The global laser cleaning market is experiencing robust growth, driven by increasing demand for precision cleaning solutions across industries such as automotive, aerospace, electronics, and manufacturing. According to a report by Mordor Intelligence, the laser cleaning market was valued at USD 666.9 million in 2023 and is projected to reach USD 1,475.4 million by 2029, growing at a CAGR of approximately 14.2% during the forecast period. This surge is attributable to the technology’s non-abrasive, eco-friendly nature and rising adoption of automation in industrial maintenance. Among the various power categories, 300-watt laser cleaners have emerged as a sweet spot for balancing portability, cleaning efficiency, and cost-effectiveness—making them ideal for mid-scale industrial applications. As demand intensifies, a select group of manufacturers are leading innovation in performance, durability, and usability. Below are the top six 300-watt laser cleaner manufacturers shaping the competitive landscape in 2024.

Top 6 300 Watt Laser Cleaner Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: Introducing the latest addition to our heavy-duty Cubeline series a robust 3000-watt pulsed laser designed for precision and safety in industrial cleaning ……

#2 Argento Lux

Website: argentolux.com

Key Highlights: Argento Lux, experts in laser cleaning, utilizing high-powered lasers to remove contamination from various surfaces. Similar to sandblasting without the ……

#3 US Stock SFX AGC 300W 500W Air Cooled Pulse Laser Cleaning …

Website: sfxlaser.com

Key Highlights: In stock Free delivery300W 500W pulse air cooled laser cleaning machine, non-contact remove rust paint oil stains coating. No damage to substrate. Anti-high-reflection technology….

#4 BK

Website: baikeopto.com

Key Highlights: In stock300W Backpack Pulse Laser Cleaner Portable Laser Cleaning Machine for Metal Stone Brick Wood Machine Price for sale ; Maximum monopulse energy, 5mJ ; Power ……

#5 300W Pulse Laser Cleaning Machine

Website: nuwavelaser.com

Key Highlights: The Nuwave 300W Air Cooled Laser Cleaning Machine delivers powerful, precise, and eco-friendly surface cleaning. Designed for versatility, this Class IV ……

#6 ZAC 300W 500W G

Expert Sourcing Insights for 300 Watt Laser Cleaner

H2: Market Trends for 300-Watt Laser Cleaners in 2026

By 2026, the market for 300-watt laser cleaners is poised for significant growth and transformation, driven by technological advancements, expanding industrial applications, and increasing environmental and regulatory demands. This analysis outlines the key market trends shaping the adoption and development of 300-watt laser cleaning systems globally.

