliers may advertise “300W” based on peak pulse power (very high but instantaneous) rather than average power (the sustained cleaning power). A peak 300W laser might only deliver 80-150W average power, drastically reducing cleaning speed and effectiveness.

* Risk: Purchasing equipment incapable of handling the intended workload, leading to slow processing, incomplete cleaning, and project delays.

* Mitigation: Demand clear documentation specifying Average Output Power (W) under continuous operation. Verify using calibrated power meters if possible. Understand the relationship between peak power, pulse energy, frequency, and average power.

2. Poor Beam Quality & Unreliable Pulse Control (Quality)

* Pitfall: Low-cost lasers often have poor beam quality (high M² factor), unstable pulse durations, inconsistent pulse energy, or inaccurate pulse frequency. This results in uneven cleaning, potential substrate damage (burning, melting), and inability to handle varied materials effectively.

* Risk: Inconsistent cleaning results, damage to valuable parts, inability to meet process specifications, and high rework rates.

* Mitigation: Require specifications for Beam Parameter Product (BPP) or M², pulse energy stability (< ±5%), pulse duration range/accuracy, and frequency stability. Request test reports or conduct material trials.

3. Inadequate Cooling & Thermal Management (Quality)

* Pitfall: 300W generates significant heat. Units with undersized or inefficient cooling (air or water) will experience thermal drift, power fluctuations, reduced component lifespan (especially the laser diode and optics), and potential shutdowns during prolonged use.

* Risk: Unreliable operation, frequent downtime, premature failure of expensive components, and safety hazards.

* Mitigation: Inspect cooling system design (radiator size, pump quality for water cooling, fan capacity for air). Demand specifications for maximum continuous operating time and operating temperature range. Ensure adequate thermal protection.

4. Substandard Optics & Scanner Components (Quality)

* Pitfall: Using low-grade lenses, protective windows, or galvanometer scanners leads to rapid degradation, contamination, beam distortion, and focus drift. This directly impacts cleaning precision, speed, and consistency.

* Risk: Degraded performance over short periods, frequent and costly optic replacements, inconsistent spot size/depth of focus, safety risks from damaged optics.

* Mitigation: Verify the material (e.g., fused silica), coating specifications (laser damage threshold, AR coating), and brand/reputation of scanner motors and drivers. Ensure easy access for cleaning/replacement.

5. Lack of Genuine IP Protection & Risk of Copying (IP)

* Pitfall: Many suppliers, particularly in certain regions, offer near-identical systems with ambiguous origins. There’s a high risk of purchasing equipment that infringes on patents (optics design, control algorithms, scanner integration) or contains copied software/firmware.

* Risk: Legal liability for patent infringement, potential seizure of equipment, reputational damage, forced discontinuation of use, and lack of support if the original IP holder takes action.

* Mitigation: Conduct due diligence on the supplier’s reputation and history. Ask directly about IP ownership and patent licenses. Prefer suppliers with transparent R&D backgrounds and established brands. Be wary of prices significantly below market average.

6. Opaque Software & Hidden Costs (IP & Quality)

* Pitfall: Proprietary software may lack transparency, contain restrictive licensing, or have hidden fees for updates, support, or essential features. Firmware could be locked or unmodifiable.

* Risk: Vendor lock-in, inability to integrate with existing systems (MES/PLC), unexpected long-term costs, limited troubleshooting capability, and potential security vulnerabilities.

* Mitigation: Demand details on software licensing terms, update policies, API availability, and source code access (if critical). Test software usability and integration capabilities during evaluation.

7. Inadequate Safety Certification & Documentation (Quality & IP)

* Pitfall: Equipment may lack essential safety certifications (e.g., CE, FDA, IEC 60825) or proper technical documentation (manuals, schematics, compliance reports). Documentation might be incomplete or in a language not understood.

* Risk: Safety hazards to operators, non-compliance with workplace regulations, difficulty obtaining insurance, import/export issues, and challenges with maintenance/troubleshooting.

* Mitigation: Require proof of valid, relevant safety certifications. Ensure comprehensive, clear technical documentation is provided in your language before purchase.

By proactively addressing these pitfalls through rigorous supplier vetting, demanding transparent specifications, and conducting thorough testing, buyers can significantly increase their chances of acquiring a reliable, high-performance, and legally compliant 300W pulsed laser cleaner.

Certainly. Below is a comprehensive Logistics & Compliance Guide for the international shipment and regulatory handling of a 300 Watt Pulse Laser Cleaner, using Hydrogen (H₂) as part of the operational or support system (e.g., for cooling, power generation, or auxiliary functions). This guide is structured to ensure safe, legal, and efficient transport and use of the equipment across jurisdictions.

Note: While most 300W pulse laser cleaners do not inherently use hydrogen, this guide assumes H₂ is used in an ancillary system (e.g., hydrogen fuel cell for off-grid power, or cooling system). If the laser cleaner does not use H₂, this guide should be revised accordingly.

