The global lamp socket market is experiencing steady growth, driven by rising demand for energy-efficient lighting solutions and expanding infrastructure in residential, commercial, and industrial sectors. According to Mordor Intelligence, the global lighting market—of which lamp sockets are a critical component—is projected to grow at a CAGR of approximately 6.5% from 2024 to 2029. This growth is fueled by technological advancements in LED lighting, increased smart lighting adoption, and growing emphasis on sustainable building practices. Within this landscape, 3-terminal lamp sockets have gained prominence due to their enhanced safety features and compatibility with grounded lighting fixtures, particularly in commercial and industrial applications. As demand rises, a select group of manufacturers have emerged as leaders in innovation, quality, and global distribution. Below, we spotlight the top nine manufacturers shaping the 3-terminal lamp socket market through proven performance, compliance with international standards, and strong supply chain networks.

Top 9 3 Terminal Lamp Socket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sockets

Domain Est. 1996

Website: satco.com

Key Highlights: SATCO® is a leading supplier of lighting products, offering solutions for commercial, residential, and industrial markets. Read more About us. Our Company….

#2 Sockets

Domain Est. 1996

#3 SATCO® 90

Domain Est. 1996

Website: stateelectric.com

Key Highlights: In stock Rating 5.0 6 SATCO® 90-1548 2-Circuit Turn 3-Terminal Lamp Socket, 75 W Lamp, 600 VAC, Bi-Pin G24d-3/GX24d-3 Fluorescent Lamp….

#4 3

Domain Est. 1997

#5 Lamp Sockets

Domain Est. 1999

Website: bplampsupply.com

Key Highlights: Lamp Sockets, B&P Lamp Supply is the #1 source for wholesale lamp parts and lighting hardware. We offer reproduction antique lamp parts and antique lighting ……

#6 Lamp Sockets

Domain Est. 2001

Website: us.rs-online.com

Key Highlights: Shop lamp sockets at RS. Find the right lamp receptacle and light sockets for your lighting projects. Get the parts you need – browse and buy now….

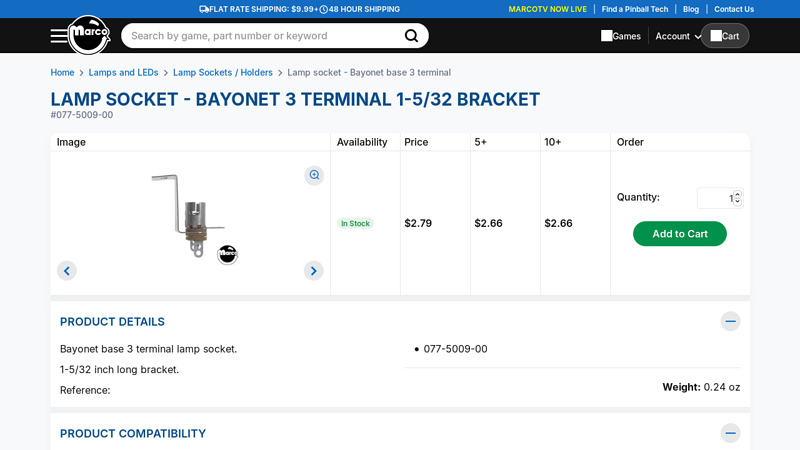

#7 077

Domain Est. 2004

Website: marcospecialties.com

Key Highlights: Bayonet base 3 terminal lamp socket. 1-5/32 inch long bracket. Reference: Weight: 0.24 oz Product compatibility Data East Stern…

#8 3

Domain Est. 2015

Website: prolampsales.com

Key Highlights: 6-day delivery 30-day returnsSave on 3-Pin sockets/lampholders at ProLampSales.com. Find the 3-Pin light socket you need today. Low prices, fast shipping, great service on all 3-Pi…

#9 Lamp Socket

Domain Est. 1996

Website: doitbest.com

Key Highlights: 2-day deliveryBest Lamp Socket at a hardware store near you. Buy Leviton, Jandorf, Eaton Lamp & Fixture Parts at lowest prices. Pick up in-store or get fast delivery….

