The global chisel plow market is experiencing steady growth, driven by rising demand for conservation tillage practices that enhance soil health and improve crop yields. According to Grand View Research, the global agricultural machinery market was valued at USD 188.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030, with tillage equipment—including 3-point chisel plows—representing a significant segment. As farmers increasingly adopt efficient, low-disturbance tillage solutions to reduce soil erosion and fuel consumption, the demand for high-performance chisel plows has surged. This growing market, supported by advancements in durable frame designs, adjustable shank configurations, and compatibility with a wide range of tractor sizes, has led to intense innovation among manufacturers. In this landscape, nine key players have emerged as leaders in producing reliable, high-quality 3-point chisel plows, combining engineering precision with field-tested performance to meet the evolving needs of modern agriculture.

Top 9 3 Point Chisel Plow Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

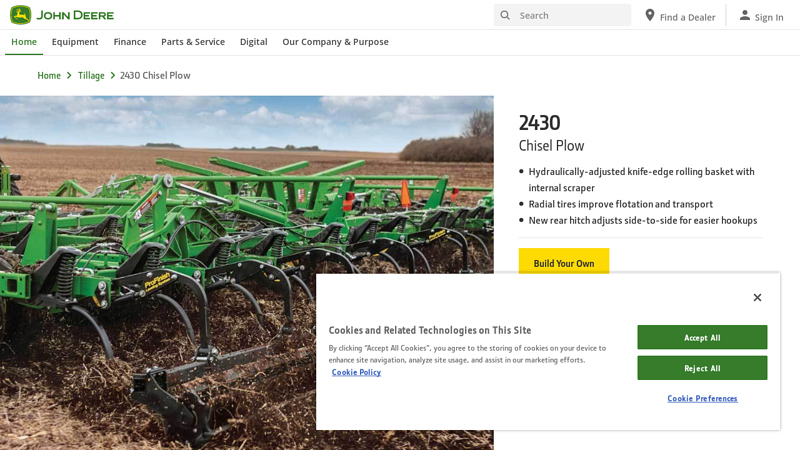

#1 2430 Chisel Plow

Domain Est. 1990

Website: deere.com

Key Highlights: The 2430 Chisel Plow has excellent residue-handling capability in primary tillage at all residue levels….

#2 Chisel Plow

Domain Est. 1995

Website: caseih.com

Key Highlights: The Case IH Flex-Till 600 chisel plow is durably designed to handle tough tillage conditions. Its range of shank spacing and trip point load options match ……

#3 Chisel Plow

Domain Est. 1996

Website: landoll.com

Key Highlights: The Brillion Chisel Plow is the foundation tillage tool that brought Brillion into the primary tillage business many years ago….

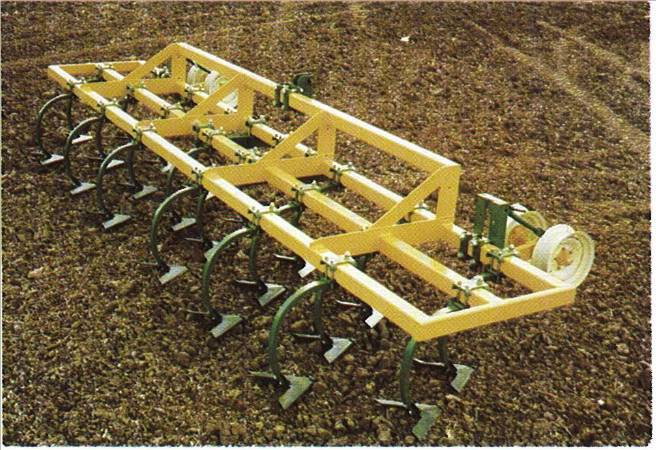

#4 Bush Hog® All Purpose Plows

Domain Est. 1996

Website: bushhog.com

Key Highlights: All Purpose Plows range in working widths from 44” to 80”. · Three point lift Cat. 1 Standard or Quick Hitch. · Frame construction is 2-1/2” x 2-1/2” x 3/8” angle ……