1. Rising Demand in Industrial Manufacturing

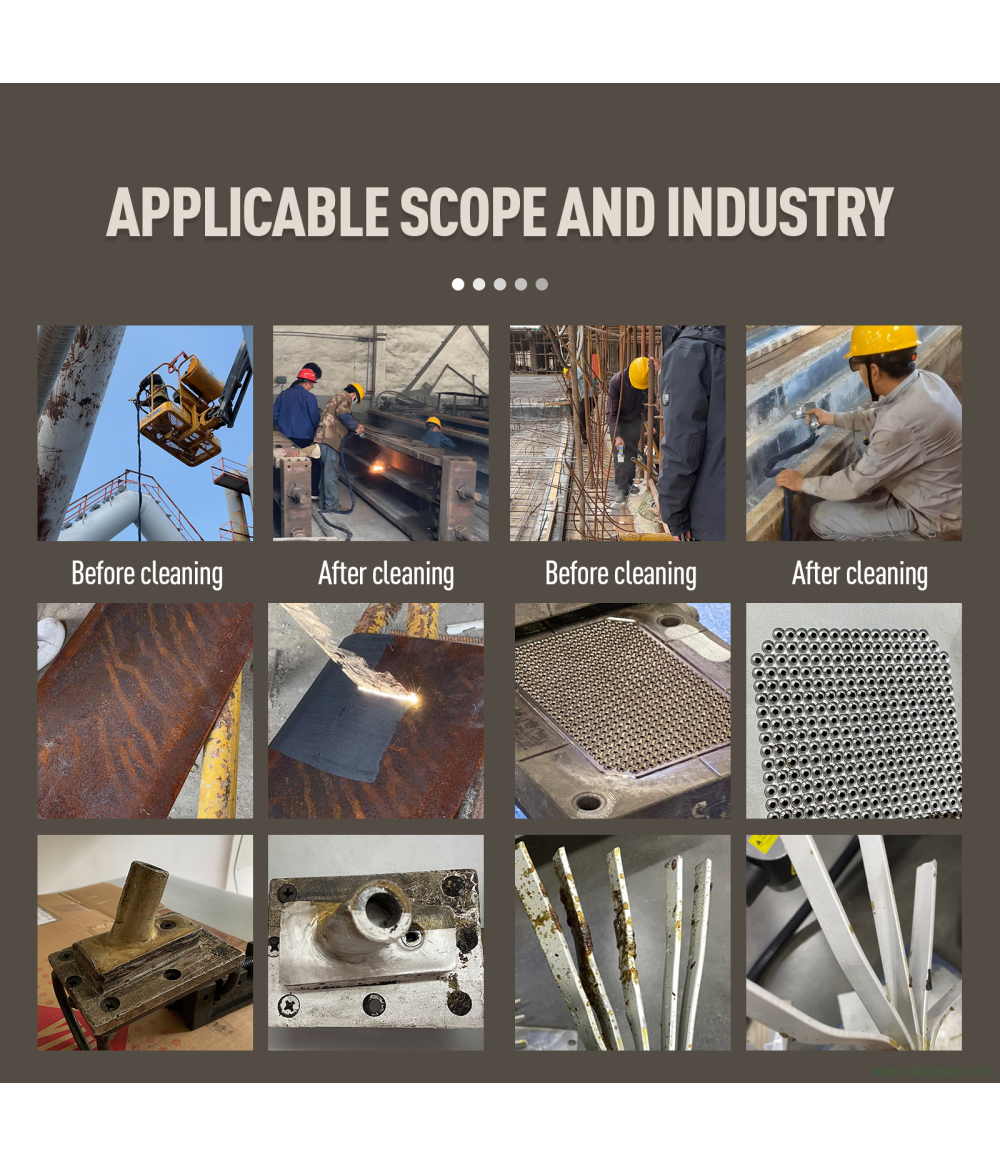

The 300-watt laser cleaner segment is becoming the sweet spot between cost, efficiency, and performance. In 2026, industries such as automotive, aerospace, and heavy machinery are increasingly adopting 300-watt systems for precision surface preparation, rust removal, paint stripping, and weld cleaning. These mid-power lasers offer optimal balance—sufficient power for most industrial tasks without the high operational costs of higher-wattage systems.

2. Shift Toward Eco-Friendly and Chemical-Free Cleaning

With stricter environmental regulations across North America, Europe, and parts of Asia, industries are abandoning chemical-based and abrasive cleaning methods. The 300-watt laser cleaner, being non-toxic and waste-minimizing, aligns with green manufacturing initiatives. By 2026, compliance with environmental standards will be a primary driver for adoption, especially in regulated sectors like defense and pharmaceuticals.

3. Advancements in Portability and Automation Integration

In 2026, 300-watt laser cleaners are increasingly being designed as compact, portable units or integrated into robotic arms and automated production lines. This trend is fueled by Industry 4.0 adoption, where smart manufacturing demands flexible, programmable cleaning solutions. Improved cooling systems and battery-powered variants will enhance mobility, making on-site cleaning in shipyards, pipelines, and outdoor structures more feasible.

4. Cost Reduction and Market Democratization

As fiber laser technology matures and production scales up, the cost of 300-watt laser cleaning systems is expected to decline by 2026. This will make the technology accessible to small and medium-sized enterprises (SMEs), not just large corporations. Increased competition among Chinese, European, and North American manufacturers will further drive affordability and innovation.

