The global hydraulic cylinder market is experiencing robust growth, driven by rising demand in construction, mining, and transportation sectors. According to Grand View Research, the global hydraulic cylinders market size was valued at USD 5.8 billion in 2022 and is expected to expand at a CAGR of 5.2% from 2023 to 2030, fueled by increased adoption of heavy machinery and advancements in hydraulic technology. Within this landscape, 3-stage telescopic hydraulic cylinders have become critical components for dump trucks, enabling enhanced lifting capacity and extended stroke lengths in compact designs. As demand for high-performance dump trucks grows across infrastructure and resource sectors, manufacturers specializing in multi-stage telescopic cylinders are seeing increased market traction. Based on production capabilities, innovation in sealing and materials, global reach, and market reputation, here are the top 7 manufacturers leading the 3-stage telescopic hydraulic cylinder space for dump truck applications.

Top 7 3 Stage Telescopic Hydraulic Cylinder For Dump Truck Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 3 Stage Telescopic Hydraulic Cylinder for Dump Truck

Domain Est. 2018

Website: dallasthydraulics.com

Key Highlights: DALLAST offers 3 stage telescopic hydraulic cylinder for dump truck. As a leader manufacturer of hydraulic industry in China with experience and technology ……

#2 Mailhot Industries

Domain Est. 2000 | Founded: 1956

Website: mailhotindustries.com

Key Highlights: Mailhot Industries, North American leader in engineering and manufacturing 100% nitrided, hydraulic telescopic and rod cylinders since 1956….

#3 Replacement Telescopic Hydraulic Cylinders

Domain Est. 2014

Website: hydrauliccylindersinc.com

Key Highlights: 4-day delivery 30-day returnsShop a wide selection of replacement single-acting telescopic hydraulic cylinders in various multistage configurations at Hydraulic Cylinders, Inc….

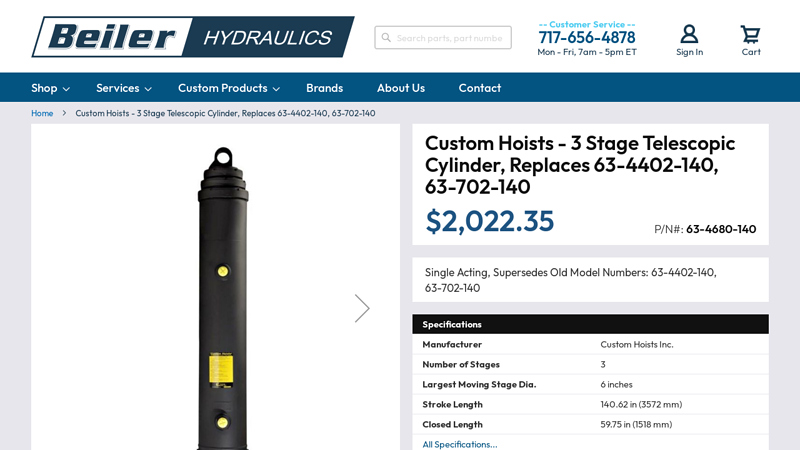

#4 3 Stage Telescopic Cylinder, Replaces 63

Domain Est. 2001

Website: beilerhydraulics.com

Key Highlights: Custom Hoist 4000 Series Model Number: 63-4680-140 A single-acting, telescopic cylinder designed to meet today’s ridgid application requirements….

#5 Telescopic Hydraulic Cylinders for Sale

Domain Est. 2010

Website: farmandranchdepot.com

Key Highlights: 15-day returnsShop our selection of telescopic hydraulic cylinders for sale. We have a wide variety of high-quality aftermarket replacement telescoping cylinders in stock….

#6 Telescopic Hydraulic Cylinders

Domain Est. 2013

Website: baileyhydraulics.com

Key Highlights: Free delivery over $35 45-day returnsMaxim 12 Ton Single Acting Telescopic Hydraulic Cylinder, 3 Stage, 108 Stroke – D … Call 800-800-1810 for availability. Out Of Stock….