#5 Chisel Plow

Domain Est. 1999

Website: summersmfg.com

Key Highlights: Designed to break compaction in some of the toughest conditions, the Chisel Plow is the ultimate chisel plow. Featuring well-spaced chisel shanks mounted ……

#6 Chisel Plows

Domain Est. 1999

Website: kuhn-usa.com

Key Highlights: The KUHN Krause 4000 chisel plow provides durable, economical primary tillage with a variety of shanks and point options to meet different requirements. This ……

#7 Chisel Plows & ATV / Tractor Implements

Domain Est. 1999

Website: kunzeng.com

Key Highlights: The Till-Ease line of tow behind and 3-point mounted chisel plows is ideal for lawn & garden, construction, & agriculture. Shop today at Kunz Engineering….

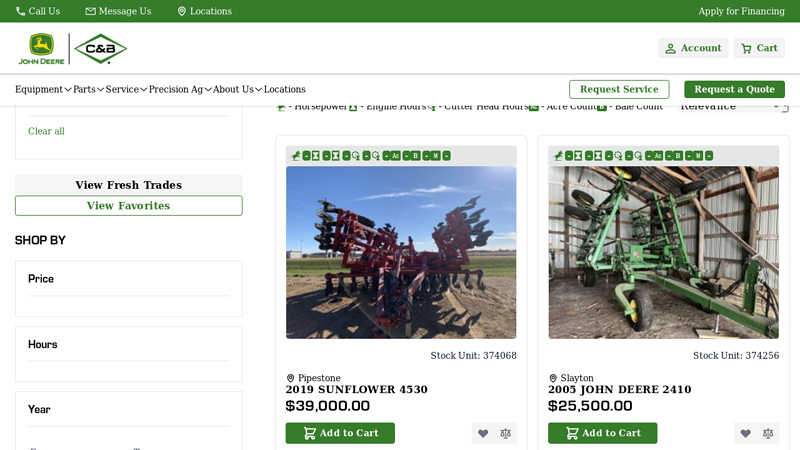

#8 Chisel Plows

Domain Est. 2001

Website: deerequipment.com

Key Highlights: 2025 2430 3-Section Drawn Flexible C-Shank Chisel Plow 12 Ft. Cen new Stock Unit: 367643 Pipestone 2025 2430 3-Section Drawn Flexible C-Shank Chisel Plow…

#9 Chisel Plows & Field Cultivators

Domain Est. 2020

Website: isomtractor.com

Key Highlights: CHISEL PLOWS ; GLENCOE GIANT G CHISEL (13678) · $2,995.00 ; FORD 9′ CHISEL PLOW (13537) · $2,500.00 ; KRAUSE 2860 CONSERVATION PLOW (13519) · $4,995.00 ; ARMSTRONG AG ……

Expert Sourcing Insights for 3 Point Chisel Plow

H2: 2026 Market Trends for 3-Point Chisel Plow

The global market for 3-point chisel plows is poised for steady growth and transformation by 2026, driven by shifting agricultural practices, technological advancements, and increasing demand for sustainable soil management. Key trends shaping the market include:

1. Rising Demand for Conservation Tillage

Farmers are increasingly adopting conservation tillage methods to reduce soil erosion, retain moisture, and improve long-term soil health. The 3-point chisel plow, known for its ability to loosen compacted soil without inverting soil layers, aligns well with these practices. This growing preference for minimal soil disturbance is expected to boost demand, particularly in North America and Europe.

2. Integration with Smart Farming Technologies

By 2026, the integration of precision agriculture tools—such as GPS-guided systems, variable depth control, and real-time monitoring—is becoming more common in tillage equipment. Leading manufacturers are incorporating smart hydraulics and sensor-based depth adjustment in 3-point chisel plows, enhancing efficiency and reducing fuel consumption. This trend is especially prominent among mid-to-large-scale farms seeking to optimize input use.

3. Growth in Smallholder and Mid-Size Farm Adoption

In emerging markets such as India, Brazil, and parts of Africa, government subsidies and access to affordable compact tractors are enabling small and medium-sized farms to adopt 3-point hitch implements. The versatility and cost-effectiveness of 3-point chisel plows make them attractive for diverse cropping systems, supporting market expansion in these regions.

