The global flail mower market is experiencing robust growth, driven by increasing demand for efficient land maintenance solutions across agricultural, municipal, and commercial sectors. According to Grand View Research, the global agricultural mowers market size was valued at USD 8.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by rising mechanization in farming, expanding green space management needs, and growing emphasis on landscape aesthetics in urban planning. With 3-point flail mowers offering superior versatility, durability, and performance on rough terrain, demand for high-quality models continues to rise. In this competitive landscape, a select group of manufacturers has emerged as industry leaders, combining engineering excellence with innovative design to capture significant market share. The following analysis identifies the top 10 3-point flail mower manufacturers based on production capacity, technological advancement, global distribution, and customer reviews, providing stakeholders with data-backed insights into the leading players shaping the future of land maintenance equipment.

Top 10 3 Point Flail Mower Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 390 Offset Flail Mower

Domain Est. 1990

Website: deere.com

Key Highlights: Rating 4.5 (2) · Free delivery over $50 · 30-day returnsAll John Deere flail mowers feature this rugged, heavy-duty gearbox with a continuous 65-hp rating and an intermittent …

#2 Flail Cutter Attachment

Domain Est. 1997

Website: bobcat.com

Key Highlights: Delivers excellent cutting, mulching, and mowing action of materials up to 3 inches in diameter; Thick steel deck design protects the attachment and provides ……

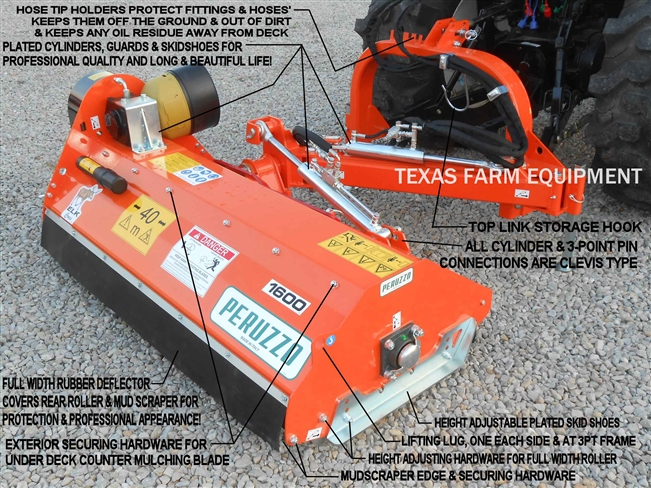

#3 Fox

Domain Est. 1998

Website: peruzzo.it

Key Highlights: Fox-S can be retrofitted to tractors with a 3-point category 1N attachment and is produced in various widths to adapt to the power on the appropriate track….

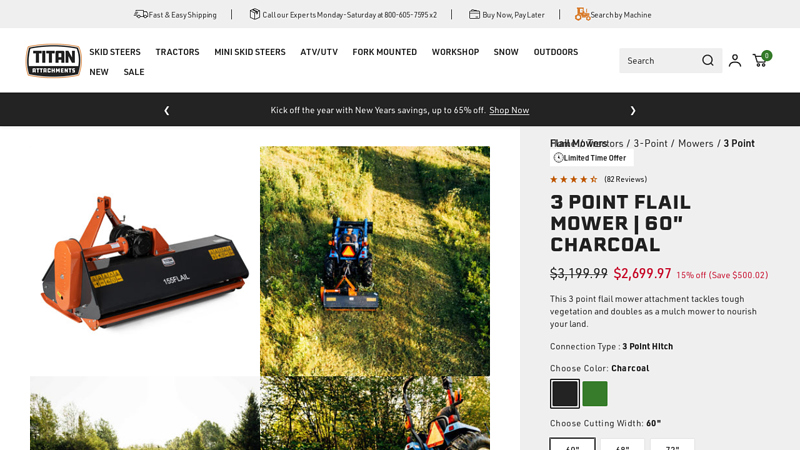

#4 3 Point Flail Mowers

Domain Est. 2002

Website: palletforks.com

Key Highlights: In stock Rating 4.2 (82) This heavy-duty 3 point flail mower efficiently handles vegetation up to 3 inches thick, making quick work of grass, brush, and vines….