#7 NOLANSE 3 Stage Telescopic Hydraulic Cylinder for Dump Truck …

Domain Est. 2018

Website: nolanse.com

Key Highlights: Unlike single or two-stage cylinders, its three-section design balances compact retraction with extended reach, solving the space constraints common in modern ……

Expert Sourcing Insights for 3 Stage Telescopic Hydraulic Cylinder For Dump Truck

H2: 2026 Market Trends for 3-Stage Telescopic Hydraulic Cylinder for Dump Trucks

The global market for 3-stage telescopic hydraulic cylinders for dump trucks is projected to experience steady growth and significant transformation by 2026, driven by evolving construction, mining, and infrastructure development demands. These cylinders are essential components in heavy-duty dump trucks, enabling efficient load dumping through extended stroke capabilities in compact designs. Key market trends shaping the industry in 2026 include:

-

Increasing Infrastructure Investment

Governments across Asia-Pacific, North America, and the Middle East are launching large-scale infrastructure projects, including roads, bridges, and urban development. This surge in construction activity is driving demand for heavy-duty dump trucks, directly boosting the need for high-performance telescopic hydraulic cylinders. -

Growth in Mining and Off-Highway Applications

The mining sector continues to rely on articulated and rigid dump trucks equipped with 3-stage telescopic cylinders for high payload efficiency. Rising mineral extraction activities, especially in Africa, Australia, and South America, are expected to sustain demand for robust hydraulic systems capable of withstanding extreme operating conditions. -

Technological Advancements and Material Innovation

By 2026, manufacturers are focusing on lightweight, high-strength materials such as advanced alloys and composite coatings to enhance cylinder durability and corrosion resistance. Integration of smart sensors for real-time pressure monitoring and predictive maintenance is emerging as a competitive differentiator, improving operational efficiency and reducing downtime. -

Shift Toward Fuel Efficiency and Emission Compliance

With stricter emissions regulations (e.g., Euro VI, EPA Tier 4), dump truck manufacturers are optimizing hydraulic systems for energy efficiency. 3-stage telescopic cylinders are being redesigned to reduce internal friction and improve response time, contributing to lower fuel consumption and compliance with environmental standards. -

Regional Market Dynamics

- Asia-Pacific remains the largest and fastest-growing market due to rapid urbanization in India, China, and Southeast Asia. Local manufacturing of hydraulic components is expanding, reducing dependency on imports.

- North America sees steady demand driven by road maintenance and shale oil transportation needs.

- Europe emphasizes sustainability and smart hydraulics, fostering innovation in eco-friendly cylinder designs.

-

Latin America and Africa present emerging opportunities due to increasing mining and infrastructure development.

-

Supply Chain Localization and Aftermarket Growth

Post-pandemic supply chain disruptions have prompted companies to localize production and build resilient supply networks. Additionally, the aftermarket for replacement and refurbished cylinders is expanding, particularly in developing economies where cost-effective solutions are preferred. -

Consolidation and Strategic Partnerships

Major hydraulic system manufacturers are engaging in mergers, acquisitions, and joint ventures to enhance R&D capabilities and global reach. Partnerships with dump truck OEMs are critical for customizing cylinder designs to meet specific vehicle requirements.

In summary, the 2026 market for 3-stage telescopic hydraulic cylinders for dump trucks is characterized by technological innovation, regional growth imbalances, and a strong emphasis on durability, efficiency, and sustainability. Companies that invest in smart hydraulics, localized manufacturing, and compliance with global standards are poised to lead the market.

Common Pitfalls When Sourcing a 3-Stage Telescopic Hydraulic Cylinder for Dump Trucks (Quality & IP)

Sourcing a 3-stage telescopic hydraulic cylinder for dump trucks is critical for performance, safety, and longevity. However, several pitfalls can compromise quality and intellectual property (IP) protection. Being aware of these issues is essential for making informed procurement decisions.

Quality-Related Pitfalls

1. Compromised Materials and Construction

Many suppliers cut costs by using substandard materials, such as low-grade steel for the cylinder barrel or piston rods. This leads to reduced durability, increased risk of bending, and susceptibility to corrosion—especially problematic in harsh dump truck environments.

2. Inadequate Sealing Systems

Poor-quality or incorrectly specified seals (e.g., using NBR instead of polyurethane or PTFE in high-wear areas) result in leaks, reduced efficiency, and frequent maintenance. Seal design must account for multi-stage pressure differentials and contamination exposure.

3. Insufficient Surface Hardening and Plating

Inadequate chrome plating or improper surface treatment on piston rods increases wear and promotes pitting. This accelerates seal failure and internal contamination, shortening the cylinder’s operational life.

4. Lack of Precision Machining and Tolerances

Low-cost manufacturers may lack the machining precision required for consistent internal diameters and rod straightness. Misalignment between stages can cause binding, uneven wear, and catastrophic failure under load.

5. Absence of Rigorous Testing and Certification

Reputable cylinders undergo pressure testing, cycle testing, and dimensional verification. Suppliers who skip these steps or provide falsified test reports risk delivering units prone to early failure, especially under real-world dump cycle stress.