Expert Sourcing Insights for 3 Terminal Lamp Socket

H2: 2026 Market Trends for 3 Terminal Lamp Socket

The global market for 3 terminal lamp sockets is poised for steady growth and transformation by 2026, driven by advancements in lighting technology, rising energy efficiency standards, and increased demand across residential, commercial, and industrial sectors. This analysis outlines key trends shaping the 3 terminal lamp socket market through 2026 under the H2 framework—highlighting key drivers, challenges, opportunities, and regional dynamics.

-

H2: Technological Advancements and Smart Integration

A major trend influencing the 3 terminal lamp socket market is the integration with smart lighting systems. As the Internet of Things (IoT) gains traction, lamp sockets—including 3 terminal variants—are being redesigned to support smart controls, dimming functions, and compatibility with LED drivers and wireless protocols (e.g., Zigbee, Bluetooth, Wi-Fi). Manufacturers are incorporating enhanced electrical safety features and improved heat resistance to accommodate high-output LED lamps, which are increasingly replacing traditional incandescent and halogen bulbs. -

H2: Regulatory Pressure and Energy Efficiency Standards

Global regulations promoting energy-efficient lighting—such as the EU Ecodesign Directive and U.S. Department of Energy standards—are accelerating the shift toward LED-compatible infrastructure. The 3 terminal lamp socket, often used in high-intensity discharge (HID) and industrial lighting applications, is being adapted to meet stricter safety and performance benchmarks. Compliance with IEC and UL standards is now a market prerequisite, pushing manufacturers to innovate in materials (e.g., ceramic, high-temperature thermoplastics) and design for better durability and electrical insulation. -

H2: Expansion in Industrial and Commercial Applications

The 3 terminal lamp socket remains critical in industrial lighting setups, including warehouses, factories, and outdoor installations, where robustness and reliability are paramount. With the global push toward modernizing infrastructure and adopting energy-efficient solutions in commercial buildings, demand for durable lamp sockets capable of handling high-wattage lamps is rising. Retrofitting projects in older facilities are creating additional demand for compatible 3 terminal sockets that support both legacy and modern lighting systems. -

H2: Regional Growth and Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, is expected to be the fastest-growing region for 3 terminal lamp sockets by 2026 due to rapid urbanization, industrial development, and government-led energy conservation programs. North America and Europe will continue to see moderate growth, driven by smart building initiatives and replacement cycles in aging infrastructure. Latin America and the Middle East present emerging opportunities tied to construction and industrial expansion. -

H2: Supply Chain Resilience and Sustainability

Post-pandemic supply chain disruptions have prompted manufacturers to localize production and diversify sourcing. By 2026, companies are expected to prioritize sustainable materials and recyclable components in socket manufacturing to meet ESG (Environmental, Social, and Governance) goals. Digital supply chain tools and predictive analytics are being adopted to enhance inventory management and reduce lead times.

In conclusion, the 3 terminal lamp socket market in 2026 will be shaped by technological innovation, regulatory compliance, and expanding application scopes. While competition from integrated LED fixtures poses a challenge, the adaptability and reliability of 3 terminal sockets ensure their continued relevance—especially in industrial and retrofit markets. Companies that invest in smart-ready designs, sustainability, and regional customization will be best positioned to capture growth in this evolving landscape.

Common Pitfalls When Sourcing 3 Terminal Lamp Sockets (Quality & IP Rating)

Sourcing 3 terminal lamp sockets involves more than just finding the right electrical configuration. Overlooking key quality and ingress protection (IP) factors can lead to product failures, safety hazards, and costly replacements. Here are common pitfalls to avoid:

1. Prioritizing Low Cost Over Material Quality

Choosing the cheapest option often means sacrificing material integrity. Inferior plastics may crack under heat or UV exposure, while substandard metals in terminals can corrode or fail to maintain a secure connection. This compromises both safety and longevity.