4. Focus on Durability and Customization

Manufacturers are responding to farmer demands for longer-lasting equipment by using hardened steel shanks, improved point designs, and modular configurations. Customization options—such as adjustable shank spacing and interchangeable points—allow farmers to adapt equipment for different soil types and field conditions, enhancing product appeal.

5. Environmental Regulations and Carbon Farming Incentives

Stricter environmental regulations and initiatives promoting carbon sequestration in agriculture are encouraging reduced tillage. While full inversion plowing declines, chisel plowing remains a viable compromise for deep tillage needs without excessive soil disruption. Incentives for sustainable practices may further drive adoption of tools like the 3-point chisel plow in carbon farming programs.

6. Competitive Landscape and Regional Dynamics

Established players such as John Deere, KUHN, and Land Pride continue to dominate, but regional manufacturers are gaining ground through localized production and pricing strategies. North America remains the largest market, while Asia-Pacific is expected to witness the highest growth rate due to expanding mechanization.

In summary, the 3-point chisel plow market in 2026 will be shaped by sustainability goals, technological integration, and broader access to mechanized farming. These trends position the equipment as a critical tool in the transition toward efficient, conservation-oriented agriculture.

Common Pitfalls When Sourcing a 3 Point Chisel Plow (Quality and Intellectual Property)

Sourcing a 3-point chisel plow—especially from offshore or lesser-known manufacturers—can present significant challenges related to both product quality and intellectual property (IP) concerns. Being aware of these pitfalls helps ensure you get a durable, reliable tool that doesn’t expose your business to legal or operational risks.

Poor Manufacturing Quality and Substandard Materials

One of the most frequent issues when sourcing chisel plows is receiving units made with inferior materials or poor craftsmanship. Low-cost suppliers may use thinner gauge steel, low-grade heat treatment on shanks and points, or inadequate welding, leading to premature failure under field conditions. Look for inconsistent welds, rough finishes, or misaligned components as red flags.

Lack of Standardization and Fit Compatibility

Not all 3-point hitch systems or chisel plow dimensions adhere to universal standards. Some sourced plows may not properly align with your tractor’s Category I, II, or III hitch, resulting in unsafe operation or inefficient performance. Verify compatibility with your equipment’s lift capacity, lower link spacing, and top link geometry before purchase.

Inadequate or Missing Quality Assurance Documentation

Reputable manufacturers provide proof of quality control, such as material certifications, load testing results, or ISO compliance. Suppliers offering chisel plows without such documentation increase the risk of receiving subpar equipment. Always request and verify quality assurance records as part of the sourcing process.

Intellectual Property Infringement Risks

Many chisel plow designs—especially those with patented shank configurations, depth control systems, or frame geometry—are protected by intellectual property rights. Sourcing a copycat or counterfeit version, even unknowingly, can expose your business to legal liability, seizure of goods, or reputational damage. Ensure the supplier holds proper licensing or offers original, non-infringing designs.

Misrepresentation of Brand or Design Origin

Some suppliers falsely claim affiliation with established agricultural brands or suggest their product is an “original equipment” (OE) equivalent when it is not. This misrepresentation can be a sign of broader dishonesty about quality and IP compliance. Conduct due diligence by checking trademarks, contacting original manufacturers, and reviewing customer feedback.

Limited Warranty and After-Sales Support

Low-cost chisel plows often come with weak or non-existent warranties and poor customer service. If a critical component fails, obtaining replacement parts or technical support can be difficult or impossible. Prioritize suppliers who offer clear warranty terms and accessible support channels.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: inspect sample units, verify material specs, confirm IP legitimacy, and choose suppliers with transparent manufacturing and business practices. Investing time upfront can prevent costly failures, downtime, and legal complications down the line.

Logistics & Compliance Guide for 3 Point Chisel Plow

Product Overview

A 3 Point Chisel Plow is a heavy-duty agricultural implement designed to break up compacted soil layers without inverting the soil profile. It attaches to a tractor via the Category I, II, or III three-point hitch system and uses strong shanks with replaceable points to penetrate and aerate the soil. This guide outlines the logistics and compliance considerations for transporting, storing, and operating this equipment.