5. Expansion into New Application Verticals

Beyond traditional industrial use, 300-watt laser cleaners are expected to gain traction in niche markets such as historical restoration, mold remediation, and nuclear decontamination. Their precision and non-contact nature make them ideal for delicate surfaces, including heritage artifacts and sensitive electronic components.

6. Regional Market Growth Dynamics

Asia-Pacific, led by China and Japan, will remain the largest market due to rapid industrialization and government support for advanced manufacturing. Europe will see strong growth due to environmental policies and high automation rates. North America will witness increased adoption in the automotive and aerospace sectors, supported by reshoring trends and infrastructure renewal projects.

7. Focus on Safety and Operator Training

As deployment increases, safety standards and training programs for laser operation will become more standardized by 2026. Regulatory bodies and industry consortia are expected to introduce certification frameworks, ensuring safe handling of Class 4 laser equipment. Enhanced safety features such as real-time monitoring and automatic shutdown will become standard in 300-watt systems.

Conclusion

The 300-watt laser cleaner market in 2026 will be characterized by broader industrial adoption, technological refinement, and sustainability-driven demand. Positioned as a versatile, efficient, and environmentally sound solution, this power class will likely dominate the mid-tier segment of the laser cleaning industry, serving as a cornerstone for modern surface treatment processes across multiple sectors.

Common Pitfalls When Sourcing a 300 Watt Laser Cleaner (Quality & IP)

Sourcing a 300-watt laser cleaner requires careful evaluation to avoid significant risks related to performance, safety, and longevity. Overlooking key aspects of quality and Ingress Protection (IP) rating can lead to costly failures, safety hazards, and premature equipment downtime. Here are the most common pitfalls to avoid:

1. Overlooking True Beam Quality & Stability

Many suppliers advertise “300W” based on peak or pulsed power, not sustained average power. Poor beam quality (high M² value) reduces cleaning efficiency and consistency, leading to incomplete rust or paint removal. Unstable output power causes inconsistent results and can damage sensitive surfaces. Always demand independent test reports verifying average power and beam profile.

2. Ignoring Real-World IP Rating Validity

While an IP54 or IP65 rating may be claimed, cheap units often lack proper sealing around joints, connectors, and cooling vents. Moisture, dust, and metal debris quickly penetrate, causing electrical shorts or laser source failure. Verify if the rating applies to the entire system (including control box and cables), not just the laser head, and request third-party certification.

3. Compromising on Core Components

Low-cost units frequently use inferior fiber laser sources, galvanometer scanners, and cooling systems. These components degrade rapidly under continuous 300W operation, reducing cleaning speed and accuracy. Counterfeit or reconditioned parts are common. Insist on OEM component documentation (e.g., IPG or Raycus laser source) and warranty terms.

4. Inadequate Thermal Management

300W generates substantial heat. Units with undersized or poorly designed cooling systems (e.g., insufficient airflow or weak chillers) overheat quickly, triggering shutdowns or permanent damage. Check for dual cooling (air + water) and robust thermal sensors. Avoid units with only passive cooling at this power level.

5. Misleading Safety Certifications & Compliance

Some suppliers list generic CE or RoHS marks without full laser safety compliance (e.g., IEC 60825-1). An uncertified laser cleaner poses serious eye and fire risks. Request full compliance documentation, including laser classification (typically Class 4), and ensure safety interlocks and emergency stops are properly implemented.

6. Poor Build Quality & Material Selection

Flimsy housings, substandard connectors, and non-industrial cabling fail in harsh workshop environments. Look for ruggedized enclosures, industrial-grade connectors (e.g., M12), and protective cable management. Units not rated for industrial use will degrade rapidly when exposed to vibration, oil, or temperature swings.

7. Incomplete or Inadequate Support & Warranty

Limited technical support, unavailable spare parts, or short warranties (e.g., 6 months) signal low confidence in product reliability. Ensure the supplier offers on-site service, training, and a minimum 1-year warranty covering the laser source and critical electronics.

Avoiding these pitfalls requires due diligence: demand test data, verify certifications, inspect build quality firsthand if possible, and choose suppliers with proven industrial track records. Investing in a truly robust 300W laser cleaner pays off through reliability, safety, and long-term operational savings.