2. Assuming All Plastics Are Heat-Resistant

Not all socket housings are rated for high temperatures. Using a socket made from low-grade thermoplastic in high-wattage or enclosed fixtures can lead to deformation, melting, or even fire hazards. Always verify the material’s temperature rating matches your application.

3. Overlooking Terminal Contact Quality and Durability

Poorly designed or manufactured terminals may loosen over time, leading to arcing, overheating, or intermittent connections. Ensure terminals are made from high-conductivity, corrosion-resistant materials like brass with tin or nickel plating, and that they maintain strong grip on lamp bases.

4. Misunderstanding or Ignoring IP Ratings

Assuming a socket is suitable for damp or outdoor use without verifying its IP rating is a critical error. For example, using an IP20-rated socket (basic protection against touch) in a bathroom or outdoor fixture exposes it to moisture, risking short circuits and electrocution.

5. Selecting Inadequate IP Rating for the Environment

Even if an IP rating is specified, choosing one that’s insufficient for the intended environment is a common mistake. For instance, an IP44 socket might suffice for a sheltered outdoor light, but a fully exposed fixture may require IP65 or higher for dust and water jet resistance.

6. Failing to Verify Compliance with Safety Standards

Using sockets not certified to relevant regional standards (e.g., UL in the US, CE in Europe, or CCC in China) can void insurance, fail inspections, or pose legal liabilities. Always request and verify compliance documentation.

7. Neglecting Long-Term Environmental Resistance

Some sockets degrade when exposed to UV light, humidity, or chemicals. Ensure the materials are suitable for the operating environment—especially important in industrial, marine, or outdoor applications.

8. Inconsistent Quality from Unverified Suppliers

Sourcing from suppliers without a proven track record often results in inconsistent quality. Batches may vary in material composition, terminal strength, or IP performance. Audit suppliers and request samples before bulk ordering.

Avoiding these pitfalls ensures reliable performance, compliance, and safety in your lighting applications. Always prioritize verified quality and appropriate IP ratings over initial cost savings.

H2: Logistics & Compliance Guide for 3 Terminal Lamp Socket

This guide outlines the essential logistics and compliance considerations for the import, export, distribution, and use of a 3 Terminal Lamp Socket. Ensuring adherence to international regulations, safety standards, and logistical best practices is critical for smooth operations and market access.

1. Product Classification & HS Code

- Product Description: 3 Terminal Lamp Socket (used in lighting fixtures to connect lamps with three electrical terminals, typically including live, neutral, and earth/ground connections).

- HS Code (Harmonized System): 8536.50 (Electrical apparatus for switching or protecting electrical circuits – for voltages ≤ 1,000 V).

- Note: Confirm the exact HS code with local customs authorities, as sub-classifications may vary by country (e.g., 8536.50.00 in the U.S. HTS, 8536 50 00 in EU TARIC).

2. Key Compliance Standards

Ensure the 3 Terminal Lamp Socket complies with international and regional safety and electromagnetic standards:

- IEC 61184: International standard for lamp holders (covers safety, dimensions, and performance for lamp sockets).

- UL 1446 / UL 1076 (U.S.): Underwriters Laboratories standards for insulating systems and electrical components in lighting fixtures.

- EN 61184 (Europe): Harmonized standard under the EU Low Voltage Directive (2014/35/EU).

- RoHS Compliance (EU & China): Restriction of Hazardous Substances – must be free of lead, mercury, cadmium, etc.

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals.

- CE Marking: Required for sale in the European Economic Area (EEA); indicates conformity with health, safety, and environmental protection standards.

- UKCA Marking: Required for sale in Great Britain (post-Brexit).

- CCC Certification (China): Mandatory for electrical components sold in China.

- PSE Mark (Japan): Required for electrical products under the DENAN Law.