Intellectual Property (IP) and Sourcing Risks

1. Design Copying and Reverse Engineering

Many generic suppliers replicate OEM designs without authorization, infringing on patents or trade secrets. While these cylinders may appear identical, subtle design flaws or material substitutions can severely impact reliability and safety.

2. Lack of Traceability and Documentation

Unethical suppliers often fail to provide proper engineering drawings, material certifications, or test reports. This lack of documentation not only raises IP concerns but also complicates warranty claims and compliance with safety standards.

3. Use of Counterfeit or Knock-Off Components

Some manufacturers use counterfeit internal parts (e.g., valves, bearings) or misrepresent component origins. This undermines performance and exposes buyers to legal and safety liabilities.

4. Hidden IP Infringement in Private Labeling

When sourcing through intermediaries or private-label suppliers, buyers may unknowingly purchase cylinders that violate existing patents. This exposes the end-user to potential legal action, especially in regulated markets.

5. Inadequate Protection of Custom Designs

If you’re sourcing a custom-engineered cylinder, failing to secure proper IP agreements (e.g., NDAs, IP ownership clauses) with the manufacturer risks losing control over proprietary designs, which could later be sold to competitors.

Best Practices to Avoid Pitfalls

- Verify certifications: Look for ISO 9001, CE, or industry-specific standards.

- Request material and test documentation: Ensure full traceability.

- Conduct factory audits: Assess manufacturing capabilities and quality control.

- Protect IP legally: Use NDAs and clear IP ownership contracts.

- Avoid the lowest bid: Prioritize proven reliability over initial cost.

By addressing these common pitfalls proactively, buyers can ensure they source high-quality, legally compliant telescopic cylinders that enhance dump truck performance and safety.

Logistics & Compliance Guide for 3-Stage Telescopic Hydraulic Cylinder for Dump Truck

Product Overview

The 3-Stage Telescopic Hydraulic Cylinder is a critical component used in dump trucks to enable controlled lifting and dumping of heavy loads. This heavy-duty hydraulic actuator consists of three nested stages that extend sequentially under hydraulic pressure, providing a long stroke in a compact retracted form. These cylinders are typically used in side or rear dump truck applications and must comply with rigorous safety, performance, and regulatory standards.

Packaging & Handling Requirements

Protective Packaging

– The cylinder must be shipped in a robust, weather-resistant crate or custom-designed wooden/palletized container with internal bracing to prevent movement during transit.

– All ports and hydraulic connections must be sealed with protective caps or plugs to prevent contamination from dirt, moisture, or debris.

– Use anti-corrosion coating or VCI (Vapor Corrosion Inhibitor) paper to protect metal surfaces during storage and shipping, especially in humid environments.

Handling Instructions

– Use lifting slings or forklifts with padded arms to avoid damaging the polished rod surface or cylinder body.

– Never lift the cylinder by its rod or mounting pins.

– Maintain the cylinder in a horizontal position during transport to prevent internal leakage or seal damage.

Transportation Guidelines

Domestic Shipping (e.g., within the U.S.)

– Use flatbed or step-deck trailers for oversize or heavy loads, securing the unit with ratchet straps or chains.

– Ensure proper load distribution and compliance with DOT weight and dimension regulations.

– Provide clear labeling indicating “Fragile,” “This Side Up,” and “Do Not Stack.”

International Shipping

– Comply with International Maritime Dangerous Goods (IMDG) Code if hydraulic fluid is pre-filled (typically non-hazardous when empty).

– For sea freight, use ISO-standard containers with dunnage to prevent shifting.

– Complete all required export documentation, including commercial invoice, packing list, and certificate of origin.

Air Freight (If Applicable)

– Air transport is generally not recommended due to weight and cost; however, if required, ensure the cylinder is degreased and certified as non-hazardous.

– Confirm compliance with IATA regulations and airline-specific cargo policies.

Import/Export Compliance

Export Controls

– Verify if the cylinder falls under any export control regulations (e.g., EAR – Export Administration Regulations). Most standard hydraulic cylinders are EAR99, meaning they are low-risk and do not require a license for most destinations.

– Conduct end-user screening to prevent shipment to embargoed countries or restricted parties (e.g., OFAC, BIS Denied Persons List).

Import Regulations

– Classify the product under the correct HS Code (e.g., 8412.21 for hydraulic cylinders) to determine duty rates and import restrictions in the destination country.