Transportation Logistics

- Weight & Dimensions: Confirm the chisel plow’s weight (typically 500–1,500 lbs depending on width and shank count) and folded/working dimensions to ensure compatibility with transport vehicles.

- Loading & Securing: Use a trailer with appropriate load capacity and secure the plow using heavy-duty chains or ratchet straps. Ensure it is centered and locked in the transport position.

- Hitch Compatibility: Verify that the towing vehicle has the correct three-point category and hydraulic connections if lift assist is required.

- Road Regulations: Check local and interstate regulations for equipment transport, including height, width, and lighting requirements. Oversized loads may require permits or escort vehicles.

Storage Requirements

- Indoor vs. Outdoor: Store in a dry, covered area when possible to prevent rust and corrosion. If stored outdoors, use a waterproof tarp and elevate off the ground.

- Shank Protection: Install protective caps on chisel points to prevent damage and enhance safety.

- Lubrication & Maintenance: Before long-term storage, lubricate pivot points and inspect hydraulic cylinders (if applicable) for leaks.

- Security: Lock or chain the plow to a fixed structure if stored on-site to deter theft.

Regulatory Compliance

- DOT & Transportation Laws: Comply with Department of Transportation (DOT) regulations for non-commercial and commercial hauling, including load securement (FMCSA Part 393).

- OSHA Guidelines: Follow OSHA safety standards for workplace handling, especially when using forklifts or cranes to move the plow.

- Environmental Regulations: Avoid operating or storing near waterways to prevent contamination from lubricants or rust runoff. Adhere to local environmental protection laws.

Safety & Operational Compliance

- Operator Training: Ensure operators are trained in hitching procedures, depth adjustment, and safe field operation per the manufacturer’s manual.

- PTO & Hydraulic Safety: If equipped with hydraulic lift or adjustment, confirm all hoses and fittings meet industry standards (e.g., SAE J517). Never service under a raised plow.

- Wear & Replacement: Regularly inspect shanks, points, and mounting hardware. Replace worn parts to maintain performance and avoid hazardous failures.

Documentation & Certification

- Operator Manual: Maintain the original manual on file for reference to specifications, maintenance schedules, and compliance data.

- Proof of Compliance: Keep records of any third-party inspections, load certifications, or modifications.

- Warranty Registration: Register the plow with the manufacturer to ensure warranty coverage and receive compliance updates.

International Considerations (if applicable)

- Customs & Import Regulations: For cross-border shipments, provide accurate HS codes (e.g., 8433.51 for agricultural machinery) and comply with import duties.

- CE/UKCA Marking: In Europe or the UK, verify the plow meets applicable machinery directives (e.g., 2006/42/EC) if sold or operated there.

- Language & Manuals: Provide multilingual operation and safety instructions as required by destination country regulations.

By adhering to this guide, users can ensure safe, legal, and efficient handling of the 3 Point Chisel Plow throughout its lifecycle.

Conclusion for Sourcing a 3-Point Chisel Plow

Sourcing a 3-point chisel plow requires careful consideration of several key factors including compatibility with your tractor’s horsepower and hitch system, intended soil conditions, tine configuration, frame durability, and overall build quality. After evaluating various suppliers, brands, and user feedback, it is clear that investing in a well-constructed, appropriately sized chisel plow from a reputable manufacturer ensures long-term performance, improved soil aeration, and effective residue management.

Opting for models with adjustable shanks and heat-treated components enhances versatility and longevity, especially in tough or rocky soils. Additionally, considering warranty, availability of replacement parts, and after-sales support can significantly reduce downtime and maintenance costs. While cost is an important factor, prioritizing value over the lowest price often leads to greater efficiency and return on investment in the field.

In conclusion, a strategic sourcing approach—balancing quality, compatibility, and support—will lead to the successful integration of a 3-point chisel plow into your tillage operations, supporting sustainable soil health and optimal planting conditions.