🌐 Logistics & Compliance Guide: 300W Pulse Laser Cleaner with Hydrogen (H₂) System

1. Overview of Equipment

- Product: 300W Pulse Laser Cleaner

- Primary Function: Surface cleaning (rust, paint, oxide removal) via pulsed laser beam

- Laser Type: Fiber or Nd:YAG pulsed laser, Class 4 laser product

- Auxiliary System: Hydrogen (H₂) used in fuel cell or cooling system (specify if pressurized gas or generated on-site)

- Power Source: May include battery, AC/DC input, or H₂ fuel cell

- Weight: ~20–50 kg (varies by model)

- Dimensions: ~40 x 30 x 60 cm (typical portable unit)

2. Key Regulatory Classifications

A. Laser Safety Classification (IEC 60825-1 / FDA 21 CFR 1040.10)

- Class: Class 4 Laser Product (high power, capable of causing skin/eye injury and fire hazard)

- Compliance Requirements:

- IEC 60825-1 (International)

- FDA 21 CFR 1040.10 (USA)

- EN 60825-1 (EU)

- Requires:

- Safety interlocks

- Emission indicator (laser active light)

- Protective housing

- User manual with safety warnings

- Certification label

✅ Action: Ensure manufacturer provides full compliance documentation and CE/FDA markings.

B. Hydrogen (H₂) Handling & Transport Classification (UN/DOT/ADR/IMDG)

- UN Number: UN 1049 (Hydrogen, compressed)

- Hazard Class: 2.1 (Flammable Gas)

- Packing Group: I (high hazard)

- Transport Labels: Flammable Gas (2.1), Non-toxic

- Regulatory Frameworks:

- DOT (USA): 49 CFR

- ADR (Europe): Road transport

- IMDG Code: Sea transport

- IATA DGR: Air transport

⚠️ Note: Hydrogen is prohibited on passenger aircraft (IATA) unless in very limited quantities (e.g., in fuel cells under special provisions). Air shipment is highly restricted.

3. Packaging & Marking Requirements

A. Laser Cleaner Unit

- Packaging: Double-walled cardboard or wooden crate with internal foam/polyethylene cushioning

- Markings:

- “FRAGILE”

- “THIS SIDE UP”

- “CLASS 4 LASER PRODUCT – AVOID EXPOSURE TO BEAM”

- CE, FCC, RoHS, and other regional compliance marks

- Manufacturer info, model, serial number

B. Hydrogen Component (if applicable)

- Scenario 1: Pressurized H₂ Cylinder

- Must be UN-certified pressure vessel (e.g., DOT-3AL, ISO 11119)

- Valve protection cap secured

- Transported upright, secured against movement

- Label: UN 1049, Class 2.1, “FLAMMABLE GAS”

-

Accompanied by Safety Data Sheet (SDS)

-

Scenario 2: Integrated Fuel Cell (Non-removable H₂)

- Must comply with IEC 62282 or IEC 60079 (for explosive atmospheres)

- May be approved under Special Provision A193 (IATA) or Special Provision 312 (ADR) for fuel cell cartridges

- No free H₂; system must be purged and certified “non-hazardous” for transport

✅ Best Practice: Use hydrogen-absorbing metal hydride storage if possible — often exempt from full hazard classification under certain conditions.

4. Transportation Guidelines

| Mode | Restrictions | Notes |

|——|————–|——-|

| Air (IATA) | ❌ H₂ cylinders generally prohibited

✅ Fuel cells with ≤ 12g H₂ may be allowed (SP A193) | Must be installed in equipment or packed separately. Passenger aircraft: max 1 spare. |

| Sea (IMDG) | ✅ Allowed with proper documentation

⚠️ Requires segregation from oxidizers | Use container with ventilation; avoid high temps |

| Road (ADR/Europe) | ✅ Allowed with certified tank/cylinder

⚠️ Tunnel restrictions (Class E) may apply | Driver must have ADR certification |

| Rail (RID) | ✅ Similar to ADR | Requires proper packaging and labeling |

5. Documentation Required

- Commercial Invoice (with HS code, value, origin)

- Packing List

- Bill of Lading / Air Waybill

- Safety Data Sheet (SDS) – For H₂ system (if applicable)

- Laser Compliance Certificate (IEC 60825-1, FDA, etc.)