#5 Del Morino S.r.l.

Domain Est. 2003

Website: delmorino.it

Key Highlights: We design and manufacture agricultural equipment for cultivation, gardening, landscaping, handling, and harvesting. Since 1875, our growth has been guided ……

#6 Boom Mowers

Domain Est. 2006

Website: tigermowers.com

Key Highlights: Flail Mowers · Side Mounted · Super Duty Flail · Extreme Duty Flail · Wildkat Flail · Rear Mounted · Super Duty Rear Flail · Extreme Duty Rear Flail · Twin ……

#7 3-Point PTO Flail Mowers – Cut Grass, Weeds & Brush

Domain Est. 2021

#8 Mowers & Cutters

Domain Est. 2022

Website: ironcraftusa.com

Key Highlights: The FMH series is suitable for tractors from 35 horsepower to 70 horsepower with a category 1 hitch. Offset Flail Mower. 20-100 Tractor HP. Offset Flail Mower….

#9 Best Offset Flail Mower for Tractors, 78″ Cut

Domain Est. 2016

Website: peruzzousa.com

Key Highlights: Peruzzo Offset Flail Mower: Best Quality Flail Mower, Best Features & 1-Pass Results in Any Conditions! 78″ Cut Flail Mower for 75HP-125HP Tractors….

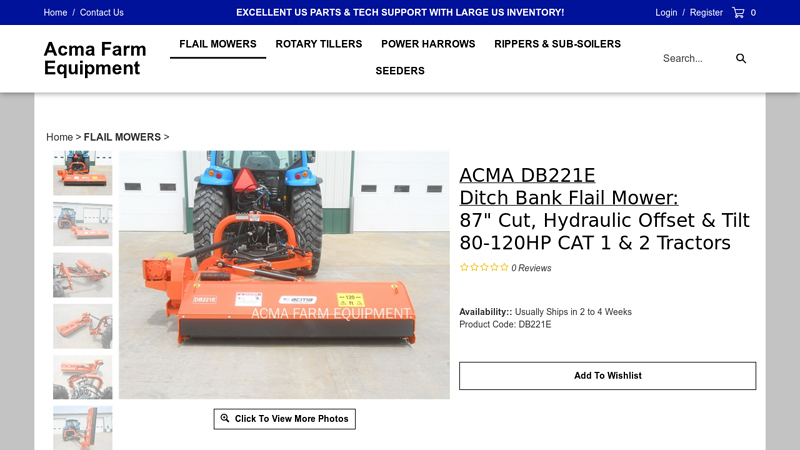

#10 Best 3

Domain Est. 2020

Website: acmafarmequipment.com

Key Highlights: 87″ ACMA 3-Pt Ditch Bank Flail Mower, Hyd Offset & Tilt, for 80HP-120HP Tractors. ACMA Flail Mowers: Best Features, Quality & 1-Pass Results!…

Expert Sourcing Insights for 3 Point Flail Mower

2026 Market Trends for 3-Point Flail Mowers

The global market for 3-point flail mowers is poised for continued evolution in 2026, driven by technological advancements, shifting end-user demands, and broader agricultural and landscaping trends. As vital implements for efficient vegetation management across diverse terrains, flail mowers face both challenges and opportunities in the coming years.

Growing Demand in Specialized Applications

By 2026, demand for 3-point flail mowers is expected to rise significantly in niche sectors such as vineyard and orchard maintenance, rights-of-way management (including utility corridors and transportation infrastructure), and ecological land conservation. These applications benefit from the mower’s precise cutting capabilities, minimal soil disturbance, and ability to handle uneven or rocky terrain. Increased investment in sustainable land management and infrastructure projects will further fuel adoption in these specialized areas.

Integration of Smart Technology and Connectivity

A key trend shaping the 2026 market is the integration of smart technology into agricultural machinery. Leading manufacturers are incorporating features such as remote monitoring, blade wear sensors, and GPS-guided operation into flail mowers. While full autonomy remains limited for 3-point implements, enhanced connectivity allows operators to track performance, schedule maintenance, and optimize mowing patterns—improving efficiency and reducing downtime.