– Provide a detailed technical specification sheet for customs clearance, including bore size, stroke length, operating pressure, material composition, and weight.

– Some countries (e.g., China, India, Brazil) may require product certification (e.g., CCC, INMETRO) or conformity assessment.

Safety & Regulatory Standards

Industry Standards

– Ensure design and manufacturing comply with ISO 4413 (Hydraulic fluid power – General rules and safety requirements) and ISO 6020-2 (Dimensions for mounting of hydraulic cylinders).

– Confirm adherence to SAE J1306 (Hydraulic cylinders for construction, mining, and industrial machines).

– Rod surface hardness and finish should meet SAE J1210 or equivalent for wear resistance.

Pressure Equipment Directive (EU)

– If selling in the European Union, the cylinder may need to comply with the Pressure Equipment Directive (PED) 2014/68/EU.

– Classify the cylinder based on fluid group, volume, and maximum allowable pressure (PS). Most dump truck cylinders fall under Article 4(3) exemptions if below specified thresholds; otherwise, CE marking and notified body involvement may be required.

North American Requirements

– Follow ANSI/BHMA or CSA safety standards as applicable.

– No specific NRTL (Nationally Recognized Testing Laboratory) certification is required for hydraulic cylinders alone, but integration into the truck must meet FMVSS and OSHA standards.

Documentation Requirements

Essential Shipping Documents

– Commercial Invoice (with declared value, Incoterms, and Harmonized Code)

– Packing List (itemizing contents, weights, dimensions)

– Bill of Lading (for sea/air) or Freight Bill (for land)

– Certificate of Origin (for preferential tariffs under trade agreements)

– Export Declaration (e.g., AES filing in the U.S. for shipments over $2,500)

Compliance & Quality Documents

– Test Certificates (proof pressure test, stroke test, leak test)

– Material Certification (e.g., EN 10204 3.1 for steel components)

– ISO 9001 Quality Management Certificate (from manufacturer)

– RoHS/REACH Compliance Declaration (if applicable for material content)

Installation & End-User Compliance

Installation Best Practices

– Follow the OEM’s installation manual for proper alignment, mounting, and hose routing.

– Use calibrated torque wrenches for mounting bolts and hydraulic fittings.

– Bleed the hydraulic system thoroughly to prevent air entrapment and cavitation.

Operator Safety & Maintenance

– Train operators on safe dumping procedures and load limits.

– Implement a preventive maintenance schedule including seal inspection, rod scoring checks, and fluid contamination monitoring.

– Replace damaged wipers, seals, or rods immediately to avoid failure.

Environmental & End-of-Life Considerations

Waste Management

– At end-of-life, cylinders should be drained of hydraulic fluid and recycled as metal scrap.

– Used hydraulic oil must be disposed of in compliance with local environmental regulations (e.g., EPA regulations in the U.S.).

– Follow WEEE or ELV directives in the EU if applicable.

Sustainability

– Encourage remanufacturing or refurbishment programs to extend product life.

– Use recyclable packaging materials and minimize single-use plastics.

Adherence to this logistics and compliance guide ensures safe, legal, and efficient handling of 3-Stage Telescopic Hydraulic Cylinders throughout the supply chain, reducing risk and ensuring customer satisfaction.

Conclusion: Sourcing a 3-Stage Telescopic Hydraulic Cylinder for Dump Truck

After thorough evaluation of technical requirements, performance expectations, supplier capabilities, and cost considerations, sourcing a 3-stage telescopic hydraulic cylinder for a dump truck requires a strategic approach focused on quality, reliability, and long-term durability. These cylinders are critical components that directly impact the truck’s dumping efficiency, load capacity, and operational safety.

Key factors in the sourcing decision include selecting a manufacturer with proven experience in heavy-duty hydraulic systems, adherence to international standards (such as ISO or DIN), and the ability to customize stroke length, bore size, and mounting configurations to match specific truck models. Additionally, robust materials, advanced sealing technology, and corrosion protection are essential to ensure performance under harsh operating conditions.

Prioritizing suppliers that offer comprehensive warranties, technical support, and after-sales service further reduces downtime and maintenance costs. While initial pricing is a consideration, long-term value—including service life, reliability, and reduced operational disruptions—should weigh more heavily in the final decision.

In conclusion, successfully sourcing a 3-stage telescopic hydraulic cylinder involves balancing performance specifications with supplier credibility and total cost of ownership. A well-informed sourcing strategy will enhance dump truck productivity, ensure operational safety, and contribute to lower lifecycle costs.