- KC Certification (South Korea): Required for electrical safety.

3. Packaging & Labeling Requirements

- Packaging: Use anti-static, moisture-resistant packaging to protect components during transit. Clearly label contents, quantity, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

- Labeling:

- Manufacturer name and address

- Model number and part number

- Voltage and current rating (e.g., 250V~, 2A)

- Compliance marks (CE, UL, RoHS, etc.)

- Date of manufacture and batch/lot number

- Country of origin

4. Shipping & Logistics

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, EXW, DDP). Recommended: FOB (Free On Board) for international shipments.

- Weight & Dimensions: Typical weight per unit: ~20–50g; packaging unit: 100–500 units per box. Confirm exact specs with supplier.

- Transportation:

- Sea freight: Cost-effective for large volumes; use moisture-barrier bags and desiccants.

- Air freight: Faster but more expensive; suitable for urgent or low-volume shipments.

- Ground transport: Use ESD-safe containers for domestic distribution.

- Documentation:

- Commercial invoice

- Packing list

- Bill of lading (B/L) or air waybill (AWB)

- Certificate of Compliance (CoC)

- Test reports (e.g., IEC 61184 compliance)

- Material Safety Data Sheet (MSDS), if applicable

5. Import/Export Regulations

- Export Controls: Generally not subject to dual-use or ITAR controls, but verify with national export agencies (e.g., U.S. Department of Commerce).

- Import Duties & Taxes:

- Check duty rates based on HS code in destination country.

- Some countries offer reduced or zero tariffs under trade agreements (e.g., USMCA, ASEAN).

- Customs Clearance:

- Provide accurate product description and value.

- Include compliance certificates (CE, UL, RoHS) to avoid delays.

6. Storage & Handling

- Store in a dry, temperature-controlled environment (10–30°C, 30–70% RH).

- Avoid direct sunlight and corrosive atmospheres.

- Use first-in, first-out (FIFO) inventory management.

- Handle with ESD-safe tools and grounded workstations.

7. End-of-Life & Environmental Compliance

- WEEE Directive (EU): Must be collected and recycled separately from household waste. Include WEEE symbol on packaging if sold to consumers.

- Recycling: Design for disassembly; use recyclable materials (e.g., thermoset plastics, brass contacts).

- Take-back Programs: Required in some jurisdictions for electronic components.

8. Supplier & Quality Assurance

- Require suppliers to provide:

- ISO 9001 certification

- Product test reports

- RoHS/REACH compliance declarations

- Conduct periodic audits and sample testing.

Summary Checklist

| Item | Required |

|——|———-|

| HS Code Confirmation | ✅ |

| IEC/EN 61184 Compliance | ✅ |

| CE/UKCA/UL/CCC Certification | ✅ (as applicable) |

| RoHS & REACH Compliance | ✅ |

| Proper Packaging & Labeling | ✅ |

| Shipping Documentation | ✅ |

| Customs Clearance Support | ✅ |

| ESD-Safe Handling | ✅ |

| WEEE Compliance (if applicable) | ✅ |

By following this guide, businesses can ensure that 3 Terminal Lamp Sockets are transported, labeled, and sold in full compliance with global regulatory and logistical standards. Always consult local authorities and legal experts for jurisdiction-specific requirements.

In conclusion, sourcing a 3-terminal lamp socket requires careful consideration of key factors such as electrical specifications, material quality, compliance with safety standards (e.g., UL, CE), and compatibility with the intended application. It is essential to evaluate suppliers based on reliability, pricing, lead times, and product certifications to ensure consistent quality and supply chain efficiency. Whether for industrial, commercial, or residential use, selecting a well-designed, durable 3-terminal lamp socket from a reputable source contributes to the safety, performance, and longevity of lighting systems. Conducting thorough market research and potentially obtaining samples for testing can lead to an optimal sourcing decision that balances cost, quality, and reliability.