Focus on Durability and Low Maintenance

End-users continue to prioritize robust construction and ease of maintenance. In 2026, manufacturers are responding with hardened steel components, improved blade retention systems, and modular designs that simplify repairs. The emphasis on durability is particularly strong in regions with rugged terrain or high vegetation density, where equipment reliability directly impacts productivity and operational costs.

Expansion in Emerging Markets

Developing economies in Latin America, Southeast Asia, and Africa are expected to see increased adoption of 3-point flail mowers as small-to-medium farms and government agencies modernize land maintenance practices. Affordable, compact models compatible with sub-30 HP tractors are gaining traction, supported by rising tractor ownership and infrastructure development.

Sustainability and Environmental Considerations

Environmental regulations and consumer demand for sustainable practices are influencing design choices. Mowers featuring reduced noise emissions, improved fuel efficiency (when paired with efficient tractors), and mulching capabilities that enhance soil health are becoming more popular. Additionally, some manufacturers are exploring recyclable materials and eco-conscious manufacturing processes to align with broader ESG goals.

Competitive Landscape and Innovation

The market remains competitive, with established brands like Land Pride, Alamo Group (including Rhino and Terrain King), and Bucher Unimog expanding their product lines. Innovation in blade design—such as high-lift or bi-directional flails—and adjustable cutting heights will differentiate offerings. Customization options for different tractor models and regional vegetation types will also be a key differentiator in 2026.

In conclusion, the 3-point flail mower market in 2026 will be characterized by technological enhancement, specialization, and global expansion. Manufacturers that prioritize durability, smart features, and sustainability will be best positioned to capture growing demand across both traditional and emerging applications.

Common Pitfalls When Sourcing a 3-Point Flail Mower (Quality & Intellectual Property)

Sourcing a 3-point flail mower—especially from overseas suppliers—can be cost-effective, but it comes with significant risks related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls is crucial for protecting your business, reputation, and bottom line.

Quality Control Issues

One of the most prevalent challenges in sourcing flail mowers is ensuring consistent, reliable quality. Many suppliers, particularly low-cost manufacturers, may cut corners to reduce production costs, leading to subpar performance and safety hazards.

- Inferior Materials: Blades, rotor shafts, and housing may be made from low-grade steel that wears quickly or fails under stress. This reduces machine lifespan and increases maintenance costs.

- Poor Welding and Assembly: Weak or inconsistent welds on the mower deck or hitch points can lead to structural failure during operation, posing serious safety risks.

- Imbalanced Rotors: Improperly balanced cutting drums cause excessive vibration, accelerating wear on bearings and gearboxes, and reducing cutting efficiency.

- Substandard Gearboxes and Bearings: These critical components may be undersized or poorly manufactured, leading to premature breakdowns and costly downtime.

- Lack of Testing and Certification: Many sourced units lack third-party testing for safety standards (e.g., CE, ISO) or durability benchmarks, increasing liability exposure.

Without rigorous quality audits, on-site inspections, or third-party testing, buyers risk receiving machinery that underperforms or fails prematurely, damaging customer trust and increasing warranty claims.

Intellectual Property (IP) Infringement Risks

Another major pitfall is the unintentional sourcing of products that violate intellectual property rights. Many low-cost manufacturers replicate designs from well-known brands without authorization, putting importers at legal risk.

- Design Patent Infringement: Flail mower designs—including deck shape, blade configuration, or hitch mechanisms—may be protected by design patents. Copying these can lead to legal action, seized shipments, or fines.

- Trademark Violations: Suppliers may use logos, branding, or model names similar to established brands, misleading customers and exposing buyers to trademark litigation.

- Utility Patent Infringement: Functional innovations such as anti-scalping systems, quick-change blade mechanisms, or driveline protections may be patented. Reproducing these without a license is illegal.

- Lack of IP Due Diligence: Buyers may assume “white label” or OEM products are IP-safe, but without proper vetting, they could be importing counterfeit or cloned equipment.

Engaging in IP infringement—even unknowingly—can result in customs seizures, lawsuits, reputational damage, and forced product recalls. It is essential to conduct IP clearance searches and require suppliers to provide proof of design ownership or licensing.