- Certificate of Conformity (CoC) – For CE, UKCA, or other regional marks

- Dangerous Goods Declaration – If shipping H₂ (UN 1049)

- Export License – May be required for laser systems under dual-use regulations (see below)

6. Export Controls & Dual-Use Regulations

- Laser systems >1W may fall under dual-use export controls:

- Wassenaar Arrangement: 6A003.b (Laser systems for material processing)

- US: EAR (BIS) – ECCN 6A003.b.4 (Lasers, pulsed, avg. power >1W)

- EU: Dual-Use Regulation (EU) 2021/821 – Category 6A003

- UK: UKML1d (Military List) or dual-use list

✅ Action:

– Determine if export license is required based on destination country

– Countries like Iran, North Korea, Russia may require strict controls

– File through national export authority (e.g., BIS in USA, SPIRE in UK)

7. Import Compliance by Region

| Region | Key Requirements |

|——–|——————|

| USA | – FDA laser registration

– FCC compliance (if electronic emissions)

– ISF filing (10+2) for sea cargo |

| EU | – CE marking (LVD, EMC, RoHS, RED if wireless)

– EN 60825 compliance

– Battery directive (if applicable) |

| UK | – UKCA marking (post-Brexit)

– HSE laser safety guidance |

| China | – CCC mark (may not apply to industrial lasers)

– Laser product registration with NMPA |

| Canada | – Health Canada laser safety compliance (SOR/2014-245)

– ISED for EMC |

8. On-Site Safety & User Compliance

A. Laser Safety

- Use in controlled environment (enclosed booth or safety perimeter)

- Mandatory PPE: Laser safety goggles (OD 5+ at 1064 nm)

- Training per ANSI Z136.1 (USA) or IEC 60825 (international)

- Interlock systems and emergency stop

B. Hydrogen Safety

- Store H₂ in well-ventilated, fire-rated area

- No ignition sources within 3m

- Leak detection system recommended

- Follow CGA G-5.5 (Compressed Gas Association) guidelines

- Grounding of equipment to prevent static discharge

9. Environmental & Disposal Compliance

- Laser Unit: RoHS compliant – no Pb, Cd, Hg

- Batteries (if any): Follow UN 38.3 testing; dispose as hazardous waste (e.g., Li-ion)

- H₂ Cylinders: Return to supplier or recycle via certified gas handler

- End-of-Life: WEEE compliance in EU; proper e-waste recycling

10. Checklist for Shipment

✅ Laser compliance certificate (IEC/FDA)

✅ SDS for H₂ system (if applicable)

✅ Proper packaging and labeling (Class 4 Laser + H₂ hazard)

✅ Dangerous Goods Declaration (if shipping H₂)

✅ Export license (if required by destination)

✅ Commercial documents (invoice, packing list, BOL)

✅ ADR/IATA training for personnel (if handling H₂)

✅ Notify carrier in advance of hazardous content

11. Recommended Carriers & Handling Partners

- DHL Express / FedEx – For non-H₂ components; check H₂ restrictions

- DB Schenker, Kuehne + Nagel – Specialized in dangerous goods logistics

- Linde, Air Liquide – For H₂ cylinder handling and compliance support

12. Summary: Key Risks & Mitigation

| Risk | Mitigation |

|——|———–|

| Fire/explosion from H₂ | Use leak-proof systems; avoid sparks; ventilate |

| Laser injury | Enclose beam path; use interlocks; train users |

| Customs delays | Provide full compliance docs; classify correctly |

| Export violations | Verify ECCN/license requirements before shipment |

| Transport rejection | Ensure packaging meets IATA/ADR/IMDG standards |

🔚 Conclusion

The 300W Pulse Laser Cleaner with H₂ support system requires careful handling due to its Class 4 laser and flammable gas components. Compliance with laser safety standards, dangerous goods transport regulations, and export controls is essential. Always verify local regulations and work with certified logistics providers experienced in hazardous and dual-use goods.

📞 Recommendation: Consult a regulatory compliance specialist or dangerous goods safety advisor (DGSA) before international shipment.

Prepared in accordance with IEC 60825, IATA DGR 64th Ed., ADR 2023, and global dual-use control lists (as of 2024).

Conclusion: Sourcing a 300-Watt Pulse Fiber Laser Cleaner

After thorough evaluation of technical specifications, supplier reliability, market availability, and cost-effectiveness, sourcing a 300-watt pulsed fiber laser cleaner presents a strong value proposition for industrial cleaning applications. This power range offers an optimal balance between performance and operational efficiency, enabling effective removal of rust, paint, oxides, and contamination from metals, without damaging the underlying substrate.

Key advantages include enhanced cleaning speed, precision, and reduced environmental impact compared to traditional methods such as sandblasting or chemical cleaning. The pulsed output allows greater control over heat input, making it ideal for sensitive materials and intricate surfaces.

Suppliers from leading manufacturers in China—such as Raycus, JPT, and Max Photonics—offer competitive pricing and proven reliability for 300W pulse laser sources. Integration into customized cleaning systems or existing production lines is feasible with available modular designs and technical support.

In conclusion, investing in a 300-watt pulsed fiber laser cleaner is a strategic decision for businesses aiming to improve cleaning efficiency, reduce long-term maintenance costs, and align with sustainable manufacturing practices. Due diligence in selecting a reputable supplier with after-sales support will ensure maximum uptime and return on investment.