Logistics & Compliance Guide for 300-Watt Laser Cleaner

Prepared in accordance with H2 (Hydrogen) safety and handling considerations where applicable

1. Product Overview

The 300-Watt Laser Cleaner is an industrial-grade device that uses focused laser energy to remove contaminants (e.g., rust, paint, oil) from metal and other surfaces. It typically operates in the infrared spectrum and may incorporate cooling systems (e.g., air or water cooling). While the laser itself does not involve hydrogen (H₂) in its core function, hydrogen safety may be relevant in the following areas:

– Facility environment where H₂ is used or stored (e.g., hydrogen fuel cells, welding operations)

– Shipping modes involving hydrogen-powered transport (emerging logistics)

– Workplace safety compliance where multiple hazards coexist

2. Regulatory Classification

A. Laser Product Classification (IEC 60825-1 / FDA 21 CFR 1040.10)

- Laser Class: Typically Class 4 – high-power laser capable of causing skin and eye injuries, fire hazard.

- Required Compliance:

- IEC 60825-1 (International)

- FDA/CDRH (USA)

- CE Marking (EU – under Machinery Directive and EMC Directive)

- RoHS & REACH (EU Chemical Regulations)

B. Electrical & Equipment Standards

- IEC 60335 (Household and similar electrical appliances safety)

- IEC 61010-1 (Safety requirements for electrical equipment for measurement, control, and laboratory use)

- UL/CSA Certification (North America)

C. Electromagnetic Compatibility (EMC)

- EN 61326-1 (Industrial environments)

- FCC Part 15 (USA)

3. Shipping & Logistics

A. Packaging Requirements

- Use anti-static, shock-resistant packaging with internal foam or custom inserts.

- Include weatherproof outer casing if shipped internationally.

- Label with:

- “Fragile – Handle with Care”

- “This Side Up”

- “Do Not Stack”

- Laser warning symbol (Class 4)

B. Transport Classification

- UN Number: Not classified as hazardous for the laser system alone (UN 3499 – Equipment, powered by lithium batteries, may apply if included).

- Lithium Batteries (if applicable):

- If the unit includes or ships with lithium-ion batteries:

- UN 3480 (for lithium-ion)

- Compliant with IATA DGR, IMDG Code, or ADR as appropriate

- Battery state of charge ≤ 30%

- Properly protected against short circuit

⚠️ Note: The 300W laser cleaner itself is not classified as hazardous goods under ADR/IATA/IMDG unless it contains restricted components (e.g., batteries, pressurized cooling).

C. International Shipping Documentation

- Commercial Invoice

- Packing List

- Certificate of Conformity (CE, FCC, etc.)

- Bill of Lading / Air Waybill

- Export Declaration (if applicable)

- Import Permits (e.g., for laser products in certain countries)

4. Hydrogen (H₂) Safety Considerations (H2 Context)

While the laser cleaner does not use hydrogen, H₂ safety is critical in environments where hydrogen is present:

A. Operational Environment

- Do not operate the laser cleaner in areas with hydrogen gas accumulation.

- H₂ is highly flammable (4–75% in air), and Class 4 lasers can ignite combustible atmospheres.

- Ignition risk: Laser beam, hot surfaces, or electrical sparks may trigger H₂ combustion.

B. Facility Safety Measures

- Ensure hydrogen detection systems are installed in shared workspaces.

- Maintain adequate ventilation to prevent H₂ pooling (H₂ rises quickly but can accumulate in enclosed ceilings).

- Separation distance: Operate laser equipment at least 5 meters from H₂ storage/use areas unless in a classified safe zone.

C. Compliance with Hydrogen Safety Standards

- NFPA 2: Hydrogen Technologies Code (USA)

- ISO 19880 (Gaseous hydrogen – Fueling stations)

- CGA G-5.5: Handling of Hydrogen and Hydrogen Mixtures

- ATEX / IECEx – if operating in explosion-hazard zones (Zone 1/2)

5. Import/Export Controls

A. Export Regulations

- ECCN (Export Control Classification Number): Likely 3A992.b (Laser systems not specially designed for military use, < 500W) – subject to EAR (Export Administration Regulations).