Conclusion

To mitigate these risks, buyers should:

– Conduct factory audits and request product samples for independent testing.

– Work with legal counsel to perform IP due diligence before finalizing supplier agreements.

– Include quality assurance clauses and IP indemnification terms in contracts.

– Consider sourcing from reputable manufacturers with verifiable certifications and design ownership.

Avoiding these common pitfalls ensures you deliver a reliable, legally compliant product to your market.

Logistics & Compliance Guide for 3-Point Flail Mower

This guide provides essential information for the safe transportation, handling, and regulatory compliance of a 3-point flail mower, a common implement used in agricultural, landscaping, and grounds maintenance operations.

Transportation and Handling

Ensure the flail mower is securely attached to the appropriate category of the tractor’s three-point hitch system before any movement. During transport, keep the mower in the raised position using the tractor’s hydraulic system or mechanical locking pins, if available, to prevent accidental lowering. Always engage the tractor’s parking brake and turn off the engine when mounting or dismounting the implement. Use appropriate lifting equipment or a tractor with sufficient lifting capacity when handling the mower independently. Never stand under a suspended mower.

Load Securing for Road Transport

When transporting the flail mower on a trailer or flatbed, secure it using heavy-duty tie-down straps or chains rated for the implement’s weight. Attach straps to the mower’s designated lifting or hitch points and anchor them firmly to the trailer’s securement points. Use a minimum of four tie-downs (two front, two rear) and ensure they are properly tensioned to prevent shifting. Cover rotating parts and blades during transport to reduce aerodynamic drag and prevent debris from being thrown.

Weight and Clearance Considerations

Verify the mower’s weight and ensure the towing vehicle and trailer are rated to handle the combined load. Check that the overall width, height, and length of the mower (especially when attached to a tractor) comply with local road transport regulations. Extended blades or side discharge chutes may require folding or removal for road use. Be mindful of overhead clearance when transporting under bridges, power lines, or trees.

Regulatory Compliance

Adhere to all applicable local, state, and federal regulations for transporting agricultural equipment on public roads. This may include requirements for slow-moving vehicle (SMV) emblems, lighting (e.g., tail lights, reflectors), and hazard warning signs. In some jurisdictions, permits are required for oversized loads. Ensure the implement meets Occupational Safety and Health Administration (OSHA) standards and relevant ANSI safety guidelines for agricultural machinery.

Operator and Maintenance Compliance

Only trained and authorized personnel should operate or service the flail mower. Follow the manufacturer’s operation and maintenance manual for inspection schedules, blade replacement, and lubrication. Keep all safety guards and shields in place during operation. Maintain records of inspections, repairs, and compliance training as required by workplace safety regulations.

Environmental and Noise Regulations

Operate the flail mower in compliance with local noise ordinances, especially in residential areas or during restricted hours. When mowing near waterways or environmentally sensitive zones, follow best practices to minimize soil erosion and prevent chemical runoff. Dispose of worn blades, lubricants, and other waste materials according to local environmental regulations, such as those governed by the Environmental Protection Agency (EPA) or equivalent bodies.

Documentation and Recordkeeping

Maintain up-to-date documentation including the owner’s manual, service records, transportation permits, and safety training logs. These records support regulatory compliance during inspections and help ensure long-term safe operation of the equipment.

In conclusion, sourcing a 3-point flail mower requires careful consideration of several key factors to ensure optimal performance, durability, and value for money. It is essential to assess your specific land management needs—such as terrain type, vegetation density, and frequency of use—when selecting the right size and power capacity. Compatibility with your tractor’s horsepower and hydraulic capabilities is critical for efficient operation and safety.

When sourcing, evaluate reputable suppliers and manufacturers known for quality construction and reliable customer support. Comparing features such as blade type, cutting width, gearbox durability, and ease of maintenance will help identify a mower that offers long-term reliability. Additionally, reviewing warranties, service availability, and user feedback can further inform your decision.

Ultimately, investing in a high-quality 3-point flail mower from a trusted source not only enhances mowing efficiency but also reduces downtime and operating costs over time. By taking a strategic approach to sourcing, you can secure a durable, versatile, and effective solution for maintaining your land to a professional standard.