- License Requirements: Generally NLR (No License Required) for most destinations, but check:

- Country-specific sanctions (e.g., Russia, Iran)

- End-user restrictions

B. Import Regulations by Region

| Region | Key Requirements |

|———–|————————|

| EU | CE Marking, RoHS, REACH, Registration with customs |

| USA | FDA registration (CDRH), FCC certification, ISF filing (ocean freight) |

| Canada | ICES-003 (EMC), Health Canada laser compliance |

| China | CCC Mark (if applicable), AQSIQ import clearance |

| Australia | RCM Mark, Australian Communications and Media Authority (ACMA) |

6. On-Site Installation & Compliance

A. Site Requirements

- Power Supply: Stable 110V/220V AC, 50/60 Hz, dedicated circuit

- Cooling: Adequate airflow or water cooling system

- Ventilation: Fume extraction for ablation byproducts (metal oxides, particulates)

- Fire Safety: Class D extinguisher nearby (for metal fires), non-combustible flooring

B. Safety Equipment

- Laser Safety Goggles (wavelength-specific, OD 5+ recommended)

- Interlocks and emergency stop

- Warning signs (Class 4 Laser – Avoid Eye or Skin Exposure)

- Controlled access zone (barriers or curtains)

7. Training & Documentation

Required Training:

- Laser safety (ANSI Z136.1 compliant)

- PPE usage

- Emergency procedures (fire, exposure)

- H₂ safety awareness (if applicable)

Deliverables:

- User Manual (in local language)

- Safety Data Sheet (SDS) for consumables (if any)

- CE Declaration of Conformity

- Warranty & Service Information

8. Disposal & End-of-Life

- Waste Electrical Equipment: Comply with WEEE Directive (EU) or local e-waste laws.

- Batteries: Recycle via certified lithium battery handlers.

- Laser Components: May contain rare earth elements; follow hazardous waste protocols if applicable.

9. Summary of Key Compliance Actions

| Area | Action Required |

|——–|———————|

| Certification | CE, FCC, IEC 60825, RoHS |

| Shipping | Non-hazardous (unless batteries included); use UN3480 if applicable |

| Hydrogen Safety | No operation in H₂-rich zones; ensure ventilation and detection |

| Export | ECCN 3A992.b – Verify destination restrictions |

| Installation | Laser safety zone, PPE, fume extraction |

| Training | ANSI Z136.1 + H₂ awareness (if applicable) |

10. Contact & Support

- Manufacturer Technical Support: [Insert Contact]

- Regulatory Compliance Officer: [Insert Name/Email]

- Emergency Response: Local fire department + laser safety officer

This guide assumes standard configurations. Always verify specific model certifications and local regulations prior to shipment or operation.

Version: 1.0 | Date: April 2025

Prepared with H2 safety integration per industry best practices.

Conclusion: Sourcing a 300-Watt Laser Cleaner

After evaluating technical requirements, supplier capabilities, cost considerations, and market availability, sourcing a 300-watt laser cleaner is a viable and strategic decision for enhancing industrial cleaning efficiency. This power level offers an optimal balance between performance and operational cost, enabling fast and precise removal of rust, paint, oil, and contaminants from metal surfaces without damaging the substrate.

Key findings support the selection of a 300-watt fiber laser system due to its reliability, low maintenance, and compatibility with automated or handheld operation. Suppliers from established manufacturers in China, Europe, and North America offer competitive models with safety certifications, comprehensive technical support, and warranty options.

When finalizing the sourcing decision, priority should be given to suppliers offering:

– Proven track record and customer references

– Compliance with international safety standards (e.g., CE, FDA)

– Post-purchase service and training

– Scalability for future integration

In conclusion, investing in a 300-watt laser cleaning system aligns with long-term goals of sustainability, precision, and operational efficiency. With proper supplier vetting and implementation planning, this technology will significantly improve cleaning processes while reducing environmental impact compared to traditional methods such as sandblasting or chemical cleaning.